ASTM D3394-94(2009)

(Test Method)Standard Test Methods for Sampling and Testing Electrical Insulating Board

Standard Test Methods for Sampling and Testing Electrical Insulating Board

SIGNIFICANCE AND USE

Apparent density affects the dielectric and physical characteristics of insulating board and is a factor in the economics of its use in apparatus. This test is useful for specification, design, and quality control purposes.

SCOPE

1.1 These test methods cover the sampling and testing of electrical insulating boards. These boards are porous, usually fibrous sheets used for dielectric and structural purposes in electrical apparatus.

1.2 These test methods are not intended for testing vulcanized fibre or molded laminated sheets.

1.3 These test methods are applicable to board materials having a nominal thickness of at least 0.030 in. (0.76 mm).

Note 1—For materials thinner than 0.030 in. (0.76 mm) see Test Methods D202.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3394 − 94 (Reapproved 2009)

Standard Test Methods for

Sampling and Testing Electrical Insulating Board

This standard is issued under the fixed designation D3394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 These test methods cover the sampling and testing of

electrical insulating boards. These boards are porous, usually

2. Referenced Documents

fibrous sheets used for dielectric and structural purposes in

2.1 ASTM Standards:

electrical apparatus.

D149 Test Method for Dielectric Breakdown Voltage and

1.2 These test methods are not intended for testing vulca-

DielectricStrengthofSolidElectricalInsulatingMaterials

nized fibre or molded laminated sheets.

at Commercial Power Frequencies

1.3 These test methods are applicable to board materials

D202 Test Methods for Sampling and Testing Untreated

having a nominal thickness of at least 0.030 in. (0.76 mm).

Paper Used for Electrical Insulation

D374 Test Methods for Thickness of Solid Electrical Insu-

NOTE 1—For materials thinner than 0.030 in. (0.76 mm) see Test

Methods D202. lation (Withdrawn 2013)

D586 Test Method for Ash in Pulp, Paper, and Paper

1.4 The test methods appear in the following sections:

Products (Withdrawn 2009)

ASTM Method

D644 Test Method for Moisture Content of Paper and

Sections Reference

Apparent Density 18–23

Paperboard by Oven Drying (Withdrawn 2010)

Aqueous Extract Characteristics 36 – 42 D202

D664 Test Method for Acid Number of Petroleum Products

Ash Content 43–46 T 413

by Potentiometric Titration

Compatibility with Dielectric 47 – 52 D664, D877, D924,

Liquids D971, D974, D1169,

D685 Practice for Conditioning Paper and Paper Products

D1500, D1816,

for Testing

D3455, D3487

D877 Test Method for Dielectric Breakdown Voltage of

Compressibility 79–85

Conditioning 11 D685

Insulating Liquids Using Disk Electrodes

Degree of Polymerization 86 – 89 D4243

D924 Test Method for Dissipation Factor (or Power Factor)

Dielectric Strength in Air 53 – 59 D149

and Relative Permittivity (Dielectric Constant) of Electri-

Dielectric Strength in Oil 60 – 65 D149, D2413, D3426

Dimensions of Sheets 12–17

cal Insulating Liquids

Moisture Content 31 – 35 D644

D971 Test Method for Interfacial Tension of Oil Against

Oil Absorption 72–78

Water by the Ring Method

Reports 10

Sampling 6 – 9 D3636

D974 Test Method for Acid and Base Number by Color-

Shrinkage 24 – 30 D644

Indicator Titration

Tensile Properties 66 – 71 D202

D1169 Test Method for Specific Resistance (Resistivity) of

1.5 The values stated in inch-pound units are to be regarded

Electrical Insulating Liquids

as standard. The values given in parentheses are mathematical

D1500 Test Method forASTM Color of Petroleum Products

conversions to SI units that are provided for information only

(ASTM Color Scale)

and are not considered standard.

