ASTM C167-98(2003)

(Test Method)Standard Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

Standard Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

SIGNIFICANCE AND USE

Proper measurements of thickness and density of blanket or batt insulations are essential for determining thermal insulation properties. For a particular batt or blanket product, thickness and density are usually directly related to thermal insulating value.

These test methods are of significant value in manufacturing quality control, to ensure that claimed insulation values of products are maintained.

SCOPE

1.1 These test methods cover the determination of thickness and density of flexible, felted, or woven thermal insulating blankets, rolls, or batts composed of fibrous materials, with or without surface covering or reinforcement.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C167–98 (Reapproved 2003)

Standard Test Methods for

Thickness and Density of Blanket or Batt Thermal

Insulations

This standard is issued under the fixed designation C 167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 These test methods cover the determination of thickness

and density of flexible, felted, or woven thermal insulating

blankets, rolls, or batts composed of fibrous materials, with or

without surface covering or reinforcement.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 168 Terminology Relating to Thermal Insulation

3. Terminology

3.1 Definitions—Terminology C 168 shall be considered as

applicable to the terms used in these test methods.

4. Significance and Use

4.1 Proper measurements of thickness and density of blan-

ket or batt insulations are essential for determining thermal

insulation properties. For a particular batt or blanket product,

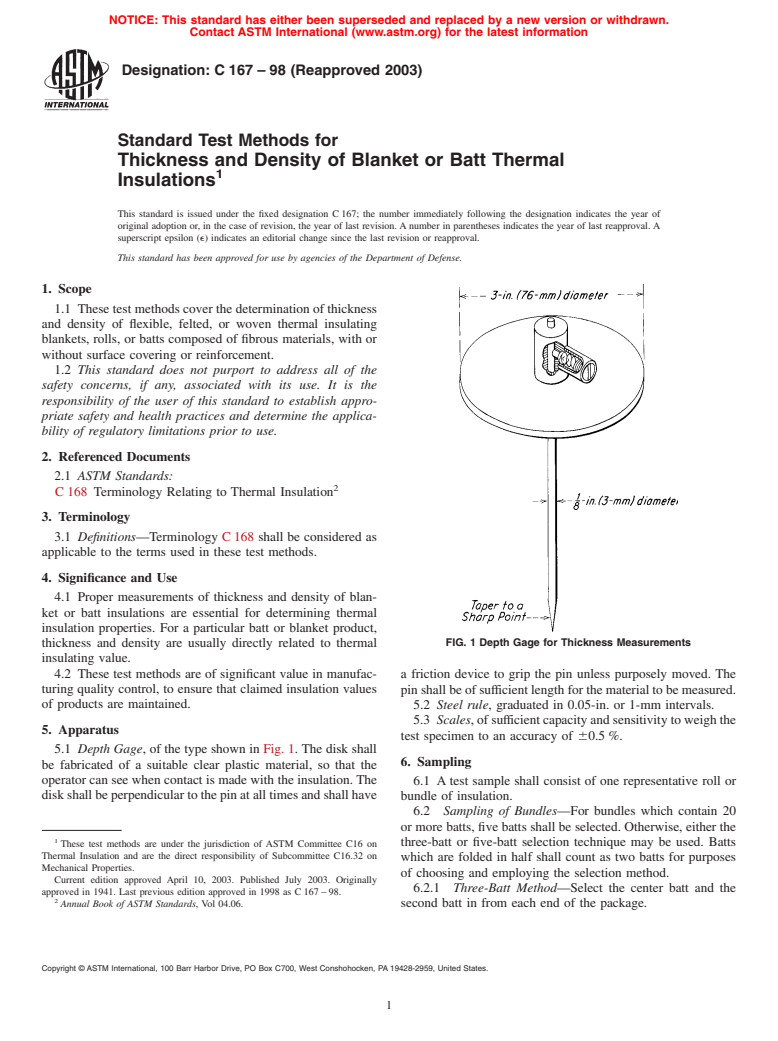

FIG. 1 Depth Gage for Thickness Measurements

thickness and density are usually directly related to thermal

insulating value.

