ASTM D1056-20

(Specification)Standard Specification for Flexible Cellular Materials—Sponge or Expanded Rubber

Standard Specification for Flexible Cellular Materials—Sponge or Expanded Rubber

ABSTRACT

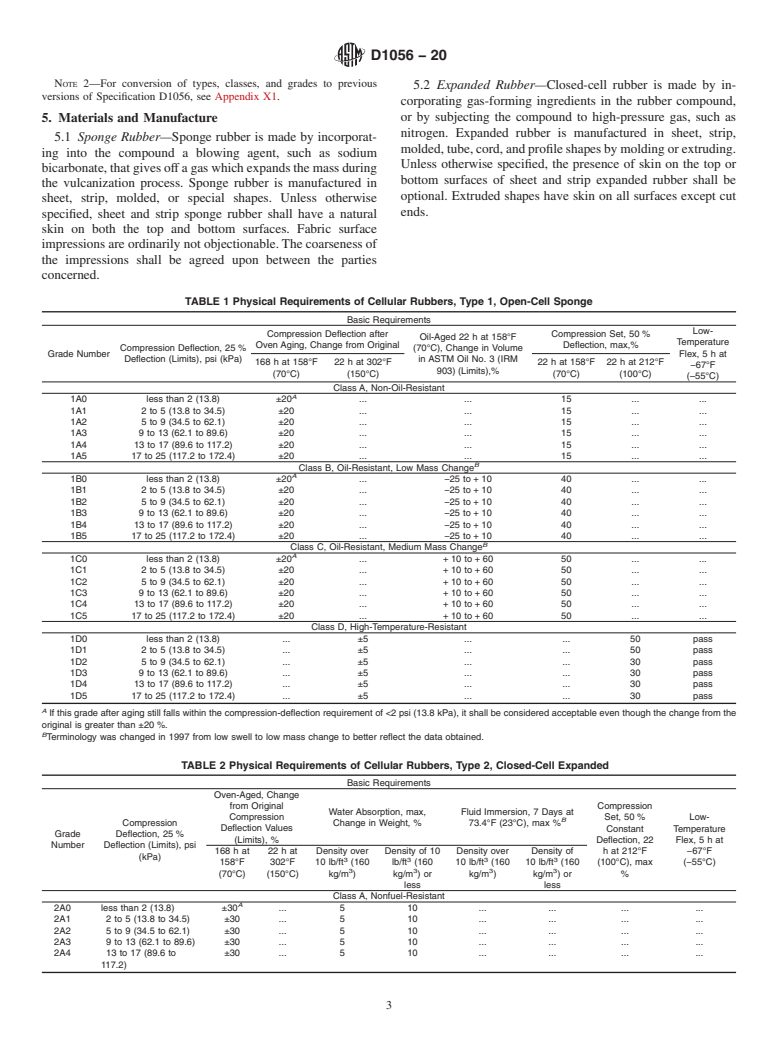

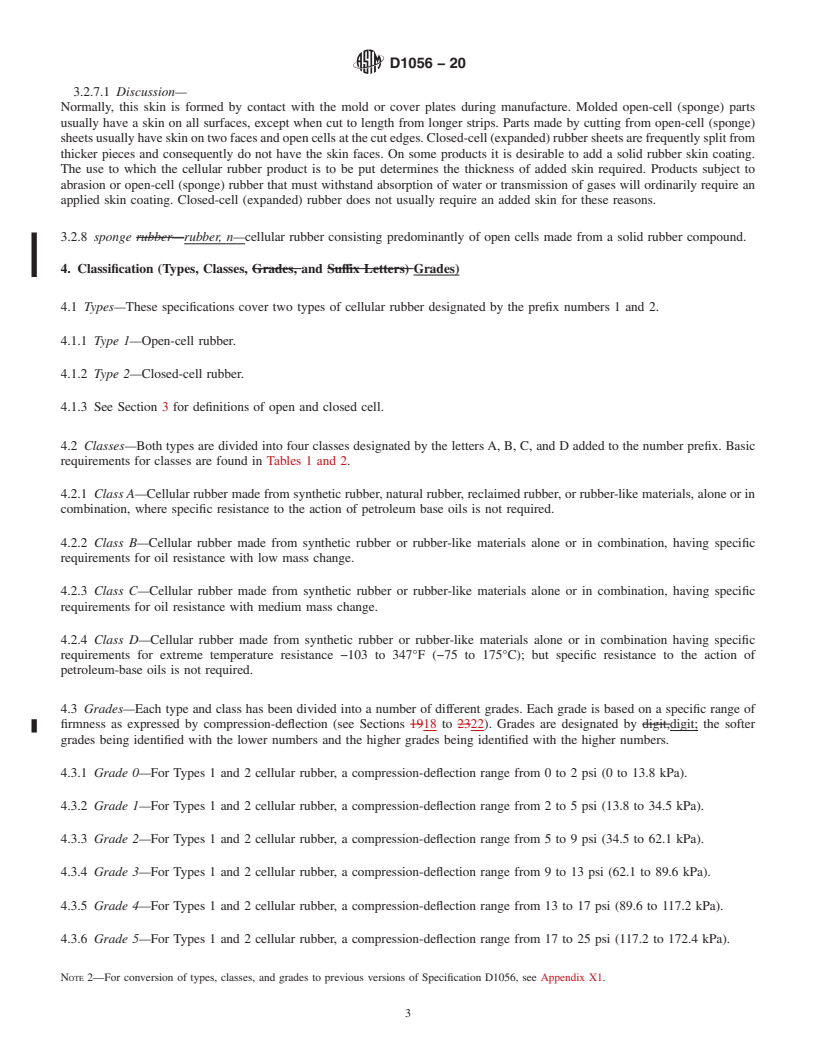

This specification covers flexible cellular rubber products known as sponge rubber and expanded rubber, but does not apply to latex foam rubber or ebonite cellular rubber. The base material for an open/closed cellular product may be made of synthetic, natural, or reclaimed rubber, or a mixture, and may contain other polymers or chemicals, or both, which may be modified by organic or inorganic additives. The cellular rubber shall be categorized by types, classes, suffixes, and grades: Types 1 and 2; Classes A, B, C, and D; Grades 0, 1, 2, 3, 4, and 5. The various grades of cellular rubber shall conform to the requirements as to physical properties specified. The following test methods shall be performed: accelerated aging tests; compression-deflection tests; oil-immersion test (open-cell sponge); fluid immersion tests (closed cell); water absorption test; density tests; and low-temperature flex test.

SCOPE

1.1 This specification covers flexible cellular rubber products known as sponge rubber and expanded rubber, but does not apply to latex foam rubber or ebonite cellular rubber. The base material for an open/closed cellular product may be made of synthetic, natural, or reclaimed rubber, or a mixture, and may contain other polymers or chemicals, or both, which may be modified by organic or inorganic additives. These elastomeric materials have properties similar to those of vulcanized rubber, namely (1) the ability to be converted from a thermoplastic to a thermosetting state by crosslinking (vulcanization) or (2) the substantial recovery of their original shapes when strained or elongated, or both.

1.2 Extruded or molded shapes of sizes too small for cutting standard test specimens are difficult to classify or test by these methods and will usually require special testing procedures.

1.3 In case of conflict between the provisions of this general specification and those of detailed specifications or test methods for a particular product, the latter shall take precedence. Reference to the test methods in this specification should specifically state the particular test or tests desired.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: ISO 6916-1 is similar to this specification.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D1056 −20