D1816 Test Method for Dielectric Breakdown Voltage of

1.6 This standard does not purport to address all of the

Insulating Liquids Using VDE Electrodes

safety concerns, if any, associated with its use. It is the

D2413 Practice for Preparation of Insulating Paper and

responsibility of the user of this standard to consult and

Board Impregnated with a Liquid Dielectric

1 2

These test methods are under the jurisdiction of ASTM Committee D09 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical and Electronic Insulating Materials and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D09.01 on Electrical Insulating Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2009. Published February 2010. Originally the ASTM website.

approved in 1975. Last previous edition approved in 2005 as D3394 – 94 (2005). The last approved version of this historical standard is referenced on

DOI: 10.1520/D3394-94R09. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3394 − 94 (2009)

D2865 Practice for Calibration of Standards and Equipment 7.1.2 unit of product—an entity of electrical insulating

for Electrical Insulating Materials Testing board on which one or more quality characteristics may be

D3426 Test Method for Dielectric Breakdown Voltage and determined. A unit of product may be a sheet, pallet, box,

DielectricStrengthofSolidElectricalInsulatingMaterials carton, case, package, or bundle. The unit of product is

Using Impulse Waves established by the customer and may or may not be the same

D3455 Test Methods for Compatibility of Construction Ma- as the unit of purchase, supply, production, or shipment.

terial with Electrical Insulating Oil of Petroleum Origin

D3487 Specification for Mineral Insulating Oil Used in 8. Establishing Acceptable Quality Levels (AQLs)

Electrical Apparatus

8.1 Acceptable quality levels (AQLs) for each major and

D3636 Practice for Sampling and Judging Quality of Solid

minor property (as defined in Practice D3636) shall be as

Electrical Insulating Materials

mutually agreed upon between the purchaser and the seller. In

D4243 Test Method for Measurement ofAverage Viscomet-

addition, group AQLs may be established for given groups of

ric Degree of Polymerization of New andAged Electrical

propertiesandthesetooshallbemutuallyagreeduponbetween

Papers and Boards

the purchaser and the seller.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

9. Selection of Sample and Identification of Lot Sample

2.2 TAPPI Standard:

4 9.1 Samples shall be in accordance with Practice D3636,

T 413 Determination of Ash in Paper

with the exception of those paragraphs pertaining specifically

to rolls, pads, or bobbins.

3. Terminology

9.2 Mark each unit of the sample so that it may be identified

3.1 Definitions of Terms Specific to This Standard:

at any time by the seller and the purchaser.

3.1.1 electrical insulating board—a sheet structure, usually

composed of cellulosic fibers, utilized for dielectric or struc-

REPORTS

tural purposes or both in a variety of electrical apparatus.

Board is herein arbitrarily differentiated from paper in that it is

10. Report

at least 0.030 in. (0.76 mm) thick and is manufactured only in

10.1 At the completion of all tests record the results in a test

sheets of limited length. Other names for these products are

report that includes the following:

pressboard, transformer board, fuller board, and press pan.

10.1.1 Identification (of the board sampled and tested) by

4. Summary of Test Methods

lot number, type, grade, etc.,

10.1.2 Dates of testing,

4.1 This standard is a compilation of test methods for

10.1.3 Locationofthetestinglaboratoryandthenameofthe

electrical insulating board. Provisions are included for

person responsible for testing,

sampling, testing, and judging acceptability of a given quantity

10.1.4 Remarks indicating the method used and any devia-

of board.

tion from the standard,

5. Reagents 10.1.5 Testresultsasspecifiedintheindividualmethod,and

10.1.6 Specification limits for each property measured for

5.1 Reagents shall conform to the requirements set forth in

the board being tested.

Test Methods D202.

10.2 Report the results as calculated or observed values

SAMPLING

rounded to the nearest unit in the last right-hand place of

figures used in the material specification to express the limiting

6. Scope

value (see Practice E29).

6.1 This test method covers the determination of lot accept-

CONDITIONING

ability of electrical insulating board. It is designed for the

purpose of determining acceptability of all or that portion of a

11. Conditioning

shipment to a customer identified by a manufacturer’s lot

number. It is not intended to cover internal board mill quality

11.1 Conditionsamplesandspecimenscutfromthesamples

control plans. The method is intended for use in conjunction

(with the exception of samples taken for moisture determina-

with product specifications for electrical insulating board.

tion or as otherwise specified) in a circulating-air atmosphere

maintained at 50 6 2 % relative humidity and a temperature of

7. Terminology

23 6 2°C, using procedures as specified in Method D685.

