ASTM D1265-04a

(Practice)Standard Practice for Sampling Liquefied Petroleum (LP) Gases (Manual Method)

Standard Practice for Sampling Liquefied Petroleum (LP) Gases (Manual Method)

SCOPE

1.1 This practice covers equipment and procedures for obtaining a representative sample of specification Liquefied Petroleum Gas (LPG), such as specified in Specification D 1835, GPA 2140, and comparable international standards.

1.2 This practice is suitable for obtaining representative samples for all routine tests for LP gases required by Specification D 1835. In the event of a dispute involving sample integrity when sampling for testing against Specification D 1835 requirements, Practice D 3700 shall be used as the referee sampling procedure.

1.3 This practice may also be used for other Natural Gas Liquid (NGL) products that are normally single phase (NGL mix, field butane, etc.), defined in other industry specifications or contractual agreements. It is not intended for non-specification products that contain significant quantities of undissolved gases (N2, CO2), free water or other separated phases, such as raw or unprocessed gas/liquids mixtures and related materials. The same equipment can be used for these purposes, but additional precautions are generally needed to obtain representative samples of multiphase products (see Appendix A of Practice D 3700).Note 1

Practice D 3700 describes a recommended practice for obtaining a representative sample of a light hydrocarbon fluid and the subsequent preparation of that sample for laboratory analysis when dissolved gases are present. Use of Practice D 1265 will result in a small but predictable low bias for dissolved gases due to the liquid venting procedure to establish the 20 % minimum ullage.

1.4 This practice includes recommendations for the location of a sample point in a line or vessel. It is the responsibility of the user to ensure that the sampling point is located so as to obtain a representative sample.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 1265 – 04a

Standard Practice for

1

Sampling Liquefied Petroleum (LP) Gases, Manual Method

This standard is issued under the fixed designation D 1265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice covers equipment and procedures for

obtaining a representative sample of specification Liquefied

2. Referenced Documents

Petroleum Gas (LPG), such as specified in Specification

2

2.1 ASTM Standards:

D 1835D 1835, GPA 2140, and comparable international stan-

D 1835 Specification for Liquefied Petroleum (LP) Gases

dards.

D 3700 Practice for Obtaining LPG Samples Using a Float-

1.2 This practice is suitable for obtaining representative

ing Piston Cylinder

samples for all routine tests for LP gases required by Specifi-

cation D 1835D 1835. In the event of a dispute involving

3. Terminology

sample integrity when sampling for testing against Specifica-

3.1 Definitions:

tion D 1835D 1835 requirements, Practice D 3700 shall be

3.1.1 high pressure sample cylinder—a receptacle used for

used as the referee sampling procedureD 3700.

storage and transportation of a sample obtained at pressures

1.3 This practice may also be used for other Natural Gas

above atmospheric pressure.Also referred to as a “pressurized

Liquid (NGL) products that are normally single phase (NGL

sample container” or “sample bomb.” The term “sample

mix, field butane, etc.), defined in other industry specifications

bomb” is not preferred.

or contractual agreements. It is not intended for non-

3.1.2 maximum fill density (reduced fill density)—the vol-

specification products that contain significant quantities of

ume of a container occupied by the sample, usually expressed

undissolved gases (N,CO ), free water or other separated

2 2

as a percentage of the total capacity. Transportation legislation

phases, such as raw or unprocessed gas/liquids mixtures and

such as U.S. CFR 49, Canadian Transportation of Dangerous

related materials. The same equipment can be used for these

Goods Regulations and IATA regulations limit the percent fill

purposes, but additional precautions are generally needed to

of containers used for shipping LPG, and may quote this

obtain representative samples of multiphase products (see

requirement as a reduced fill density or maximum fill density

Appendix A of Practice D 3700D 3700).

