ASTM D6200-00

(Test Method)Standard Test Method for Determination of Cooling Characteristics of Quench Oils by Cooling Curve Analysis

Standard Test Method for Determination of Cooling Characteristics of Quench Oils by Cooling Curve Analysis

SCOPE

1.1 This test method describes the equipment and the procedure for evaluation of a quenching oil's quenching characteristics by cooling rate determination.

1.2 This test is designed to evaluate quenching oils in a non-agitated system. There is no correlation between these test results and the results obtained in agitated systems.

1.3 The values in SI units are to be regarded as the standard. The values in parenthesis are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6200 – 00 An American National Standard

Standard Test Method for

Determination of Cooling Characteristics of Quench Oils by

Cooling Curve Analysis

This standard is issued under the fixed designation D 6200; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

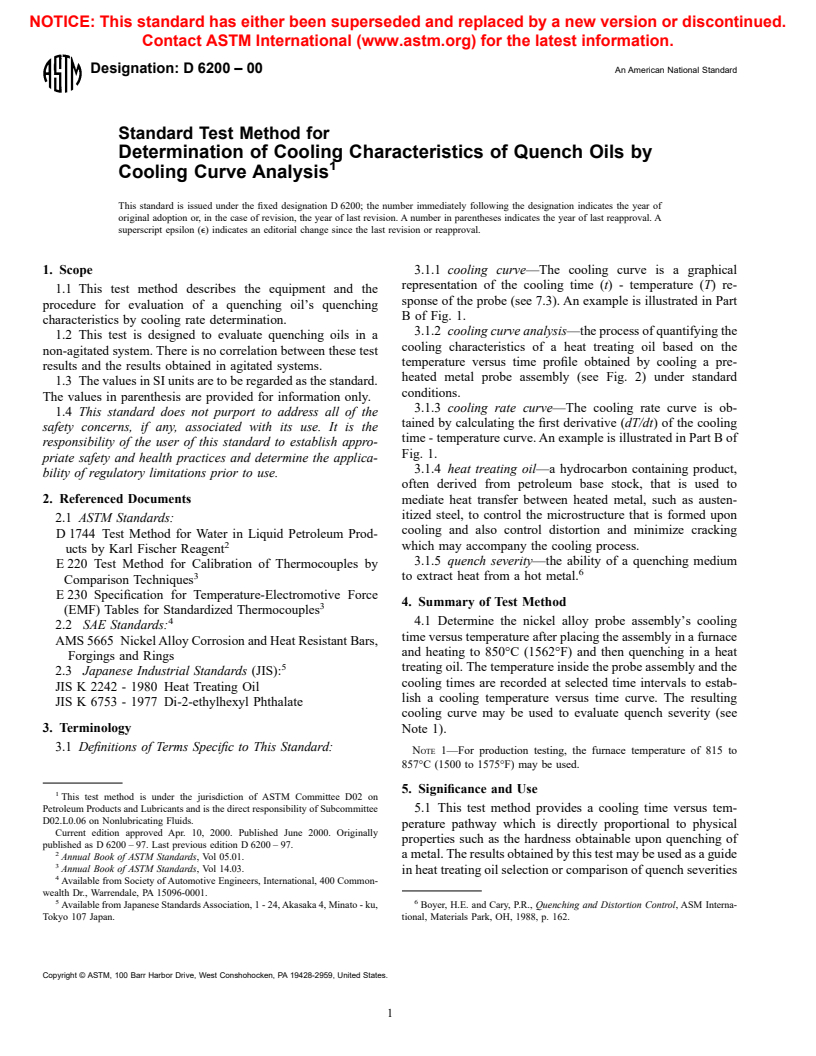

1. Scope 3.1.1 cooling curve—The cooling curve is a graphical

representation of the cooling time (t) - temperature (T) re-

1.1 This test method describes the equipment and the

sponse of the probe (see 7.3). An example is illustrated in Part

procedure for evaluation of a quenching oil’s quenching

B of Fig. 1.

characteristics by cooling rate determination.

