ASTM E499-95(2006)

(Test Method)Standard Test Methods for Leaks Using the Mass Spectrometer Leak Detector in the Detector Probe Mode

Standard Test Methods for Leaks Using the Mass Spectrometer Leak Detector in the Detector Probe Mode

SIGNIFICANCE AND USE

Test Method A is frequently used to test large systems and complex piping installations that can be filled with a trace gas. Helium is normally used. The test method is used to locate leaks but cannot be used to quantify except for approximation. Care must be taken to provide sufficient ventilation to prevent increasing the helium background at the test site. Results are limited by the helium background and the percentage of the leaking trace gas captured by the probe.

Test Method B is used to increase the concentration of trace gas coming through the leak by capturing it within an enclosure until the signal above the helium background can be detected. By introducing a calibrated leak into the same volume for a recorded time interval, leak rates can be measured.

SCOPE

1.1 These test methods cover procedures for testing and locating the sources of gas leaking at the rate of 4.5 x 10 13 mol/s (1 x 108 Std cm 3/s) or greater. The test may be conducted on any device or component across which a pressure differential of helium or other suitable tracer gas may be created, and on which the effluent side of the leak to be tested is accessible for probing with the mass spectrometer sampling probe.

1.2 Two test methods are described:

1.2.1 Test Method A - Direct probing, and

1.2.2 Test Method B - Accumulation.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E499–95 (Reapproved 2006)

Standard Test Methods for

Leaks Using the Mass Spectrometer Leak Detector in the

,

1 2

Detector Probe Mode

This standard is issued under the fixed designation E499; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

1. Scope ANSI/ASNT CP-189 ASNT Standard for Qualification and

Certification of Nondestructive Testing Personnel

1.1 These test methods cover procedures for testing and

−13

locating the sources of gas leaking at the rate of 4.5 310

3. Terminology

−8 3

mol/s (1 310 Std cm /s) or greater. The test may be

3.1 Definitions—For definitions of terms used in this stan-

conductedonanydeviceorcomponentacrosswhichapressure

dard, see Terminology E1316, Section E.

differential of helium or other suitable tracer gas may be

created, and on which the effluent side of the leak to be tested

4. Summary of Test Methods

is accessible for probing with the mass spectrometer sampling

4.1 Section1.8oftheLeakageTestingHandbook willbeof

probe.

value to some users in determining which leak test method to

1.2 Two test methods are described:

use.

1.2.1 Test Method A—Direct probing, and

4.2 These test methods require a leak detector with a

1.2.2 Test Method B—Accumulation.

−12 −7

full-scale readout of at least 4.5 310 mol/s (1 310 Std

1.3 This standard does not purport to address all of the

3 3

cm /s) on the most sensitive range, a maximum 1-min drift of

safety concerns, if any, associated with its use. It is the

zero and sensitivity of 65% of full scale on this range, and

responsibility of the user of this standard to establish appro-

62% or less on others (see 7.1). The above sensitivities are

priate safety and health practices and determine the applica-

those obtained by probing an actual standard leak in atmo-

bility of regulatory limitations prior to use.

sphere with the detector, or sampling, probe, and not the

sensitivityofthedetectortoastandardleakattacheddirectlyto

2. Referenced Documents

4 the vacuum system.

