ASTM D4474-00

(Classification)Standard Classification System for Styrenic Thermoplastic Elastomer Injection Molding and Extrusion Materials (TES) (Withdrawn 2008)

Standard Classification System for Styrenic Thermoplastic Elastomer Injection Molding and Extrusion Materials (TES) (Withdrawn 2008)

SCOPE

1.1 This classification and subsequent line callout (specification) cover styrenic block copolymer thermoplastic elastomer materials for injection molding and extrusion. Copolymers consist of polystyrene segments bound to rubbery segments. The rubbery segments may be saturated or unsaturated. Compounding ingredients may be present as necessary for the application. The compounding ingredients may consist of reinforcements, resins, plasticizers, fillers, stabilizers, and colorants. Recycled styrenic thermoplastic elastomers are not covered in this classification.

1.2 The properties included in this classification are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics that are important to specialized applications. These may be described by using the suffixes specified in Section 5.

1.3 The values stated in SI units, as detailed in IEEE/ASTM SI 10, are to be regarded as the standard.

Note 1--There is no equivalent ISO standard.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee D20 on Plastics, this classification was withdrawn in April 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4474 – 00

Standard Classification System for

Styrenic Thermoplastic Elastomer Injection Molding and

Extrusion Materials (TES)

This standard is issued under the fixed designation D 4474; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This classification system is intended to be a means of calling out materials used in the fabrication

of end items or parts. It is not intended for the selection of materials. Material selection should be

made by those having expertise in the plastics field after careful consideration of the design and

performance required of the part, the environment to which it will be exposed, the fabrication process

to be employed, the inherent properties of the material other than those covered by this classification

system, and the economics.

1. Scope* D 624 Test Method for Tear Strength of Conventional

Vulcanized Rubber and Thermoplastic Elastomers

1.1 This classification and subsequent line callout (specifi-

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

cation) cover styrenic block copolymer thermoplastic elas-

and Reinforced Plastics and Electrical Insulating Materials

tomer materials for injection molding and extrusion. Copoly-

D 792 TestMethodsforDensityandSpecificGravity(Rela-

mers consist of polystyrene segments bound to rubbery

tive Density) of Plastics by Displacement

segments. The rubbery segments may be saturated or unsatur-

D 883 Terminology Relating to Plastics

ated. Compounding ingredients may be present as necessary

D 1600 Terminology for Abbreviated Terms Relating to

for the application. The compounding ingredients may consist

Plastics

of reinforcements, resins, plasticizers, fillers, stabilizers, and

D 1898 Practice for Sampling of Plastics

colorants. Recycled styrenic thermoplastic elastomers are not

D 2240 Test Method for Rubber Property—Durometer

covered in this classification.

Hardness

1.2 The properties included in this classification are those

D 3892 Practice for Packaging/Packing of Plastics

required to identify the compositions covered. There may be

D 4000 Classification System for Specifying Plastic Mate-

other requirements necessary to identify particular character-

rials

istics that are important to specialized applications. These may

D 5740 Guide for Writing Material Standards in the Clas-

be described by using the suffixes specified in Section 5.

sification D 4000 Format

1.3 The values stated in SI units, as detailed in IEEE/

E 29 Practice for Using Significant Digits in Test Data to

ASTM SI 10, are to be regarded as the standard.

Determine Conformance with Specification

NOTE 1—There is no equivalent ISO standard.

IEEE/ASTM SI 10 Standard for Use of the International

System of Units (SI): The Modern Metric System

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

D 412 Test Methods for Vulcanized Rubber and Thermo-

3.1 Definitions:

plastic Elastomers—Tension

3.1.1 Fordefinitionsoftechnicaltermspertainingtoplastics

D 618 Practice for Conditioning Plastics for Testing

used in this classification, see Terminology D 883.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 styrenic thermoplastic elastomer (TES)—acopolymer

ThisclassificationsystemisunderthejurisdictionofASTMCommitteeD20on

material comprising styrenic end-block segments which are

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials. bound to a rubbery segment that may be saturated or unsatur-