3.1.2 cooling curve analysis—the process of quantifying the

1.2 This test is designed to evaluate quenching oils in a

cooling characteristics of a heat treating oil based on the

non-agitated system. There is no correlation between these test

temperature versus time profile obtained by cooling a pre-

results and the results obtained in agitated systems.

heated metal probe assembly (see Fig. 2) under standard

1.3 The values in SI units are to be regarded as the standard.

conditions.

The values in parenthesis are provided for information only.

3.1.3 cooling rate curve—The cooling rate curve is ob-

1.4 This standard does not purport to address all of the

tained by calculating the first derivative (dT/dt) of the cooling

safety concerns, if any, associated with its use. It is the

time - temperature curve. An example is illustrated in Part B of

responsibility of the user of this standard to establish appro-

Fig. 1.

priate safety and health practices and determine the applica-

3.1.4 heat treating oil—a hydrocarbon containing product,

bility of regulatory limitations prior to use.

often derived from petroleum base stock, that is used to

2. Referenced Documents mediate heat transfer between heated metal, such as austen-

itized steel, to control the microstructure that is formed upon

2.1 ASTM Standards:

cooling and also control distortion and minimize cracking

D 1744 Test Method for Water in Liquid Petroleum Prod-

which may accompany the cooling process.

ucts by Karl Fischer Reagent

3.1.5 quench severity—the ability of a quenching medium

E 220 Test Method for Calibration of Thermocouples by

to extract heat from a hot metal.

Comparison Techniques

E 230 Specification for Temperature-Electromotive Force

4. Summary of Test Method

(EMF) Tables for Standardized Thermocouples

4.1 Determine the nickel alloy probe assembly’s cooling

2.2 SAE Standards:

time versus temperature after placing the assembly in a furnace

AMS 5665 Nickel Alloy Corrosion and Heat Resistant Bars,

and heating to 850°C (1562°F) and then quenching in a heat

Forgings and Rings

treating oil. The temperature inside the probe assembly and the

2.3 Japanese Industrial Standards (JIS):

cooling times are recorded at selected time intervals to estab-

JIS K 2242 - 1980 Heat Treating Oil

lish a cooling temperature versus time curve. The resulting

JIS K 6753 - 1977 Di-2-ethylhexyl Phthalate

cooling curve may be used to evaluate quench severity (see

3. Terminology

Note 1).

3.1 Definitions of Terms Specific to This Standard:

NOTE 1—For production testing, the furnace temperature of 815 to

857°C (1500 to 1575°F) may be used.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee 5.1 This test method provides a cooling time versus tem-

D02.L0.06 on Nonlubricating Fluids.

perature pathway which is directly proportional to physical

Current edition approved Apr. 10, 2000. Published June 2000. Originally

properties such as the hardness obtainable upon quenching of

published as D 6200 – 97. Last previous edition D 6200 – 97.

a metal. The results obtained by this test may be used as a guide

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 14.03.

in heat treating oil selection or comparison of quench severities

Available from Society of Automotive Engineers, International, 400 Common-

wealth Dr., Warrendale, PA 15096-0001.

5 6

Available from Japanese Standards Association, 1 - 24, Akasaka 4, Minato - ku, Boyer, H.E. and Cary, P.R., Quenching and Distortion Control, ASM Interna-

Tokyo 107 Japan. tional, Materials Park, OH, 1988, p. 162.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6200

FIG. 1 Typical Temperature/Time and Temperature/Cooling Rate Plots For Test Probe Cooled in a Quenching Oil

