ASTM E190-14

(Test Method)Standard Test Method for Guided Bend Test for Ductility of Welds

Standard Test Method for Guided Bend Test for Ductility of Welds

SIGNIFICANCE AND USE

5.1 The guided bend test as described in this test method is used to evaluate the quality of welds as a function of ductility as evidenced by their ability to resist cracking during bending.

SCOPE

1.1 This test method covers a guided bend test for the determination of soundness and ductility of welds in ferrous and nonferrous products. Flaws, not shown by X rays, may appear in the surface of a specimen when it is subjected to progressive localized overstressing. This guided bend test has been developed primarily for plates and is not intended to be substituted for other methods of bend testing.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E190 − 14

Standard Test Method for

1

Guided Bend Test for Ductility of Welds

This standard is issued under the fixed designation E190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.2 Additional welding terms including defect,

discontinuity, flaw, thermal cutting, weld root, weld face, and

1.1 This test method covers a guided bend test for the

weldment are defined in AWS A3.0M/A3.0:2010.

determination of soundness and ductility of welds in ferrous

and nonferrous products. Flaws, not shown by X rays, may

4. Summary of Test Method

appear in the surface of a specimen when it is subjected to

4.1 The specimen is bent in a U-shaped die by means of a

progressive localized overstressing. This guided bend test has

centrally applied force to the weldment in a flat specimen

been developed primarily for plates and is not intended to be

supported at two positions equidistant from the line of force

substituted for other methods of bend testing.

application. The specimen is forced into the die by a plunger

1.2 The values stated in inch-pound units are to be regarded

having the shape necessary to produce the desired contour.The

as standard. The values given in parentheses are mathematical

convex surface of the bent specimen is examined for cracks or

conversions to SI units that are provided for information only

other open flaws.

and are not considered standard.

5. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.1 The guided bend test as described in this test method is

responsibility of the user of this standard to establish appro- used to evaluate the quality of welds as a function of ductility

priate safety and health practices and determine the applica-

as evidenced by their ability to resist cracking during bending.

bility of regulatory limitations prior to use.

6. Apparatus

2. Referenced Documents 6.1 The guided bend test jig is shown in Fig. 1.

2

2.1 ASTM Standards:

7. Sampling

E6 Terminology Relating to Methods of Mechanical Testing

7.1 Sample accord with the requirements of relevant speci-

2.2 AWS Standard:

fications and codes.

AWSA3.0M/A3.0 Standard Welding Terms and Definitions;

Including Terms for Adhesive Bonding, Brazing, 8. Test Specimens

3

Soldering, Thermal Cutting, and Thermal Spraying

8.1 The types of specimens generally used for guided bend

testing are rectangular ones machined from plates and pipes.

3. Terminology

The weld-face surface of the flat specimen contains the greater

3.1 Terms in this standard are defined in E6 Terminology width of the weld material, while the opposite side is called the

Relating to Methods of Mechanical Testing. weld-root surface.