2.1 ASTM Standards:

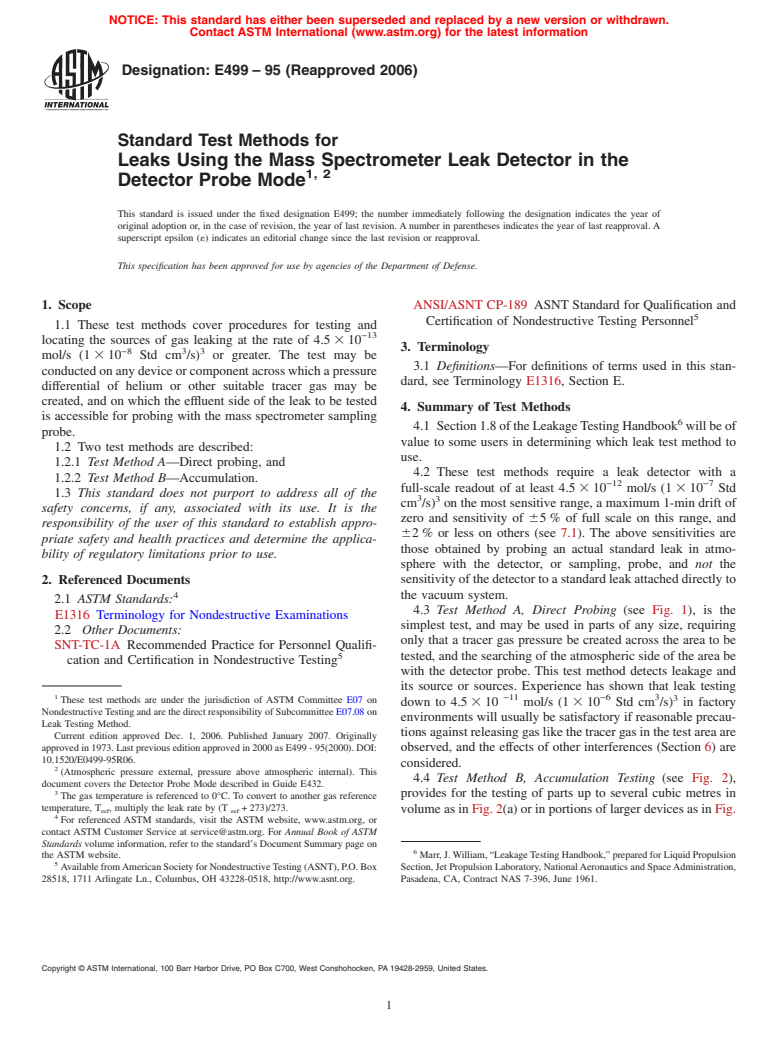

4.3 Test Method A, Direct Probing (see Fig. 1), is the

E1316 Terminology for Nondestructive Examinations

simplest test, and may be used in parts of any size, requiring

2.2 Other Documents:

only that a tracer gas pressure be created across the area to be

SNT-TC-1A Recommended Practice for Personnel Qualifi-

5 tested, and the searching of the atmospheric side of the area be

cation and Certification in Nondestructive Testing

with the detector probe. This test method detects leakage and

its source or sources. Experience has shown that leak testing

−11 −6 3

These test methods are under the jurisdiction of ASTM Committee E07 on

down to 4.5 310 mol/s (1 310 Std cm /s) in factory

NondestructiveTestingandarethedirectresponsibilityofSubcommitteeE07.08on

environments will usually be satisfactory if reasonable precau-

Leak Testing Method.

tionsagainstreleasinggaslikethetracergasinthetestareaare

Current edition approved Dec. 1, 2006. Published January 2007. Originally

approvedin1973.Lastpreviouseditionapprovedin2000asE499-95(2000).DOI:

observed, and the effects of other interferences (Section 6) are

10.1520/E0499-95R06.

considered.

