ASTM F1428-92(2017)

(Specification)Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners

Standard Specification for Aluminum Particle-Filled Basecoat/Organic or Inorganic Topcoat, Corrosion Protective Coatings for Fasteners

ABSTRACT

This specification covers corrosion-resistant coating consisting of an inorganic aluminum particle-filled basecoat and an organic or inorganic topcoat. The basecoat is a water-dilutable slurry containing aluminum particles dispersed in a liquid binder of chromate/phosphate compounds. The organic topcoats consist of polymer resins and dispersed pigments. The inorganic topcoats consist of ceramic oxide pigments dispersed in a liquid binder of chromate/phosphate compounds. These coatings are applied by conventional dip/spin, dip/drain, or spray methods. The coating systems defined by this specification can be applied to ferrous alloy steels, aluminum, and ferritic and austenitic stainless steels. The inorganic aluminum particle-filled basecoat and the subsequent topcoats are classified into three groups, with subsequent subgroups. Materials shall be tested and the individual grades shall conform to specified values of appearance, adhesion, corrosion, thread-fit, weathering, coating thickness, and humidity.

SCOPE

1.1 This specification covers the basic requirements for a corrosion-resistant coating consisting of an inorganic aluminum particle-filled basecoat and an organic or inorganic topcoat, depending on the specific requirements.

1.2 The coating may be specified with basecoat only, or with the top coated with compatible organic polymer or inorganic topcoats, depending on the specific requirements.

1.3 The basecoat is a water-dilutable slurry containing aluminum particles dispersed in a liquid binder of chromate/phosphate compounds.

1.4 The organic topcoats consist of polymer resins and dispersed pigments and are for service where temperatures do not exceed 230°C (450°F).

1.5 The inorganic topcoats consist of ceramic oxide pigments dispersed in a liquid binder of chromate/phosphate compounds and are for service where temperatures do not exceed 645°C (1200°F).

1.6 These coatings are applied by conventional dip/spin, dip/drain, or spray methods.

1.7 The coating process does not normally induce hydrogen embrittlement, provided that the parts to be coated have not been subjected to an acid cleaner or pretreatment (see Note 1).

Note 1: Although this coating material contains water, it has a relatively low susceptibility to inducing hydrogen embrittlement in steel parts of tensile strengths equal to or greater than 1000 MPa (approximately RC31). Normal precautions for preparing, descaling, and cleaning steels of these tensile strengths must be observed. An initial stress relief treatment should be considered prior to any chemical treatment or cleaning operation. Acids or other treatments that evolve hydrogen should be avoided. Mechanical cleaning methods may be considered. Some steels are more susceptible to hydrogen embrittlement than others and may also require hydrogen embrittlement relief baking after cleaning but before coating. Since no process can completely guarantee freedom from embrittlement, careful consideration must be given to the entire coating process and the specific steel alloy employed.

1.8 The coating systems defined by this specification can be applied to ferrous alloy steels, aluminum, and ferritic and austenitic stainless steels.

1.9 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.10 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of Internat...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1428 − 92 (Reapproved 2017)

Standard Specification for

Aluminum Particle-Filled Basecoat/Organic or Inorganic

Topcoat, Corrosion Protective Coatings for Fasteners

This standard is issued under the fixed designation F1428; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

process and the specific steel alloy employed.

1. Scope

1.8 The coating systems defined by this specification can be

1.1 This specification covers the basic requirements for a

applied to ferrous alloy steels, aluminum, and ferritic and

corrosion-resistant coating consisting of an inorganic alumi-

austenitic stainless steels.

num particle-filled basecoat and an organic or inorganic

topcoat, depending on the specific requirements.

1.9 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.2 The coating may be specified with basecoat only, or with

only.

the top coated with compatible organic polymer or inorganic

topcoats, depending on the specific requirements.

