ASTM F2042-00(2011)

(Guide)Standard Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part II—Crosslinking and Fabrication

Standard Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part II—Crosslinking and Fabrication

SIGNIFICANCE AND USE

This guide is intended to provide guidance for the specification and selection of fabrication methods for silicones used in medical devices. It also provides guidance relative to testing that might be done to qualify lots of acceptable material, based on desired performance properties.

Silicone manufacturers supplying material to the medical device industry should readily provide information regarding non-proprietary product formulation to their customers either directly or through the US FDA Master File program.

SCOPE

1.1 This guide is intended to educate potential users of silicone elastomers, gels and foams relative to their fabrication and processing. It does not provide information relative to silicone powders, fluids, pressure sensitive adhesives, or other types of silicone products.

1.2 The information provided is offered to guide users in the selection of appropriate processing conditions for specific medical device applications.

1.3 Formulation and selection of appropriate starting materials is covered in the companion document, F2038 Part I. This monograph addresses only the curing, post-curing, and processing of elastomers, gels and foams as well as how the resulting product is evaluated.

1.4 Silicone biocompatibility issues can be addressed at several levels, but ultimately the device manufacturer must assess biological suitability relative to intended use. Biocompatibility testing may be done on cured elastomers prior to final fabrication, but the most relevant data are those obtained on the finished device. Data on selected lots of material are only representative when compounding, and fabrication are performed under accepted quality systems such as ISO 9001 and current Good Manufacturing Practice Regulations. Extractables analyses may also be of interest for investigation of biocompatibility, and the procedures for obtaining such data depend on the goal of the study (see F619, the HIMA Memorandum 7/14/93, and USP 23, for examples of extraction methods).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2042 − 00 (Reapproved 2011)

Standard Guide for

Silicone Elastomers, Gels, and Foams Used in Medical

Applications Part II—Crosslinking and Fabrication

This standard is issued under the fixed designation F2042; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D412 Test Methods forVulcanized Rubber andThermoplas-

tic Elastomers—Tension

1.1 This guide is intended to educate potential users of

D430 Test Methods for Rubber Deterioration—Dynamic

silicone elastomers, gels and foams relative to their fabrication

Fatigue

and processing. It does not provide information relative to

D624 Test Method for Tear Strength of Conventional Vul-

silicone powders, fluids, pressure sensitive adhesives, or other

canized Rubber and Thermoplastic Elastomers

types of silicone products.

D792 Test Methods for Density and Specific Gravity (Rela-

1.2 Theinformationprovidedisofferedtoguideusersinthe

tive Density) of Plastics by Displacement

selection of appropriate processing conditions for specific

D813 TestMethodforRubberDeterioration—CrackGrowth

medical device applications.

D814 Test Method for Rubber Property—Vapor Transmis-

1.3 Formulation and selection of appropriate starting mate- sion of Volatile Liquids

D926 Test Method for Rubber Property—Plasticity and

rials is covered in the companion document, F2038 Part I.This

monograph addresses only the curing, post-curing, and pro- Recovery (Parallel Plate Method)

D955 Test Method of Measuring Shrinkage from Mold

cessing of elastomers, gels and foams as well as how the

resulting product is evaluated. Dimensions of Thermoplastics

D1349 Practice for Rubber—Standard Conditions for Test-

1.4 Silicone biocompatibility issues can be addressed at

ing

several levels, but ultimately the device manufacturer must

D1566 Terminology Relating to Rubber

assess biological suitability relative to intended use. Biocom-

D2240 Test Method for Rubber Property—Durometer Hard-

patibilitytestingmaybedoneoncuredelastomerspriortofinal

ness

fabrication,butthemostrelevantdataarethoseobtainedonthe

F619 Practice for Extraction of Medical Plastics

finished device. Data on selected lots of material are only

F719 Practice for Testing Biomaterials in Rabbits for Pri-

representative when compounding, and fabrication are per-

mary Skin Irritation

formed under accepted quality systems such as ISO 9001 and

F720 PracticeforTestingGuineaPigsforContactAllergens:

current Good Manufacturing Practice Regulations. Extract-

Guinea Pig Maximization Test

ables analyses may also be of interest for investigation of

F748 PracticeforSelectingGenericBiologicalTestMethods

biocompatibility, and the procedures for obtaining such data

for Materials and Devices

depend on the goal of the study (see F619, the HIMA

F813 Practice for Direct Contact Cell Culture Evaluation of

Memorandum 7/14/93, and USP23, for examples of extraction

Materials for Medical Devices

methods).

