ASTM C885-87(2012)

(Test Method)Standard Test Method for Young's Modulus of Refractory Shapes by Sonic Resonance

Standard Test Method for Young's Modulus of Refractory Shapes by Sonic Resonance

SIGNIFICANCE AND USE

Young's modulus is a fundamental mechanical property of a material.

This test method is used to determine the dynamic modulus of elasticity of rectangular shapes. Since the test is nondestructive, specimens may be used for other tests as desired.

This test method is useful for research and development, engineering application and design, manufacturing process control, and for developing purchasing specifications.

The fundamental assumption inherent in this test method is that a Poisson's ratio of 1/6 is typical for heterogeneous refractory materials. The actual Poisson's ratio may differ.

SCOPE

1.1 This test method covers a procedure for measuring the resonance frequency in the flexural (transverse) mode of vibration of rectangular refractory brick or rectangularly shaped monoliths at room temperature. Young's modulus is calculated from the resonance frequency of the shape, its mass (weight) and dimensions.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Although the Hertz (Hz) is an SI unit, it is derived from seconds which is also an inch-pound unit.

1.3 This standard does not purport to address all of the safety concerns, if any,associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C885 − 87 (Reapproved 2012)

Standard Test Method for

Young’s Modulus of Refractory Shapes by Sonic

Resonance

This standard is issued under the fixed designation C885; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C848 Test Method for Young’s Modulus, Shear Modulus,

and Poisson’s Ratio For Ceramic Whitewares by Reso-

1.1 This test method covers a procedure for measuring the

nance

resonance frequency in the flexural (transverse) mode of

vibration of rectangular refractory brick or rectangularly

3. Summary of Test Method

shaped monoliths at room temperature. Young’s modulus is

calculated from the resonance frequency of the shape, its mass 3.1 Test specimens are vibrated in flexure over a broad

frequencyrange;mechanicalexcitationisprovidedthroughthe

(weight) and dimensions.

use of a vibrating driver that transforms an initial electrical

1.2 Units—The values stated in inch-pound units are to be

signal into a mechanical vibration. A detector senses the

regarded as standard. The values given in parentheses are

resultingmechanicalvibrationsofthespecimenandtransforms

mathematical conversions to SI units that are provided for

them into an electrical signal that can be displayed on the

information only and are not considered standard.

screen of an oscilloscope to detect resonance by a Lissajous

1.2.1 Although the Hertz (Hz) is an SI unit, it is derived

figure.The calculation ofYoung’s modulus from the resonance

from seconds which is also an inch-pound unit.

frequency measured is simplified by assuming that Poisson’s

1.3 This standard does not purport to address all of the

ratio is ⁄6 for all refractory materials.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

4.1 Young’s modulus is a fundamental mechanical property

bility of regulatory limitations prior to use.

of a material.

2. Referenced Documents

4.2 This test method is used to determine the dynamic

modulus of elasticity of rectangular shapes. Since the test is

2.1 ASTM Standards:

nondestructive, specimens may be used for other tests as

C134 Test Methods for Size, Dimensional Measurements,

desired.

and Bulk Density of Refractory Brick and Insulating

Firebrick

4.3 Thistestmethodisusefulforresearchanddevelopment,

C215 Test Method for Fundamental Transverse,

engineering application and design, manufacturing process

Longitudinal, and Torsional Resonant Frequencies of

control, and for developing purchasing specifications.

Concrete Specimens

4.4 The fundamental assumption inherent in this test

C623 Test Method for Young’s Modulus, Shear Modulus,

method is that a Poisson’s ratio of ⁄6 is typical for heteroge-

and Poisson’s Ratio for Glass and Glass-Ceramics by

neous refractory materials. The actual Poisson’s ratio may

Resonance

differ.

