ASTM D3249-95(2019)

(Practice)Standard Practice for General Ambient Air Analyzer Procedures

Standard Practice for General Ambient Air Analyzer Procedures

SIGNIFICANCE AND USE

5.1 The significance of this practice is adequately covered in Section 1.

SCOPE

1.1 This practice is a general guide for ambient air analyzers used in determining air quality.

1.2 The actual method, or analyzer chosen, depends on the ultimate aim of the user: whether it is for regulatory compliance, process monitoring, or to alert the user of adverse trends. If the method or analyzer is to be used for federal or local compliance, it is recommended that the method published or referenced in the regulations be used in conjunction with this and other ASTM methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3249 − 95 (Reapproved 2019)

Standard Practice for

General Ambient Air Analyzer Procedures

This standard is issued under the fixed designation D3249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D3609Practice for Calibration Techniques Using Perme-

ation Tubes

1.1 Thispracticeisageneralguideforambientairanalyzers

D3670Guide for Determination of Precision and Bias of

used in determining air quality.

Methods of Committee D22

1.2 The actual method, or analyzer chosen, depends on the

E177Practice for Use of the Terms Precision and Bias in

ultimate aim of the user: whether it is for regulatory

ASTM Test Methods

compliance, process monitoring, or to alert the user of adverse

E200Practice for Preparation, Standardization, and Storage

trends. If the method or analyzer is to be used for federal or

of Standard and Reagent Solutions for ChemicalAnalysis

localcompliance,itisrecommendedthatthemethodpublished

orreferencedintheregulationsbeusedinconjunctionwiththis

3. Terminology

and other ASTM methods.

3.1 Definitions—For definitions of terms used in this prac-

1.3 The values stated in SI units are to be regarded as

tice other than those following, refer to Terminology D1356.

standard. No other units of measurement are included in this

3.1.1 analyzer, n—the instrumental equipment necessary to

standard.

perform automatic analysis of ambient air through the use of

1.4 This standard does not purport to address all of the

physical and chemical properties and giving either cyclic or

safety concerns, if any, associated with its use. It is the

continuous output signal.

responsibility of the user of this standard to establish appro-

3.1.1.1 analyzer system, n—all sampling, analyzing, and

priate safety, health, and environmental practices and deter-

readoutinstrumentationrequiredtoperformambientairquality

mine the applicability of regulatory limitations prior to use.

analysis automatically.

For specific hazard statements, see Section 6.

3.1.1.2 sample system, n—equipment necessary to provide

1.5 This international standard was developed in accor-

the analyzer with a continuous representative sample.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1.1.3 readout instrumentation, n—outputmeters,recorder,

Development of International Standards, Guides and Recom-

or data acquisition system for monitoring analytical results.

mendations issued by the World Trade Organization Technical

3.1.2 full scale, n—the maximum measuring limit for a

Barriers to Trade (TBT) Committee.

given range of an analyzer.

2. Referenced Documents

3.1.3 interference, n—an undesired output caused by a

substance or substances other than the one being measured.

2.1 ASTM Standards:

The effect of interfering substance(s), on the measurement of

D1356Terminology Relating to Sampling and Analysis of

interest, shall be expressed as: (6) percentage change of

Atmospheres

measurement compared with the molar amount of the interfer-

D1357Practice for Planning the Sampling of the Ambient

ent. If the interference is nonlinear, an algebraic expression

Atmosphere

should be developed (or curve plotted) to show this varying

effect.

ThispracticeisunderthejurisdictionofASTMCommitteeD22onAirQuality

3.1.4 lag time, n—thetimeintervalfromastepchangeinthe

and is the direct responsibility of Subcommittee D22.03 on Ambient Atmospheres

and Source Emissions.

inputconcentrationattheanalyzerinlettothefirstcorrespond-

Current edition approved Oct. 1, 2019. Published October 2019. Originally

ing change in analyzer signal readout.

approved in 1973. Last previous edition approved in 2011 as D3249–95 (2011).

DOI: 10.1520/D3249-95R19.

