ASTM D3664-04

(Specification)Standard Specification for Biaxially Oriented Polymeric Resin Film for Capacitors in Electrical Equipment

Standard Specification for Biaxially Oriented Polymeric Resin Film for Capacitors in Electrical Equipment

ABSTRACT

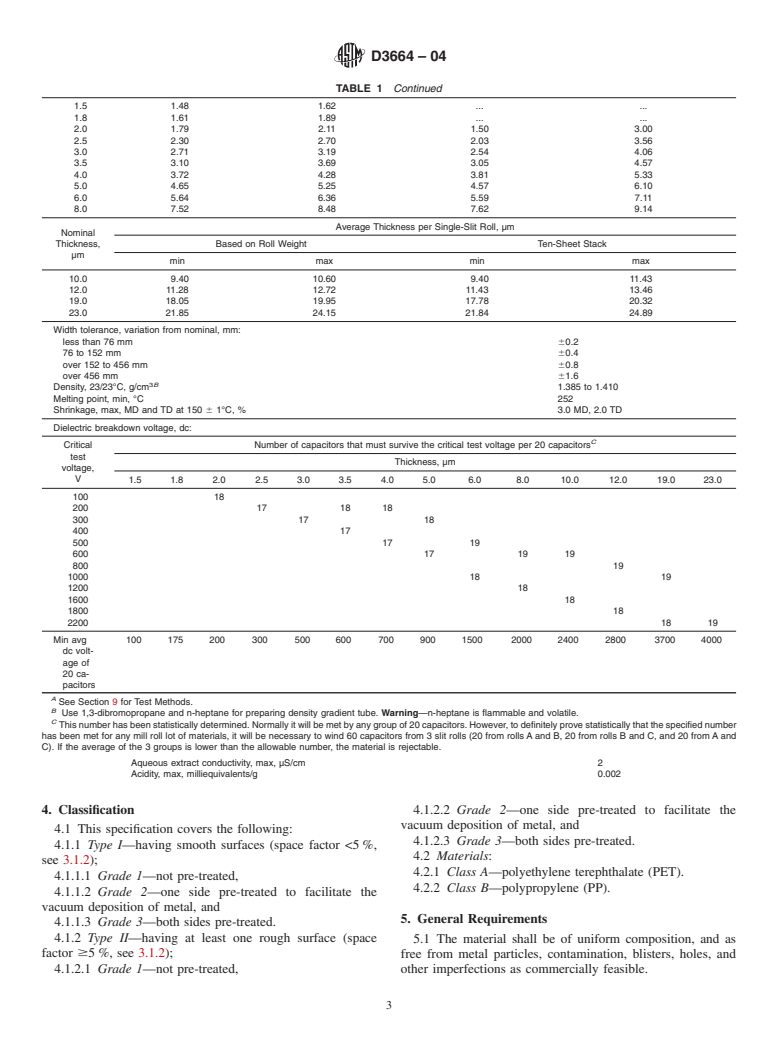

This specification covers two types and three grades of thin biaxially oriented polymeric resin film composed of polyethylene terephthalate (PET, Class A) or polypropylene (PP, Class B) for use in capacitors for electrical equipment. Type I has smooth surfaces, while Type II has at least one rough surface. Each of these types is further subdivided into the following grades: Grade 1, not pre-treated; Grade 2, one side pre-treated to facilitate the vacuum deposition of metal; and Grade 3, both side pre-treated. The physical, mechanical, and electrical requirements for which the polymer films shall be tested on for conformance are as follows: tensile strength and modulus, and break elongation; insulation resistance and conducting paths; permittivity, dissipation factor, and dielectric breakdown voltage; nominal thickness and width; density; melting point; shrinkage; tear and impact strength, and fold endurance; color or clarity; moisture absorption and permeability; oxygen index and permeability; resistance to corrosive agents; heat or solvent resistance, and hygroscopic coefficient of expansion; aqueous extract conductivity; and acidity. Thicknesses of the capacitor films shall be carried out by either the roll weight, ten-sheet stack, or gravimetric methods.

SCOPE

1.1 This specification covers thin biaxially oriented polymeric resin film for use in capacitors for electrical equipment. The material is biaxially oriented to improve the tensile properties in the machine (MD) and transverse (TD) directions.