C747 Test Method for Moduli of Elasticity and Fundamental

Frequencies of Carbon and Graphite Materials by Sonic

5. Apparatus

Resonance

5.1 A block diagram of a suggested test apparatus arrange-

ment is shown in Fig. 1. Details of the equipment are as

This test method is under the jurisdiction of ASTM Committee C08 on

follows:

Refractories and is the direct responsibility of Subcommittee C08.01 on Strength.

5.1.1 Audio Oscillator, having a continuously variable

Current edition approved March 1, 2012. Published April 2012. Originally

ε1

calibrated-frequency output from about 50 Hz to at least 10

approved in 1978. Last previous edition approved in 2007 as C885 – 87 (2007) .

DOI: 10.1520/C0885-87R12.

kHz.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.2 Audio Amplifier, having a power output sufficient to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ensure that the type of driver used can excite the specimen; the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. output of the amplifier must be adjustable.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C885 − 87 (2012)

FIG. 1 Block Diagram of Apparatus

5.1.3 Driver, which may consist of a transducer or a their length to thickness ratio should be at least 3 to 1.

loudspeaker from which the cone has been removed and Maximumspecimensizeandmassareprimarilydeterminedby

replaced with a probe (connecting rod) oriented parallel to the the test system’s energy capability and by the resonance

direction of the vibration; suitable vibration-isolating mounts. response characteristics of the material. Minimum specimen

size and mass are primarily determined by adequate and

NOTE 1—For small specimens, an air column may preferably be used

optimum coupling of the driver and the detector to the

for “coupling” the loudspeaker to the specimen.

specimen, and by the resonance response characteristics of the

5.1.4 Detector, which may be a transducer or a balance-

material. Measure the mass (weight) and dimensions of the dry

mounted monaural (crystal or magnetic) phonograph pick-up

specimens in accordance with Test Methods C134 and record.

cartridge of good frequency response; the detector should be

movable across the specimen; suitable vibration-isolating

7. Procedure

mounts.

7.1 Refractories can vary markedly in their response to the

5.1.5 Pre-Scope Amplifier in the detector circuit,

driver’s frequency; the geometry of the specimens also plays a

impedance-matched with the detector used; the output must be

significant role in their response characteristics. Variations in

adjustable.

