ASTM D7016/D7016M-20

(Test Method)Standard Test Method to Evaluate Edge Binding Components Used in Mattresses After Exposure to An Open Flame

Standard Test Method to Evaluate Edge Binding Components Used in Mattresses After Exposure to An Open Flame

SIGNIFICANCE AND USE

5.1 This test method evaluates the edge binding assembly used to determine how well the two external elements along the mattress edge, essentially, the edge tape and FR sewing thread, behave after exposure to an open flame and a hot air oven. These data can be used to confirm that either the mattress or foundation, or both will pass when tested using 16 CFR1633. Evaluation of raw material components is a vital and ongoing part of any manufacturing operation, especially when each item can contribute to the technical performance of the final product.

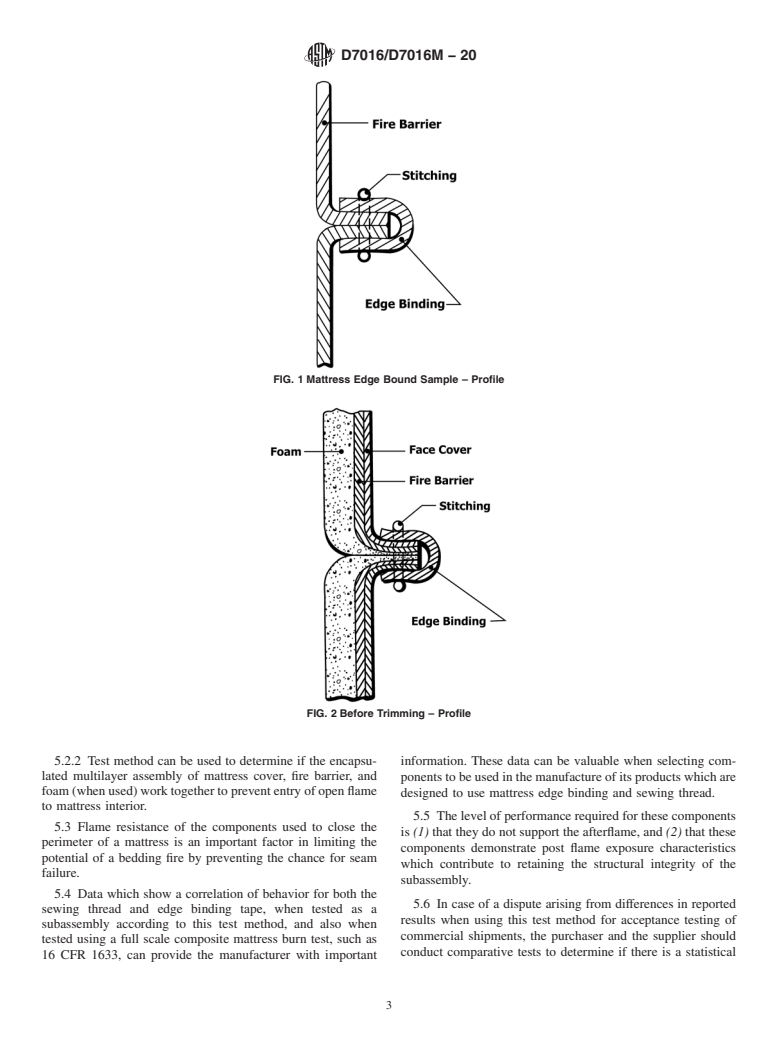

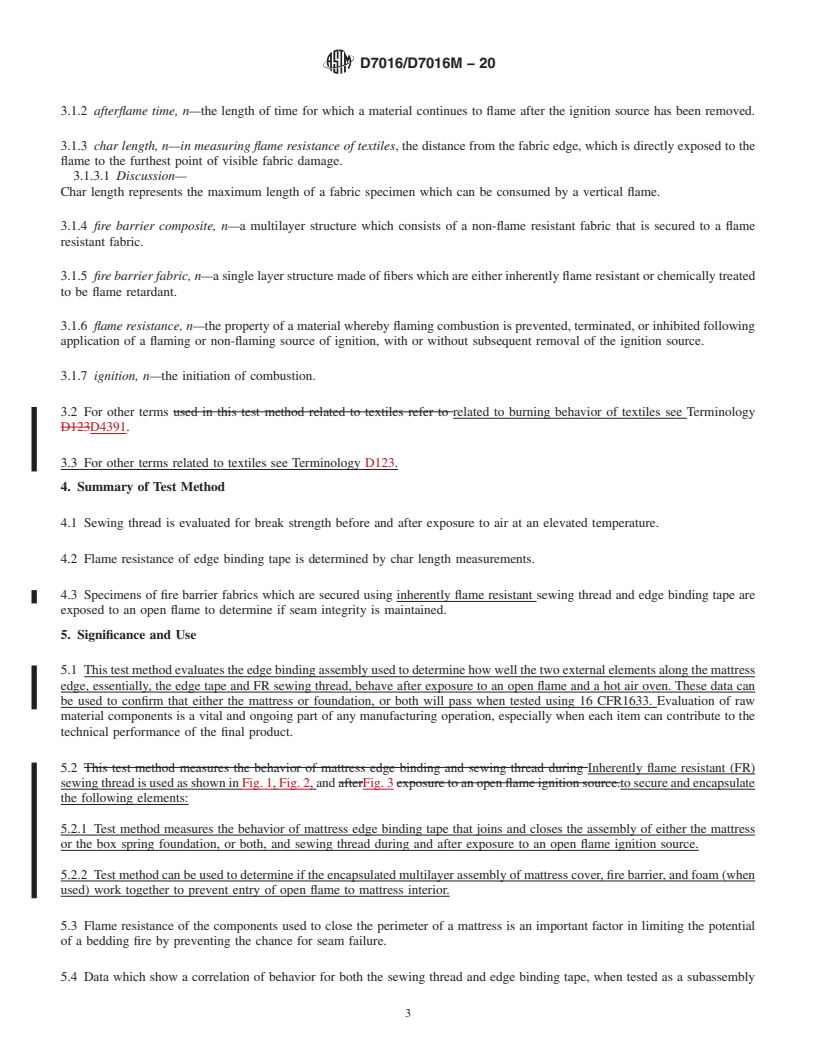

5.2 Inherently flame resistant (FR) sewing thread is used as shown in Fig. 1, Fig. 2, and Fig. 3 to secure and encapsulate the following elements:

FIG. 1 Mattress Edge Bound Sample – Profile

FIG. 2 Before Trimming – Profile

FIG. 3 After Trimming – Profile

5.2.1 Test method measures the behavior of mattress edge binding tape that joins and closes the assembly of either the mattress or the box spring foundation, or both, and sewing thread during and after exposure to an open flame ignition source.

5.2.2 Test method can be used to determine if the encapsulated multilayer assembly of mattress cover, fire barrier, and foam (when used) work together to prevent entry of open flame to mattress interior.

5.3 Flame resistance of the components used to close the perimeter of a mattress is an important factor in limiting the potential of a bedding fire by preventing the chance for seam failure.

5.4 Data which show a correlation of behavior for both the sewing thread and edge binding tape, when tested as a subassembly according to this test method, and also when tested using a full scale composite mattress burn test, such as 16 CFR 1633, can provide the manufacturer with important information. These data can be valuable when selecting components to be used in the manufacture of its products which are designed to use mattress edge binding and sewing thread.