(Atmospheric pressure external, pressure above atmospheric internal). This

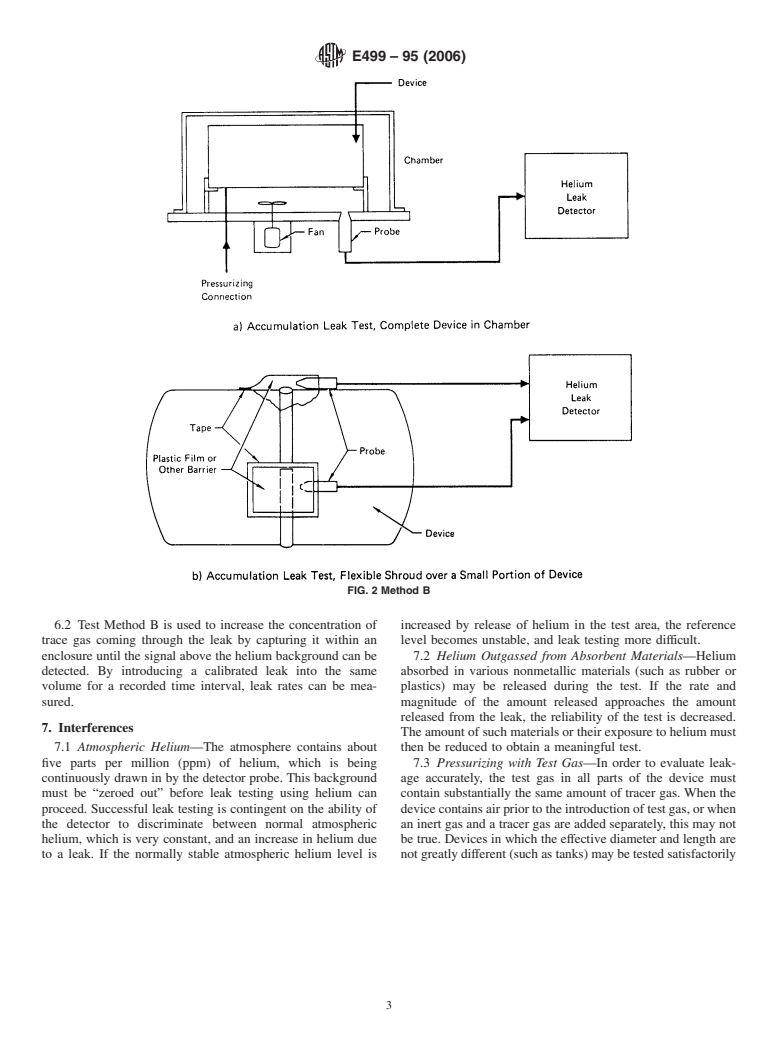

4.4 Test Method B, Accumulation Testing (see Fig. 2),

document covers the Detector Probe Mode described in Guide E432.

provides for the testing of parts up to several cubic metres in

The gas temperature is referenced to 0°C. To convert to another gas reference

temperature, T , multiply the leak rate by (T +273)/273.

ref ref volumeasinFig.2(a)orinportionsoflargerdevicesasinFig.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Marr,J.William,“LeakageTestingHandbook,”preparedforLiquidPropulsion

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box Section,JetPropulsionLaboratory,NationalAeronauticsandSpaceAdministration,

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. Pasadena, CA, Contract NAS 7-396, June 1961.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E499–95 (2006)

FIG. 1 Method A

2(b). This is accomplished by allowing the leakage to accu- 5. Personnel Qualification

mulate in the chamber for a fixed period, while keeping it well

5.1 It is recommended that personnel performing leak test-

mixed with a fan, and then testing the internal atmosphere for

ing attend a dedicated training course on the subject and pass

an increase in tracer gas content with the detector probe. The

a written examination.The training course should be appropri-

practical sensitivity attainable with this method depends pri-

ate for NDT level II qualification according to Recommended

marilyontwothings:first,onthevolumebetweenthechamber

Practice No. SNT-TC-1A of theAmerican Society for Nonde-

and the object; and second, on the amount of outgassing of

structive Testing or ANSI/ASNT Standard CP-189.

tracer gas produced by the object. Thus, a part having consid-

6. Significance and Use

erable exposed rubber, plastic, blind cavities or threads cannot

be tested with the sensitivity of a smooth metallic part. The 6.1 Test Method A is frequently used to test large systems

time in which a leak can be detected is directly proportional to and complex piping installations that can be filled with a trace

the leak rate and inversely proportional to the volume between gas.Heliumisnormallyused.Thetestmethodisusedtolocate

the chamber and the part. In theory, extremely small leaks can leaks but cannot be used to quantify except for approximation.

bedetectedbythistestmethod;however,thetimerequiredand Care must be taken to provide sufficient ventilation to prevent

the effects of other interferences limit the practical sensitivity increasing the helium background at the test site. Results are

−13 −8

of this test method to about 4.5 310 mol/s (1 310 Std limited by the helium background and the percentage of the

cm /s) for small parts. leaking trace gas captured by the probe.