the following procedure are permissible as long as flexural and

5.1.6 Indicating Devices, including an oscilloscope, a reso-

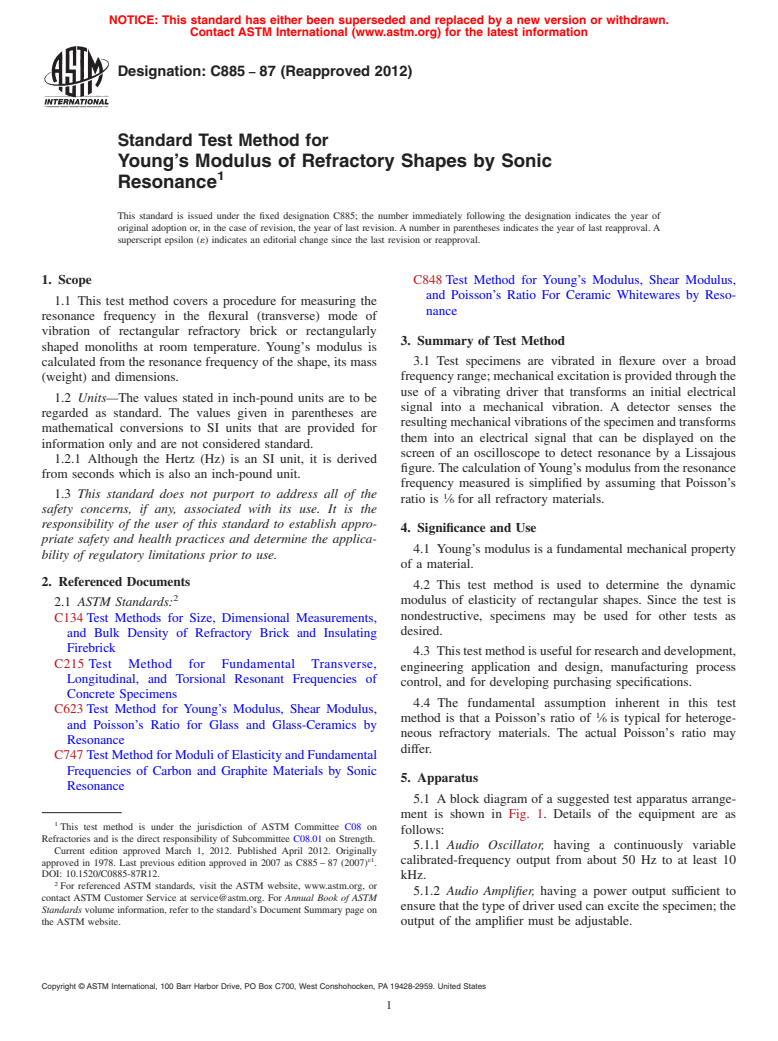

fundamental resonance are verified (Note 6 and Note 7). Fig. 2

nance indicator (voltmeter or ammeter), and a frequency

and Fig. 3 illustrate a typical specimen positioning and the

indicator, which may be the control dial of the audio-oscillator

desired mode of vibration, respectively.

(accurately readable to 630 Hz or better) or, preferably, a

7.2 Sample Placement—Place the specimen “flat” (thick-

frequency meter, for example, a digital frequency counter.

ness dimension perpendicular to supports) on parallel knife

5.1.7 Specimen Support, consisting of two knife edges (can

edges at 0.224 l (where l is the length of the specimen) from its

be steel, rubber-coated steel, or medium-hard rubber) of a

ends. Optionally, the specimen can be placed on a foam rubber

length at least equal to the width of the specimens; the distance

pad.

between the knife edges must be adjustable.

NOTE 2—The support for the knife edges may be a foam rubber pad,

and should be vibration-isolated from drive and detector supports.

NOTE 3—Alternatively, knife edges can be omitted and the specimen

may be placed directly on a foam rubber pad if the test material is easily

excitable due to its composition and geometry.

6. Sampling and Specimen Preparation

6.1 Specimensmustberectangularprisms.Theymaybefull

straight brick or rectangular samples cut from brick shapes;

rectangular straight shapes of monolithic refractories, or rect-

FIG. 2 Typical Specimen Positioning for Measurement of Flexural

angularspecimenscutfrommonolithicshapes.Forbestresults, Resonance

C885 − 87 (2012)

is indicated by an oval to circular Lissajous figure at the

oscilloscope and maximum output is shown at the resonance

indicator. Record the resonance frequency.

NOTE 6—To verify the flexural mode of vibration, move the detector to

the top center of the specimen. The oval or circular oscilloscope pattern

shall be maintained. Placement of the detector above the nodal points (at

0.224 l) shall cause a Lissajous pattern and high output at the resonance

indicator to disappear.

FIG. 3 Fundamental Mode of Vibration in Flexure (Side View)

NOTE 7—To verify the fundamental mode of flexural resonance, excite

the specimen at one half of the frequency established in 7.5. A “figure

7.3 Driver Placement—Place the driver preferably at the eight” Lissajous pattern should appear at the oscilloscope when the

detector is placed at the end center or at the top center of the specimen.

center of the top or bottom face of the specimen using

moderate balanced pressure or spring action.

8. Calculation

NOTE 4—Especially with small (thin) specimens, the lightest possible

8.1 Data determined on individual specimens include:

driver pressure to ensure adequate “coupling” must be used in order to

8.1.1 l = length of specimen, in.,

achieve proper resonance response. In small specimens, exact placement

8.1.2 b = width of specimen, in.,

of the driver at the very center of the flat specimen is important; also, an

air column may be used for “coupling.” 8.1.3 t = thickness of specimen, in.,

8.1.4 w = mass (weight) of specimen, lb, and

7.4 Detector Placement—Place the detector preferably at

8.1.5 f = fundamental flexural resonance frequency, Hz.

one end of the specimen and at the center of either the width or

thickness (considering the orientation of maximum response of 8.2 CalculateYoung’s modulus E, in psi, of the specimen as

the detector) using minimal pressure.

follows:

NOTE5—Makesurethatthestylusofthephonographcartridge(ifused) E 5 C ·w·f (1)

is well secured.

