ASTM C1057-03(2010)

(Practice)Standard Practice for Determination of Skin Contact Temperature from Heated Surfaces Using A Mathematical Model and Thermesthesiometer

Standard Practice for Determination of Skin Contact Temperature from Heated Surfaces Using A Mathematical Model and Thermesthesiometer

SIGNIFICANCE AND USE

The procedures in this practice support the determination of the burn hazard potential for a heated surface. These procedures provide an estimate of the maximum skin contact temperature and must be used in conjunction with Guide C1055 to evaluate the surface hazard potential.

The two procedures outlined herein are both based upon the same heat transfer principles. Method A uses a mathematical model to predict the contact temperature, while Method B uses a plastic rubber probe having similar heat transfer characteristics to the human finger to “measure” the contact temperature on real systems.

These procedures serve as an estimate for the skin contact temperatures which might occur for the “average” individual. Unusual conditions of exposure, incorrect design assumptions, subject health conditions, or unforeseen operating conditions may negate the validity of the estimations.

These procedures are limited to direct contact exposure only. Conditions of personal exposure to periods of high ambient temperatures, direct flame exposure, or high radiant fluxes may cause human injury in periods other than determined herein. Evaluation of exposures other than direct contact are beyond the scope of this practice.

Cold Surface Exposure—No consensus criteria exists for the destruction of skin cells by freezing. If, at some future time, such criteria are developed, extrapolation of the techniques presented here will serve as a basis for cold surface exposure evaluation.

SCOPE

1.1 This practice covers a procedure for evaluating the skin contact temperature for heated surfaces. Two complimentary procedures are presented. The first is a purely mathematical approximation that can be used during design or for worst case evaluation. The second method describes the thermesthesiometer, an instrument that analogues the human sensory mechanism and can be used only on operating systems.

Note 1—Both procedures listed herein are intended for use with Guide C1055. When used in conjunction with that guide, these procedures can determine the burn hazard potential for a heated surface.

1.2 A bibliography of human burn evaluation studies and surface hazard measurement is provided in the References at the end of Guide C1055. Thermesthesiometer and mathematical modeling references are provided in the References at the end of this practice (1-5).

1.3 This practice addresses the skin contact temperature determination for passive heated surfaces only. The analysis procedures contained herein are not applicable to chemical, electrical, or other similar hazards that provide a heat generation source at the location of contact.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1057 − 03(Reapproved 2010)

Standard Practice for

Determination of Skin Contact Temperature from Heated

Surfaces Using a Mathematical Model and

Thermesthesiometer

This standard is issued under the fixed designation C1057; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers a procedure for evaluating the skin

C680Practice for Estimate of the Heat Gain or Loss and the

contact temperature for heated surfaces. Two complimentary

Surface Temperatures of Insulated Flat, Cylindrical, and

procedures are presented. The first is a purely mathematical

Spherical Systems by Use of Computer Programs

approximationthatcanbeusedduringdesignorforworstcase

C1055Guide for Heated System Surface Conditions that

evaluation. The second method describes the

Produce Contact Burn Injuries

thermesthesiometer, an instrument that analogues the human

sensorymechanismandcanbeusedonlyonoperatingsystems.

3. Terminology

NOTE 1—Both procedures listed herein are intended for use with Guide

3.1 Definitions of Terms Specific to This Standard:

C1055. When used in conjunction with that guide, these procedures can

3.1.1 acceptable contact time—the limit of time of contact

determine the burn hazard potential for a heated surface.

for the heated surface and the exposed skin. Practice has

1.2 A bibliography of human burn evaluation studies and

suggested limits of 5 s for industrial processes and up to 60 s

surface hazard measurement is provided in the References at

for consumer items.

the end of Guide C1055. Thermesthesiometer and mathemati-

3.1.2 burns:

cal modeling references are provided in the References at the

3.1.2.1 first degree burn—thereactiontoanexposurewhere

end of this practice (1-5).

the intensity and duration is insufficient to cause complete

1.3 This practice addresses the skin contact temperature

necrosis of the epidermal layer. The normal response to this

determination for passive heated surfaces only. The analysis

level of exposure is dilation of the superficial blood vessels

procedures contained herein are not applicable to chemical, (reddening of the skin).

electrical, or other similar hazards that provide a heat genera-

3.1.2.2 second degree burn—the reaction to an exposure

tion source at the location of contact. wheretheintensityanddurationissufficienttocausecomplete

necrosis of the epidermis but no significant damage to the

1.4 The values stated in SI units are to be regarded as

dermis. The normal response to this exposure is blistering of

standard. No other units of measurement are included in this

the epidermis.

standard.