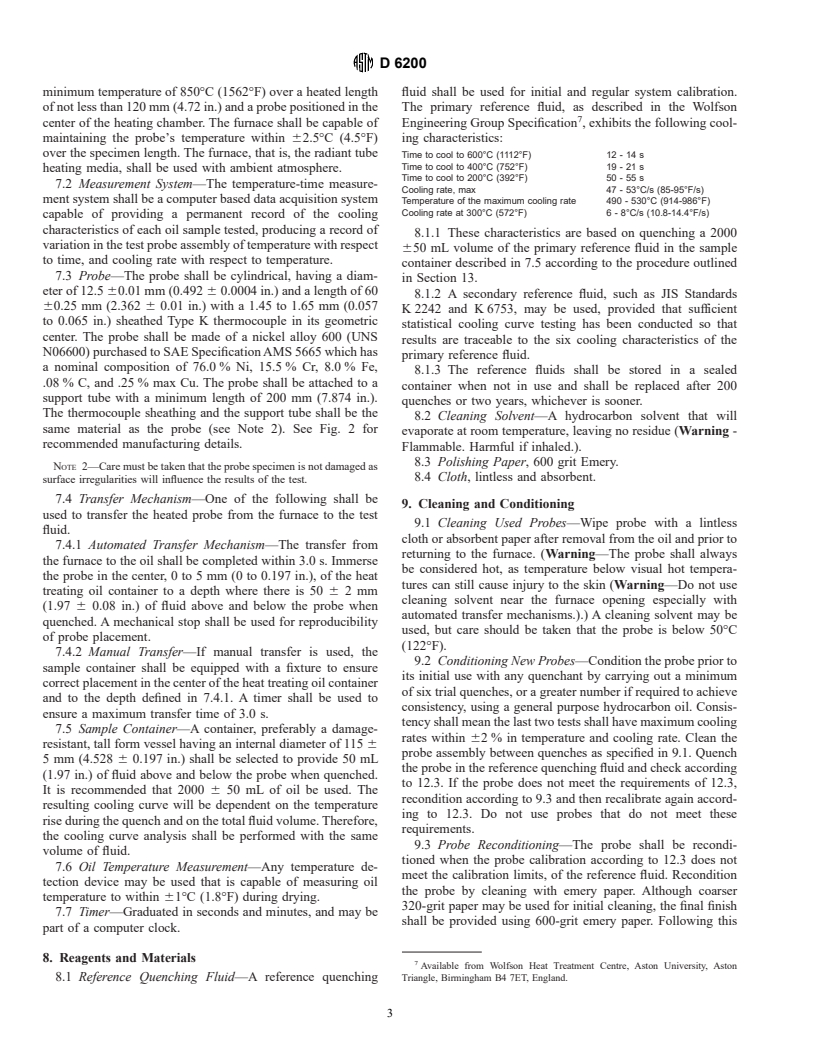

FIG. 2 Probe Details and General Probe Assembly

of different heat treating oils, new or used. shall be dried at a minimum temperature of 102°C (216°F)

until Test Method D 1744 indicates water content at or below

6. Interferences

0.01 %.

6.1 The presence of water in a heat treating oil has a major

7. Apparatus

effect upon the results obtained with this test method. Water

content of calibration fluids shall be confirmed by Test Method 7.1 Furnace—Use a horizontal or vertical electrical resis-

D 1744. If water is present above 0.01 %, the calibration fluid tance tube-type furnace capable of maintaining a constant

D 6200

minimum temperature of 850°C (1562°F) over a heated length fluid shall be used for initial and regular system calibration.

of not less than 120 mm (4.72 in.) and a probe positioned in the The primary reference fluid, as described in the Wolfson

center of the heating chamber. The furnace shall be capable of Engineering Group Specification , exhibits the following cool-

maintaining the probe’s temperature within 62.5°C (4.5°F) ing characteristics:

over the specimen length. The furnace, that is, the radiant tube

Time to cool to 600°C (1112°F) 12 - 14 s

Time to cool to 400°C (752°F) 19 - 21 s

heating media, shall be used with ambient atmosphere.