1.10 The following safety hazards caveat pertains only to

the test methods portion, Section 6, of this specification: This

1.3 The basecoat is a water-dilutable slurry containing

standard does not purport to address all of the safety concerns,

aluminum particles dispersed in a liquid binder of chromate/

if any, associated with its use. It is the responsibility of the user

phosphate compounds.

of this standard to establish appropriate safety, health, and

1.4 The organic topcoats consist of polymer resins and

environmental practices and determine the applicability of

dispersed pigments and are for service where temperatures do

regulatory limitations prior to use.

not exceed 230°C (450°F).

1.11 This international standard was developed in accor-

1.5 The inorganic topcoats consist of ceramic oxide pig-

dance with internationally recognized principles on standard-

ments dispersed in a liquid binder of chromate/phosphate ization established in the Decision on Principles for the

compounds and are for service where temperatures do not

Development of International Standards, Guides and Recom-

exceed 645°C (1200°F). mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.6 These coatings are applied by conventional dip/spin,

dip/drain, or spray methods.

2. Referenced Documents

1.7 The coating process does not normally induce hydrogen

2.1 ASTM Standards:

embrittlement, provided that the parts to be coated have not

B117 Practice for Operating Salt Spray (Fog) Apparatus

been subjected to an acid cleaner or pretreatment (see Note 1).

B487 Test Method for Measurement of Metal and Oxide

NOTE 1—Although this coating material contains water, it has a

Coating Thickness by Microscopical Examination of

relatively low susceptibility to inducing hydrogen embrittlement in steel

Cross Section

parts of tensile strengths equal to or greater than 1000 MPa (approxi-

B568 Test Method for Measurement of Coating Thickness

mately RC31). Normal precautions for preparing, descaling, and cleaning

by X-Ray Spectrometry

steels of these tensile strengths must be observed. An initial stress relief

treatment should be considered prior to any chemical treatment or D1186 Test Methods for Nondestructive Measurement of

cleaning operation. Acids or other treatments that evolve hydrogen should

Dry Film Thickness of Nonmagnetic Coatings Applied to

be avoided. Mechanical cleaning methods may be considered. Some steels 3

a Ferrous Base (Withdrawn 2006)

are more susceptible to hydrogen embrittlement than others and may also

D2247 Practice for Testing Water Resistance of Coatings in

require hydrogen embrittlement relief baking after cleaning but before

100 % Relative Humidity

coating. Since no process can completely guarantee freedom from

embrittlement, careful consideration must be given to the entire coating

D3359 Test Methods for Rating Adhesion by Tape Test

1 2

This specification is under the jurisdiction of ASTM Committee F16 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fasteners. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2017. Published December 2017. Originally the ASTM website.

approved in 1992. Last previous edition approved in 2011 as F1428 – 92 (2011). The last approved version of this historical standard is referenced on www.ast-

DOI: 10.1520/F1428-92R17. m.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1428 − 92 (2017)

E122 Practice for Calculating Sample Size to Estimate, With of the coatings. All topcoat colors shall be agreed upon by both

Specified Precision, the Average for a Characteristic of a the purchaser and the supplier.

Lot or Process

5.2 Adhesion—The coating shall show no evidence of blis-

E376 Practice for Measuring Coating Thickness by

tering or other appearance changes after exposure to humidity

Magnetic-Field or Eddy Current (Electromagnetic) Test-

testing for 96 h, it shall show no more than 3.0-mm peel-back

ing Methods

from the intersection of scribed lines that are tape-tested

immediately after a 10-min recovery period from the humidity

3. Classification

test, and there shall be no other peeling under the tape.

3.1 The inorganic aluminum particle-filled basecoat and the

5.3 Corrosion—These coatings shall be capable of with-

subsequent topcoats are classified into three groups, with

standing neutral salt spray testing for the minimum time

subsequent subgroups formed according to the requirements

specified in Table 1. Unless otherwise defined, acceptable

given in Table 1. The coating bath requirements and cure

corrosion resistance shall be considered to be met where there

temperatures recommended by the chemical manufacturer

is no base metal corrosion on significant surfaces.

should be followed.