Standard Specification for

1,2

Flexible Cellular Materials—Sponge or Expanded Rubber

This standard is issued under the fixed designation D1056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* standard to establish appropriate safety, health, and environ-

mental practices and determine the applicability of regulatory

1.1 This specification covers flexible cellular rubber prod-

limitations prior to use.

ucts known as sponge rubber and expanded rubber, but does

not apply to latex foam rubber or ebonite cellular rubber. The

NOTE 1—ISO 6916-1 is similar to this specification.

basematerialforanopen/closedcellularproductmaybemade

1.6 This international standard was developed in accor-

of synthetic, natural, or reclaimed rubber, or a mixture, and

dance with internationally recognized principles on standard-

may contain other polymers or chemicals, or both, which may

ization established in the Decision on Principles for the

be modified by organic or inorganic additives. These elasto-

Development of International Standards, Guides and Recom-

meric materials have properties similar to those of vulcanized

mendations issued by the World Trade Organization Technical

rubber, namely (1) the ability to be converted from a thermo-

Barriers to Trade (TBT) Committee.

plastic to a thermosetting state by crosslinking (vulcanization)

or (2) the substantial recovery of their original shapes when

2. Referenced Documents

strained or elongated, or both.

3

2.1 ASTM Standards:

1.2 Extrudedormoldedshapesofsizestoosmallforcutting

D395Test Methods for Rubber Property—Compression Set

standard test specimens are difficult to classify or test by these

D412TestMethodsforVulcanizedRubberandThermoplas-

methods and will usually require special testing procedures.

tic Elastomers—Tension

D471Test Method for Rubber Property—Effect of Liquids

1.3 Incaseofconflictbetweentheprovisionsofthisgeneral

D573Test Method for Rubber—Deterioration in an Air

specification and those of detailed specifications or test meth-

Oven

ods for a particular product, the latter shall take precedence.

