ASTM D3520-04

(Test Method)Standard Test Method for Quenching Time of Heat-Treating Fluids (Magnetic Quenchometer Method) (Withdrawn 2008)

Standard Test Method for Quenching Time of Heat-Treating Fluids (Magnetic Quenchometer Method) (Withdrawn 2008)

SIGNIFICANCE AND USE

The results obtained by the test method described are useful as guides in selecting fluids with respect to quenching speed characteristics desired for metal quenching applications.

Note 3—Although this test method has been found useful for some water-based fluids, the statistical significance of the test has been established only by round-robin testing of petroleum-based fluids.

These results will provide a measure of quenching speed (cooling rate) from approximately 885°C (1625°F) to 354°C (670°F) and are not directly proportional to hardness obtainable on metals quenched therein as many other factors are involved in the quenching process in actual plant operation with production parts.

Note 4—Test Method D 6200 describes the equipment and procedure for characterizing the time-temperature performance of a quenching oil through the entire cooling process.

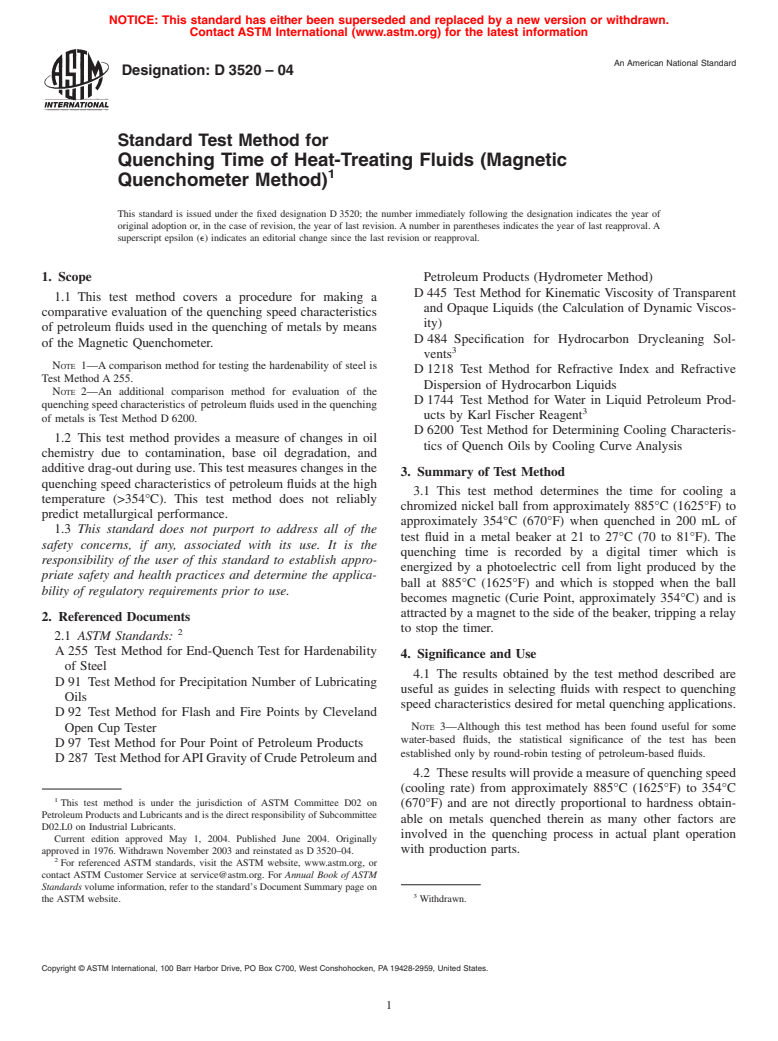

FIG. 1 Magnetic Quenchometer

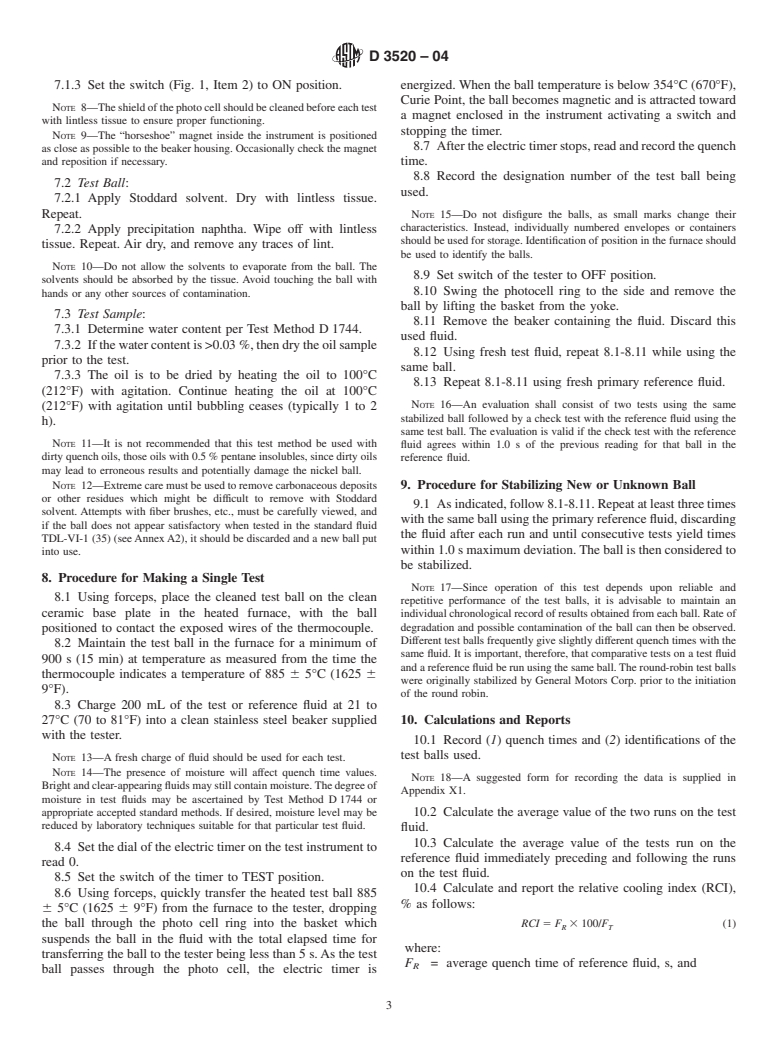

FIG. 2 Test Sequence in Beaker

SCOPE

1.1 This test method covers a procedure for making a comparative evaluation of the quenching speed characteristics of petroleum fluids used in the quenching of metals by means of the Magnetic Quenchometer.

Note 1—A comparison method for testing the hardenability of steel is Test Method A 255.

Note 2—An additional comparison method for evaluation of the quenching speed characteristics of petroleum fluids used in the quenching of metals is Test Method D 6200.

1.2 This test method provides a measure of changes in oil chemistry due to contamination, base oil degradation, and additive drag-out during use. This test measures changes in the quenching speed characteristics of petroleum fluids at the high temperature (>354°C). This test method does not reliably predict metallurgical performance.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

WITHDRAWN RATIONALE

This test method covers a procedure for making a comparative evaluation of the quenching speed characteristics of petroleum fluids used in the quenching of metals by means of the Magnetic Quenchometer.

Formerly under the jurisdiction of Committee D02 on Petroleum Products and Lubricants, this test method was withdrawn in November 2008.

This test method is being withdrawn without replacement since equipment and materials used in the standard are no longer available from any commercial supplier.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3520–04

Standard Test Method for

Quenching Time of Heat-Treating Fluids (Magnetic

1

Quenchometer Method)

This standard is issued under the fixed designation D3520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Petroleum Products (Hydrometer Method)

D445 Test Method for Kinematic Viscosity of Transparent

1.1 This test method covers a procedure for making a

and Opaque Liquids (the Calculation of Dynamic Viscos-

comparative evaluation of the quenching speed characteristics

ity)

of petroleum fluids used in the quenching of metals by means

D484 Specification for Hydrocarbon Drycleaning Sol-

of the Magnetic Quenchometer.

3

vents

NOTE 1—Acomparison method for testing the hardenability of steel is

D1218 Test Method for Refractive Index and Refractive

