ASTM D4846-96(2016)

(Test Method)Standard Test Method for Resistance to Unsnapping of Snap Fasteners

Standard Test Method for Resistance to Unsnapping of Snap Fasteners

SIGNIFICANCE AND USE

5.1 This test method may be used for acceptance testing of commercial shipments of snap fasteners, but caution is advised since information on between laboratory precision is incomplete. Comparative tests as directed in 5.1.1 are advisable.

5.1.1 In case of a dispute arising from differences in reported test results when using Test Method D4846 for acceptance testing of commercial shipments, the purchaser and seller should conduct comparative tests to determine if there is statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens then should be assigned randomly in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and seller must agree to interpret future test results in the light of the known bias.

SCOPE

1.1 This test method covers the determination of the force required to disengage snap fasteners by a pull perpendicular to and parallel with the plane of the snap fastener.

1.2 This test method requires attachment of snaps to specimens using specifications provided by the producers of the snaps.

1.3 This test method is used to establish correlation to wear conditions and for comparing different brands and types of snap fasteners.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in the parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4846 − 96 (Reapproved 2016)

Standard Test Method for

1

Resistance to Unsnapping of Snap Fasteners

This standard is issued under the fixed designation D4846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

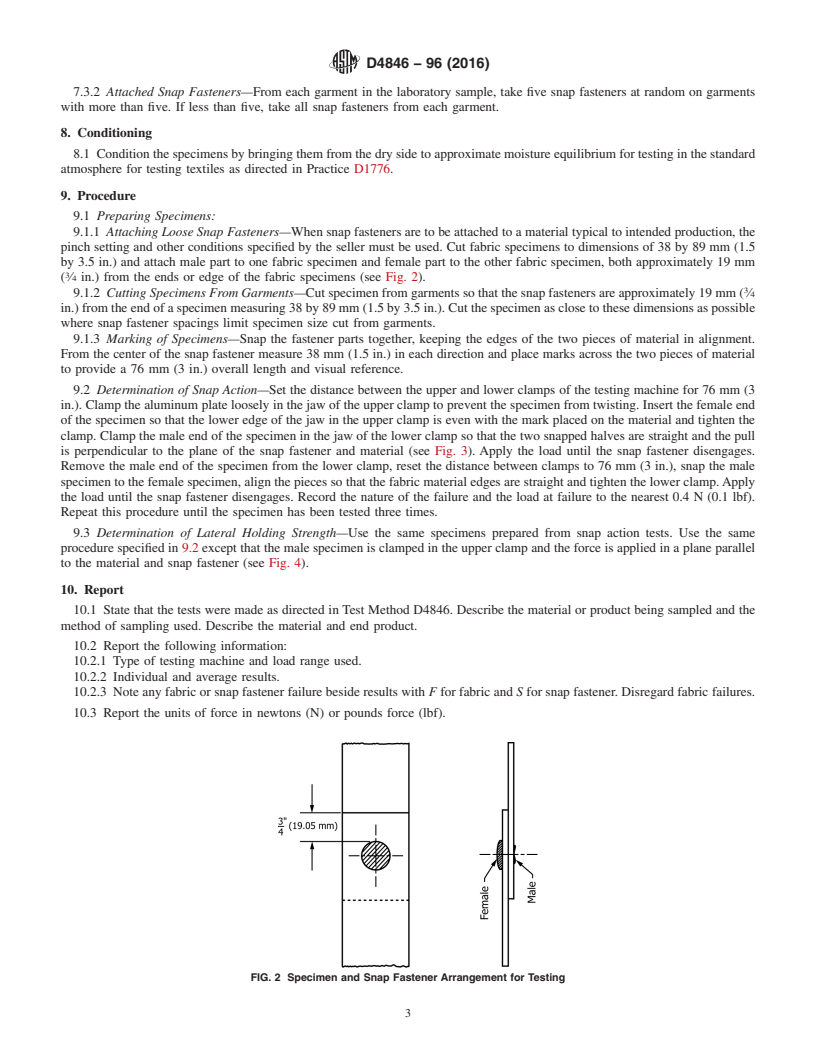

1. Scope 3.2 snap action, n—the force required to disengage a snap

fastenerresultingfromapullexertedperpendiculartotheplane

1.1 This test method covers the determination of the force

of material to which the snap fastener is attached.

required to disengage snap fasteners by a pull perpendicular to

and parallel with the plane of the snap fastener.

3.3 snap fastener, n—a device for attaching one material to

another consisting of matching male and female parts, each of

1.2 This test method requires attachment of snaps to speci-

which is attached to a separate material so that the parts can be

mens using specifications provided by the producers of the

joined by a low compressive force and separated by a low

snaps.

perpendicular tensile force.

1.3 This test method is used to establish correlation to wear

conditions and for comparing different brands and types of 3.4 For definitions of other textile terms used in this test

method, refer to Terminology D123.

snap fasteners.

1.4 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard. The values stated in the parentheses are for informa-

tion only.