The following safety hazards caveat pertains only to the test methods section of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements see and footnote B.

1.2 The values stated in SI units are the standard. The values in parentheses are for information only.

Note 1—This standard resembles IEC 60674-3-2, Specification for plastic films for electrical use, in title only. The content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D3664 – 04

Standard Specification for

Biaxially Oriented Polymeric Resin Film for Capacitors in

1

Electrical Equipment

This standard is issued under the fixed designation D3664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D543 Practices for Evaluating the Resistance of Plastics to

Chemical Reagents

1.1 This specification covers thin biaxially oriented poly-

D570 Test Method for Water Absorption of Plastics

meric resin film for use in capacitors for electrical equipment.

D756 Practice for Determination of Weight and Shape

The material is biaxially oriented to improve the tensile

Changes of Plastics Under Accelerated Service Condi-

propertiesinthemachine(MD)andtransverse(TD)directions.

3

tions

1.2 The following safety hazards caveat pertains only to the

3

D774/D774M Test Method for Bursting Strength of Paper

test methods section of this specification. This standard does

D882 Test Method for Tensile Properties of Thin Plastic

not purport to address all of the safety concerns, if any,

Sheeting

associated with its use. It is the responsibility of the user of this

D1004 Test Method for Tear Resistance (Graves Tear) of

standard to establish appropriate safety and health practices

Plastic Film and Sheeting

and determine the applicability of regulatory limitations prior

D1204 Test Method for Linear Dimensional Changes of

to use. For specific warning statements see 9.3 and Table 1

Nonrigid Thermoplastic Sheeting or Film at Elevated

footnote B.

Temperature

1.3 ThevaluesstatedinSIunitsarethestandard.Thevalues

D1434 Test Method for Determining Gas Permeability

in parentheses are for information only.

Characteristics of Plastic Film and Sheeting

NOTE 1—This standard resembles IEC60674–3–2, Specification for

D1435 Practice for Outdoor Weathering of Plastics

plastic films for electrical use, in title only. The content is significantly

D1505 Test Method for Density of Plastics by the Density-

different.

Gradient Technique

D2176 Test Method for Folding Endurance of Paper by the

2. Referenced Documents

M.I.T. Tester

2

2.1 ASTM Standards:

D2305 Test Methods for Polymeric Films Used for Electri-

D149 Test Method for Dielectric Breakdown Voltage and

cal Insulation

Dielectric Strength of Solid Electrical Insulating Materials

D2863 Test Method for Measuring the Minimum Oxygen

at Commercial Power Frequencies

Concentration to Support Candle-Like Combustion of

D150 Test Methods for AC Loss Characteristics and Per-

Plastics (Oxygen Index)

mittivity (Dielectric Constant) of Solid Electrical Insula-

D3417 Test Method for Enthalpies of Fusion and Crystal-

tion

lization of Polymers by Differential Scanning Calorimetry

D202 Test Methods for Sampling and Testing Untreated

3

(DSC)

Paper Used for Electrical Insulation

D3420 Test Method for Pendulum Impact Resistance of

D257 Test Methods for DC Resistance or Conductance of

Plastic Film

Insulating Materials

D3636 Practice for Sampling and Judging Quality of Solid

D374 Test Methods for Thickness of Solid Electrical Insu-

Electrical Insulating Materials

lation

D3755 Test Method for Dielectric Breakdown Voltage and

Dielectric Strength of Solid Electrical Insulating Materials

1

Under Direct-Voltage Stress

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

D3985 Test Method for Oxygen Gas Transmission Rate

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

Through Plastic Film and Sheeting Using a Coulometric

Current edition approved March 1, 2004. Published April 2004. Originally

Sensor

approved in 1978. Last previous edition approved in 2000 as D3664-00. DOI:

10.1520/D3664-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3664 – 04

D6054 Practice for Conditioning Electrical Insulating Ma- 3. Terminology

terials for Testing

3.1 Definitions of Terms Specific to This Standard:

E96/E96M Test Methods for Water Vapor Transmission of

3.1.1 shiner, n—as related to dielectric films, a protrusion

Materials

of material beyond the plane of either edge of the roll.

E252 Test Metho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.