3.1.5 linearity, n—the maximum deviation between an ac-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tual analyzer reading and the reading predicted by a straight

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

line drawn between upper and lower calibration points. This

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. deviation is expressed as a percentage of full scale.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3249 − 95 (2019)

3.1.6 minimum detection limit, n—the smallest input con- information, calibration techniques, methods for validating

centration that can be determined as the concentration ap- results, and general comments related to ambient air analyzer

proaches zero. methodsofanalysis.Thisisintendedtobeacommonreference

method which can be applied to all automatic analyzers in this

3.1.7 noise, n—random deviations from a mean output not

category.

caused by sample concentration changes.

3.1.8 operating humidity range of analyzer, n—the range of

5. Significance and Use

ambientrelativehumidityofairsurroundingtheanalyzer,over

5.1 Thesignificanceofthispracticeisadequatelycoveredin

which the analyzer will meet all performance specifications.

Section 1.

3.1.8.1 operating humidity range of sample, n—therangeof

ambient relative humidity of air which passes through the 6. Hazards

analyzer’s sensing system, over which the monitor will meet

6.1 Each analyzer installation should be given a thorough

all performance specifications. 3

safety engineering study.

3.1.9 operational period, n—the period of time over which

6.2 Electricallytheanalyzersystemaswellastheindividual

the analyzer can be expected to operate unattended within

components shall meet all code requirements for the particular

specifications.

area classification.

3.1.10 operating temperature range of analyzer, n—the

6.2.1 Allanalyzersusing120-V,a-c,60-Hz,3-wiresystems

range of ambient temperatures of air surrounding the analyzer,

should observe proper polarity and should not use mechanical

over which the monitor will meet all performance specifica-

adapters for 2-wire outlets.

tions.

6.2.2 The neutral side of the power supply at the analyzer

3.1.10.1 operating temperature range of sample, n—the

should be checked to see that it is at ground potential.

rangeofambienttemperaturesofair,whichpassesthroughthe

6.2.3 The analyzer’s ground connection should be checked

analyzer’s sensing system, over which the analyzer will meet

to earth ground for proper continuity.

all performance specifications.

6.2.4 Any analyzer containing electrically heated sections

should have a temperature-limit device.

3.1.11 output, n—asignalthatisrelatedtothemeasurement,

6.2.5 Theanalyzer,andanyrelatedelectricalequipment(the

and intended for connection to a readout or data acquisition

system), should have a power cut-off switch, and a fuse or

device. Usually this is an electrical signal expressed as milli-

breaker, on the “hot” side of the line(s) of each device.

volts or milliamperes full scale at a given impedance.

3.1.12 precision, n—see Guide D3670.

6.3 Full consideration must be given to safe disposal of the

analyzer’s spent samples and reagents.

3.1.12.1 repeatability, n—a measure of the precision of the

analyzer to repeat its results on independent introductions of

6.4 Pressurereliefvalves,ifapplicable,shallbeprovidedto

the same sample at different time intervals. This is that

protect both the analyzer and analyzer system.

differencebetweentwosuchsingleinstrumentresults,obtained

6.5 Precautions should be taken when using cylinders con-

during a stated time interval, that would be exceeded in the

taining gases or liquids under pressure. Helpful guidance may

long run in only one case in twenty when the analyzer is

be obtained from Refs (1-5).

operating normally.

6.5.1 Gascylindersmustbefastenedtoarigidstructureand

3.1.12.2 reproducibility, n—a measure of the precision of

not exposed to direct sun light or heat.

different analyzers to repeat results on the same sample.

6.5.2 Specialsafetyprecautionsshouldbetakenwhenusing

3.1.13 range, n—theconcentrationregionbetweenthemini-

or storing combustible or toxic gases to ensure that the system

mum and maximum measurable limits.

is safe and free from leaks.

3.1.14 response time, n—the time interval from a step

7. Installation of Analyzer System

change in the input concentration at the analyzer inlet to an

output reading of 90% of the ultimate reading. 7.1 Assure that information required for installation and

operation of the analyzer system is supplied by the manufac-

3.1.15 rise time, n—response time minus lag time.

turer.

