ASTM D3612-02

(Test Method)Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography

Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography

SIGNIFICANCE AND USE

Oil and oil-immersed electrical insulation materials may decompose under the influence of thermal and electrical stresses, and in doing so, generate gaseous decomposition products of varying composition which dissolve in the oil. The nature and amount of the individual component gases that may be recovered and analyzed may be indicative of the type and degree of the abnormality responsible for the gas generation. The rate of gas generation and changes in concentration of specific gases over time are also used to evaluate the condition of the electric apparatus.

Note 1—Guidelines for the interpretation of gas-in-oil data are given in IEEE C57.104.

SCOPE

1.1 This test method covers three procedures for extraction and measurement of gases dissolved in electrical insulating oil having a viscosity of 20 cSt (100 SUS) or less at 40°C (104°F), and the identification and determination of the individual component gases extracted. Other methods have been used to perform this analysis.

1.2 The individual component gases that may be identified and determined include: Hydrogen—H2 Oxygen—O2 Nitrogen—N2 Carbon monoxide—CO Carbon dioxide—CO2 Methane—CH4 Ethane—C2H6 Ethylene—C2H4 Acetylene—C2H2 Propane—C3H8 Propylene—C3H6

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements see 6.1.8, 30.2.2 and 30.3.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 3612–02

Standard Test Method for

Analysis of Gases Dissolved in Electrical Insulating Oil by

1

Gas Chromatography

This standard is issued under the fixed designation D 3612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D2780 Test Method for Solubility of Fixed Gases in

3

Liquids

1.1 This test method covers three procedures for extraction

D3613 TestMethodsofSamplingElectricalInsulatingOils

and measurement of gases dissolved in electrical insulating oil

2

for Gas Analysis and Determination of Water Content

havingaviscosityof20cSt(100SUS)orlessat40°C(104°F),

D 4051 Practice for Preparation of Low-Pressure Gas

and the identification and determination of the individual

3

Blends

component gases extracted. Other methods have been used to

4

E260 Practice for Packed Column Gas Chromatography

perform this analysis.

2.2 IEEE Standard:

1.2 The individual component gases that may be identified

C57.104 GuidefortheInterpretationofGasesGeneratedin

and determined include:

5

Oil-Immersed Transformers

Hydrogen—H

2

2.3 IEC Standard:

Oxygen—O

2

Nitrogen—N

2 Publication No. 567 Guide for the Sampling of Gases and

Carbon monoxide—CO

of Oil from Oil-Filled Electrical Equipment and for the

Carbon dioxide—CO

2

6

Analysis of Free and Dissolved Gases

Methane—CH

4

Ethane—C H

2 6

Ethylene—C H

2 4 3. Terminology

Acetylene—C H

2 2

3.1 Definitions of Terms Specific to This Standard:

Propane—C H

3 8

Propylene—C H

3 6

3.1.1 gas content of oil by volume—in Method A, the total

volume of gases, corrected to 760 torr (101.325 kPa) and 0°C,

1.3 This standard does not purport to address all of the

contained in a given volume of oil, expressed as a percentage.

safety concerns, if any, associated with its use. It is the

In Methods B and C, the sum of the individual gas concentra-

responsibility of the user of this standard to establish appro-

tionscorrectedto760torr(101.325kPa)and0°C,expressedin

priate safety and health practices and determine the applica-

percent or parts per million.

bility of regulatory limitations prior to use. For specific

3.1.2 headspace—a volume of gas phase in contact with a

warning statements see 6.1.8, 30.2.2 and 30.3.1.

volume of oil in a closed vessel.The vessel is a headspace vial

2. Referenced Documents

of 20-mL nominal capacity.

3.1.2.1 Discussion—Other vessel volumes may also be

2.1 ASTM Standards:

used, but the analytical performance may be somewhat differ-

D2140 Test Method for Carbon-Type Composition of In-

2

ent than that specified in Method C.

sulating Oils of Petroleum Origin

3.1.3 parts per million (ppm) by volume of (specific gas) in

D2300 Test Method for Gassing of Insulating Oils Under

2

oil—thevolumeofthatgascorrectedto760torr(101.325kPa)

Electrical Stress and Ionization Modified Pirelli Method

6

and 0°C, contained in 10 volume of oil.

D2779 Test Method for Estimation of Solubility of Gases

3

3.1.4 sparging, v—agitatingtheliquidsampleusingagasto

in Petroleum Liquids

strip other gases free.

3.1.5 volume concentration of (specific gas) in the gas

1

sample—the volume of the specific gas contained in a given

This test method is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

volumeofthegassampleatthesametemperatureandpressure

mittee D27.03 on Analytical Tests.

Current edition approved Oct. 10, 2002. Published December 2002. Originally

4

approved in 1977. Last previous edition approved in 2001 as D3612–01. Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 10.03. Available from IEEE, 345 E. 47th St., New York, NY 10017.

3 6

Annual Book of ASTM Standards, Vol 05.02. Available from IEC.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3612–02

NOTE 2—Thissamplesizehasbeenfoundtobesufficientformostoils.

(as the measured total volume), expressed either as a percent-

However, oil that has had only limited exposure to air may contain much

age or in parts per million.

smalleramountsofnitrogenandoxygen.Fortheseoilsitmaybedesirable

to increase the size of the sample and the extraction apparatus.

4. Summary of Test Method

NOTE 3—Alternative apparatus designs including the use of a Toepler

pump have also been found successful.