7.1 Definitions of Terms Specific to This Standard:

11.2 For referee purposes, the conditioning specified in 11.1

7.1.1 The descriptions of terms used in this test method,

will give most consistent results. However, for routine testing

with the exception of the definition of “unit of product,” are in

under factory or other non-standard atmospheric conditions, if

accordance with Practice D3636.

theboardhasamoisturecontentwithintherangefrom5to7 %

as determined in Sections31–34, there will be only slight

variations from properties as determined after conditioning

Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

15 Technology Parkway South, Norcross, GA 30092, http://www.tappi.org. specified above.

D3394 − 94 (2009)

DIMENSIONS OF SHEETS APPARENT DENSITY

12. Apparatus

18. Scope

12.1 Scale—A scale of suitable length graduated such that

18.1 This test method may be used for determination of

lengths, widths, and diagonals can be directly read to within

apparent density of insulating board, using measurements of

half of the allowable tolerance for these dimensions. The scale

dimensions and weight made after appropriate conditioning.

shallbeproperlycalibratedinaccordancewithPracticeD2865.

18.2 Procedures are given for determining either the “wet-

12.2 Thickness-Measuring Device—Machinist micrometer

wet” or the “dry-dry” density.

with ratchet as specified in Test Methods D374.

19. Significance and Use

13. Sampling

19.1 Apparent density affects the dielectric and physical

13.1 Sample in accordance with Sections6–9.

characteristics of insulating board and is a factor in the

economics of its use in apparatus. This test is useful for

14. Test Specimens

specification, design, and quality control purposes.

14.1 Specimens for determination of length, width, and

squareness of sheets shall be whole sheets. For thickness

20. Apparatus

determinations, a whole sheet may be used or, if desired, a

20.1 Scale or Calipers,graduatedinunitsoflength,withthe

portion of a whole sheet will serve as a specimen. If a portion

smallest graduation equal to, or less than, 0.25 % of the

is selected as a specimen for thickness determination, that

smallest dimension to be measured, calibrated in accordance

portion shall be representative of the full width (cross-grain

with Practice D2865.

direction) of the sheet.

20.2 Balance, graduated in units of weight, with the small-

14.2 Determine the dimensions as received, provided the

est graduation equal to, or less than, 0.25 % of the specimen

moisture content is in the specification range for the material

weight, calibrated in accordance with Recommended Practice

being tested (see 11.2).

D2865.

15. Procedure

20.3 Thickness-Measuring Device, conforming to the re-

15.1 Measure the length and the width of each specimen to quirements of Test Methods D374, Method A.

the nearest appropriate unit. Make at least two measurements

20.4 Oven, conforming to the requirements of Test Method

in each direction.

D644.

15.2 Measure each of the two diagonals of each specimen.

21. Procedure

15.3 Measure the thickness in accordance with Test Meth-

21.1 From each unit of product in the sample obtained in

ods D374, Method A. Make at least five thickness determina-

tions across the sheet. accordance with Sections 6 through 9, prepare at least two

rectangular specimens having an area of at least 75 in. (0.05

NOTE 2—Points of measurement should be selected to include the areas

m ) each.

most likely to be the extremes.

21.2 Procedure A: Wet-Wet Density—Condition the speci-

16. Report

mens in accordance with Section 11.

16.1 The report shall conform to Section 10 and shall

21.3 Procedure B: Dry-Dry Density—Dry the specimens to

include the following:

constant weight in an oven at 105 6 3°C, in accordance with

16.1.1 Sheet size, reported as the average of the measure-

Test Method D644. Cool to room temperature, using a desic-

ments in each direction.

cator or other means to prevent reabsorption of moisture.

16.1.2 Squareness of the sheet, reported as the quotient of

Exposure to the open air while making the measurements

the shorter diagonal divided by the longer diagonal (for

specified in 21.4 shall be sufficiently brief that there will not be

convenience, squareness is expressed as a percent).

aweightincreaseofmorethan0.1 %oftheoven-dryweightof

the specimens.

