ASTM D5751-99(2005)

(Specification)Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products

Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products

ABSTRACT

This specification covers performance levels for adhesives to be used in laminate joints in nonstructural lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded lumber panels. This specification is to be used to evaluate adhesives as well as the adhesive bonds in nonstructural-glued-lumber products. Dry test, soak test, elevated temperature test, boil test, and vacuum pressure test shall be performed to meet the requirements prescribed. The precision and bias of exposure condition shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers performance levels for adhesives to be used in laminate joints in nonstructural lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded lumber panels. This specification is to be used to evaluate adhesives as well as the adhesive bonds in nonstructural-glued-lumber products. Note 1

This specification supersedes the laminate-joint portion of Specification D 3110. Note 2

See and for descriptions of a dry-use-nonstructural adhesive and a wet-use-nonstructural adhesive.

1.2 This specification applies to laminate-joint specimens made under both laboratory and field conditions. See Section for limitations in using this specification to evaluate industrially manufactured laminate joint products.

The following safety caveat applies only to the apparatus and test methods portions, Sections , , , and of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in inch-pound units are to be regarded as standard.

1.4 In this specification, laminate joint refers to both face and edge joints.

1.5 The following index is provided as a guide to the test methods in this specification:SectionApparatus6Conditioning7Material and Preparation of Assemblies and Specimens8Exposure Conditions and Treatments9Testing, Calculation, and Reporting10Note 3

The conditioning needed for various stages in the preparation of the specimens and for the exposure tests are given in Sections 7, 8, and 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5751 −99(Reapproved2005)

Standard Specification for

Adhesives Used for Laminate Joints in Nonstructural

Lumber Products

This standard is issued under the fixed designation D5751; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 3—The conditioning needed for various stages in the preparation

1. Scope

of the specimens and for the exposure tests are given in Sections 7, 8, and

1.1 This specification covers performance levels for adhe-

9.

sives to be used in laminate joints in nonstructural lumber

products. Such products include, but are not limited to, interior 2. Referenced Documents

andexteriormouldings,windowanddoorcomponentsorparts,

2.1 ASTM Standards:

and bonded lumber panels. This specification is to be used to

D905 Test Method for Strength Properties of Adhesive

evaluate adhesives as well as the adhesive bonds in

Bonds in Shear by Compression Loading

nonstructural-glued-lumber products.

D907 Terminology of Adhesives

D2016 Methods of Test for Moisture Content of Wood

NOTE 1—This specification supersedes the laminate-joint portion of

Specification D3110.

(Withdrawn 1987)

NOTE 2—See 3.2.1 and 3.2.2 for descriptions of a dry-use-nonstructural

D2555 PracticeforEstablishingClearWoodStrengthValues

adhesive and a wet-use-nonstructural adhesive.

D3110 Specification for Adhesives Used in Laminate Joints

1.2 This specification applies to laminate-joint specimens

for Nonstructural Glued Lumber Products (Withdrawn

made under both laboratory and field conditions. See Section 4

1996)

for limitations in using this specification to evaluate industri-

D5266 Practice for Estimating the Percentage of Wood

ally manufactured laminate joint products.

Failure in Adhesive Bonded Joints

E4 Practices for Force Verification of Testing Machines

1.3 The following safety caveat applies only to the appara-

E6 Terminology Relating to Methods of Mechanical Testing

tus and test methods portions, Sections 6, 7, 8, and 9 of this

E41 Terminology Relating To Conditioning

specification: This standard does not purport to address all of

E177 Practice for Use of the Terms Precision and Bias in

the safety concerns, if any, associated with its use. It is the

ASTM Test Methods

responsibility of the user of this standard to establish appro-

E691 Practice for Conducting an Interlaboratory Study to

priate safety and health practices and determine the applica-

Determine the Precision of a Test Method

bility of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded

3. Terminology

as standard.

3.1 Definitions:

1.5 In this specification, laminate joint refers to both face

3.1.1 Many terms in this specification are defined in Termi-

and edge joints.

nologies D907, E6, and E41.

1.6 The following index is provided as a guide to the test

3.1.2 bond, n—the union of materials by adhesives.

methods in this specification:

3.1.3 laminate joint, n—in wood bonding, a joint made by

Section

bonding layers of adherends face-to-face or edge-to-edge to

Apparatus 6

form thicker or wider stock.

Conditioning 7

Material and Preparation of Assemblies and 8

3.1.4 edge joint, n—in wood bonding, a type of laminate

Specimens

Exposure Conditions and Treatments 9 joint made by bonding adherends edge-to-edge with grain

Testing, Calculation, and Reporting 10

directions parallel to form wider stock.