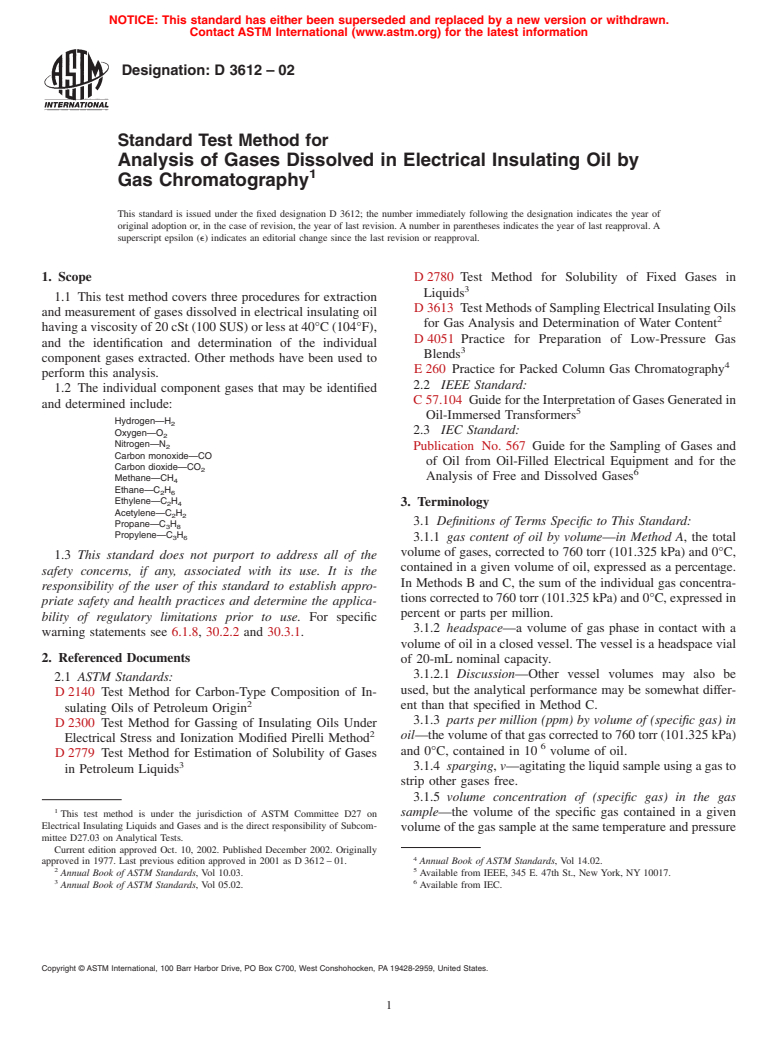

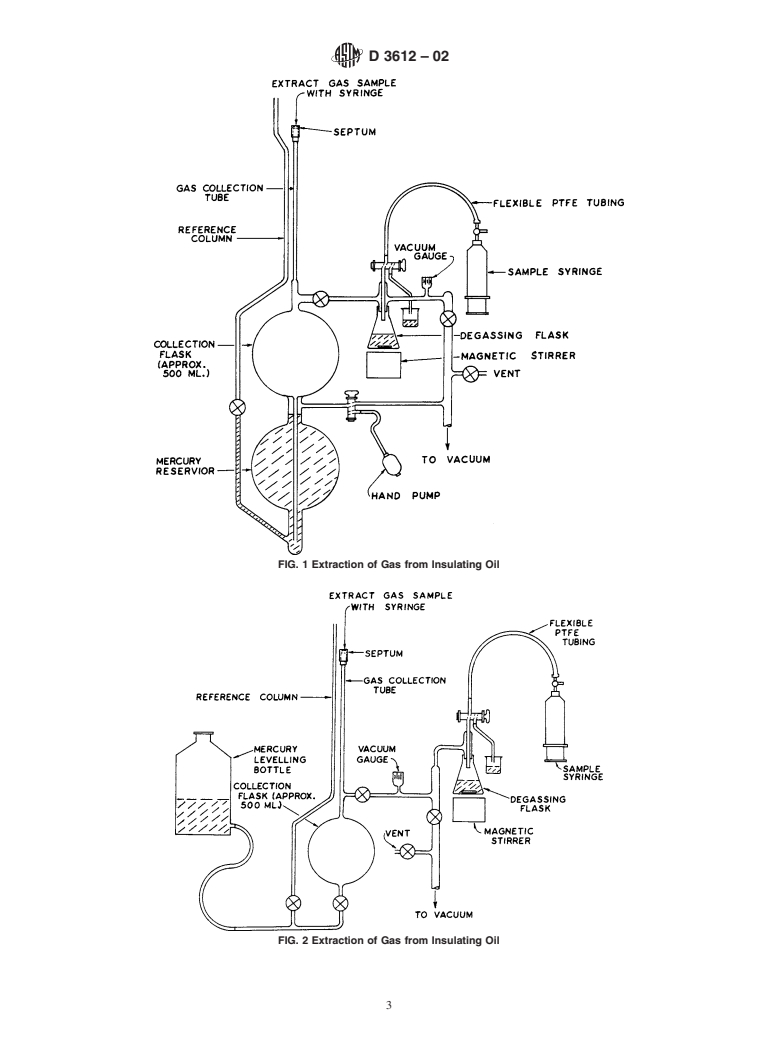

4.1 MethodA—Dissolvedgasesareextractedfromasample

of oil by introduction of the oil sample into a pre-evacuated

6.1.1 Polytetrafluoroethylene (PTFE) Tubing, narrow-bore,

known volume. The evolved gases are compressed to atmo-

terminatedwith

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.