F981 Practice for Assessment of Compatibility of Biomate-

rials for Surgical Implants with Respect to Effect of

2. Referenced Documents

Materials on Muscle and Bone

2.1 ASTM Standards:

F1905 Practice For Selecting Tests for Determining the

D395 Test Methods for Rubber Property—Compression Set

Propensity of Materials to Cause Immunotoxicity (With-

drawn 2011)

This guide is under the jurisdiction of ASTM Committee F04 on Medical and

F1906 Practice for Evaluation of Immune Responses In

Surgical Materials and Devices and is the direct responsibility of Subcommittee

BiocompatibilityTestingUsingELISATests,Lymphocyte

F04.11 on Polymeric Materials.

Proliferation, and Cell Migration (Withdrawn 2011)

Current edition approved Dec. 1, 2011. Published January 2012. Originally

approved in 2000. Last previous edition approved in 2005 as F2042 – 00 (2005). F1984 Practice for Testing for Whole Complement Activa-

DOI: 10.1520/F2042-00R11.

tion in Serum by Solid Materials

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2042 − 00 (2011)

F2038 GuideforSiliconeElastomers,Gels,andFoamsUsed PCB Test Methods such as those used for MRI project No.

in Medical Applications Part I—Formulations and Un- 4473, 1/24/97,

cured Materials Biological Performance of Materials: J. Black, Marcel

2.2 Other Biocompatibility Standards: Dekker, NY 1992

United States Pharmacopeia, current edition (appropriate

3. Terminology

monographs may include: <87>, <88>, <151>, <381>)

FDA Department of Health and Human Services General

3.1 The classification of silicone elastomers is based upon a

Program Memorandum #G95–1, May 1, 1995: Use of

number of interrelated factors which include the chemical

International Standard ISO-10993, Biological Evaluation

system used to crosslink the elastomer, the physical character-

of Medical Devices Part I: Evaluation and Testing

istics of the uncured elastomer, and the methods used to

ANSI/AAMI 10993–1 Biological Evaluation of Medical

fabricate the elastomers.Additional pertinent terms are defined

Devices, Part I: Guidance on Selection of Tests

in standard D1566.

HIMA Memorandum Guidance for Manufacturers of Sili-

3.2 Definitions:

cone Devices Affected by Withdrawal of Dow Corning

7 3.2.1 manufacture—the process which occurs in the suppli-

Silastic Materials, 7/14/93

er’s facility in which the various components of the elastomer

2.3 Sterilization Standards:

are brought together, allowed to interact, and are packaged to

ANSI/AAMI ST46 Good Hospital Practice: Steam Steriliza-

provide the uncured elastomer for sale.

tion and Sterility Assurance

3.2.2 fabrication—the process by which the uncured elasto-

ANSI/AAMI ST41 Good Hospital Practice: Ethylene Oxide

mer is converted into a fully vulcanized elastomer of the

Sterilization and Sterility Assurance

desired size and shape. This process may occur in the same

ANSI/AAMI ST50 Dry Heat (Heated Air) Sterilizers

facility as the manufacture of the uncured elastomer but is

ANSI/AAMI ST29 Recommended Practice for Determining

more typically performed at the facility of a customer of the

Ethylene Oxide in Medical Devices

silicone manufacturer.

ANSI/AAMI ST30 Determining Residual Ethylene Chloro-

hydrin and Ethylene Glycol in Medical Devices

3.2.2.1 injection molding—fabrication of elastomers into

AAMI 13409–251 Sterilization of Health Care Products—

forms defined by molds constructed so that the uncured

Radiation Sterilization—Substantiation of 25kGy as a

elastomer can be transferred by pumping into the closed mold.

Sterilization Dose for Small or Infrequent Production

This method requires venting of the mold in some manner.The

Batches

elastomer may be vulcanized by heating the mold after it is

AAMI TIR8–251 Microbiological Methods for Gamma Ir-

filled but more typically the molding conditions (temperature

radiation Sterilization of Medical Devices and filling rate) are adjusted so that uncured elastomer can be

2.4 Quality Standards: addedtoapre-heatedmoldinwhichitwillthencure.Themold

ANSI/ASQC Q9001 Quality Systems—Model for Quality is than opened and the part removed and post-cured, if

Assurance in Design, Development, Production, Installa-

necessary.

tion and Servicing

3.2.2.2 compression molding—a process in which the un-

21 CFR 820 Quality System Regulation (current revision)

cured elastomer is placed in an open mold. The mold is closed

21 CFR 210 Current Good Manufacturing Practice in

and pressure applied to the mold to fill the cavity. Heat is

Manufacturing, Processing, Packing or Holding of Drugs:

applied to vulcanize the elstomer, the mold is than opened and

General (current revision)

the fabricated part is removed.