2 2

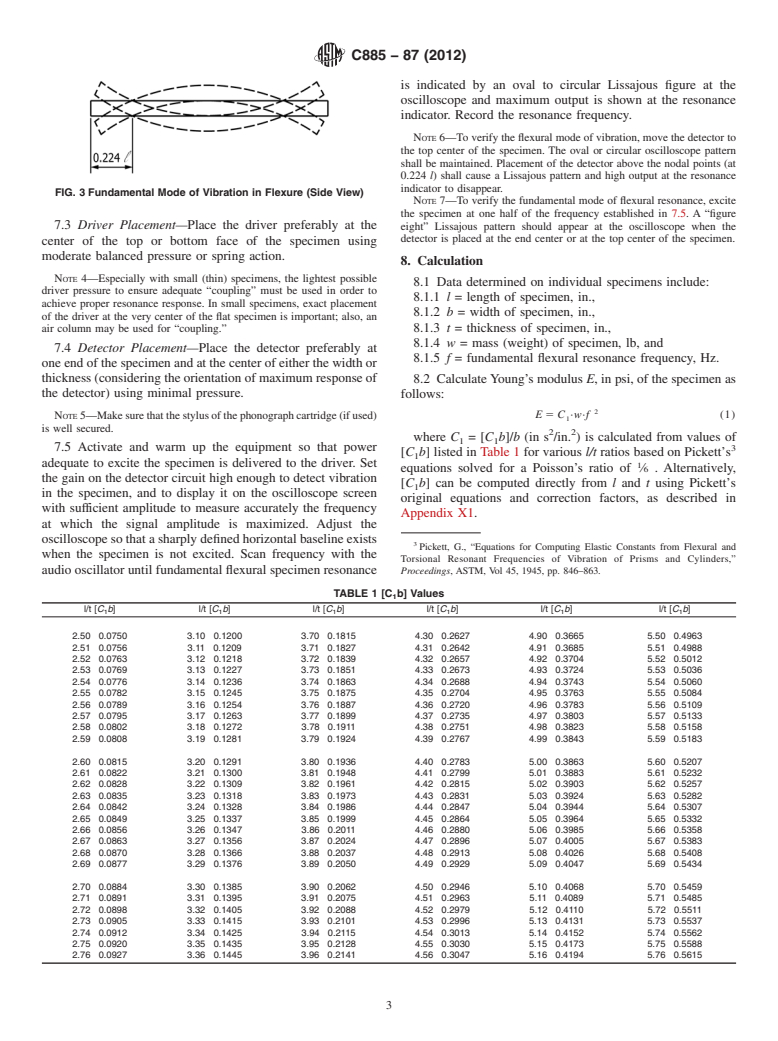

where C =[C b]/b (in s /in. ) is calculated from values of

1 1

7.5 Activate and warm up the equipment so that power 3

[C b] listed in Table 1 for various l/t ratios based on Pickett’s

adequate to excite the specimen is delivered to the driver. Set

equations solved for a Poisson’s ratio of ⁄6 . Alternatively,

the gain on the detector circuit high enough to detect vibration

[C b] can be computed directly from l and t using Pickett’s

in the specimen, and to display it on the oscilloscope screen

original equations and correction factors, as described in

with sufficient amplitude to measure accurately the frequency

Appendix X1.

at which the signal amplitude is maximized. Adjust the

oscilloscope so that a sharply defined horizontal baseline exists

Pickett, G., “Equations for Computing Elastic Constants from Flexural and

when the specimen is not excited. Scan frequency with the

Torsional Resonant Frequencies of Vibration of Prisms and Cylinders,”

audio oscillator until fundamental flexural specimen resonance Proceedings, ASTM, Vol 45, 1945, pp. 846–863.

