ASTM D3609-00

(Practice)Standard Practice for Calibration Techniques Using Permeation Tubes

Standard Practice for Calibration Techniques Using Permeation Tubes

SCOPE

1.1 This practice describes a means for utilizing permeation tubes for dynamically calibrating instruments, analyzers, and analytical procedures used in measuring concentrations of gases or vapors in atmospheres (1, 2).

1.2 Typical materials that may be sealed in permeation tubes include: sulfur dioxide, nitrogen dioxide, hydrogen sulfide, chlorine, ammonia, propane, and butane (1).

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3609–00

Standard Practice for

Calibration Techniques Using Permeation Tubes

This standard is issued under the fixed designation D 3609; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Permeation tubes are held at constant temperature in a

carrier-gas stream of dry air or nitrogen to produce a gas

1.1 This practice describes a means for using permeation

concentration dependent on the permeation rate and the flow of

tubes for dynamically calibrating instruments, analyzers, and

the carrier gas.

analytical procedures used in measuring concentrations of

gases or vapors in atmospheres (1,2).

5. Significance and Use

1.2 Typicalmaterialsthatmaybesealedinpermeationtubes

5.1 Most analytical methods used in air pollutant measure-

include: sulfur dioxide, nitrogen dioxide, hydrogen sulfide,

ments are comparative in nature and require calibration or

chlorine, ammonia, propane, and butane (1).

standardization, or both, often with known blends of the gas of

1.3 The values stated in SI units are to be regarded as the

interest. Since many of the important air pollutants are reactive

standard.

andunstable,itisdifficulttostorethemasstandardmixturesof

1.4 This standard does not purport to address all of the

known concentration for extended calibration purposes. An

safety concerns, if any, associated with its use. It is the

alternative is to prepare dynamically standard blends as re-

responsibility of the user of this standard to establish appro-

quired. This procedure is simplified if a constant source of the

priate safety and health practices and determine the applica-

gas of interest can be provided. Permeation tubes provide this

bility of regulatory limitations prior to use.

constant source, if properly calibrated and if maintained at

2. Referenced Documents constant temperature. Permeation tubes have been specified as

reference calibration sources, for certain analytical procedures,

2.1 ASTM Standards:

by the Environmental Protection Agency (3).

D 1356 Terminology Relating to Sampling and Analysis of

Atmospheres

6. Interferences and Precautions

D 3195 Practice for Rotameter Calibration

4 6.1 Permeation tubes are essentially devices to provide a

E 1 Specification for ASTM Thermometers

constant rate of emission of a specific gaseous substance over

3. Terminology periodoftime.Theyconsistofatwo-phase(gas-liquid)system

to maintain a constant vapor pressure (at constant temperature)

3.1 Definitions—For definitions of terms used in this

which is the driving force for emission of the gas through a

method, refer to Terminology D 1356.

semipermeable membrane (tube walls). They can be expected

4. Summary of Practice

to maintain a constant emission rate that is temperature

dependent as long as a significant amount of liquid is present

4.1 Aliquefiable gas, when enclosed in an inert plastic tube,

inthedevice.Theliquidshallbepure,elseitscompositionmay

escapes by permeating the tubing wall at a constant, reproduc-

change during the life time of the tube, due to differential

ible, temperature-dependent rate.

evaporation, with consequent vapor pressure changes. Care

4.2 Permeationtubesarecalibratedgravimetrically,withthe

must also be exercised that the diffusion membrane (tube

weight loss of the tube equated to the weight of the escaping

walls) is not damaged or altered during use. The contents of

material.

permeation tubes are under relatively high pressure. Accord-

ingly, there is the possibility of violent rupture of tube walls

This practice is under the jurisdiction of ASTM Committee D22 on Sampling

under high temperature exposure. Permeation rates have tem-

and Analysis of Atmospheres and is the direct responsibility of Subcommittee

perature coefficients up to 10 % per degree Celsius. When

D22.01on Quality Control.

temperature coefficients are large, above 3 % per degree

Current edition approved Sept. 10, 2000. Published November 2000. Originally

published as D 3609 – 77. Last previous edition D 3609 – 96.