1 2

This specification is under the jurisdiction of ASTM Committee D14 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Adhesives. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2005. Published May 2005. Originally the ASTM website.

approved in 1995. Last previous edition approved in 1999 as D5751 – 99. DOI: The last approved version of this historical standard is referenced on

10.1520/D5751-99R05. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5751−99(2005)

3.1.5 face joint, n—in wood bonding, a type of laminate temperature. This test method is intended to simulate condi-

joint made by bonding adherends face-to-face with grain tionsthatmightbeexperiencedintransit,furtherprocessing,or

directions parallel to form thicker stock.

in service.

3.2 Definitions of Terms Specific to This Standard:

NOTE 4—These typical service conditions may include stress and time

3.2.1 dry-use nonstructural adhesive, n— an adhesive ca-

under stress, as well as elevated temperature.

pable of producing sufficient strength and durability to make

4.2 This specification may be used to evaluate the adhesive

the bonded lumber product serviceable in nonstructural use,

bonds in a laminate joint that is the industrial-end product of a

under conditions in which the EMC of the wood does not

manufacturing process. The use of the specification for this

exceed 16 %.

purpose requires close evaluation of the configuration of the

3.2.2 wet-use nonstructural adhesive, n—an adhesive ca-

joint, the wood used, and the manufacturing process.

pable of producing sufficient strength and durability to make

4.2.1 An industrially manufactured laminate joint should be

the bonded lumber product serviceable in nonstructural use,

evaluated using the requirements for compliance to the speci-

under conditions in which the EMC of the wood may be 16 %

or greater. fication set forth in 5.1.1, 5.1.2, and 5.2.

4.2.2 To measure up to the criteria of the controlled condi-

3.3 Abbreviations:

tions of a laboratory-made specimen, hand pick the lumber,

3.3.1 EMC—equilibrium moisture content.

prepare extra joints, and select those joints that most closely

3.3.2 MC—moisture content.

meet the requirements of 5.1 and 5.2.

4. Significance and Use

4.3 Specialcircumstancesmayrequiremodificationofsome

4.1 Adhesives are classified as dry use or wet use. Each of the details of these procedures. Record these variations in

classification includes consideration of short-term in-transit

the report sections, as they may have an impact on the results

exposure conditions at temperatures up to 220°F. These test

obtained.

methods are designed to determine the performance level of a

4.4 As the industrially manufactured laminate joint product

nonstructuralwoodadhesivewhenusedinalaminatejoint.See

is often handled, machined, and shipped within a few hours of

Fig. 1 for a depiction of a laminate joint.

manufacture, it may not have reached the maximum perfor-

4.1.1 The dry test and exposure conditions and treatments

mance level before it is shipped or tested. To avoid potential

aretoevaluateadhesivesandadhesivebondsoflaminatejoints

product damage, the adhesive-performance level should be

in nonstructural bonded lumber products for typical service

determined by the laminate-joint manufacturer prior to initial

conditions.

4.1.2 The 220°F test, a more severe test, is designed to handling and early shipment. Before beginning the full testing

evaluate the product after exposure to short-term elevated process, the testing laboratory should ensure that the product

Dimensions:

A

Dimension Face Joint (Example)

Measurement, in. (mm) Tolerance, in. (mm)

Specimen width 2 (50.8) + 0.32 (0.79)

Single lamina length 1.75 (44.4) + 0.32 (0.79)

Single lamina thickness (preferred) 0.75 (19) + 0.010 (0.25)

Single lamina thickness (alternative) 0.688 (17.5) + 0.010 (0.25)

Overall specimen thickness 1.5 (38.1) + 0.32 (0.79)

Overlap between adherends 1.5 (38.1) + 0.32 (0.79)

A

The ratio of width to height should be maintained at 4/3.

FIG. 1 Block Shear Specimens

D5751−99(2005)