21 CFR 211 Current Good Manufacturing Practice for

3.2.2.3 freshening—becauseoftheinteractionthatcanoccur

Finished Pharmaceuticals (current revision)

between the fumed silica and silicone polymers, thick uncured

2.5 Other Standards:

high consistency elastomers can become so stiff over time that

Dow Corning CTM 0155 (Gel-Like Materials With Modi-

they are very difficult to process. To overcome this problem, a

fied Penetrometer)

two–roll mill is used to disrupt this interaction, resulting in a

Dow Corning CTM 0813 (Gel-Like Materials With One

material which is easier to fabricate. This process is called

Inch Diameter Head Penetrometer)

freshening and is typically done immediately before catalyza-

tion.

Available from U.S. Pharmacopeia (USP), 12601Twinbrook Pkwy., Rockville,

3.2.2.4 transfer molding—a process in which the mixed,

MD 20852-1790, http://www.usp.org.

uncured elastomer is placed in a compartment connected to the

Available from Food and Drug Administration (FDA), 10903 New Hampshire

mold. The compartment is then closed, pressure is applied to

Ave., Silver Spring, MD 20993-0002, http://www.fda.gov.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

transfer the uncured elastomer to the mold, filling the cavity.

4th Floor, New York, NY 10036, http://www.ansi.org.

Heat and pressure are applied to the mold to vulcanize the

Available from Advanced Medical Technology Association, 1200 G St. N.W.

elastomer, the mold is then opened, and the fabricated part is

Suite 400 Washington, D.C. 20005–3814, http://www.advamed.org.

Available from Association for the Advancement of Medical Instrumentation removed.

(AAMI), 4301 N. Fairfax Dr., Suite 301, Arlington, VA 22203-1633, http://

www.aami.org.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http:// Available from Midwest Research Institute, 425 Volker Blvd., Kansas City,

dodssp.daps.dla.mil. MO 64110–2299.

F2042 − 00 (2011)

3.2.2.5 extrusion—acontinuousprocessinwhichthemixed, As a result, loads are distributed over a wider area. These

uncured elastomer is forced through an orifice having the materials may also be used to provide protection from envi-

desired cross-sectional profile. The elastomer is then vulca- ronmental contaminants.

nizedbypassingitthrougheitherahotairorradiantheatoven.

3.2.9 foam—a crosslinked material which has a component

The most common application of extrusion processing is the

added to it which generates a volatile gas as the material is

fabrication of tubing but it can be used to produce other items

being vulcanized. This vulcanization process results in a

as well.

material with a relatively low density. Foams are usually

3.2.2.6 post-cure—the process of subjecting a vulcanized two-part formulations utilizing a platinum catalyzed addition

curesystem.Theyconformastheyexpandtoirregularsurfaces

elastomer to elevated temperature, usually in a hot-air oven,

after its initial fabrication. This process step is done to just as gels do to provide intimate contact and protection from

the environment but are more rigid and provide more strength

complete cross-linking of the object, remove peroxide by-

products, and eliminate changes in its physical properties. than gels. Since foams are expanded elastomers, on a weight

basis, they are highly crosslinked relative to gels. Most cure

Post-cure is often necessary when the component is only

partially cross-liked by molding; it is performed in an attempt conditions will result in a closed cell foam.

to accelerate molding process, and increase its output.

4. Significance and Use

3.2.2.7 calendaring—the process of forming an uncured,

4.1 This guide is intended to provide guidance for the

mixed elastomer into a thin sheet or film by passing it between

specification and selection of fabrication methods for silicones

two rolls.

used in medical devices. It also provides guidance relative to

3.2.2.8 dispersion—the process of placing an uncured elas-

testing that might be done to qualify lots of acceptable

tomerinasolvent.Thislowerstheviscosityofthematerialand

material, based on desired performance properties.

isusuallydonetoallowthefabricationofthinnerfilmsthatcan

4.2 Silicone manufacturers supplying material to the medi-

be obtained by calendaring or to form coatings. Following

cal device industry should readily provide information regard-

dispersion use, the solvent must be removed either before or

ing non-proprietary product formulation to their customers

during the vulcanization process. Care must be taken to assure

either directly or through the US FDA Master File program.

that the solvent is compatible with the elastomer, to prevent

preferential settling of the components of the formulation by

5. Crosslinking Chemistry

excessive dilution of the elastomer.