5.3.1 Significant surfaces on threaded fasteners are defined

3.2 Regardless of the processes or materials used, the

as the surfaces exposed when the fasteners are installed in a

inorganic and organic coatings shall conform to all of the

normal manner (bolt head, nut drive, face, and so forth). On

applicable requirements of this specification.

other surfaces on which coating control cannot be obtained

under normal processing, such as holes, recesses, threads, and

4. Ordering Information

so forth, the above requirements do not apply.

4.1 Orders for material in accordance with this specification

5.4 Thread-Fit—The coating shall not have an adverse

shall include the following information:

effect

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1428 − 92 (Reapproved 2011) F1428 − 92 (Reapproved 2017)

Standard Specification for

Aluminum Particle-Filled Basecoat/Organic or Inorganic

Topcoat, Corrosion Protective Coatings for Fasteners

This standard is issued under the fixed designation F1428; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the basic requirements for a corrosion-resistant coating consisting of an inorganic aluminum

particle-filled basecoat and an organic or inorganic topcoat, depending on the specific requirements.

1.2 The coating may be specified with basecoat only, or with the top coated with compatible organic polymer or inorganic

topcoats, depending on the specific requirements.

1.3 The basecoat is a water-dilutable slurry containing aluminum particles dispersed in a liquid binder of chromate/phosphate

compounds.

1.4 The organic topcoats consist of polymer resins and dispersed pigments and are for service where temperatures do not exceed

230°C (450°F).

1.5 The inorganic topcoats consist of ceramic oxide pigments dispersed in a liquid binder of chromate/phosphate compounds

and are for service where temperatures do not exceed 645°C (1200°F).

1.6 These coatings are applied by conventional dip/spin, dip/drain, or spray methods.

1.7 The coating process does not normally induce hydrogen embrittlement, provided that the parts to be coated have not been

subjected to an acid cleaner or pretreatment (see Note 1).

NOTE 1—Although this coating material contains water, it has a relatively low susceptibility to inducing hydrogen embrittlement in steel parts of tensile

strengths equal to or greater than 1000 MPa (approximately RC31). Normal precautions for preparing, descaling, and cleaning steels of these tensile

strengths must be observed. An initial stress relief treatment should be considered prior to any chemical treatment or cleaning operation. Acids or other

treatments that evolve hydrogen should be avoided. Mechanical cleaning methods may be considered. Some steels are more susceptible to hydrogen

embrittlement than others and may also require hydrogen embrittlement relief baking after cleaning but before coating. Since no process can completely

guarantee freedom from embrittlement, careful consideration must be given to the entire coating process and the specific steel alloy employed.

1.8 The coating systems defined by this specification can be applied to ferrous alloy steels, aluminum, and ferritic and austenitic

stainless steels.

1.9 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.10 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

B487 Test Method for Measurement of Metal and Oxide Coating Thickness by Microscopical Examination of Cross Section

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.03 on Coatings on Fasteners.

Current edition approved Nov. 1, 2011Dec. 1, 2017. Published May 2012December 2017. Originally approved in 1992. Last previous edition approved in 20052011 as

F1428 – 92 (2005).(2011). DOI: 10.1520/F1428-92R05.10.1520/F1428-92R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1428 − 92 (2017)

B568 Test Method for Measurement of Coating Thickness by X-Ray Spectrometry

D1186 Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous

Base (Withdrawn 2006)

D2247 Practice for Testing Water Resistance of Coatings in 100 % Relative Humidity

D3359 Test Methods for Rating Adhesion by Tape Test

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E376 Practice for Measuring Coating Thickness by Magnetic-Field or Eddy Current (Electromagnetic) Testing Methods