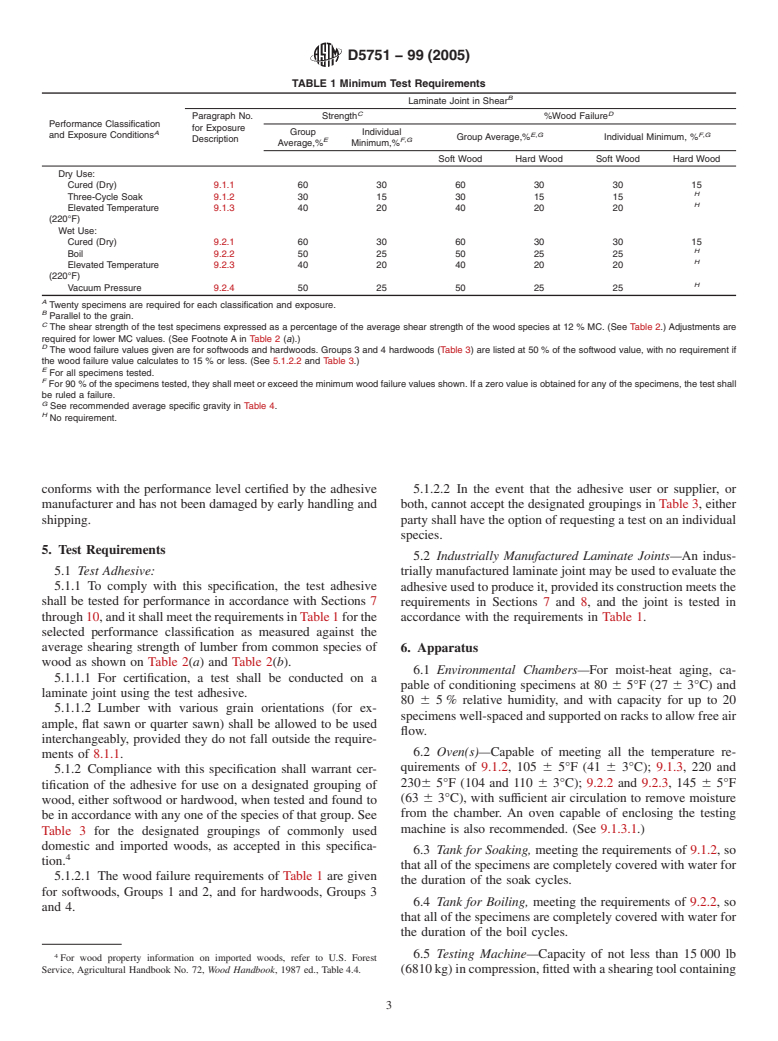

TABLE 1 Minimum Test Requirements

B

Laminate Joint in Shear

C D

Paragraph No. Strength %Wood Failure

Performance Classification

for Exposure

A Group Individual

E,G F,G

and Exposure Conditions

Group Average,% Individual Minimum, %

Description

E F,G

Average,% Minimum,%

Soft Wood Hard Wood Soft Wood Hard Wood

Dry Use:

Cured (Dry) 9.1.1 60 30 60 30 30 15

H

Three-Cycle Soak 9.1.2 30 15 30 15 15

H

Elevated Temperature 9.1.3 40 20 40 20 20

(220°F)

Wet Use:

Cured (Dry) 9.2.1 60 30 60 30 30 15

H

Boil 9.2.2 50 25 50 25 25

H

Elevated Temperature 9.2.3 40 20 40 20 20

(220°F)

H

Vacuum Pressure 9.2.4 50 25 50 25 25

A

Twenty specimens are required for each classification and exposure.

B

Parallel to the grain.

C

The shear strength of the test specimens expressed as a percentage of the average shear strength of the wood species at 12 % MC. (See Table 2.) Adjustments are

required for lower MC values. (See Footnote A in Table 2 (a).)

D

The wood failure values given are for softwoods and hardwoods. Groups 3 and 4 hardwoods (Table 3) are listed at 50 % of the softwood value, with no requirement if

the wood failure value calculates to 15 % or less. (See 5.1.2.2 and Table 3.)

E

For all specimens tested.

F

For 90 % of the specimens tested, they shall meet or exceed the minimum wood failure values shown. If a zero value is obtained for any of the specimens, the test shall

be ruled a failure.

G

See recommended average specific gravity in Table 4.

H

No requirement.

conforms with the performance level certified by the adhesive 5.1.2.2 In the event that the adhesive user or supplier, or

manufacturer and has not been damaged by early handling and both, cannot accept the designated groupings in Table 3, either

shipping. party shall have the option of requesting a test on an individual

species.

5. Test Requirements

5.2 Industrially Manufactured Laminate Joints—An indus-

5.1 Test Adhesive:

trially manufactured laminate joint may be used to evaluate the

5.1.1 To comply with this specification, the test adhesive adhesiveusedtoproduceit,provideditsconstructionmeetsthe

shall be tested for performance in accordance with Sections 7

requirements in Sections 7 and 8, and the joint is tested in

through10,anditshallmeettherequirementsinTable1forthe

accordance with the requirements in Table 1.

selected performance classification as measured against the

average shearing strength of lumber from common species of

6. Apparatus

wood as shown on Table 2(a) and Table 2(b).

6.1 Environmental Chambers—For moist-heat aging, ca-

5.1.1.1 For certification, a test shall be conducted on a

pable of conditioning specimens at 80 6 5°F (27 6 3°C) and

laminate joint using the test adhesive.