TABLE 1 [C b] Values

l/t [C b] l/t [C b] l/t [C b] l/t [C b] l/t [C b] l/t [C b]

1 1 1 1 1 1

2.50 0.0750 3.10 0.1200 3.70 0.1815 4.30 0.2627 4.90 0.3665 5.50 0.4963

2.51 0.0756 3.11 0.1209 3.71 0.1827 4.31 0.2642 4.91 0.3685 5.51 0.4988

2.52 0.0763 3.12 0.1218 3.72 0.1839 4.32 0.2657 4.92 0.3704 5.52 0.5012

2.53 0.0769 3.13 0.1227 3.73 0.1851 4.33 0.2673 4.93 0.3724 5.53 0.5036

2.54 0.0776 3.14 0.1236 3.74 0.1863 4.34 0.2688 4.94 0.3743 5.54 0.5060

2.55 0.0782 3.15 0.1245 3.75 0.1875 4.35 0.2704 4.95 0.3763 5.55 0.5084

2.56 0.0789 3.16 0.1254 3.76 0.1887 4.36 0.2720 4.96 0.3783 5.56 0.5109

2.57 0.0795 3.17 0.1263 3.77 0.1899 4.37 0.2735 4.97 0.3803 5.57 0.5133

2.58 0.0802 3.18 0.1272 3.78 0.1911 4.38 0.2751 4.98 0.3823 5.58 0.5158

2.59 0.0808 3.19 0.1281 3.79 0.1924 4.39 0.2767 4.99 0.3843 5.59 0.5183

2.60 0.0815 3.20 0.1291 3.80 0.1936 4.40 0.2783 5.00 0.3863 5.60 0.5207

2.61 0.0822 3.21 0.1300 3.81 0.1948 4.41 0.2799 5.01 0.3883 5.61 0.5232

2.62 0.0828 3.22 0.1309 3.82 0.1961 4.42 0.2815 5.02 0.3903 5.62 0.5257

2.63 0.0835 3.23 0.1318 3.83 0.1973 4.43 0.2831 5.03 0.3924 5.63 0.5282

2.64 0.0842 3.24 0.1328 3.84 0.1986 4.44 0.2847 5.04 0.3944 5.64 0.5307

2.65 0.0849 3.25 0.1337 3.85 0.1999 4.45 0.2864 5.05 0.3964 5.65 0.5332

2.66 0.0856 3.26 0.1347 3.86 0.2011 4.46 0.2880 5.06 0.3985 5.66 0.5358

2.67 0.0863 3.27 0.1356 3.87 0.2024 4.47 0.2896 5.07 0.4005 5.67 0.5383

2.68 0.0870 3.28 0.1366 3.88 0.2037 4.48 0.2913 5.08 0.4026 5.68 0.5408

2.69 0.0877 3.29 0.1376 3.89 0.2050 4.49 0.2929 5.09 0.4047 5.69 0.5434

2.70 0.0884 3.30 0.1385 3.90 0.2062 4.50 0.2946 5.10 0.4068 5.70 0.5459

2.71 0.0891 3.31 0.1395 3.91 0.2075 4.51 0.2963 5.11 0.4089 5.71 0.5485

2.72 0.0898 3.32 0.1405 3.92 0.2088 4.52 0.2979 5.12 0.4110 5.72 0.5511

2.73 0.0905 3.33 0.1415 3.93 0.2101 4.53 0.2996 5.13 0.4131 5.73 0.5537

2.74 0.0912 3.34 0.1425 3.94 0.2115 4.54 0.3013 5.14 0.4152 5.74 0.5562

2.75 0.0920 3.35 0.1435 3.95 0.2128 4.55 0.3030 5.15 0.4173 5.75 0.5588

2.76 0.0927 3.36 0.1445 3.96 0.2141 4.56 0.3047 5.16 0.4194 5.76 0.5615

C885 − 87 (2012)