Current edition approved Nov. 10, 2000. Published February 2001. Originally

ated and which normally contain substantial amounts of added

published as D 4474 – 85. Last previous edition D 4474 – 96.

materials such as other polymers, oils, fillers, and colorants.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4474–00

3.2.2 unsaturated styrenic thermoplastic elastomer proprietary nature. Consequently, there is no distinction be-

(TESU)—a copolymer material comprising styrenic end- tween reinforced and unreinforced versions. This part of the

blocks which are bound to an unsaturated rubbery segment. callout is omitted.

3.2.3 saturated styrenic thermoplastic elastomer (TESS)—a 4.3 Specific requirements shall be shown by a six character

copolymer material comprising styrenic end-blocks which are designation.The designation will consist of the letterAand the

bound to a saturated rubbery segment. five digits comprising the cell numbers for the property

3.2.4 thermoplastic elastomers (TPE)—a diverse family of requirements in the order as they appear in Table A.

rubber-like materials that, unlike conventional vulcanized rub- 4.3.1 Although the values listed are necessary to include the

bers, can be processed and recycled like thermoplastic mate- range of properties available in existing materials, users should

rials. not infer that every possible combination of the properties

exists or can be obtained.

4. Classification 4.3.2 An example of this classification system is as follows:

The designation TES 0110A22240 would indicate the follow-

4.1 Styrenic thermoplastic elastomer materials are classified

ing, with the material requirements from Table A:

into groups according to their basic composition.These groups

TES 0110 = Styrenic saturated thermoplastic elastomer hav-

are subdivided into classes and grades as shown in Table TES.

ing low hardness from Table TES.

4.1.1 An example of this classification system is as follows:

ThedesignationTES0112wouldindicateTES = thermoplastic

elastomerstyrenic, as found in Terminology D 1600, 01

A = Table A property requirements,

(group) = saturated rubber, 1 (class) = low hardness, and 2

2 = 50 Durometer A hardness, min,

(grade) with requirements given in Table TES.

2 = 50 MPa flexural modulus, min,

4.1.2 To facilitate the incorporation of future or special

2 = 5.0 MPa tensile strength, min,

materials, the “other/unspecified” category (0) for group, class,

4 = 500 % elongation, min, and

and grade is shown in Table TES. The basic properties can be 0 = Unspecified.

obtained from Table A. If no properties are specified, the designation would be TES