Test Method A255.

Dispersion of Hydrocarbon Liquids

NOTE 2—An additional comparison method for evaluation of the

D1744 Test Method for Water in Liquid Petroleum Prod-

quenching speed characteristics of petroleum fluids used in the quenching

3

ucts by Karl Fischer Reagent

of metals is Test Method D6200.

D6200 Test Method for Determining Cooling Characteris-

1.2 This test method provides a measure of changes in oil

tics of Quench Oils by Cooling Curve Analysis

chemistry due to contamination, base oil degradation, and

additivedrag-outduringuse.Thistestmeasureschangesinthe

3. Summary of Test Method

quenching speed characteristics of petroleum fluids at the high

3.1 This test method determines the time for cooling a

temperature (>354°C). This test method does not reliably

chromized nickel ball from approximately 885°C (1625°F) to

predict metallurgical performance.

approximately 354°C (670°F) when quenched in 200 mL of

1.3 This standard does not purport to address all of the

test fluid in a metal beaker at 21 to 27°C (70 to 81°F). The

safety concerns, if any, associated with its use. It is the

quenching time is recorded by a digital timer which is

responsibility of the user of this standard to establish appro-

energized by a photoelectric cell from light produced by the

priate safety and health practices and determine the applica-

ball at 885°C (1625°F) and which is stopped when the ball

bility of regulatory requirements prior to use.

becomes magnetic (Curie Point, approximately 354°C) and is

attracted by a magnet to the side of the beaker, tripping a relay

2. Referenced Documents

to stop the timer.

2

2.1 ASTM Standards:

A255 Test Method for End-Quench Test for Hardenability

4. Significance and Use

of Steel

4.1 The results obtained by the test method described are

D91 Test Method for Precipitation Number of Lubricating

useful as guides in selecting fluids with respect to quenching

Oils

speed characteristics desired for metal quenching applications.

D92 Test Method for Flash and Fire Points by Cleveland

NOTE 3—Although this test method has been found useful for some

Open Cup Tester

water-based fluids, the statistical significance of the test has been

D97 Test Method for Pour Point of Petroleum Products

established only by round-robin testing of petroleum-based fluids.

D287 TestMethodforAPIGravityofCrudePetroleumand

4.2 Theseresultswillprovideameasureofquenchingspeed

(cooling rate) from approximately 885°C (1625°F) to 354°C

1

This test method is under the jurisdiction of ASTM Committee D02 on

(670°F) and are not directly proportional to hardness obtain-

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

able on metals quenched therein as many other factors are

D02.L0 on Industrial Lubricants.

involved in the quenching process in actual plant operation

Current edition approved May 1, 2004. Published June 2004. Originally

with production parts.

approved in 1976. Withdrawn November 2003 and reinstated as D3520–04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3520–04

FIG. 1 Magnetic Quenchometer

connected controller near the heating elements can be used to minimize

temperature overrides, or both may be used. Further, 1 by 2 by 3-in. heat

sinks can be placed next to the area where the ball is to be placed to act

as heat shields and provide a more uniform temperature in this particular

area.

6. Materials

4

6.1 Ball, Chromized N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.