ASTM D4645-04

(Test Method)Standard Test Method for Determination of the In-Situ Stress in Rock Using the Hydraulic Fracturing Method

Standard Test Method for Determination of the In-Situ Stress in Rock Using the Hydraulic Fracturing Method

SCOPE

1.1 This test method covers the determination of the in-situ state of stress in rock by hydraulic fracturing. Note 1Hydraulic fracturing for stress determination is also referred to as hydrofracturing, and sometimes as minifracing. Hydraulic fracturing and hydrofracturing may also refer to fracturing of the rock by fluid pressure for the purpose of altering rock properties, such as permeability and porosity.

1.2 Hydraulic fracturing is the widely accepted field method available for in situ stress measurements at depths greater than 50 m. It can be used in drill holes of any diameter.

1.3 Hydraulic fracturing can also be used in short holes for which other stress measuring methods, such as overcoring, are also available. The advantage of hydraulic fracturing is that it yields stresses averaged over a few square metres (the size of the induced hydraulic fracture) rather than over grain size areas, as in the case of overcoring techniques.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D 6026.

1.4.1 The method used to specifiy how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard is beyond its scope.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 4645 – 04

Standard Test Method for

Determination of the In-Situ Stress in Rock Using the

1

Hydraulic Fracturing Method

This standard is issued under the fixed designation D 4645; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D 653 Terminology Relating to Soil, Rock and Contained

Fluids

1.1 This test method covers the determination of the in-situ

D 2113 Practice for Diamond Core Drilling for Site Inves-

state of stress in rock by hydraulic fracturing.

tigation

NOTE 1—Hydraulic fracturing for stress determination is also referred

D 3740 Practice for Minimum Requirements for Agencies

to as hydrofracturing, and sometimes as minifracing. Hydraulic fracturing

Engaged in the Testing and/or Inspection of Soil and Rock

and hydrofracturing may also refer to fracturing of the rock by fluid

as Used in Engineering Design and Construction

pressure for the purpose of altering rock properties, such as permeability

D 5079 Practices for Preserving and Transporting Rock

and porosity.

Core Sample

1.2 Hydraulic fracturing is the widely accepted field method

D 6026 Practice for Using Significant Digits in Geotechni-

available for in situ stress measurements at depths greater than

cal Data

50 m. It can be used in drill holes of any diameter.

1.3 Hydraulic fracturing can also be used in short holes for

3. Terminology

which other stress measuring methods, such as overcoring, are

3.1 For terminology used in this test method, refer to

also available. The advantage of hydraulic fracturing is that it

Terminology D 653.

yields stresses averaged over a few square metres (the size of

3.2 Definitions of Terms Specific to This Standard:

the induced hydraulic fracture) rather than over grain size

3.2.1 breakdown pressure—the pressure required to induce

areas, as in the case of overcoring techniques.

a hydraulic fracture in a previously intact test interval.

1.4 All observed and calculated values shall conform to the

3.2.2 in-situ stress—rock stress measured in situ (as op-

guidelines for significant digits and rounding established in

posed to by remote sensing).

Practice D 6026.

3.2.3 secondary breakdown (or fracture reopening, or re-

1.4.1 The method used to specifiy how data are collected,

frac) pressure—the pressure required to reopen a closed,

calculated, or recorded in this standard is not directly related to

previously induced hydrofracture after the test interval pressure

the accuracy to which the data can be applied in design or other

has been allowed to return to its initial condition.

uses, or both. How one applies the results obtained using this

3.2.4 shut-in pressure (or ISIP (instantaneous shut-in

standard is beyond its scope.

pressure))—the pressure reached when the induced hydrofrac-

1.5 The values stated in SI units are to be regarded as the

ture closes back after pumping is stopped.

standard.

3.2.5 vertical and horizontal principal stresses—the three

1.6 This standard does not purport to address all of the

principal stresses in situ are generally assumed to act one in the

safety problems, if any, associated with its use. It is the

vertical direction and the other two in the horizontal plane.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

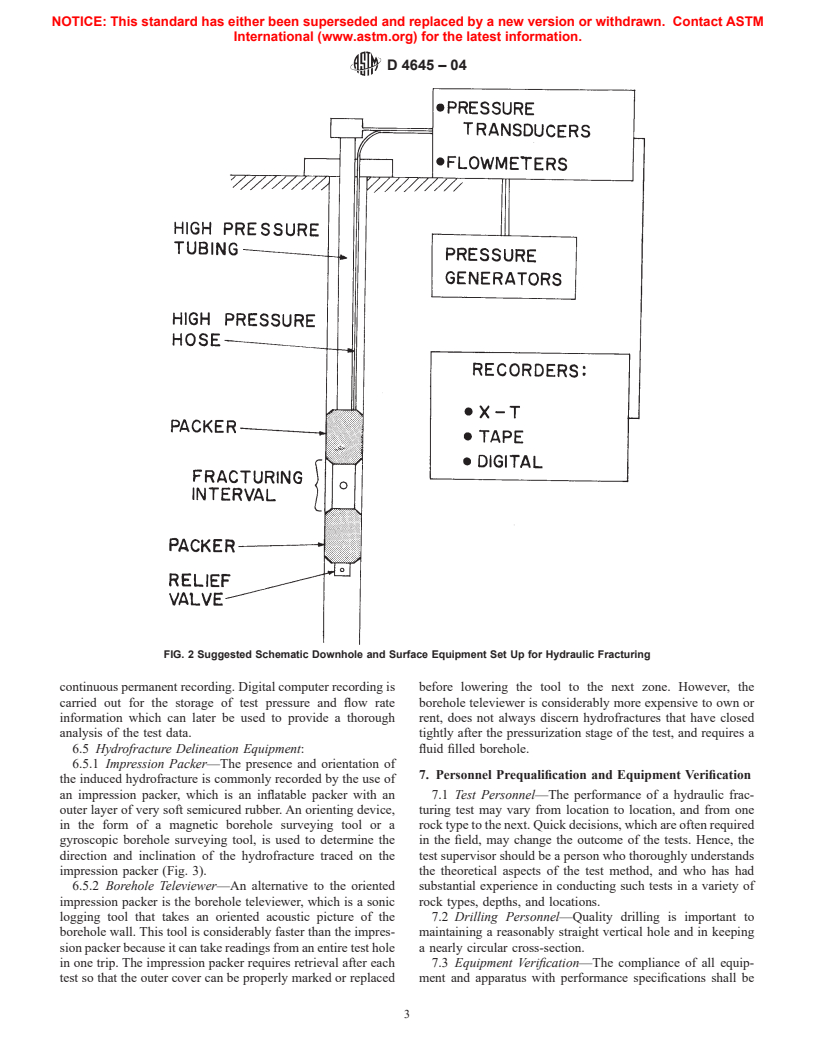

4.1 A section of the borehole is isolated by pressurizing two

inflatable rubber packers. The fluid pressure in the sealed-off

2. Referenced Documents

interval between the two packers is raised by pumping fluid

2

2.1 ASTM Standards:

into it at a controlled rate until a fracture occurs in the borehole

wall. Pumping is stopped and the pressure in the interval is

1

allowed to stabilize. The pressure is then reduced to the pore

This test method is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics. pressure level of the rock formation, and the pressurization

Current edition approved Jan. 1, 2004. Published February 2004. Originally

process is repeated several times maintaining the same flow

approved in 1987. Last previous edition approved in 1997 as D 4645 – 87 (1997).

rate. Additional pressure cycles can be conducted at different

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

flow rates. The magnitudes of the principal stresses are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

calculated from the various

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.