4.2 These test methods are of significant value in manufac-

a friction device to grip the pin unless purposely moved. The

turing quality control, to ensure that claimed insulation values pin shall be of sufficient length for the material to be measured.

of products are maintained.

5.2 Steel rule, graduated in 0.05-in. or 1-mm intervals.

5.3 Scales, of sufficient capacity and sensitivity to weigh the

5. Apparatus

test specimen to an accuracy of 60.5 %.

5.1 Depth Gage, of the type shown in Fig. 1. The disk shall

6. Sampling

be fabricated of a suitable clear plastic material, so that the

operator can see when contact is made with the insulation. The

6.1 A test sample shall consist of one representative roll or

disk shall be perpendicular to the pin at all times and shall have bundle of insulation.

6.2 Sampling of Bundles—For bundles which contain 20

or more batts, five batts shall be selected. Otherwise, either the

three-batt or five-batt selection technique may be used. Batts

These test methods are under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on

which are folded in half shall count as two batts for purposes

Mechanical Properties.

of choosing and employing the selection method.

Current edition approved April 10, 2003. Published July 2003. Originally

6.2.1 Three-Batt Method—Select the center batt and the

approved in 1941. Last previous edition approved in 1998 as C 167 – 98.

Annual Book of ASTM Standards, Vol 04.06. second batt in from each end of the package.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C167–98 (2003)

6.2.2 Five-Batt Method—Divide the package sequentially

into five groups of batts as equal in number as possible. Select

the first batt from each group. Be careful to select one and only

one batt from the two end batts within the package.

6.2.3 Cut batts which are longer than 48 in. to 48 6 0.25 in.

(122 6 0.63 cm) in length.

6.3 Sampling of Cut Rolls—Five batts will be cut of

roll-width by 48 6 0.25 in. (122 6 0.63 cm) in length.

6.3.1 Cut one batt from the center of the roll, two batts from

the ends of the roll, and the fourth and fifth from the quarter

points along the length.

6.3.2 For blankets wider than 24 in., cut each of the five

batts 24 6 0.25 in. (61 6 0.63 cm) wide by 48 6 0.25 in. (122

6 0.63 cm) long.

6.4 Sampling for Full Roll Method—This method can be

used in place of 6.3 when the roll is wider than 24 in. (61 cm)