E499–95 (2006)

FIG. 2 Method B

6.2 Test Method B is used to increase the concentration of increased by release of helium in the test area, the reference

trace gas coming through the leak by capturing it within an level becomes unstable, and leak testing more difficult.

enclosure until the signal above the helium background can be 7.2 Helium Outgassed from Absorbent Materials—Helium

detected. By introducing a calibrated leak into the same absorbed in various nonmetallic materials (such as rubber or

volume for a recorded time interval, leak rates can be mea- plastics) may be released during the test. If the rate and

sured. magnitude of the amount released approaches the amount

released from the leak, the reliability of the test is decreased.

7. Interferences

Theamountofsuchmaterialsortheirexposuretoheliummust

7.1 Atmospheric Helium—The atmosphere contains about then be reduced to obtain a meaningful test.

five parts per million (ppm) of helium, which is being 7.3 Pressurizing with Test Gas—In order to evaluate leak-

continuously drawn in by the detector probe. This background age accurately, the test gas in all parts of the device must

must be “zeroed out” before leak testing using helium can contain substantially the same amount of tracer gas. When the

proceed. Successful leak testing is contingent on the ability of devicecontainsairpriortotheintroductionoftestgas,orwhen

the detector to discriminate between normal atmospheric an inert gas and a tracer gas are added separately, this may not

helium, which is very constant, and an increase in helium due be true. Devices in which the effective diameter and length are

to a leak. If the normally stable atmospheric helium level is notgreatlydifferent(suchastanks)maybetestedsatisfactorily

E499–95 (2006)

by simply adding tracer gas. However, when long or restricted 9.1.2 Producing Premixed Test Gas—If the volume of the

systems are to be tested, more uniform tracer distribution will deviceorthequantitytobetestedissmall,premixedgasescan

be obtained by first evacuating to less than 100 Pa (a few torr), be conveniently obtained in cylinders. The user can also mix

and then filling with the test gas. The latter must be premixed gases by batch in the same way. Continuous mixing using

if not 100% tracer. calibrated orifices is another simple and convenient method

7.4 Dirt and Liquids—Astheorificeinthedetectorprobeis when the test pressure does not exceed 50% of the tracer gas

very small, the parts being tested should be clean and dry to pressure available.

avoid plugging. Reference should be frequently made to a

NOTE 2—When a vessel is not evacuated prior to adding test gas, the

standard leak to ascertain that this has not happened.

latter is automatically diluted by one atmosphere of air.

8. Apparatus 9.2 Liquid Nitrogen, or other means of cold trap refrigera-

tion as specified by the maker of the leak detector.

8.1 Helium Leak Detector, equipped with atmospheric de-

tector probe. To perform tests as specified in this standard, the

10. Calibration

detector should be adjusted for testing with helium and should

have the following minimum features:

10.1 The leak detectors used in making leak tests by these

8.1.1 Sensor Mass Analyzer. test methods are not calibrated in the sense that they are taken

8.1.2 Readout, analog or digital.

to the standards laboratory, calibrated, and then returned to the

−11

8.1.3 Range (linear)—A signal equivalent to 4.5 310 job. Rather, the leak detector is used as a comparator between

−6 3 3

mol/s (1 310 Std cm /s) or larger must be detectable.

a leak standard (8.2) (set to the specified leak size) which is

8.1.4 Response time,3sor less. part of the instrumentation, and the unknown leak. However,

8.1.5 Stability of Zero and Sensitivity—Amaximum varia-

the sensitivity of the leak detector is checked and adjusted on

tionof 65%offullscaleonthemostsensitiverangewhilethe the job so that a leak of specified size will give a readily

probe is active; a maximum variation of 62% of full scale on

observable, but not off-scale reading. More specific details are

other ranges for a period of 1 min. giveninSection11underthetestmethodbeingused.Toverify

sensitivity, reference to the leak standard should be made

NOTE 1—Variations may be a function of environmental interferences

before and after a prolonged test.When rapid repetitive testing

rather than equipment limitations.

of many items is required, refer to the leak standard often

8.1.6 Controls:

enough to ensure that desired test sensitivity is maintained.