4.2 Styrenic thermoplastic elastomers suitable for injection 0110 A00000.

molding and extrusion are fully compounded materials of a

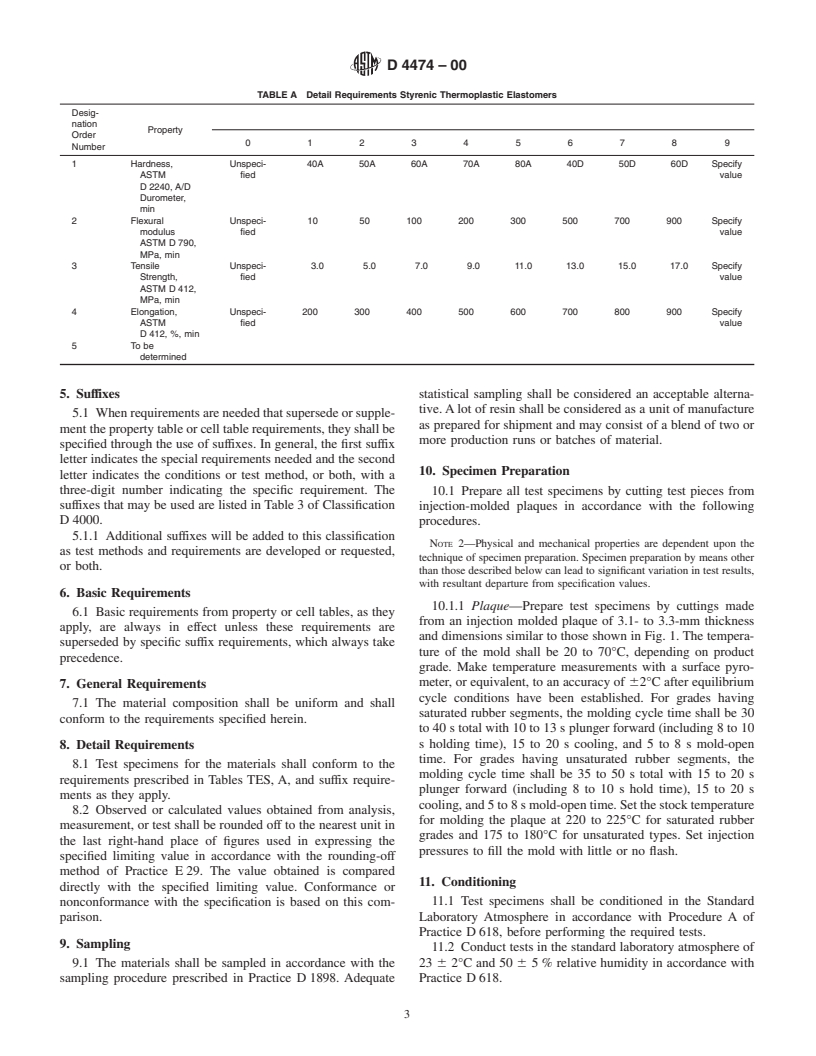

TABLE TES Detail Requirements for Styrenic Thermoplastic Elastomers

Tear Re-

Hardness,

Flexural Tensile Elongation, sistance,

ASTM Specific Grav-

Modulus, Strength, (Ultimate) ASTM

Group Description Class Description Grade Description D 2240, A/D ity, ASTM

ASTM D 790, ASTM D 412, ASTM D 412, D 624, Die

Durometer D 792, 6 0.02,

min, MPa min, MPa min, % C, min,

Typical

KN/m

01 Saturated 1 Low hardness 1 47A <10 3.0 500 13 1.19

rubber 2 55A <10 9.0 600 15 0.92

segment 3 59A 11 4.0 500 16 1.20

0 Other

2 Medium 1 82A 52 7.8 450 47 1.01

hardness 2 89A 130 3.9 300 21 1.86

3 91A 125 9.0 450 36 1.14

0 Other

3 High 1 45D 480 11 400 50 1.20

hardness 2 44D 310 12 400 70 1.14

3 49D 360 4.1 200 26 1.83

4 57D 450 15 500 85 1.02

5 60D 520 13 350 98 0.91

6 64D 1480 15 350 76 1.29

0 Other

0 Other 0 Other

02 Unsaturated 1 Low hardness 0 Other

rubber 2 Medium 0 Other

segment hardness 0 Other

3 High 1 47D 250 6.7 300 52 1.05

hardness

0 Other

0 Other 0 Other

00 Other 0 Other 0 Other

D4474–00

TABLE A Detail Requirements Styrenic Thermoplastic Elastomers

Desig-

nation

Property

Order

0 1 2345678 9

Number

1 Hardness, Unspeci- 40A 50A 60A 70A 80A 40D 50D 60D Specify

ASTM fied value

D 2240, A/D

Durometer,

min

2 Flexural Unspeci- 10 50 100 200 300 500 700 900 Specify

modulus fied value

ASTM D 790,

MPa, min

3 Tensile Unspeci- 3.0 5.0 7.0 9.0 11.0 13.0 15.0 17.0 Specify

Strength, fied value

ASTM D 412,

MPa, min

4 Elongation, Unspeci- 200 300 400 500 600 700 800 900 Specify

ASTM fied value

D 412, %, min

5Tobe

determined

5. Suffixes statistical sampling shall be considered an acceptable alterna-

tive.Alot of resin shall be considered as a unit of manufacture

5.1 Whenrequirementsareneededthatsupersedeorsupple-

as prepa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.