4.1 Snap fasteners mounted on strips of material near the

end are tested on standard tensile testing machines equipped

1.5 This standard does not purport to address all of the

for testing the strength of textile fabrics and having sensitivity

safety concerns, if any, associated with its use. It is the

for accurate low force levels.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.2 Tests are made on snap fasteners before laundering with

mine the applicability of regulatory limitations prior to use.

the option of testing again after a pre-determined number of

1.6 This international standard was developed in accor-

launderings or other types of refurbishing.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

5.1 This test method may be used for acceptance testing of

mendations issued by the World Trade Organization Technical

commercial shipments of snap fasteners, but caution is advised

Barriers to Trade (TBT) Committee.

since information on between laboratory precision is incom-

2. Referenced Documents

plete. Comparative tests as directed in 5.1.1 are advisable.

2

2.1 ASTM Standards:

5.1.1 In case of a dispute arising from differences in

D76 Specification for Tensile Testing Machines for Textiles

reported test results when using Test Method D4846 for

D123 Terminology Relating to Textiles

acceptance testing of commercial shipments, the purchaser and

D1776 Practice for Conditioning and Testing Textiles

seller should conduct comparative tests to determine if there is

statistical bias between their laboratories. Competent statistical

3. Definitions

assistance is recommended for the investigation of bias. As a

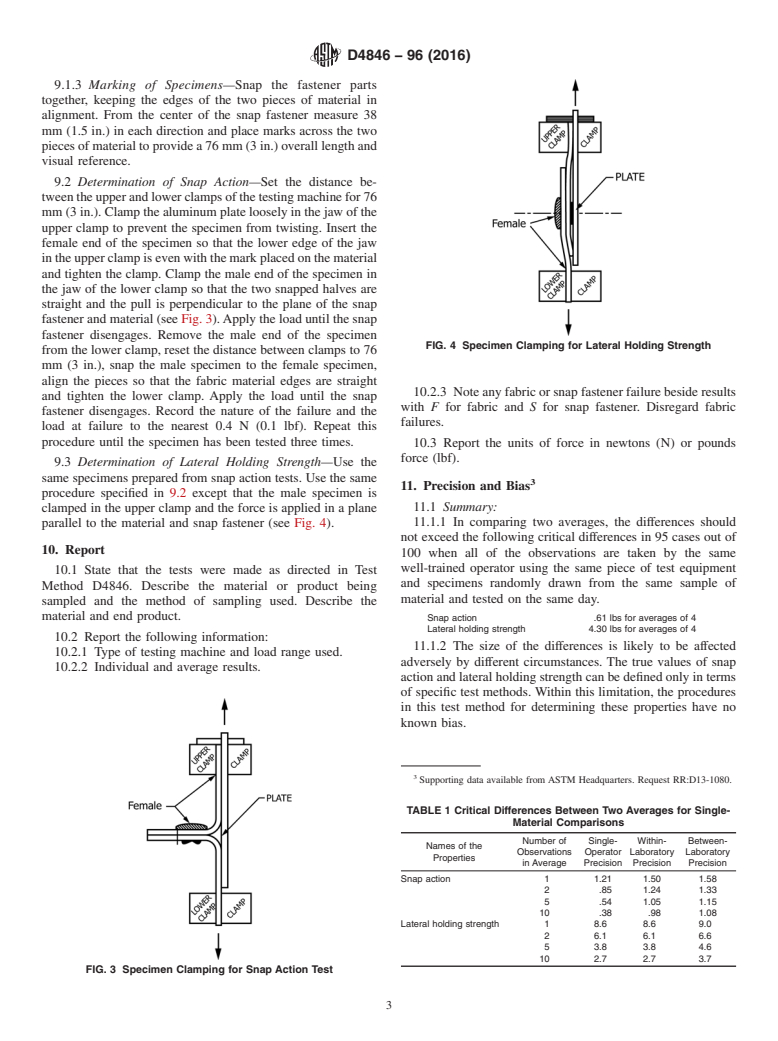

3.1 lateral holding strength, n—the force required to disen-

minimum, the two parties should take a group of test speci-

gage a snap fastener resulting from a pull in the plane parallel

mens that are as homogeneous as possible and that are from a

to the material to which the snap fastener is attached.

lot of material of the type in question. The test specimens then

should be assigned randomly in equal numbers to each

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

laboratory for testing. The average results from the two

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

laboratories should be compared using Student’s t-test for

Current edition approved Oct. 1, 2016. Published October 2016. Originally

unpaired data and an acceptable probability level chosen by the

approved in 1988. Last previous edition approved in 2011 as D4846 – 96 (2011).

DOI: 10.1520/D4846-96R16.

two parties before testing is begun. If a bias is found, either its

2

For referenced ASTM standards, visist the ASTM wbsite, www.astm.org, or

cause must be found and corrected or the purchaser and seller

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

must agree to interpret future test results in the light of the

Standardsvolume information, refer to the standard’s Document Summary page on

the ASTM we

...