5.5 The level of performance required for these comp...

SCOPE

1.1 This test method measures the flammability characteristics of mattress edge bindings and sewing threads during and after exposure to an open flame ignition source.

1.1.1 This test method is used to evaluate these components either independently or in combination for use in mattresses designed with a fire barrier fabric.

1.1.1.1 The test method is used to evaluate mattress edge binding and sewing thread when the design requires the use of these components.

1.1.2 This test method can be used as a screening test method to determine how sewing thread and mattress edge binding component combinations will perform.

1.2 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.3 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of Inter...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7016/D7016M − 20

Standard Test Method to

Evaluate Edge Binding Components Used in Mattresses

1

After Exposure to An Open Flame

This standard is issued under the fixed designation D7016/D7016M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Evaluation of raw material components is a vital and ongoing part of any manufacturing operation,

especially when each item can contribute to the technical performance of the final product.

Components used in a mattress construction govern the ultimate product performance, its comfort and

durability, and also affect its flammability behavior.

The textile components used on the exterior of the mattress—mattress tape and sewing thread—are

critical for holding the structure together. These components contribute to the aesthetics of the

structure, and they are also susceptible to ignition when exposed to an open flame hazard. Data which

indicate that these two components are able to meet minimum performance criteria when exposed to

an open flame provides the mattress manufacturers with valuable information.