(normally 80 % maximum liquid fill at 15°C). Lower percent

NOTE 1—Practice D 3700 describes a recommended practice for ob-

fill (lower fill density) may be required if sampling at lower

taining a representative sample of a light hydrocarbon fluid and the

temperatures.

subsequent preparation of that sample for laboratory analysis when

dissolved gases are present. Use of Practice D 1265 will result in a small

4. Summary of Practice

but predictable low bias for dissolved gases due to the liquid venting

4.1 A liquid sample of LPG is transferred from the source

procedure to establish the 20 % minimum ullage.

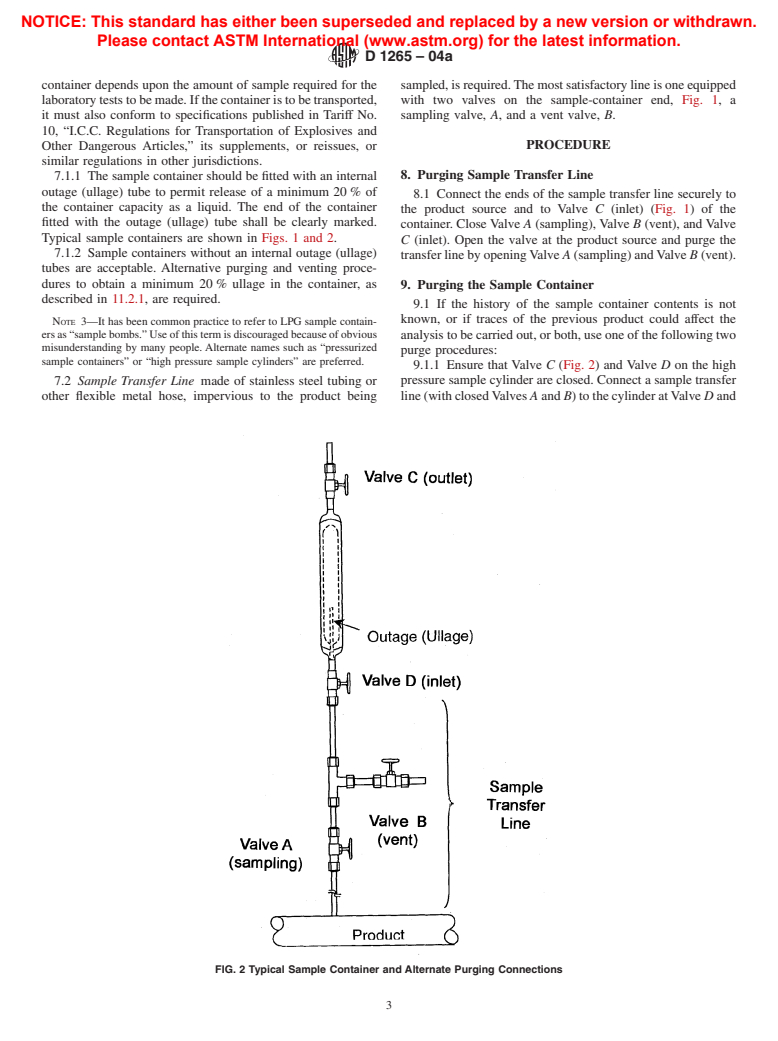

into a sample container by purging the container and filling it

1.4 This practice includes recommendations for the location

withliquid,thenprovidingaminimum20 %outagebyventing

of a sample point in a line or vessel. It is the responsibility of

liquid, so that 80 % or less of the liquid volume remains.

the user to ensure that the sampling point is located so as to

obtain a representative sample.

5. Significance and Use

1.5

5.1 Samples of liquefied petroleum gases are examined by

1.6 This standard does not purport to address all of the

various test methods to determine physical and chemical

safety concerns, if any, associated with its use. It is the

characteristics and conformance with specifications.

responsibility of the user of this standard to establish appro-

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

2

and Petroleum Products and is the direct responsibility of Subcommittee D02.H0 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Liquefied Petroleum Gas. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2004. Published November 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1953. Last previous edition approved in 2004 as D 1265–04. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.