80 6 5 % relative humidity, and with capacity for up to 20

5.1.1.2 Lumber with various grain orientations (for ex-

specimens well-spaced and supported on racks to allow free air

ample, flat sawn or quarter sawn) shall be allowed to be used

flow.

interchangeably, provided they do not fall outside the require-

6.2 Oven(s)—Capable of meeting all the temperature re-

ments of 8.1.1.

quirements of 9.1.2, 105 6 5°F (41 6 3°C); 9.1.3, 220 and

5.1.2 Compliance with this specification shall warrant cer-

2306 5°F (104 and 110 6 3°C); 9.2.2 and 9.2.3, 145 6 5°F

tification of the adhesive for use on a designated grouping of

(63 6 3°C), with sufficient air circulation to remove moisture

wood, either softwood or hardwood, when tested and found to

from the chamber. An oven capable of enclosing the testing

be in accordance with any one of the species of that group. See

machine is also recommended. (See 9.1.3.1.)

Table 3 for the designated groupings of commonly used

domestic and imported woods, as accepted in this specifica-

6.3 Tank for Soaking, meeting the requirements of 9.1.2,so

tion.

that all of the specimens are completely covered with water for

5.1.2.1 The wood failure requirements of Table 1 are given

the duration of the soak cycles.

for softwoods, Groups 1 and 2, and for hardwoods, Groups 3

6.4 Tank for Boiling, meeting the requirements of 9.2.2,so

and 4.

that all of the specimens are completely covered with water for

the duration of the boil cycles.

6.5 Testing Machine—Capacity of not less than 15 000 lb

For wood property information on imported woods, refer to U.S. Forest

Service, Agricultural Handbook No. 72, Wood Handbook, 1987 ed., Table 4.4. (6810kg)incompression,fittedwithashearingtoolcontaining

D5751−99(2005)

A

TABLE 2 (a) Average Shear Strength of Common Woods at 12% Moisture Content, psi

Dry to

B

Species Green Value Green 100 % Value 60 % Value 50 % Value 40 % Value 25 % Value 20 % Value 15 % Value

C

Ratio

Cedar, Incense Incense 834 1.05 878 527 439 351 220 176 132

Douglas-Fir, Coast-Type 904 1.25 1130 678 565 452 282 226 170

Fir, White 756 1.46 1104 662 552 442 276 221 166

Hemlock, Western 864 1.49 1287 772 644 515 322 257 193

Pine, Ponderosa 704 1.61 1133 680 567 453 283 227 170

Pine, Sugar 718 1.58 1134 680 567 454 284 227 170

D

Redwood 894 1.25 1118 671 559 447 280 224 168

A

For tests conducted in which the wood moisture content is less than or greater than 12 %, the measured strength should be adjusted upward 3 % for each 1 % decrease

in moisture content, or downward 3 % for each 1 % increase in moisture content.

B

For these or other species, values are those for shear parallel to the grain in Test Methods D2555, adjusting to 12 % moisture content using the ratios of dry to green

clear wood properties of Test Methods D2555.

C

Ratio of dry to green strength in Test Methods D2555.

D

Second growth.

A

TABLE(b) Average Shear Strength of Common Woods at 12% Moisture Content, MPa

Dry to

B

Species Green Value Green Ra- 100 % Value 60 % Value 50 % Value 40 % Value 25 % Value 20 % Value 15 % Value

C

tio

Cedar, Incense Incense 5.75 1.05 6.05 3.63 3.03 2.42 1.52 1.21 0.91

Douglas-Fir, Coast-Type 6.23 1.25 7.79 4.67 3.90 3.12 1.94 1.56 1.17

Fir, White 5.21 1.46 7.61 4.56 3.80 3.05 1.90 1.52 1.14

Hemlock, Western 5.96 1.49 8.87 5.32 4.44 3.55 2.22 1.77 1.33

Pine, Ponderosa 4.85 1.61 7.81 4.69 3.91 3.12 1.95 1.56 1.17

Pine, Sugar 4.95 1.58 7.82 4.68 3.91 3.13 1.96 1.56 1.17

D

Redwood 6.16 1.25 7.71 4.63 3.85 3.08 1.93 1.54 1.16

A

For tests conducted in which the wood moisture content is less than or greater than 12 %, the measured strength should be adjusted upward 3 % for each 1 % decrease

in moisture content, or downward 3 % for each 1 % increase in moisture content.

B

For these or other species, values are those for shear parallel to the grain in Test Methods D2555, adjusting to 12 % moisture content using the ratios of dry to green

clear wood properties of Test Methods D2555.

C

Ratio of dry to green strength in Test Methods D2555.

D

Second growth.

a self-aligning seat to ensure un

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.