The value of these data increases when the behavior of components in a small scale test correlate

to the behavior of these components in a full scale mattress burn test.The performance criteria require

that: (1) the components do not support the combustion of the afterflame and, (2) that these

components demonstrate post flame exposure characteristics which contribute to the retention of

structural integrity and prevent seam rupture. This test method can be used as a quality control

technique in a supplier quality assurance program.

1. Scope assessment of the materials, products, or assemblies under

actual fire conditions.

1.1 This test method measures the flammability character-

istics of mattress edge bindings and sewing threads during and 1.3 Fire testing of products and materials is inherently

after exposure to an open flame ignition source.

hazardous, and adequate safeguards for personnel and property

1.1.1 This test method is used to evaluate these components shall be employed in conducting these tests.

either independently or in combination for use in mattresses

1.4 The values stated in either SI units or inch-pound units

designed with a fire barrier fabric.

are to be regarded separately as standard. The values stated in

1.1.1.1 The test method is used to evaluate mattress edge

each system are not necessarily exact equivalents; therefore, to

binding and sewing thread when the design requires the use of

ensure conformance with the standard, each system shall be

these components.

used independently of the other, and values from the two

1.1.2 This test method can be used as a screening test

systems shall not be combined.

method to determine how sewing thread and mattress edge

1.5 This standard does not purport to address all of the

binding component combinations will perform.

safety concerns, if any, associated with its use. It is the

1.2 This standard is used to measure and describe the

responsibility of the user of this standard to establish appro-

response of materials, products, or assemblies to heat and

priate safety, health, and environmental practices and deter-

flame under controlled conditions, but does not by itself

mine the applicability of regulatory limitations prior to use.

incorporate all factors required for fire hazard or fire risk

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

ization established in the Decision on Principles for the

and is the direct responsibility of Subcommittee D13.52 on Flammability.

Development of International Standards, Guides and Recom-

Current edition approved Aug. 1, 2020. Published September 2020. Originally

mendations issued by the World Trade Organization Technical

approved in 2004. Last previous edition approved in 2018 as D7016–18. DOI:

10.1520/D7016_D7016M-20. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7016/D7016M − 20

2. Referenced Documents 3.1.2 afterflame time, n—the length of time for which a

2 material continues to flame after the ignition source has been

2.1 ASTM Standards:

removed.

D123 Terminology Relating to Textiles

3.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7016/D7016M − 18 D7016/D7016M − 20

Standard Test Method to

Evaluate Edge Binding Components Used in Mattresses

1

After Exposure to An Open Flame

This standard is issued under the fixed designation D7016/D7016M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Evaluation of raw material components is a vital and ongoing part of any manufacturing operation,

especially when each item can contribute to the technical performance of the final product.

Components used in a mattress construction govern the ultimate product performance, its comfort and

durability, and also affect its flammability behavior.

The textile components used on the exterior of the mattress—mattress tape and sewing thread—are

critical for holding the structure together. These components contribute to the aesthetics of the

structure, and they are also susceptible to ignition when exposed to an open flame hazard. Data which

indicate that these two components are able to meet minimum performance criteria when exposed to

an open flame provides the mattress manufacturers with valuable information.

The value of these data increases when the behavior of components in a small scale test correlate

to the behavior of these components in a full scale mattress burn test. The performance criteria require

that: (1) the components do not support the combustion of the afterflame and, (2) that these

components demonstrate post flame exposure characteristics which contribute to the retention of

structural integrity and prevent seam rupture. This test method can be used as a quality control

technique in a supplier quality assurance program.

1. Scope

1.1 This test method measures the flammability characteristics of mattress edge bindings and sewing threads during and after

exposure to an open flame ignition source.

1.1.1 This test method is used to evaluate these components either independently or in combination for use in mattresses designed

with a fire barrier fabric.

1.1.1.1 The test method is used to evaluate mattress edge binding and sewing thread when the design requires the use of these

components.

1.1.2 This test method can be used as a screening test method to determine how sewing thread and mattress edge binding

component combinations will perform.

1.2 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.52 on Flammability.

Current edition approved Aug. 1, 2018Aug. 1, 2020. Published August 2018September 2020. Originally approved in 2004. Last previous edition approved in 20142018

as D7016–14.–18. DOI: 10.1520/D7016_D7016M-18.10.1520/D7016_D7016M-20.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7016/D7016M − 20

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.3 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be

employed in conducting these tests.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Tech

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.