3.1.2.3 third degree burns—the reaction to an exposure

1.5 This standard does not purport to address all of the

where significant dermal necrosis occurs. Significant dermal

safety concerns, if any, associated with its use. It is the necrosishasbeendefinedintheliteratureasa75%destruction

responsibility of the user of this standard to establish appro- of the dermis thickness. The normal response to this exposure

is open sores that leave permanent scar tissue upon healing.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1.3 skin:

3.1.3.1 epidermis—the outermost layer of skin cells. This

layer contains no vascular or nerve cells and acts to protect the

outerskinlayers.Thethicknessofthislayeraverages0.08mm.

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

Current edition approved May 1, 2010. Published August 2010. Originally

approved in 1986. Last previous edition approved in 2003 as C1057–03. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1057-03R10. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this practice. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1057 − 03 (2010)

3.1.3.2 dermis—the second layer of skin tissue. This layer 5.2 Thetwoproceduresoutlinedhereinarebothbasedupon

containsbloodvesselsandnerveendings.Thethicknessofthis the same heat transfer principles. MethodAuses a mathemati-

layer is about 2 mm. cal model to predict the contact temperature, while Method B

3.1.3.3 necrosis—localized death of living cells. This is a uses a plastic rubber probe having similar heat transfer

clinical term that defines when damage to the skin layer has characteristics to the human finger to “measure” the contact

occurred. temperature on real systems.

3.1.4 skin contact temperature—the temperature of the skin

5.3 These procedures serve as an estimate for the skin

at a depth of 0.08 mm reached after contact with a heated

contact temperatures which might occur for the “average”

surface for a specified time.

individual. Unusual conditions of exposure, incorrect design

3.1.5 thermesthesiometer—an electromechanical device de-

assumptions,subjecthealthconditions,orunforeseenoperating

veloped by L. A. Marzetta at National Institute of Standards

conditions may negate the validity of the estimations.

and Technology to analogue the touch response of the human

5.4 These procedures are limited to direct contact exposure

skin when it contacts a heated surface. This measurement

only. Conditions of personal exposure to periods of high

concept holds U.S. Patent No. 3,878,728 datedApril 22, 1975,

ambient temperatures, direct flame exposure, or high radiant

andwasassignedtotheUSAasrepresentedbytheDepartment

fluxes may cause human injury in periods other than deter-

of Health andWelfare. No known restriction exists to limit the

minedherein.Evaluationofexposuresotherthandirectcontact

development of units based upon this principle.

are beyond the scope of this practice.

4. Summary of Practice

5.5 ColdSurfaceExposure—Noconsensuscriteriaexistsfor

thedestructionofskincellsbyfreezing.If,atsomefuturetime,

4.1 This practice provides two procedures for evaluation of

such criteria are developed, extrapolation of the techniques

theskincontacttemperaturefromheatedsurfaces.Eitherofthe

presented here will serve as a basis for cold surface exposure

two methods, a mathematical model and a physical

evaluation.

measurement, can be used depending upon the availability of

thesystem(thatis,isitbuiltandoperatingorisitinthedesign

6. Method A—Use of the Mathematical Model

state) and the operating conditions. The first step in using this

practice is to determine which procedure is to be used. Unless

6.1 This modeling approach is for use when the system is

the system of interest is operating at design “worst case”

being designed or, if for some reason, it cannot be operated at

conditions,suchashighsystemtemperaturesandhighambient

design conditions. The model approximates the transient heat

temperature, the calculational procedure is recommended. On

flow phenomena of the skin contacting a hot surface using the

the other hand, if the question is safety at the present

equation set described by Dussan (1) and Wu (5). The user is

conditions, the thermesthesiometer provides a quick measure-

required to make certain definitions of system geometry and

ment with no auxiliary calculations. Paragraphs 4.2 and 4.3

materials, the system operating conditions, and the allowable

outline the two alternative procedures available.

time of exposure. After definition of the input values, the

equation set yields an estimate of the skin contact temperature

4.2 Calculational Procedure, Method A—First the surface

needed for the hazard evaluation.The user must realize that as

temperature of the insulated system is determined by either a

with all mathematical approximations, the estimate is only as

direct measurement, using either thermocouples, thermistors,

good as the input data. Where some input parameter is known

or infrared noncontact techniques, or by modeling of the

only within some range of values, a sensitivity analysis about

system using Practice C680. Once the surface temperature is

that range is recommended.

known, the designer uses the equation set to estimate the

maximum epidermal contact temperature for the acceptable

6.2 The first step in estimating the effective skin contact

contact time. This temperature is a function of surface

temperatureistoidentifyandrecordthefollowinginformation

temperature, time of contact, and composition of both the

describing the system as input for the model:

surface material and substrate. The designer then refers to

6.2.1 System Description—Geometry, location, accessibil-

Guide C1055 to determine the burn hazard potential of the

ity.

surface.