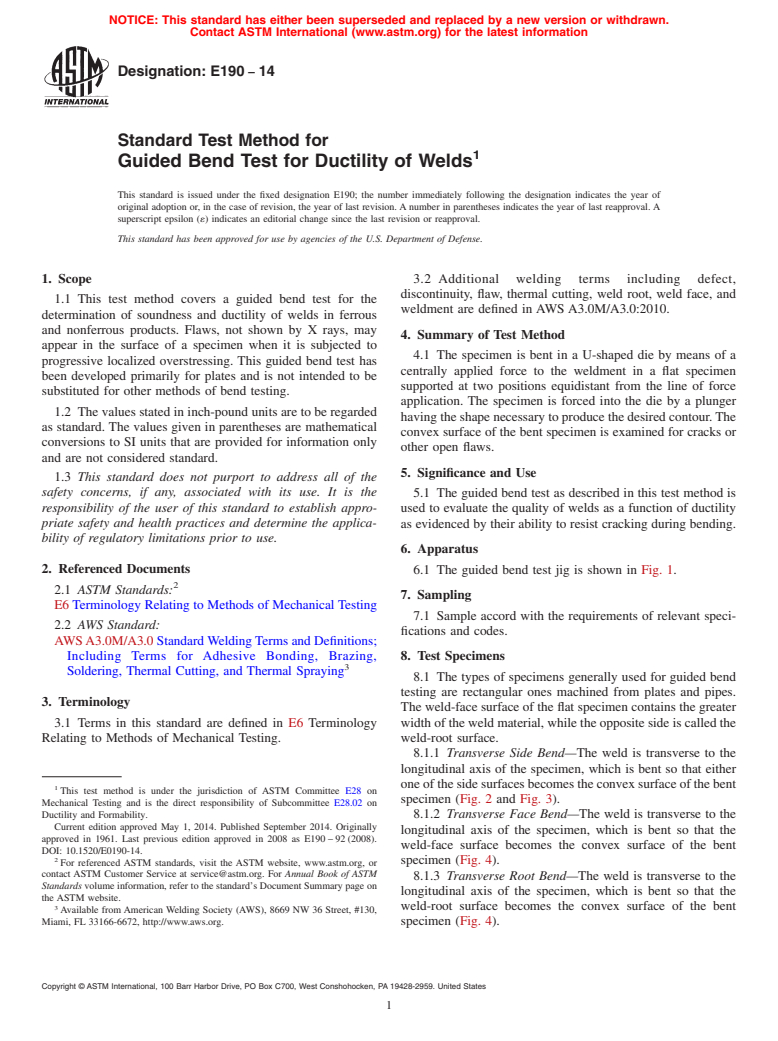

8.1.1 Transverse Side Bend—The weld is transverse to the

longitudinal axis of the specimen, which is bent so that either

oneofthesidesurfacesbecomestheconvexsurfaceofthebent

1

This test method is under the jurisdiction of ASTM Committee E28 on

specimen (Fig. 2 and Fig. 3).

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

Ductility and Formability.