8.1.6.1 Range, prefereable in scale steps of 33 and 103.

8.1.6.2 Zero,havingsufficientrangetonulloutatmospheric

11. Procedure

helium. Automatic null to zero is preferred.

11.1 General Considerations:

8.2 Helium Leak Standard—To perform leak tests as speci-

11.1.1 Test Specifications—A testing specification shall be

fied in this standard, the leak standard should meet the

in hand. This shall include:

following minimum requirements:

−8 −13 −3

11.1.1.1 The gas pressure on the high side of the device to

8.2.1 Ranges—4.5 310 to 4.5 310 mol/s (10 to

−8 3 3

betested;alsoonthelowsideifitneeddifferfromatmospheric

10 Std cm /s) full scale calibrated for discharge to atmo-

pressure.

sphere.

11.1.1.2 Thetestgascomposition,ifthereisneedtospecify

8.2.2 Adjustability—Adjustable leak standards are a conve-

it.

nience but are not mandatory.

11.1.1.3 Themaximumallowableleakrateinstandardcubic

8.2.3 Accuracy, 625% of full-scale value or better.

8.2.4 Temperature Coeffıcient, shall be stated by manufac- centimetres per second.

turer. 11.1.1.4 Whether the leak rate is for each leak or for total

8.3 Helium Leak Standard,asin 8.2 but with ranges of leakage of the device.

−12 −13 −7 −8 3

4.5 310 or 4.5 310 mol/s (10 or 10 Std cm /s). 11.1.1.5 Ifan“eachleak”specification,whetherornotother

8.4 Other Apparatus—Fixtures or other equipment specific than seams, joints, and fittings needs to be tested.

to one test method are listed under that test method.

11.1.2 Safety Factor—Where feasible, it should be ascer-

tainedthatareasonablesafetyfactorhasbeenallowedbetween

9. Material

the actual operational requirements of the device and the

9.1 Test Gas Requirements: maximum specified for testing. Experience indicates that a

factor of at least 10 should be used when possible. For

9.1.1 To be satisfactory, the test gas shall be nontoxic,

nonflammable, not detrimental to common materials, and example, if a maximum total leak rate for satisfactory opera-

−10 −6 3

tionofadeviceis2.2 310 mol/s(5 310 Stdcm /s) ,the

inexpensive. Helium, or helium mixed with air, nitrogen, or

−11 −7

someothersuitableinertgasmeetstherequirements.Ifthetest test requirement should be 2.2 310 mol/s (5 310 Std

−10 −5 3 3

cm /s) or less.

specification allows leakage of 4.5 310 mol/s (1 310

3 3

Std cm /s) or more, or if large vessels are to be tested, 11.1.3 Test Pressure—The device should be tested at or

consideration should be given to diluting the tracer gas with above its operating pressure and with the pressure drop in the

another gas such as dry air or nitrogen. This will avoid normal direction, where practical. Precautions should be taken

excessive helium input to the sensor and in the case of large sothatthedevicewillnotfailduringpressurization,orthatthe

vessels, save tracer gas expense (Note 2). operator is protected from the consequences of a failure.

E499–95 (2006)

11.1.4 Disposition or Recovery of Test Gas—Test gas 11.2.1.4 Helium Leak Standard, discharge to vacuum. Size:

−11 −6 3 3

should never be dumped into the test area if further testing is anywhere between 4.5 310 mol/s (1 310 Std cm /s)

-13 −9 3

planned. It should be vented outdoors or recovered for reuse if and 4.5 310 mol/s (1 310 Std cm /s), unless otherwise

the volume to be used makes this worthwhile. specified by maker of leak detector.

11.1.5 Detrimental Effects of Helium Tracer Gas—This gas 11.2.1.5 Test Gas, at or above specification pressure.

is quite inert, and seldom causes any problems with most 11.2.1.6 Pressure Gages, Valves, and Piping, for introduc-

materials, particula

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.