Celsius, stringent temperature control is required. Furthermore

The boldface numbers in parentheses refer to references appended to this

permeation tubes exhibit temperature hysteresis so that they

standard.

must be temperature equilibrated from 2 to 24 h before use,

Annual Book of ASTM Standards, Vol 11.03.

depending upon the temperature differential between storage

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3609

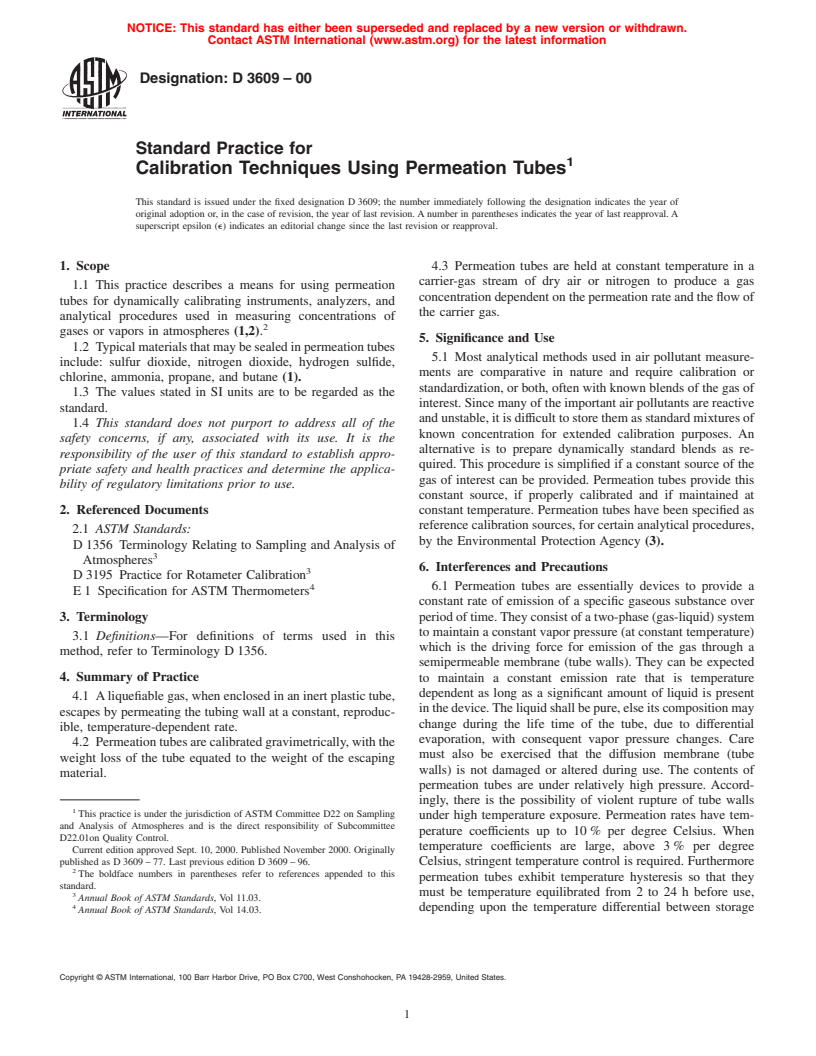

NOTE 1—This system has the advantage of smaller uncertainty of the temperature of the permeation tube.

FIG. 1 Optional System for Laboratory Use of a Permeation Tube

and use (4). It is important that permeation tubes are filled with being held at constant temperature. If lower concentrations are

anhydrous constituents of high purity. They shall be handled desired, a second gas supply (diluent gas) with its control and

with care to minimize contact with moisture, oil, and foreign measurement devices may be needed to mix with the gas from

substances. the permeation tube chamber. Equipment of this kind is

6.2 Sulfur dioxide (SO ) permeation tubes are relatively available commercially. A typical system contains a thermo-

insensitive to interferences. electrically temperature-controlled permeation tube chamber

6.3 Nitrogen dioxide (NO ) permeation tubes are sensitive with temperature control within 60.1°C over the range from

to moisture, hence they should be stored in dry atmospheres 15 to 35°C. Such equipment is well suited to field usage.

and used with relatively dry carrier gases (<10 % relative 7.3 A typical system for laboratory use that can be as-

humidity). Permeation of moisture into the contents of a tube sembled from readily available parts is shown schematically in

may damage the walls and also cause progressive decreases in Fig. 1. The parts required are described in the following

the permeation rate. Moisture incorporated in the contents subsections.

during manufacture can cause the same effect (4). 7.3.1 Flowmeters—Several, sufficient to cover the range

6.4 Hydrogen sulfide (H S) permeation tubes may turn from 0 to 15 L/min, calibrated by Practice D 3195.

white during use in the presence of oxygen because of inverse

7.3.2 Copper Tubing—Approximately 1 m long (3 ft) by

permeation and formation of collodial sulfur. This phenom-

6.25 mm (0.25 in.) in outside diameter for use as a heat

enon may affect the permeation rate, if severe, hence is a

exchanger in the water bath.

reason for recalibration. However, in an inert gas stream, the

7.3.3 Ball Joints (Ungreased) and Tubing, for the necessary

tubes are relatively stable.

connections. Butt seals may also be used made with inert

6.5 Materials of construction shall be compatible with the

materials such as polyethylene.

contents of the tube. For instance, some fluorocarbons may

7.3.4 Mixing Bulb—to ensure adequate mixing of the per-

cause FEP tubes to swell and possibly to rupture.

meated gas and the diluent gas stream. A Kjeldahl trap is

recommended.