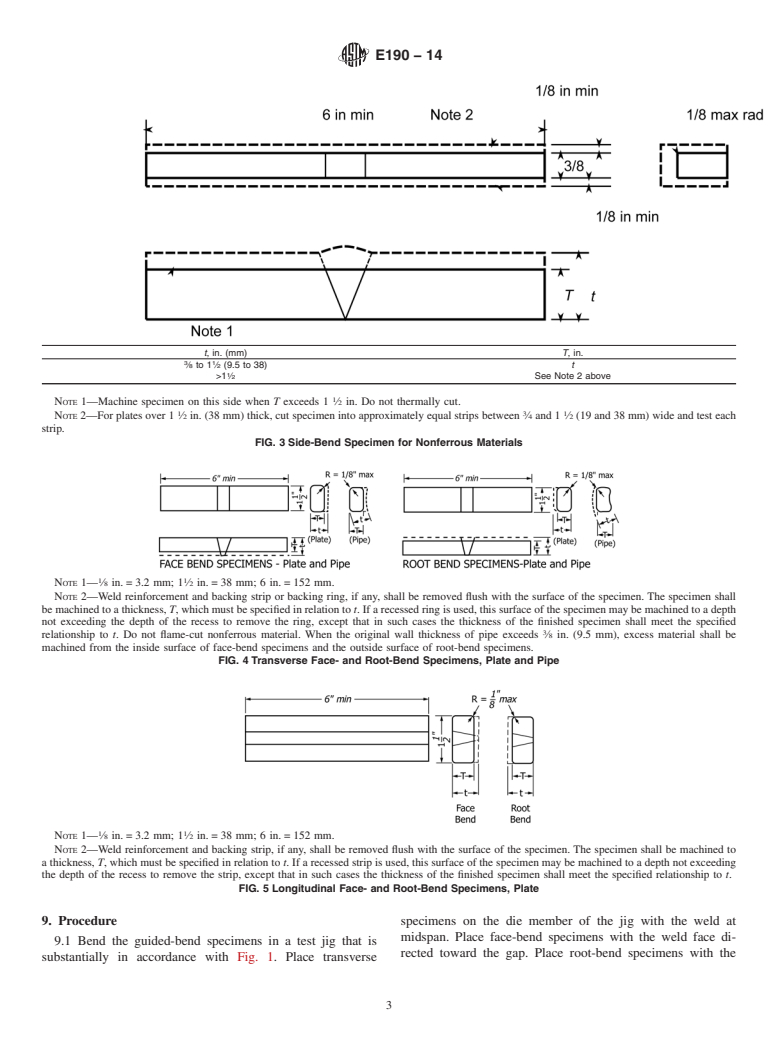

8.1.2 Transverse Face Bend—The weld is transverse to the

Current edition approved May 1, 2014. Published September 2014. Originally

longitudinal axis of the specimen, which is bent so that the

approved in 1961. Last previous edition approved in 2008 as E190 – 92 (2008).

weld-face surface becomes the convex surface of the bent

DOI: 10.1520/E0190-14.

2

specimen (Fig. 4).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1.3 Transverse Root Bend—The weld is transverse to the

Standards volume information, refer to the standard’s Document Summary page on

longitudinal axis of the specimen, which is bent so that the

the ASTM website.

3

weld-root surface becomes the convex surface of the bent

Available from American Welding Society (AWS), 8669 NW 36 Street, #130,

Miami, FL 33166-6672, http://www.aws.org. specimen (Fig. 4).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E190 − 14

Thickness of Specimen

A, in. (mm) B, in. (mm) C, in. (mm) D, in. (mm)

in. (mm)

3 1 3 3 3

⁄8 (9.5) 1 ⁄2 (38) ⁄4 (19) 2 ⁄8 (60) 1 ⁄16 (30)

1 1 1 3 3

⁄8 (3.2) 2 ⁄8 (54) 1 ⁄16 (27) 2 ⁄8 (60) 1 ⁄16 (30)

1 1

t 4t 2t 6t + ⁄8 ( + 3.2) 3t + ⁄16(+1.6)

NOTE 1—Either hardened and greased shoulders o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E190 − 92 (Reapproved 2008) E190 − 14

Standard Test Method for

1

Guided Bend Test for Ductility of Welds

This standard is issued under the fixed designation E190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a guided bend test for the determination of soundness and ductility of welds in ferrous and

nonferrous products. Defects,Flaws, not shown by X rays, may appear in the surface of a specimen when it is subjected to

progressive localized overstressing. This guided bend test has been developed primarily for plates and is not intended to be

substituted for other methods of bend testing.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 1—For additional information see Terminology E6, and American Welding Society Standard D 1.1.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

2.2 AWS Standard:

D1.1AWS A3.0M/A3.0 Structural Welding Code, SteelStandard Welding Terms and Definitions; Including Terms for Adhesive

3

Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying

3. Terminology

3.1 Terms in this standard are defined in E6 Terminology Relating to Methods of Mechanical Testing.

3.2 Additional welding terms including defect, discontinuity, flaw, thermal cutting, weld root, weld face, and weldment are

defined in AWS A3.0M/A3.0:2010.

4. Summary of Test Method

4.1 The specimen is bent in a U-shaped die by means of a centrally applied force to the weldment in a flat specimen supported

at two positions equidistant from the line of force application. The specimen is forced into the die by a plunger having the shape

necessary to produce the desired contour. The convex surface of the bent specimen is examined for cracks or other open

defects.flaws.

5. Significance and Use

5.1 The guided bend test as described in this test method is used to evaluate the quality of welds as a function of ductility as

evidenced by their ability to resist cracking during bending.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on Ductility and

Formability.