6.2.2 Present/Design Operating Conditions—Duty cycle,

operating temperatures of equipment.

4.3 Thermesthesiometer, Method B—The operator places

6.2.3 System/Surface Data (as appropriate)—Substrate (in-

the calibrated sensor probe face firmly against the heated

sulation) type and thickness, jacket type and thickness, surface

surface for the acceptable contact time. The device directly

properties, such as emissivity and condition, shiny, painted,

reads the contact temperature from the probe. The maximum

dirty, corroded.

temperature is used in conjunction with the Guide C1055 to

6.2.4 Ambient Conditions, including dry bulb temperature

determine the burn hazard potential of the surface.

and local wind velocity.

5. Significance and Use

NOTE 2—The design temperatures should be at the worst case (gener-

5.1 The procedures in this practice support the determina-

ally high operating and high ambient) conditions. Care should be used in

the selection of design conditions since the hazard design conditions are

tion of the burn hazard potential for a heated surface. These

different from the heat loss design conditions.

procedures provide an estimate of the maximum skin contact

temperature and must be used in conjunction with Guide 6.3 Using Practice C680 or a compatible program and the

C1055 to evaluate the surface hazard potential. information gathered in 6.2, calculate the maximum operating

C1057 − 03 (2010)

1/2

surface temperature. This temperature is an input to the model P 5 ρ ·C ·K (7)

~ !

1 1 1 1

for the contact temperature. 1/2

P 5 ρ ·C ·K (8)

~ !

2 2 2 2

6.3.1 Where the system is operating at design conditions,

1/2

P 5 ρ ·C ·K (9)

~ !

3 3 3 3

direct measurement can be used to determine the surface

α 5 K /ρ ·C (10)

temperature.Thermocouples,resistancethermometers,orother

1 1 1 1

meanscanbeused;however,properapplicationtechniquesare

α 5 K /ρ ·C (11)

2 2 2 2

required for accurate results. Caution must be observed since

where:

the surface temperature may be high and the surface could

T = initial tissue temperature, °C,

constitute a burn hazard.

N = integral constant, 1 > ∞,

6.4 Calculate the expected skin contact temperature versus −5

X = depth of tissue of interest, normally 8.0×10 m,

time history using the procedure below based upon the hot 2

α = thermal diffusivity of layer i,m /s,

i

surface temperature, time of contact, and system properties.