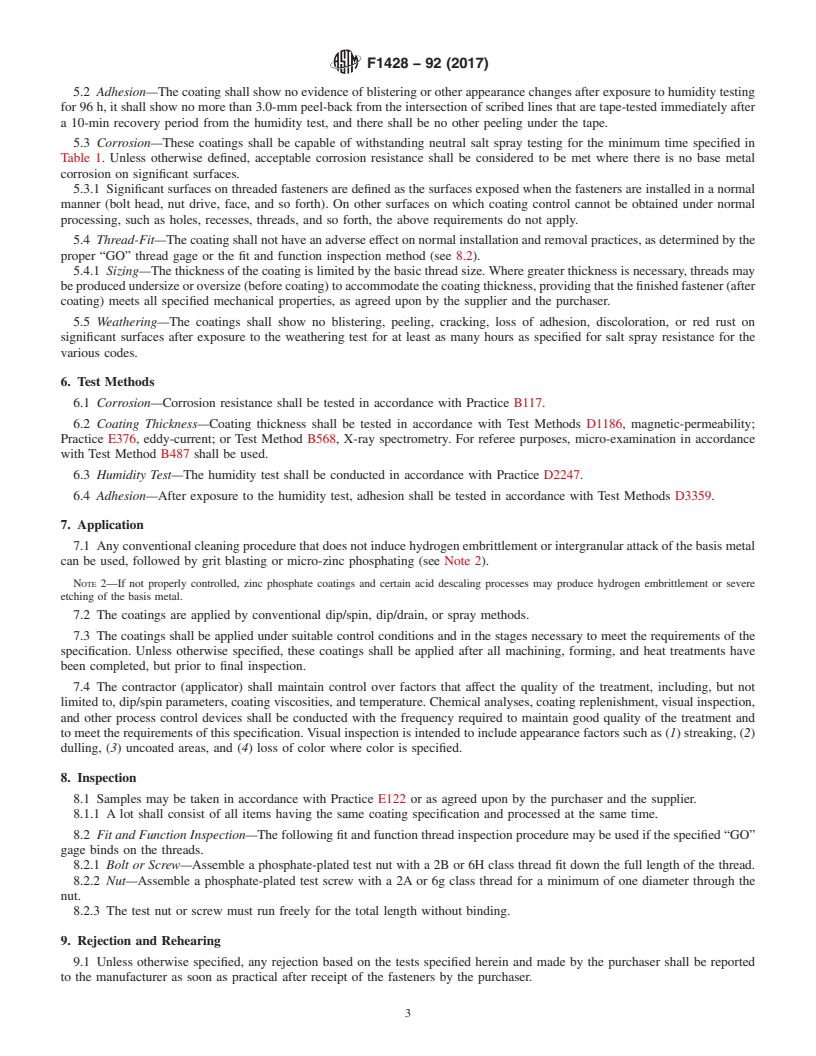

3. Classification

3.1 The inorganic aluminum particle-filled basecoat and the subsequent topcoats are classified into three groups, with

subsequent subgroups formed according to the requirements given in Table 1. The coating bath requirements and cure temperatures

recommended by the chemical manufacturer should be followed.

3.2 Regardless of the processes or materials used, the inorganic and organic coatings shall conform to all of the applicable

requirements of this specification.

4. Ordering Information

4.1 Orders for material in accordance with this specification shall include the following information:

4.1.1 Quantity of parts,

4.1.2 Grade of coating (see Table 1),

4.1.3 Color of coating,

4.1.4 Any additions to specifications as agreed upon by the purchaser and the supplier, and

4.1.5 Certification and test report requirements.

5. Requirements

5.1 Appearance—The coatings shall have a smooth, uniform appearance and shall be free of lacerations and other

discontinuities that may affect the appearance or performance of the coatings. All topcoat colors shall be agreed upon by both the

purchaser and the supplier.

TABLE 1 Classification of Coatings

NOTE 1— Grades 4A, 4B, and 2C require basecoat burnishing.

NOTE 2—The torque tension relationship of coated fasteners may be

different from those of uncoated fasteners. A wax lubricant may be

specified to improve the torque-tension characteristics of coated fasteners.

NOTE 3—When spray application methods are employed, the thickness

requirements of the two individual coats may be achieved in one single

spray application.

Grade Coats of Coats of Average Salt Spray

No. Basecoat Topcoats Thickness, Life Hours

μm

A

1A 1 1 10–15 168

2A 2 1 15

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.