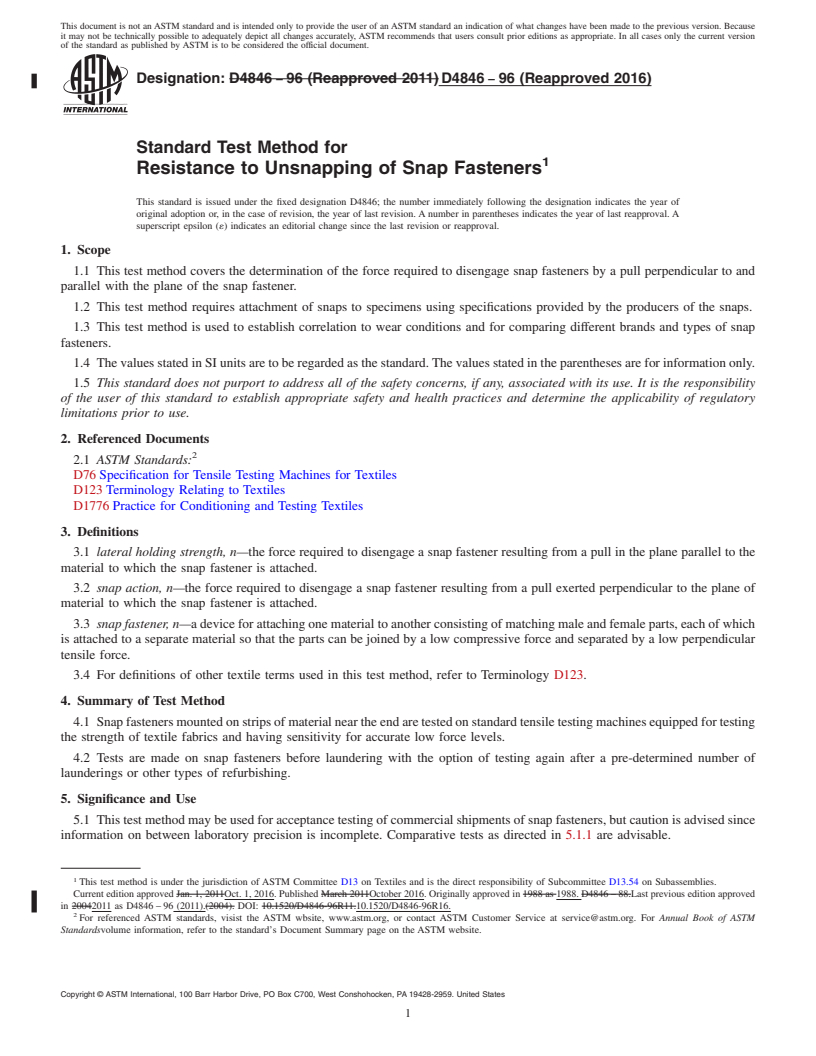

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4846 − 96 (Reapproved 2011) D4846 − 96 (Reapproved 2016)

Standard Test Method for

1

Resistance to Unsnapping of Snap Fasteners

This standard is issued under the fixed designation D4846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the force required to disengage snap fasteners by a pull perpendicular to and

parallel with the plane of the snap fastener.

1.2 This test method requires attachment of snaps to specimens using specifications provided by the producers of the snaps.

1.3 This test method is used to establish correlation to wear conditions and for comparing different brands and types of snap

fasteners.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in the parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

3. Definitions

3.1 lateral holding strength, n—the force required to disengage a snap fastener resulting from a pull in the plane parallel to the

material to which the snap fastener is attached.

3.2 snap action, n—the force required to disengage a snap fastener resulting from a pull exerted perpendicular to the plane of

material to which the snap fastener is attached.

3.3 snap fastener, n—a device for attaching one material to another consisting of matching male and female parts, each of which

is attached to a separate material so that the parts can be joined by a low compressive force and separated by a low perpendicular

tensile force.

3.4 For definitions of other textile terms used in this test method, refer to Terminology D123.

4. Summary of Test Method

4.1 Snap fasteners mounted on strips of material near the end are tested on standard tensile testing machines equipped for testing

the strength of textile fabrics and having sensitivity for accurate low force levels.

4.2 Tests are made on snap fasteners before laundering with the option of testing again after a pre-determined number of

launderings or other types of refurbishing.

5. Significance and Use

5.1 This test method may be used for acceptance testing of commercial shipments of snap fasteners, but caution is advised since

information on between laboratory precision is incomplete. Comparative tests as directed in 5.1.1 are advisable.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

Current edition approved Jan. 1, 2011Oct. 1, 2016. Published March 2011October 2016. Originally approved in 1988 as 1988. D4846 – 88.Last previous edition approved

in 20042011 as D4846 – 96 (2011).(2004). DOI: 10.1520/D4846-96R11.10.1520/D4846-96R16.

2

For referenced ASTM standards, visist the ASTM wbsite, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4846 − 96 (2016)

5.1.1 In case of a dispute arising from differences in reported test results when using Test Method D4846 for acceptance testing

of commercial shipments, the purchaser and seller should conduct comparative tests to determine if there is statistical bias between

their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties

should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question.

The test specimens then should be assigned randomly in equal numbers to each laboratory for testing. The average results from

the two laboratories should be compared using Student’s t-test for unpaired data and an accep

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.