ASTM F1632-03(2010)

(Test Method)Standard Test Method for Particle Size Analysis and Sand Shape Grading of Golf Course Putting Green and Sports Field Rootzone Mixes

Standard Test Method for Particle Size Analysis and Sand Shape Grading of Golf Course Putting Green and Sports Field Rootzone Mixes

ABSTRACT

These test methods establish the apparatus required, standard procedures, and associated calculations for determining the particle size distribution and shape grading of sand in golf course putting green and other sand-based sports field rootzone mixtures assumed to have sand contents of 80 % by weight or greater. Particles large enough to be retained on a No. 270 sieve are determined by sieving, while, the silt and clay percentages are determined by a sedimentation process using the pipet method.

SCOPE

1.1 This test method covers the determination of particle size distribution of putting green and other sand-based rootzone mixes. Particles larger than 0.05 mm (retained on a No. 270 sieve) are determined by sieving. The silt and clay percentages are determined by a sedimentation process, using the pipet method. This procedure was developed for putting green rootzone mixes, those assumed to have sand contents of 80 % by weight or greater. Particle size analysis of soils may be performed by this test method or Test Method D422. This test method also describes a qualitative evaluation of sand particle shape.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1632 − 03 (Reapproved 2010) An American National Standard

Standard Test Method for

Particle Size Analysis and Sand Shape Grading of Golf

Course Putting Green and Sports Field Rootzone Mixes

This standard is issued under the fixed designation F1632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 For MethodA—An Electric Mixer, made for mechani-

cal mixing of soils, or

1.1 This test method covers the determination of particle

3.2.2 For Method B—A Horizontal Reciprocating Shaker,

size distribution of putting green and other sand-based root-

with holder for 250 mL flasks or bottles.

zone mixes. Particles larger than 0.05 mm (retained on a No.

270 sieve) are determined by sieving. The silt and clay

3.3 Sedimentation Cylinder, a glass cylinder marked for a

percentages are determined by a sedimentation process, using

volume of 1000 mL. The height of the 1000 mL must be

the pipet method. This procedure was developed for putting

36 62 cm from the bottom on the inside.

green rootzone mixes, those assumed to have sand contents of

3.4 Thermometer, accurate to 0.5°C.

80%byweightorgreater.Particlesizeanalysisofsoilsmaybe

performed by this test method or Test Method D422. This test 3.5 Pipet Rack, a device for lowering a pipet to a precise

depth in the sedimentation cylinder.