3.1.16 span drift, n—the change in analyzer output over a

7.2 Study operational data and design parameters furnished

stated time period, usually 24 h of unadjusted continuous

by the supplier before installation.

operation, when the input concentration is at a constant, stated

upscale value. Span drift is usually expressed as a percentage

change of full scale over a 24-h operational period.

Theuser,equipmentsupplier,andinstallershouldbefamiliarwithrequirements

of the National Electrical Code, any local applicable electrical code, U.L. Safety

3.1.17 zero drift, n—the change in analyzer output over a

Codes, and the Occupational Safety & Health Standards (Federal Register, Vol 36,

statedtimeperiodofunadjustedcontinuousoperationwhenthe

No. 105, Part II, May 29, 1971). Helpful guidance may also be obtained fromAPI

input concentration is zero; usually expressed as a percentage

RP500,“ClassificationofAreasforElectricalInstallationsinPetroleumRefineries;”

ISA RP12.1, “Electrical Instruments in Hazardous Atmospheres;” ISA RP12.2,

change of full scale over a 24-h operational period.

“Intrinsically Safe and Nonincendive Electrical Instruments;” ISARP12.4, “Instru-

ment Purging for Reduction of Hazardous Area Classification;” and AP RP550,

4. Summary of Practice

“Installation of Refinery Instruments and Control Systems, Part II.”

4.1 Aprocedure for ambient air analyzer practices has been

The boldface numbers in parentheses refer to a list of references at the end of

outlined. It presents definitions and terms, sampling this standard.

D3249 − 95 (2019)

7.3 Review all sample requirements with the equipment 8.2.2 Formostapplications,aminimumofninesamplesare

supplier. The supplier must completely understand the appli- required, and these shall be withdrawn each cycle for intermit-

cation and work closely with the user and installer. It is tent analyzers or for continuous analyzers after a stable

absolutely necessary to define carefully all conditions of response is achieved.

intended operation, components in the atmosphere to be

8.2.3 Aftereachspotsamplehasbeenremoved,recorditas

analyzed, and expected variations in sample composition. to time, sample number, date and corresponding analyzer

readout.Thisequivalentreadoutisusedinestablishingasingle

7.4 Choose materials of construction in contact with the

calibration point.

ambient air sample to be analyzed to prevent reaction of

8.2.4 Each spot sample must be analyzed in duplicate using

materials with the sample, sorption of components from the

the corresponding ASTM test method and the two results

sample, and entrance of contaminants through infusion or

averaged. The standard deviation for the spot sample is

diffusion (6-9).

calculated as the difference (larger value minus the smaller

7.4.1 Choose materials of construction and components of

=

value) divided by 2. If this standard deviation exceeds the

theanalyzersystemtowithstandtheenvironmentinwhichitis

test method repeatability limit, r, (see Practice E177) then that

installed.

test average must be discarded. (This assumes that a repeat-

7.4.2 Avoid the use of pipe-thread compounds in favor of

ability limit has been determined for the test method and the

polytetrafluorethylene tape.

laboratory conducting the test. This rejection criterion will

7.5 Select the sampling point so as to provide a representa-

discard 5% of the spot sample results even if the test method

tive and measurable sample as close as possible to the sample

is operating properly.)

system and analyzer (see Practice D1357).