Time to cool to 200°C (392°F) 50 - 55 s

7.2 Measurement System—The temperature-time measure-

Cooling rate, max 47 - 53°C/s (85-95°F/s)

ment system shall be a computer based data acquisition system

Temperature of the maximum cooling rate 490 - 530°C (914-986°F)

Cooling rate at 300°C (572°F) 6 - 8°C/s (10.8-14.4°F/s)

capable of providing a permanent record of the cooling

characteristics of each oil sample tested, producing a record of

8.1.1 These characteristics are based on quenching a 2000

variation in the test probe assembly of temperature with respect

650 mL volume of the primary reference fluid in the sample

to time, and cooling rate with respect to temperature.

container described in 7.5 according to the procedure outlined

7.3 Probe—The probe shall be cylindrical, having a diam-

in Section 13.

eter of 12.5 60.01 mm (0.492 6 0.0004 in.) and a length of 60

8.1.2 A secondary reference fluid, such as JIS Standards

60.25 mm (2.362 6 0.01 in.) with a 1.45 to 1.65 mm (0.057

K 2242 and K 6753, may be used, provided that sufficient

to 0.065 in.) sheathed Type K thermocouple in its geometric

statistical cooling curve testing has been conducted so that

center. The probe shall be made of a nickel alloy 600 (UNS

results are traceable to the six cooling characteristics of the

N06600) purchased to SAE Specification AMS 5665 which has

primary reference fluid.

a nominal composition of 76.0 % Ni, 15.5 % Cr, 8.0 % Fe,

8.1.3 The reference fluids shall be stored in a sealed

.08 % C, and .25 % max Cu. The probe shall be attached to a

container when not in use and shall be replaced after 200

support tube with a minimum length of 200 mm (7.874 in.).

quenches or two years, whichever is sooner.

The thermocouple sheathing and the support tube shall be the

8.2 Cleaning Solvent—A hydrocarbon solvent that will

same material as the probe (see Note 2). See Fig. 2 for

evaporate at room temperature, leaving no residue (Warning -

recommended manufacturing details.

Flammable. Harmful if inhaled.).

8.3 Polishing Paper, 600 grit Emery.

NOTE 2—Care must be taken that the probe specimen is not damaged as

8.4 Cloth, lintless and absorbent.

surface irregularities will influence the results of the test.

7.4 Transfer Mechanism—One of the following shall be

9. Cleaning and Conditioning

used to transfer the heated probe from the furnace to the test

9.1 Cleaning Used Probes—Wipe probe with a lintless

fluid.

cloth or absorbent paper after removal from the oil and prior to

7.4.1 Automated Transfer Mechanism—The transfer from

returning to the furnace. (Warning—The probe shall always

the furnace to the oil shall be completed within 3.0 s. Immerse

be considered hot, as temperature below visual hot tempera-

the probe in the center, 0 to 5 mm (0 to 0.197 in.), of the heat

tures can still cause injury to the skin (Warning—Do not use

treating oil container to a depth where there is 50 6 2mm

cleaning solvent near the furnace opening especially with

(1.97 6 0.08 in.) of fluid above and below the probe when

automated transfer mechanisms.).) A cleaning solvent may be

quenched. A mechanical stop shall be used for reproducibility

used, but care should be taken that the probe is below 50°C

of probe placement.

(122°F).

7.4.2 Manual Transfer—If manual transfer is used, the

9.2 Conditioning New Probes—Condition the probe prior to

sample container shall be equipped with a fixture to ensure

its initial use with any quenchant by carrying out a minimum

correct placement in the center of the heat treating oil container

of six trial quenches, or a greater number if required to achieve

and to the depth defined in 7.4.1. A timer shall be used to

consistency, using a general purpose hydrocarbon oil. Consis-

ensure a maximum transfer time of 3.0 s.

tency shall mean the last two tests shall have maximum cooling

7.5 Sample Container—A container, preferably a damage-

rates within 62 % in temperature and cooling rate. Clean the

resistant, tall form vessel having an internal diameter of 115 6

probe assembly between quenches as specified in 9.1. Quench

5 mm (4.528 6 0.197 in.) shall be selected to provide 50 mL

the probe in the reference quenching fluid and check according

(1.97 in.) of fluid above and below the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.