7. Apparatus

7.3.5 Long Condenser, with large bore in which a thermom-

7.1 Permeation Tube sized in accordance with and cali- eter and a permeation tube can be inserted.

brated to concentrations needed or expected for the analysis 7.3.6 Temperature Controlled Water Bath—About 8-L (2-

method. The user should check calibration as described in gal) capacity, capable of 60.1°C or better water temperature

Section 9.1. control, with a variable temperature control range from about

7.2 Flow and Temperature Control System—Prepare or 15 to 35°C, preferably equipped with a positive displacement

purchase a system that will dry the carrier gas, and control and type recirculating pump with at least 1-L/min liquid flow rate

measure its flow as it passes over the permeation tube that is to supply water to the condenser.

D3609

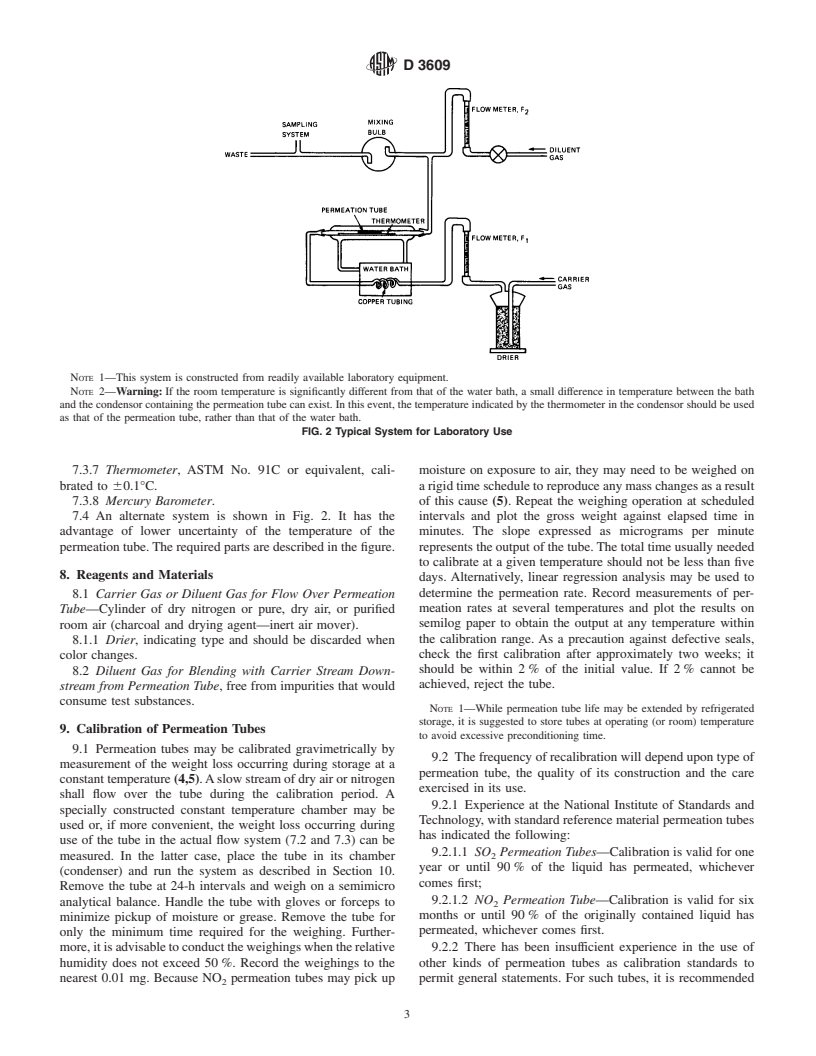

NOTE 1—This system is constructed from readily available laboratory equipment.

NOTE 2—Warning: If the room temperature is significantly different from that of the water bath, a small difference in temperature between the bath

and the condensor containing the permeation tube can exist. In this event, the temperature indicated by the thermometer in the condensor should be used

as that of the permeation tube, rather than that of the water bath.

FIG. 2 Typical System for Laboratory Use

7.3.7 Thermometer, ASTM No. 91C or equivalent, cali- moisture on exposure to air, they may need to be weighed on

brated to 60.1°C. a rigid time schedule to reproduce any mass changes as a result

7.3.8 Mercury Barometer. of this cause (5). Repeat the weighing operation at scheduled

7.4 An alternate system is shown in Fig. 2. It has the intervals and plot the gross weight against elapsed time in

advantage of lower uncertainty of the temperature of the minutes. The slope expressed as micrograms per minute

permeation tube.The required parts are described in the figure. represents the output of the tube.The total time usually needed

to calibrate at a given temperature should not be less than five

8. Reagents and Materials

days. Alternatively, linear regression analysis may b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.