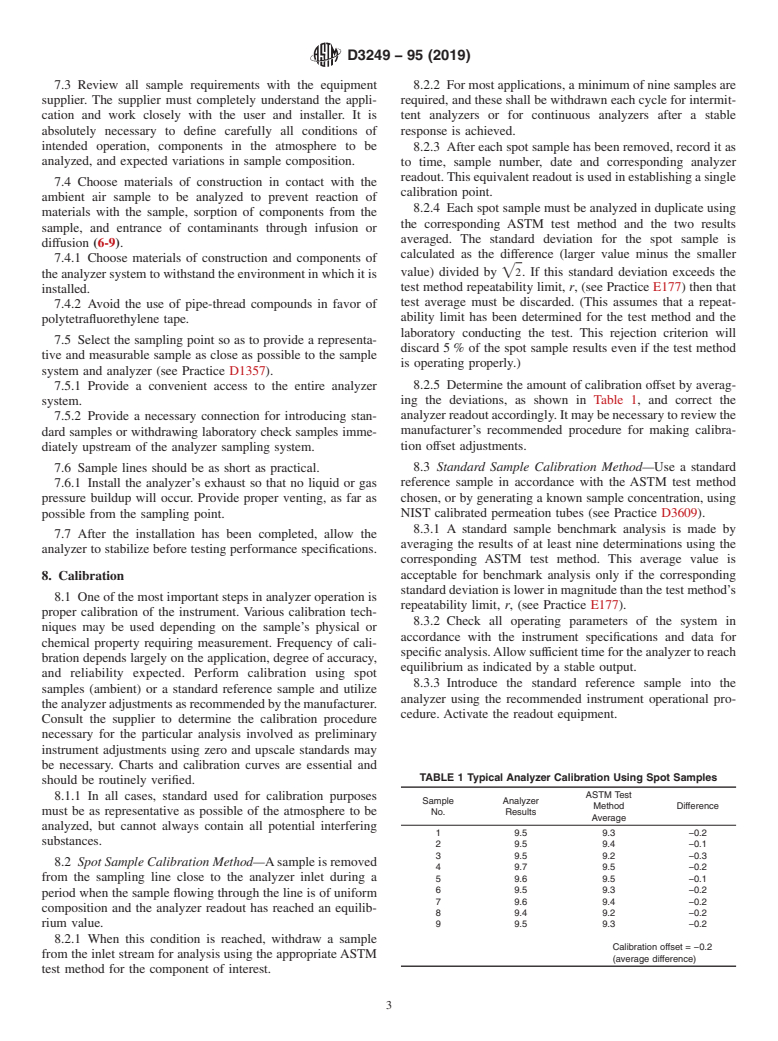

8.2.5 Determine the amount of calibration offset by averag-

7.5.1 Provide a convenient access to the entire analyzer

ing the deviations, as shown in Table 1, and correct the

system.

analyzerreadoutaccordingly.Itmaybenecessarytoreviewthe

7.5.2 Provide a necessary connection for introducing stan-

manufacturer’s recommended procedure for making calibra-

dard samples or withdrawing laboratory check samples imme-

tion offset adjustments.

diately upstream of the analyzer sampling system.

8.3 Standard Sample Calibration Method—Use a standard

7.6 Sample lines should be as short as practical.

7.6.1 Install the analyzer’s exhaust so that no liquid or gas reference sample in accordance with the ASTM test method

chosen, or by generating a known sample concentration, using

pressure buildup will occur. Provide proper venting, as far as

possible from the sampling point. NIST calibrated permeation tubes (see Practice D3609).

8.3.1 A standard sample benchmark analysis is made by

7.7 After the installation has been completed, allow the

averaging the results of at least nine determinations using the

analyzer to stabilize before testing performance specifications.

corresponding ASTM test method. This average value is

acceptable for benchmark analysis only if the corresponding

8. Calibration

standarddeviationislowerinmagnitudethanthetestmethod’s

8.1 Oneofthemostimportantstepsinanalyzeroperationis

repeatability limit, r, (see Practice E177).

proper calibration of the instrument. Various calibration tech-

8.3.2 Check all operating parameters of the system in

niques may be used depending on the sample’s physical or

accordance with the instrument specifications and data for

chemical property requiring measurement. Frequency of cali-

specificanalysis.Allowsufficienttimefortheanalyzertoreach

bration depends largely on the application, degree of accuracy,

equilibrium as indicated by a stable output.

and reliability expected. Perform calibration using spot

8.3.3 Introduce the standard reference sample into the

samples (ambient) or a standard reference sample and utilize

analyzer using the recommended instrument operational pro-

theanalyzeradjustmentsasrecommendedbythemanufacturer.

cedure. Activate the readout equipme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.