D575Test Methods for Rubber Properties in Compression

Reference to the test methods in this specification should

D624Test Method for Tear Strength of Conventional Vul-

specifically state the particular test or tests desired.

canized Rubber and Thermoplastic Elastomers

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

D832Practice for Rubber Conditioning For Low Tempera-

as standard. The values given in parentheses are mathematical

ture Testing

conversions to SI units that are provided for information only

D883Terminology Relating to Plastics

and are not considered standard.

D1171Test Method for Rubber Deterioration—Surface

1.5 The following safety hazards caveat pertains only to the

Ozone Cracking Outdoors (Triangular Specimens)

test methods portions of this specification: This standard does

D2632Test Method for Rubber Property—Resilience by

not purport to address all of the safety concerns, if any,

Vertical Rebound

associated with its use. It is the responsibility of the user of this

D3182PracticeforRubber—Materials,Equipment,andPro-

cedures for Mixing Standard Compounds and Preparing

Standard Vulcanized Sheets

1

This specification is under the jurisdiction of ASTM Committee D20 on

D3183Practice for Rubber—Preparation of Pieces for Test

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

Purposes from Products

Materials - Plastics and Elastomers.

D5132Test Method for Horizontal Burning Rate of Poly-

This standard has been approved for use by agencies of the Department of

Defense to replace Methods12001, 12005, 12011, 12021, 12031, 12041, 12151,

meric Materials Used in Occupant Compartments of

and12411 of Federal Test Method Standard No. 601.

Motor Vehicles

This standard has been approved for use by agencies of the Department of

Defense to replace MIL-STD-670 and MIL-STD-C 3133, which were discontinued

in 1986.

3

Current edition approved Oct. 1, 2020. Published November 2020. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1949. Last previous edition approved in 2014 as D1056-14. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D1056-20. Standards volume information, refer to the standard’s Document S

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1056 − 14 D1056 − 20

Standard Specification for

1,2

Flexible Cellular Materials—Sponge or Expanded Rubber

This standard is issued under the fixed designation D1056; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers flexible cellular rubber products known as sponge rubber and expanded rubber, but does not apply

to latex foam rubber or ebonite cellular rubber. The base material for an open/closed cellular product may be made of synthetic,

natural, or reclaimed rubber, or a mixture, and may contain other polymers or chemicals, or both, which may be modified by

organic or inorganic additives. These elastomeric materials have properties similar to those of vulcanized rubber, namely (1) the

ability to be converted from a thermoplastic to a thermosetting state by crosslinking (vulcanization) or (2) the substantial recovery

of their original shapes when strained or elongated, or both.

1.2 Extruded or molded shapes of sizes too small for cutting standard test specimens are difficult to classify or test by these

methods and will usually require special testing procedures.

1.3 In case of conflict between the provisions of this general specification and those of detailed specifications or test methods for

a particular product, the latter shall take precedence. Reference to the test methods in this specification should specifically state

the particular test or tests desired.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test methods portions of this specification: This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—ISO 6916-1 is similar to this specification.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials - Plastics

and Elastomers.

This standard has been approved for use by agencies of the Department of Defense to replace Methods 12001, 12005, 12011, 12021, 12031, 12041, 12151, and 12411

of Federal Test Method Standard No. 601.

This standard has been approved for use by agencies of the Department of Defense to replace MIL-STD-670 and MIL-STD-C 3133, which were discontinued in 1986.

Current edition approved March 1, 2014Oct. 1, 2020. Published April 2014November 2020. Originally approved in 1949. Last previous edition approved in 20072014

as D1056 - 07.D1056 - 14. DOI: 10.1520/D1056-14.10.1520/D1056-20.

2

This version supersedes all prior versions of this specification.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1056 − 20

2. Referenced Documents

3

2.1 ASTM Standards:

D395 Test Methods for Rubber Property—Compression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

D573 Test Method for Rubber—Deterioration in an Air Oven

D575 Test Methods for Rubber Properties in Compression

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D832 Practice for Rubber Conditioning For Low Temperature Testing

D883 Terminology Relating to Plastics

D1171 Test Method for Rubber Deterioration—Surface Ozone Cracking Outdoors (Triangular Specimens)

D2632 Test Method for Rubber Property—Resilience

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.