5.1 Silicone elastomers used in medical applications are

3.2.3 one-part elastomer—an elastomer supplied in the

typically crosslinked by one of three commonly used cure

uncured form in one package containing all of the formulation

systems. These involve the platinum catalyzed addition of a

components. It does not require mixing before fabrication.

silylhydride to an unsaturated site, the generation of free

3.2.4 two-part elastomer—an elastomer supplied in two

radicals by a peroxide or the reaction of an easily hydrolyzable

packages which must be mixed in specified proportions before

group of silicon.

fabrication.

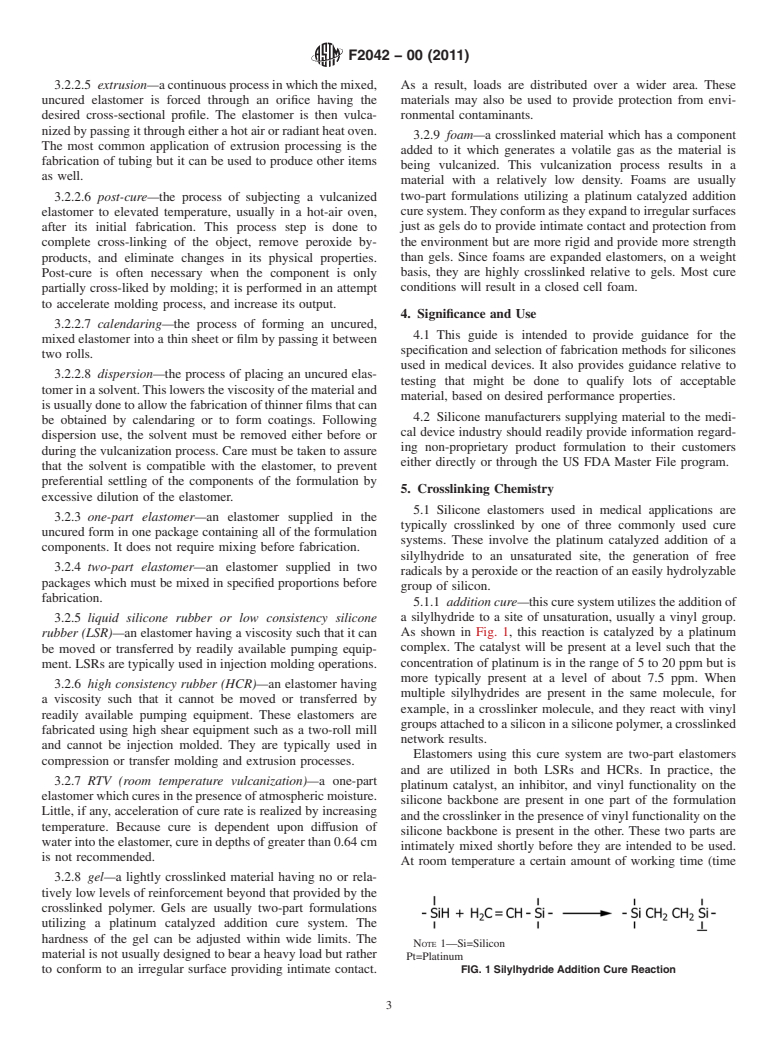

5.1.1 addition cure—thiscuresystemutilizestheadditionof

a silylhydride to a site of unsaturation, usually a vinyl group.

3.2.5 liquid silicone rubber or low consistency silicone

As shown in Fig. 1, this reaction is catalyzed by a platinum

rubber (LSR)—an elastomer having a viscosity such that it can

be moved or transferred by readily available pumping equip- complex. The catalyst will be present at a level such that the

concentration of platinum is in the range of 5 to 20 ppm but is

ment. LSRs are typically used in injection molding operations.

more typically present at a level of about 7.5 ppm. When

3.2.6 high consistency rubber (HCR)—an elastomer having

multiple silylhydrides are present in the same molecule, for

a viscosity such that it cannot be moved or transferred by

example, in a crosslinker molecule, and they react with vinyl

readily available pumping equipment. These elastomers are

groupsattachedtoasiliconinasiliconepolymer,acrosslinked

fabricated using high shear equipment such as a two-roll mill

n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.