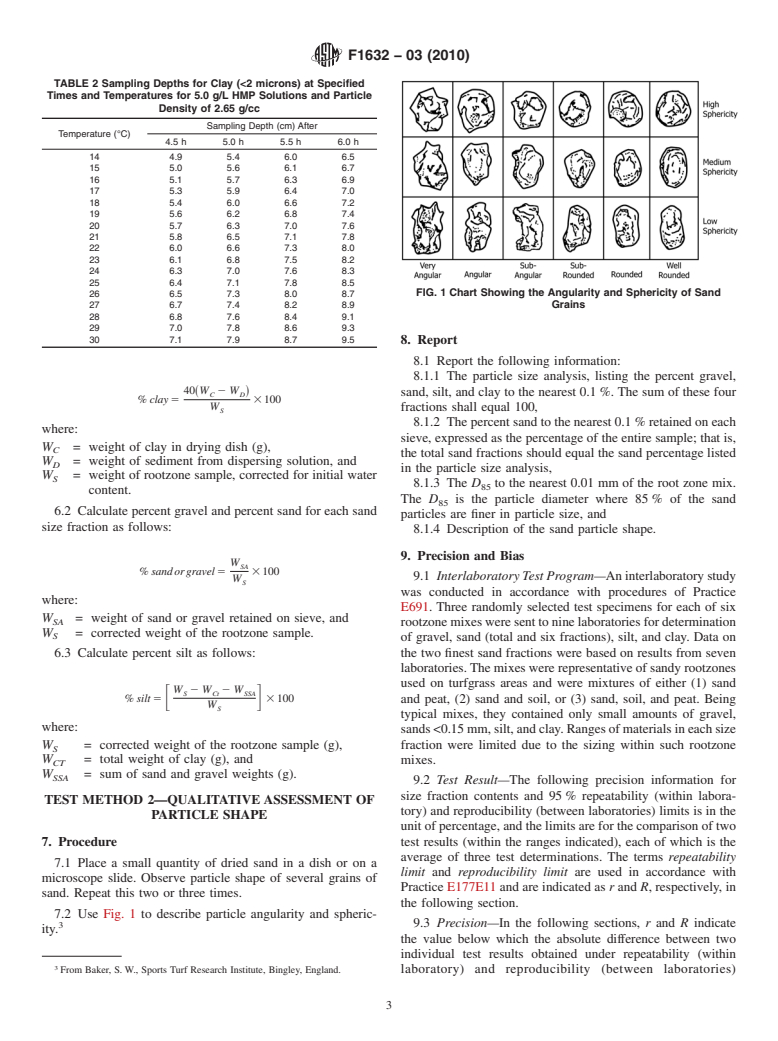

method also describes a qualitative evaluation of sand particle

shape.

3.6 Pipets,Lowyorotherwidetippedtype,25mLcapacity.

1.2 This standard does not purport to address all of the

3.7 Weighing Bottles or Beakers, glass with a capacity of

safety concerns, if any, associated with its use. It is the

100 mL.

responsibility of the user of this standard to establish appro-

3.8 Sieves, square mesh with woven wire (brass or stainless

priate safety and health practices and determine the applica-

steel). The sieves shall conform to the requirements of Speci-

bility of regulatory limitations prior to use.

fication E11. A full set of sieves shall include the following:

2. Referenced Document

3.8.1 No. 10—2 mm,

3.8.2 No. 18—1 mm,

2.1 ASTM Standards:

3.8.3 No. 35—500 µm,

D422Test Method for Particle-Size Analysis of Soils

3.8.4 No. 60—250 µm,

E11Specification forWovenWireTest Sieve Cloth andTest

Sieves 3.8.5 No. 100—149 µm,

E177Practice for Use of the Terms Precision and Bias in 3.8.6 No. 140—105 µm, and

ASTM Test Methods

3.8.7 No. 270—53 µm.

E691Practice for Conducting an Interlaboratory Study to

3.9 Sieve Shaker, type that provides vertical tapping action

Determine the Precision of a Test Method

as well as horizontal shaking.

3. Apparatus

3.10 Desiccator.

3.1 Balance, sensitive to 0.001 g.

3.11 Dispersing Agent, a 5% sodium hexametaphosphate

(HMP) solution, made by dissolving 50 g of reagent or

3.2 Stirring Apparatus, may be either of the following

technical grade HMPin 1000 mLof distilled or demineralized

types:

water.

3.12 Oven, capable of maintaining a temperature of 105 6

This test method is under the jurisdiction ofASTM Committee F08 on Sports

5°C.

Equipment, Playing Surfaces, and Facilitiesand is the direct responsibility of

Subcommittee F08.64 on Natural Playing Surfaces.

3.13 Water—shallbedistilledordemineralized,andbrought

Current edition approved Sept. 1, 2010. Published December 2010. Originally

to the temperature that is expected to prevail during the

approved in 1995. Last previous edition approved in 2003 as F1632–03. DOI:

10.1520/F1632-03R10.

sedimentation process. If air temperatures are expected to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fluctuate, cylinders should be placed in a constant temperature

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

water bath, and the distilled or demineralized water brought to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the temperature of the water bath.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1632 − 03 (2010)

3.14 Dissecting Microscope, 25 to 50× power. cylinder with waxfilm, a stopper, or watch glass. Place the

cylinder into a water bath, or allow it to stand until the

TEST METHOD 1—PROCEDURE FOR PARTICLE

temperature of the suspension is the same as the water bath or

SIZE ANALYSIS

the air temperature, respectively.