NOTE 3—This method of calculating squareness assumes that the sheet

closely approximates a parallelogram in shape. If measurements of width

21.4 Measurethewidth,length,andthicknessinaccordance

orlengthvaryatdifferentpoints,itispossiblethatahighsquarenessvalue

with Section 15 to determine the weight of each specimen.

may be calculated from measurements on a sheet that differs significantly

from being rectangular.

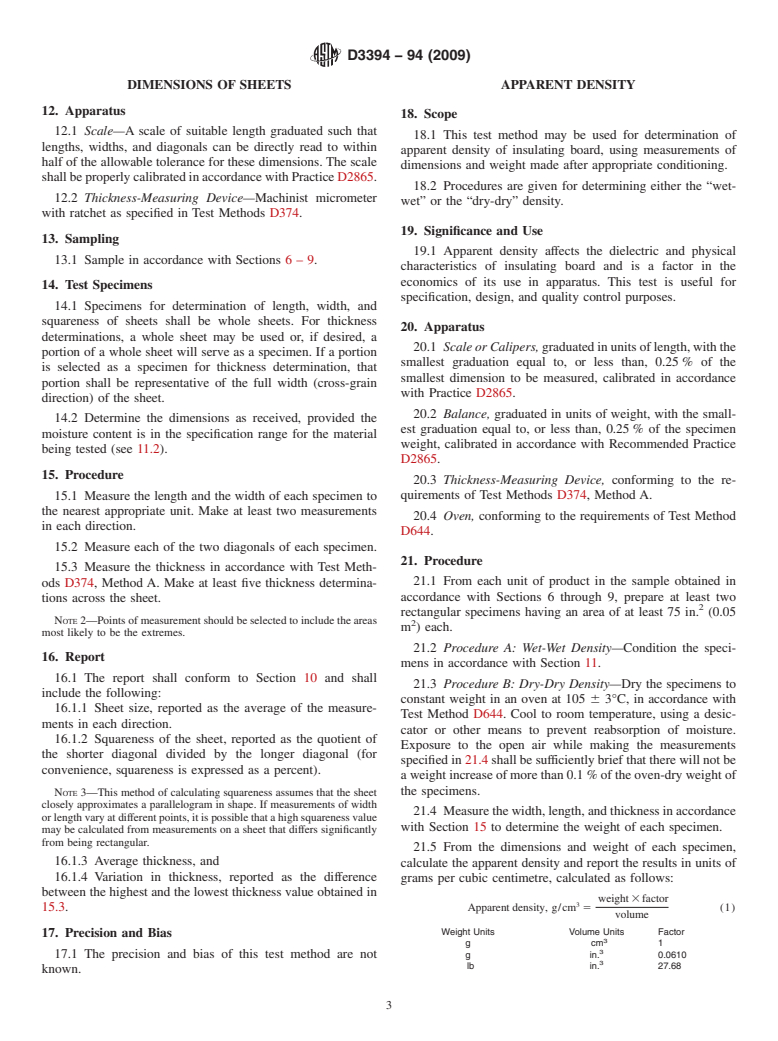

21.5 From the dimensions and weight of each specimen,

16.1.3 Average thickness, and

calculate the apparent density and report the results in units of

16.1.4 Variation in thickness, reported as the difference

grams per cubic centimetre, calculated as follows:

between the highest and the lowest thickness value obtained in

weight 3factor

Apparent density, g/cm 5 (1)

15.3.

volume

Weight Units Volume Units Factor

17. Precision and Bias

gcm 1

17.1 The precision and bias of this test method are not gin. 0.0610

lb in. 27.68

known.

D3394 − 94 (2009)

22. Report 29. Report

22.1 The report shall be in accordance with Section 10, and 29.1 The report shall be in accordance with Section 10, and

include the individual results for the apparent density of each shall include the average shrinkage for each specimen in the

specimen. grain direction, the cross direction, and the thickness.

23. Precision and Bias 30. Precision and Bias

30.1 The precision and bias of this test method are not

23.1 The precision and bias of this test method are not

known. known.

MOISTURE CONTENT

SHRINKAGE

31. Significance and Use

24. Significance and Use

24.1 The dimensions of electrical insulating boards will 31.1 Moisture content of electrical insulating board is im-

portant for economic and technical reasons. Many physical and

change as a func

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.