Current edition approved Sept. 1, 2008May 1, 2014. Published January 2009September 2014. Originally approved in 1961. Last previous edition approved in 20032008

as E190 – 92 (2003).(2008). DOI: 10.1520/E0190-92R08.10.1520/E0190-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from The American Welding Society (AWS), 550 NW LeJeune Rd., 8669 NW 36 Street, #130, Miami, FL 33126.33166-6672, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E190 − 14

6. Apparatus

6.1 The guided bend test jig is shown in Fig. 1 (see Explanatory Notes at end of this test method).

6. Sampling

6.1 Sampling is performed in accordance with the requirements of relevant specifications and codes.

7. Sampling

7.1 Sample accord with the requirements of relevant specifications and codes.

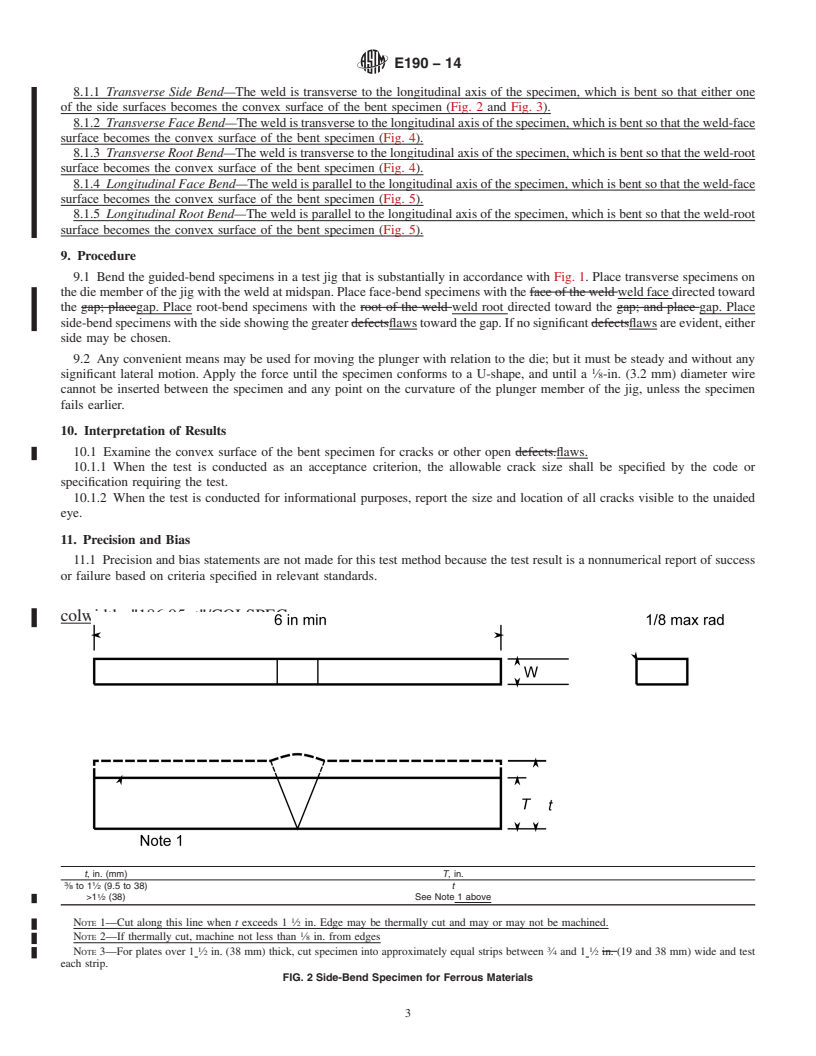

7. Test Specimens

7.1 The types of specimens generally used for guided bend testing are rectangular ones machined from plates and pipes. The

face surface of the flat specimen contains the greater width of the weld material, while the opposite side is called the root surface.

7.1.1 Transverse Side Bend—The weld is transverse to the longitudinal axis of the specimen which is bent so that either one

of the side surfaces becomes the convex surface of the bent speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.