ASTM D4644-87(1998)

(Test Method)Standard Test Method for Slake Durability of Shales and Similar Weak Rocks

Standard Test Method for Slake Durability of Shales and Similar Weak Rocks

SCOPE

1.1 This test method covers the determination of the slake durability index of a shale or other similar rock after two drying and wetting cycles with abrasion.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4644 – 87 (Reapproved 1998)

Standard Test Method for

Slake Durability of Shales and Similar Weak Rocks

This standard is issued under the fixed designation D 4644; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus

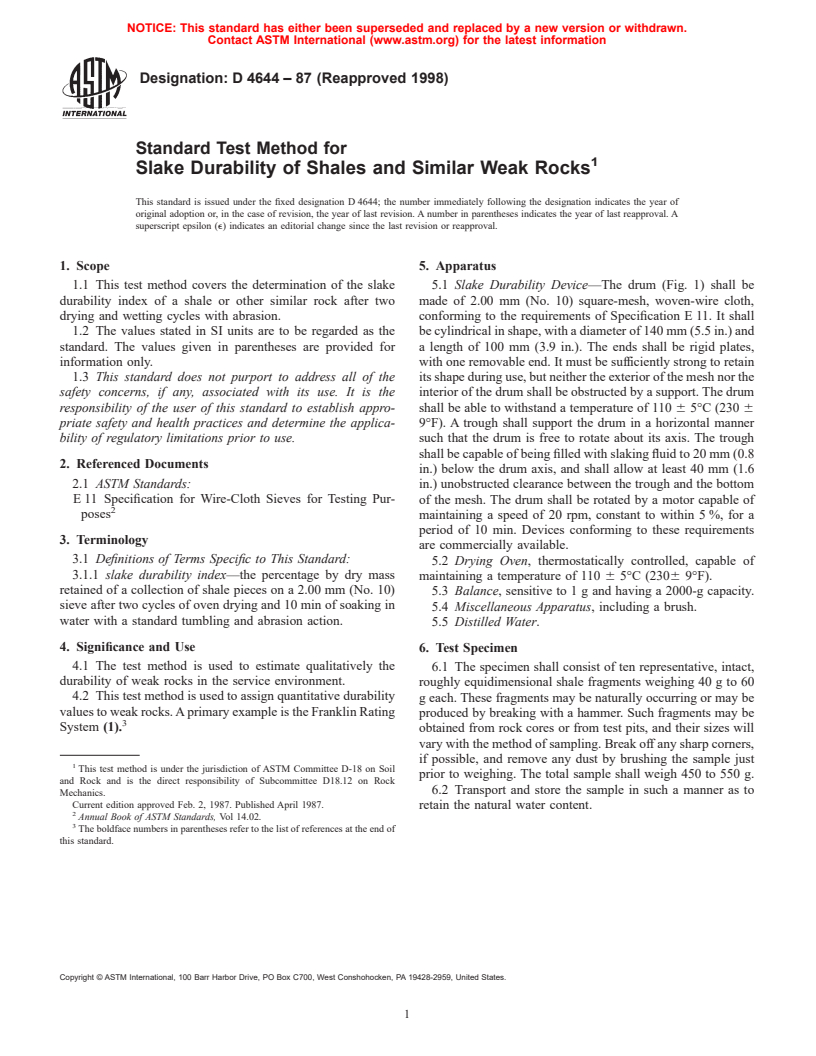

1.1 This test method covers the determination of the slake 5.1 Slake Durability Device—The drum (Fig. 1) shall be

durability index of a shale or other similar rock after two made of 2.00 mm (No. 10) square-mesh, woven-wire cloth,

drying and wetting cycles with abrasion. conforming to the requirements of Specification E 11. It shall

1.2 The values stated in SI units are to be regarded as the be cylindrical in shape, with a diameter of 140 mm (5.5 in.) and

standard. The values given in parentheses are provided for a length of 100 mm (3.9 in.). The ends shall be rigid plates,

information only. with one removable end. It must be sufficiently strong to retain

1.3 This standard does not purport to address all of the its shape during use, but neither the exterior of the mesh nor the

safety concerns, if any, associated with its use. It is the interior of the drum shall be obstructed by a support. The drum

responsibility of the user of this standard to establish appro- shall be able to withstand a temperature of 110 6 5°C (230 6

priate safety and health practices and determine the applica- 9°F). A trough shall support the drum in a horizontal manner

bility of regulatory limitations prior to use. such that the drum is free to rotate about its axis. The trough

shall be capable of being filled with slaking fluid to 20 mm (0.8

2. Referenced Documents

in.) below the drum axis, and shall allow at least 40 mm (1.6

2.1 ASTM Standards:

in.) unobstructed clearance between the trough and the bottom

E 11 Specification for Wire-Cloth Sieves for Testing Pur- of the mesh. The drum shall be rotated by a motor capable of

poses

maintaining a speed of 20 rpm, constant to within 5 %, for a

period of 10 min. Devices conforming to these requirements

3. Terminology

are commercially available.

3.1 Definitions of Terms Specific to This Standard:

5.2 Drying Oven, thermostatically controlled, capable of

3.1.1 slake durability index—the percentage by dry mass

maintaining a temperature of 110 6 5°C (2306 9°F).

retained of a collection of shale pieces on a 2.00 mm (No. 10)

5.3 Balance, sensitive to 1 g and having a 2000-g capacity.

sieve after two cycles of oven drying and 10 min of soaking in

5.4 Miscellaneous Apparatus, including a brush.

water with a standard tumbling and abrasion action.

5.5 Distilled Water.

4. Significance and Use

6. Test Specimen

4.1 The test method is used to estimate qualitatively the

6.1 The specimen shall consist of ten representative, intact,

durability of weak rocks in the service environment.

roughly equidimensional shale fragments weighing 40 g to 60

4.2 This test method is used to assign quantitative durability

g each. These fragments may be naturally occurring or may be

values to weak rocks. A primary example is the Franklin Rating

produced by breaking with a hammer. Such fragments may be

System (1).

obtained from rock cores or from test pits, and their sizes will

vary with the method of sampling. Break off any sharp corners,

if possible, and remove any dust by brushing the sample just

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

prior to weighing. The total sample shall weigh 450 to 550 g.

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

6.2 Transport and store the sample in such a manner as to

Mechanics.

Current edition approved Feb. 2, 1987. Published April 1987. retain the natural water content.

Annual Book of ASTM Standards, Vol 14.02.

The boldface numbers in parentheses refer to the list of references at the end of

this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4644

FIG. 1 Critical Dimensions of Slake Durability Equipment

7. Procedure

7.1 Place the shale fragments in the drum. Weigh, and dry in

the oven for 16 h or to constant mass. Allow the shale and drum

to cool at room temperature for 20 min and weigh again.

Calculate the natural water content as follows:

w 5 @~A 2 B!/~B 2 C!# 3 100 (1)

where:

w 5 percentage water content,

A 5 mass of drum plus sample at natural moisture content,

g,

B 5 mass of drum plus oven-dried sample before the first

cycle, g, and

C 5 mass of drum, g.

7.2 Mount the drum in the trough and couple to the motor.

Fill the trough with distilled water at room temperature to 20

mm (0.8 in.) below the drum axis. Rotate the drum at 20 r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.