or longer than 50 ft (16.4 m). Prior to unrolling the material,

weigh the entire roll to the nearest 0.25 pound (0.11 kg). Two

methods may be used to obtain the full roll weight. The first

method removes the insulation product from the packaging

prior to weighing. The material will expand and may unroll

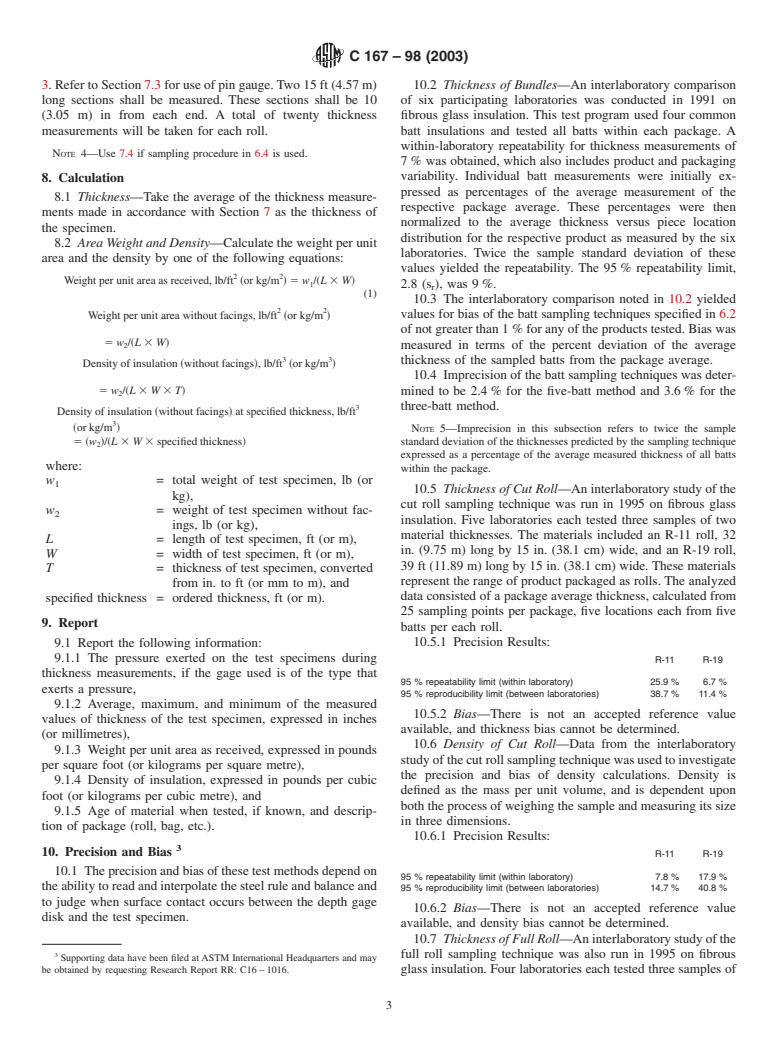

FIG. 2 Thickness Measurement Locations

slightly, care must be taken to ensure that the full roll is

weighed accurately. The second method weighs the packaged

the partially pulled roll to the end of the testing space, and

insulation product, then weighs the packaging material only.

continue to pull the material over itself.

The packaging material weight is subtracted from packaged

product weight to obtain net material weight.

NOTE 3—Use 7.1 if sampling procedure in 6.3 is used.

7.3 Measurement of Bundles and Cut Roll—Insertthepinof

7. Procedure

the thickness gage vertically into the material at the first

7.1 Expansion of Bundles and Cut Roll—Hold the first batt

measuring point with a twisting motion until it contacts the

vertically off the floor by grasping it with both hands on its

hard surface beneath. Lower the disk until it lightly and

long dimension so that the lower edge is 18 6 1 in. (460 6 25

uniformlycontactsthespecimen.Analternativeprocedureisto

mm) above the floor. Release the batt, allowing it to strike the

use a disk whose mass exerts a specified pressure of at least 0.4

floor. Repeat the above for a second time. Next, holding the

lbf/ft (20 Pa) on the specimen. With the gage disk locked

batt by the other long edge, drop twice as above. Place the

against the pin, lift the gage unit from the test specimen. While

specimen on a flat, hard surface. Repeat the above for the

holding the gage in locked position, place the disk against the

remaining four specimens. Allow specimens to reach equilib-

zero end of the rule with the pin projecting along the calibrated

rium by waiting at least 5 min before making thickness

surface of the rule. Observe and record the reading at the

measurements within 1 in. (25 mm) in any direction of five

pointed end of the pin to the nearest 0.05 in. (1 mm). Repeat

points as indicated in Fig. 2.

the above for each of the remaining measuring points as shown

NOTE 1—If 23-in. (580-mm) wide samples are tested, use a quarter or in Fig. 2.

half of that dimension to establish the test points.

7.4 Measurement of Full Roll—Record the roll length to the

NOTE 2—Some materials may require4hor more to reach equilibrium.

nearest 1 in. (2.54) cm. Take measurements on each side of the

7.2 Expansion of Full Roll—Unroll the insulation. Flip the roll. If the roll has been cut in half, take a third roll length

test roll over its entire length so the bottom surface is now on measurement along the midpoint of the roll width. Record roll

top. Next grasp one end and pull the material over itself until width at three locations to the nearest 0.125 in. (0.32 cm).

the original surface is again facing up. If there is insufficient Width measurements will be taken 10 ft (3.05 m) from each

room to pull the material over itself (less than twice the end, and in the middle of the roll length. Using a pin gauge,

unrolled length), the material may be repositioned by sliding recordthicknesstothenearest0.05in.(1mm)asshowninFig.

FIG. 3 Thickness Measurement Locations – Full Roll

C167–98 (2003)

3. Refer to Section 7.3 for use of pin gauge.Two 15 ft (4.57 m) 10.2 Thickness of Bundles—An interlaboratory comparison

long sections shall be measured. These sections shall be 10 of six participating laboratories was conducted in 1991 on

(3.05 m) in from each end. A total of twenty thickness fibrous glass insulat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.