TABLE 1 Continued

l/t [C b] l/t [C b] l/t [C b] l/t [C b] l/t [C b] l/t [C b]

1 1 1 1 1 1

2.77 0.0934 3.37 0.1455 3.97 0.2154 4.57 0.3064 5.17 0.4216 5.77 0.5641

2.78 0.0942 3.38 0.1465 3.98 0.2168 4.58 0.3081 5.18 0.4237 5.78 0.5667

2.79 0.0949 3.39 0.1475 3.99 0.2181 4.59 0.3098 5.19 0.4258 5.79 0.5693

2.80 0.0957 3.40 0.1485 4.00 0.2194 4.60 0.3116 5.20 0.4280 5.80 0.5720

2.81 0.0964 3.41 0.1496 4.01 0.2208 4.61 0.3133 5.21 0.4302 5.81 0.5746

2.82 0.0972 3.42 0.1506 4.02 0.2222 4.62 0.3150 5.22 0.4323 5.82 0.5773

2.83 0.0979 3.43 0.1516 4.03 0.2235 4.63 0.3168 5.23 0.4345 5.83 0.5799

2.84 0.0987 3.44 0.1527 4.04 0.2249 4.64 0.3185 5.24 0.4367 5.84 0.5826

2.85 0.0994 3.45 0.1537 4.05 0.2263 4.65 0.3203 5.25 0.4389 5.85 0.5853

2.86 0.1002 3.46 0.1548 4.06 0.2277 4.66 0.3220 5.26 0.4411 5.86 0.5880

2.87 0.1010 3.47 0.1558 4.07 0.2290 4.67 0.3238 5.27 0.4433 5.87 0.5907

2.88 0.1018 3.48 0.1569 4.08 0.2304 4.68 0.3256 5.28 0.4455 5.88 0.5934

2.89 0.1026 3.49 0.1579 4.09 0.2318 4.69 0.3274 5.29 0.4478 5.89 0.5961

2.90 0.1033 3.50 0.1590 4.10 0.2332 4.70 0.3292 5.30 0.4500 5.90 0.5989

2.91 0.1041 3.51 0.1601 4.11 0.2347 4.71 0.3310 5.31 0.4522 5.91 0.6016

2.92 0.1049 3.52 0.1612 4.12 0.2361 4.72 0.3328 5.32 0.4545 5.92 0.6043

2.93 0.1057 3.53 0.1623 4.13 0.2375 4.73 0.3346 5.33 0.4568 5.93 0.6071

2.94 0.1065 3.54 0.1633 4.14 0.2389 4.74 0.3364 5.34 0.4590 5.94 0.6099

2.95 0.1074 3.55 0.1644 4.15 0.2404 4.75 0.3383 5.35 0.4613 5.95 0.6126

2.96 0.1082 3.56 0.1655 4.16 0.2418 4.76 0.3401 5.36 0.4636 5.96 0.6154

2.97 0.1090 3.57 0.1667 4.17 0.2433 4.77 0.3419 5.37 0.4659 5.97 0.6182

2.98 0.1098 3.58 0.1678 4.18 0.2447 4.78 0.3438 5.38 0.4682 5.98 0.6210

2.99 0.1106 3.59 0.1689 4.19 0.2462 4.79 0.3456 5.39 0.4705 5.99 0.6238

3.00 0.1115 3.60 0.1700 4.20 0.2476 4.80 0.3475 5.40 0.4728 6.00 0.6266

3.01 0.1123 3.61 0.1711 4.21 0.2491 4.81 0.3494 5.41 0.4751 6.01 0.6294

3.02 0.1131 3.62 0.1723 4.22 0.2506 4.82 0.3513 5.42 0.4774 6.02 0.6323

3.03 0.1140 3.63 0.1734 4.23 0.2521

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.