ASTM F3268-18

(Guide)Standard Guide for in vitro Degradation Testing of Absorbable Metals

Standard Guide for <emph type="bdit">in vitro</emph> Degradation Testing of Absorbable Metals

SIGNIFICANCE AND USE

5.1 This standard provides an itemization of potential in vitro test methods to evaluate the degradation of absorbable metals. The provided approach defers to the user of this standard to pick most appropriate method(s) based on the specific requirements of the intended application. However, a minimum of at least two different corrosion evaluation methods is considered necessary for basic profiling of the material or device, with additional methods potentially needed for an adequate characterization. However, in some instances there may be only one method that correlates to in vivo degradation results.

5.2 It is recognized that not all test methods will be meaningful for every situation. In addition, some methods carry different potential than others regarding their relative approximation to the in vivo conditions within which actual use is to occur. As a result, some discussion and ranking of the relevance of the described methods is provided by this guidance.

5.3 It should be noted that degradation of absorbable metals is not linear. Thus, precautions should be taken that evaluations of the degradation profile of a metal or metal device are appropriately adapted to reflect the varying stages and rates of degradation. Relevant factors can include the amount or percentage (%) of tissue coverage of the implanted device and the metabolic rate of surrounding tissue, which is not necessarily accompanied by a high perfusion rate.

5.4 It is recognized that in vivo environments will impart specialized considerations that can directly affect the corrosion rate, even when compared with other in vivo locations. Thus, a basic understanding of the biochemistry and physiology of the specific targeted implant location (e.g. hard tissue; soft tissue; high, low or zero perfusion areas/tissue; high, low or zero loading environments) is needed to optimize in vitro and in vivo evaluations.

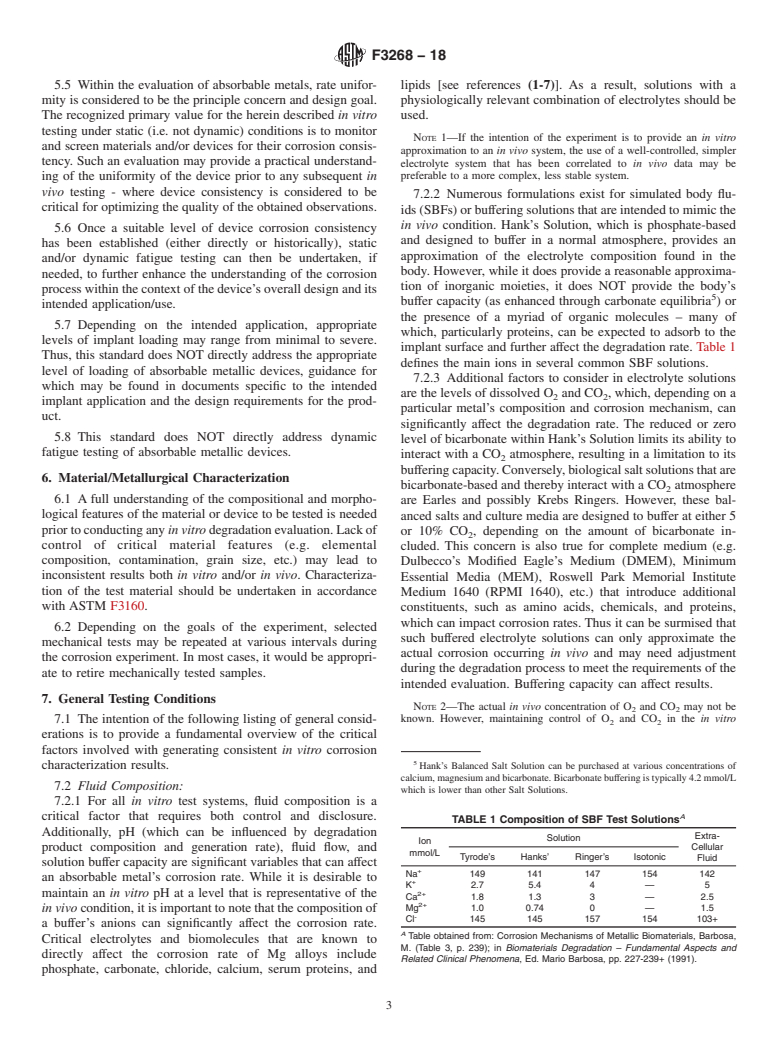

5.5 Within the evaluation of absorbable metals, rate uniformity is considered to be ...

SCOPE

1.1 The purpose of this standard is to outline appropriate experimental approaches for conducting an initial evaluation of the in vitro degradation properties of a device or test sample fabricated from an absorbable metal or alloy.