4.3.2 After the temperature is constant, resuspend the silt

4. Procedure

and clay by one of the two following methods: (a) stir

4.1 Dispersion of Sample:

thoroughly with a hand stirrer, using an up and down motion

4.1.1 Weigh 100 65 g of air-dried rootzone mix to the

for at least 30 s; or (b) stopper the cylinder and shake end over

nearest 0.1 g and place in mixing cup (Test MethodA) or flask

end for 1 min.

(Test Method B). Place a duplicate sample into a drying oven

4.3.3 Use Tables 1 and 2 or appropriate calculations using

set at 105 6 5°C for correction to oven dried basis.

Stoke’s Law to determine sampling depths and times for the

4.1.2 Add100mLofdispersingagent.Stirorswirluntilthe

suspension temperature.

rootzonemixisthoroughlywet.Allowtostandfor4h.Ifusing

4.3.4 Turn on the vacuum and withdraw a 25 mLsample in

Test Method B, place the flasks or bottles on the shaker and

about 12 s. Rate of withdraw is important.

shake for 16 h or overnight.

4.3.5 Discharge the sample into a tared beaker or drying

4.1.3 Test Method A—Add about 100 mL of water to the

dish.

mixing cup and place onto the mixer. Mix for 5 min on low

4.3.6 Towashoutanyresidualmaterialinthepipetdraw25

speed.

mLof water into the pipet, and discharge into the same drying

4.2 Determination of the Sand (2.0 to 0.05 mm) Fractions dish.

and Gravel (material >2 mm): 4.3.7 Evaporate the water and dry the clay at 105 6 5°C.

4.2.1 PlaceataredNo.270sieveontoalargefunnelheldby 4.3.8 Cool in a desiccator and weigh to the nearest 0.001 g.

astandoverasedimentationcylinder.Pourthesuspensiononto

5. Determination of Correction for Dispersing Solution

thesieve.Rinseremainingsandmaterialoutofthecuporflask

with water onto the sieve. Wash the collected sand and gravel

5.1 Dispense 100 mL of dispersing solution into 1 L

with misted water to wash any remaining silt or clay particles

container.

through the sieve into the cylinder.

5.2 Add distilled or demineralized water to 1 Lvolume, stir

4.2.2 An alternative for collecting sand and gravel is to

or swirl until thoroughly mixed.

separate following the sampling for clay (4.3). In this case the

suspension is poured and washed onto a No. 270 sieve after 5.3 Draw 25 mLand dispense into a tared beaker or drying

dish.

pipeting has been completed. The sample is then washed until

only sand and gravel remain on the sieve. Then continue the

5.4 Draw 25 mL of water and dispense into same dish.

procedure at 4.2.3. If this alternative method is used, the

5.5 Evaporate in an oven at 105 6 5°C.

volumeofsiltplusclaysuspensionatpipetingtimeislessthan

1000 ml due to the presence of sand and gravel. Thus the clay 5.6 Weigh the sediment in the beaker (W ) to the nearest

D

percentage as calculated in 6.1 must be corrected.Assuming a 0.001 g.

particle density of 2.65 g/cc for sand and gravel, conversion

6. Calculation for Test Method 1

factors for various sand plus gravel weights in the cylinder are

as follows:

6.1 Calculate percent clay as follows:

Sand and Gravel Conversion Factor to

in Cylinder, g Correct % Clay in 6.1

TABLE 1 Settling Velocities and Settling Times (at 10-cm depth)

68 to 92 0.97

for 5 g/L HMP Solutions and Particle Density of 2.65 g/cc when

93 to 100 0.96

Sampling for Clay (<2 microns) at Various Temperatures

Temperature, °C Settling Velocity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.