l = layer thickness of jacket material, m,

The development of the equations below is taken from Dussan

22 21

P =

layer thermal inertia; W·m ·K ·=s,

(1). A more detailed derivation of the equation set used is

t = time of contact, s,

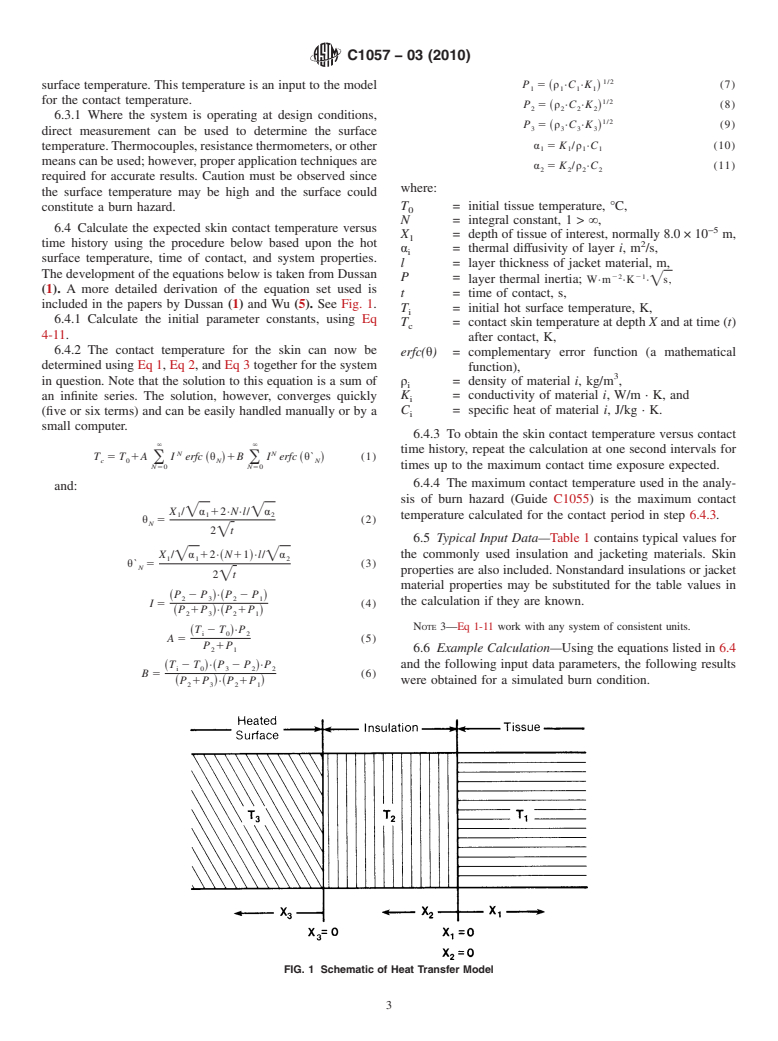

included in the papers by Dussan (1) and Wu (5). See Fig. 1.

T = initial hot surface temperature, K,

i

6.4.1 Calculate the initial parameter constants, using Eq

T = contact skin temperature at depth X and at time (t)

c

4-11.

after contact, K,

6.4.2 The contact temperature for the skin can now be

erfc(θ) = complementary error function (a mathematical

determined using Eq 1, Eq 2, and Eq 3 together for the system

function),

in question. Note that the solution to this equation is a sum of

ρ = density of material i, kg/m ,

i

K = conductivity of material i, W/m · K, and

an infinite series. The solution, however, converges quickly

i

C = specific heat of material i,J/kg·K.

(five or six terms) and can be easily handled manually or by a

i

small computer.

6.4.3 To obtain the skin contact temperature versus contact

` `

time history, repeat the calculation at one second intervals for

N N

T 5 T 1A I erfc θ 1B I erfc θ` (1)

~ ! ~ !

c 0 N N

( (

N50 N50 times up to the maximum contact time exposure expected.

6.4.4 The maximum contact temperature used in the analy-

and:

sis of burn hazard (Guide C1055) is the maximum contact

X /=α 12·N·l/=α

1 1 2

temperature calculated for the contact period in step 6.4.3.

θ 5 (2)

N

2=t

6.5 Typical Input Data—Table 1 contains typical values for

X /=α 12·~N11!·l/=α the commonly used insulation and jacketing materials. Skin

1 1 2

θ` 5 (3)

N

properties are also included. Nonstandard insulations or jacket

2=t

material properties may be substituted for the table values in

~P 2 P !·~P 2 P !

2 3 2 1

the calculation if they are known.

I 5 (4)

P 1P · P 1P

~ ! ~ !

2 3 2 1

NOTE 3—Eq 1-11 work with any system of consistent units.

~T 2 T !·P

i 0 2

A 5 (5)

P 1P

2 1 6.6 Example Calculation—Using the equations listed in 6.4

T 2 T · P 2 P ·P and the following input data parameters, the following results

~ ! ~ !

i 0 3 2 2

B 5 (6)

~P 1P !·~P 1P ! were obtained for a simulated burn condition.

2 3 2 1

FIG. 1 Schematic of Heat Transfer Model

C1057 − 03 (2010)

TABLE 1 Typical Properties (23°C)

Specific Conduc-

Density,

Heat, tivity,

Code Material kg/m ·

J/kg W/m·

K·10 K

1 steel 7.80 0.46 45.200

2 aluminum 2.70 0.96 154.800

3 brass 8.90 0.38 85.400

4 borosilicate glass 2.25 0.84 1.130

5 porcelain 2.20 0.84 1.210

6 concrete 2.47 0.92 2.430

7 brick 1.70 0.84 0.630

8 stone 2.30 0.84 0.920

9 plastics 1.28 1.55 0.250

10 phenolics 1.25 1.38 0.042

11 nylons 1.11 2.09 0.209

12 ABS resins 1.04 1.51 0.170

13 wood 0.66 1.72 0.130

14 paper 0.60 2.81 0.084

15 human tissue 0.90 4.60 0.544

16 water 1.00 4.19 0.602

17 cork 0.13 2.01 0.042

18 mineral wool 0.19 1.00 0.059

19 cal silicate 0.24 1.09 0.067

20 foam glass 0.13 0.76 0.071

21 organic foam 0.05 1.05 0.021

22 glass cloth 0.40 0.63 0.084

23 fiberglas-LD 0.10 1.00 0.046

24 TFE-fluorocarbon 2.15 1.05 0.243

25 masonite 1.00 1.67 0.173

6.6.1 Problem—Assume a heated system is to be insulated

with light density fibrous glass. Jacketing material choices

FIG. 2 Time-Contact Temperatur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.