1.2 The described experimental approaches are intended to control the corrosion test environment through standardization of conditions and utilization of physiologically relevant electrolyte fluids. Evaluation of a standardized degradation control material is also incorporated to facilitate comparison and normalization of results across laboratories.

1.3 The obtained test results may be used to screen materials and/or constructs prior to evaluation of a more refined fabricated device. The described tests may also be utilized to define a device’s performance threshold prior to more extensive in vitro performance evaluations (e.g. fatigue testing) or in vivo evaluations.

1.4 This standard is considered to be applicable to all absorbable metals, including magnesium, iron, and zinc-based metals and alloys.

1.5 The described tests are not considered to be representative of in vivo conditions and could potentially provide a more rapid or slower degradation rate than an absorbable metal’s actual in vivo corrosion rate. The herein described test methods are to be used for material comparison purposes only and are not to act as either a predictor or substitute for evaluation of the in vivo degradation properties of a device.

1.6 This standard only provides guidance regarding the in vitro degradation of absorbable metals and does not address any aspect regarding either in vivo or biocompatibility evaluations.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limit...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3268 − 18

Standard Guide for

1

in vitro Degradation Testing of Absorbable Metals

This standard is issued under the fixed designation F3268; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 The purpose of this standard is to outline appropriate

ization established in the Decision on Principles for the

experimentalapproachesforconductinganinitialevaluationof

Development of International Standards, Guides and Recom-

the in vitro degradation properties of a device or test sample

mendations issued by the World Trade Organization Technical

fabricated from an absorbable metal or alloy.

Barriers to Trade (TBT) Committee.

1.2 The described experimental approaches are intended to

control the corrosion test environment through standardization

2. Referenced Documents

of conditions and utilization of physiologically relevant elec-

2

2.1 ASTM Standards:

trolyte fluids. Evaluation of a standardized degradation control

B943 Specification for Zinc and Tin Alloy Wire Used in

material is also incorporated to facilitate comparison and

Thermal Spraying for Electronic Applications

normalization of results across laboratories.

B954 Test Method for Analysis of Magnesium and Magne-

1.3 Theobtainedtestresultsmaybeusedtoscreenmaterials

sium Alloys by Atomic Emission Spectrometry

and/or constructs prior to evaluation of a more refined fabri-

E2375 Practice for Ultrasonic Testing of Wrought Products

cated device. The described tests may also be utilized to define

F1854 Test Method for Stereological Evaluation of Porous

a device’s performance threshold prior to more extensive in

Coatings on Medical Implants

vitro performance evaluations (e.g. fatigue testing) or in vivo

F2129 Test Method for Conducting Cyclic Potentiodynamic

evaluations.

Polarization Measurements to Determine the Corrosion

Susceptibility of Small Implant Devices

1.4 This standard is considered to be applicable to all

F2739 Guide for Quantifying Cell Viability within Bioma-

absorbable metals, including magnesium, iron, and zinc-based

terial Scaffolds

metals and alloys.

F3160 Guide for Metallurgical Characterization of Absorb-

1.5 The described tests are not considered to be representa-

able Metallic Materials for Medical Implants

tive of in vivo conditions and could potentially provide a more

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

rapid or slower degradation rate than an absorbable metal’s

sion Test Specimens

actual in vivo corrosion rate.The herein described test methods

G3 Practice for Conventions Applicable to Electrochemical

are to be used for material comparison purposes only and are

Measurements in Corrosion Testing

nottoactaseitherapredictororsubstituteforevaluationofthe

G4 Guide for Conducting Corrosion Tests in Field Applica-

in vivo degradation properties of a device.

tions

1.6 This standard only provides guidance regarding the in

G16 Guide for Applying Statistics to Analysis of Corrosion

vitro degradation of absorbable metals and does not address

Data

any aspect regarding either in vivo or biocompatibility evalu-

G31 Guide for Laboratory Immersion Corrosion Testing of

ations.

Metals

G46 Guide for Examination and Evaluation of Pitting Cor-

1.7 This standard does not purport to address all of the

rosion

safety concerns, if any, associated with its use. It is the

G59 Test Method for Conducting Potentiodynamic Polariza-

responsibility of the user of this standard to establish appro-

tion Resistance Measurements

priate safety, health, and environmental practices and deter-

G102 Practice for Calculation of Corrosion Rates and Re-

mine the applicability of regulatory limitations prior to use.

lated Information from Electrochemical Measurements

1

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

2

Surgical Materials and Devices and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F04.15 on Material Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2018. Published May 2018. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3268-18.vb h the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3268 − 18

G106 Practice for Verification of Algorithm and Equipment durin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.