ASTM E968-02(2008)

(Practice)Standard Practice for Heat Flow Calibration of Differential Scanning Calorimeters

Standard Practice for Heat Flow Calibration of Differential Scanning Calorimeters

SIGNIFICANCE AND USE

Differential scanning calorimetry is used to determine the heat or enthalpy of transition. For this information to be meaningful in an absolute sense, heat flow calibration of the apparatus or comparison of the resulting data to that of a known standard is required.

This practice is useful in calibrating the heat flow axis of differential scanning calorimeters or quantitative differential thermal analyzers for subsequent use in the measurement of transition energies and specific heat capacities of unknowns.

SCOPE

1.1 This practice covers the heat flow calibration of differential scanning calorimeters over the temperature range from − 130 °C to + 800 °C.

1.2 Values given in SI units are to be regarded as the standard.

1.3 Computer or electronic based instruments, techniques or data manipulation equivalent to this practice may also be used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See also Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E968 − 02 (Reapproved2008)

Standard Practice for

1

Heat Flow Calibration of Differential Scanning Calorimeters

This standard is issued under the fixed designation E968; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope divided by their average. It is usually multiplied by 100 and

expressed as a percentage.

1.1 This practice covers the heat flow calibration of differ-

ential scanning calorimeters over the temperature range

NOTE 1—The term quantitative differential thermal analysis refers to

from−130 °C to+800 °C. differential thermal analyzers that are designed to obtain quantitative or

semiquantitative heat flow results. This procedure may also be used to

1.2 The values stated in SI units are to be regarded as

calibrate such apparatus.

standard. No other units of measurement are included in this

standard.

4. Summary of Practice

1.3 Computerorelectronicbasedinstruments,techniquesor

4.1 Differential scanning calorimeters measure heat flow

data manipulation equivalent to this practice may also be used.

(power) into or out of a test specimen and provide a signal

output proportional to this measurement. This signal often is

1.4 This standard does not purport to address all of the

recorded as a function of a second signal proportional to

safety concerns, if any, associated with its use. It is the

temperature or time. If this heat flow signal is integrated over

responsibility of whoever uses this standard to consult and

time, the resultant value is proportional to energy (or enthalpy

establish appropriate safety and health practices and deter-

orheat).Toobtainthedesiredenergyinformation,theobserved

mine the applicability of regulatory limitations prior to use.

instrument response (such as the area under the curve scribed)

See also Section 7.

must be multiplied by a proportionality constant that converts

2. Referenced Documents

the units of instrument output into the desired energy units.

2

This proportionality constant is called the instrument calibra-

2.1 ASTM Standards:

tion coefficient (E). The value and dimensions (units) of E

E473Terminology Relating to Thermal Analysis and Rhe-

depend upon the particular differential scanning calorimeter

ology

andrecordingsystembeingusedand,moreover,mayvarywith

E793Test Method for Enthalpies of Fusion and Crystalliza-

temperature.

tion by Differential Scanning Calorimetry

E967Test Method for Temperature Calibration of Differen-

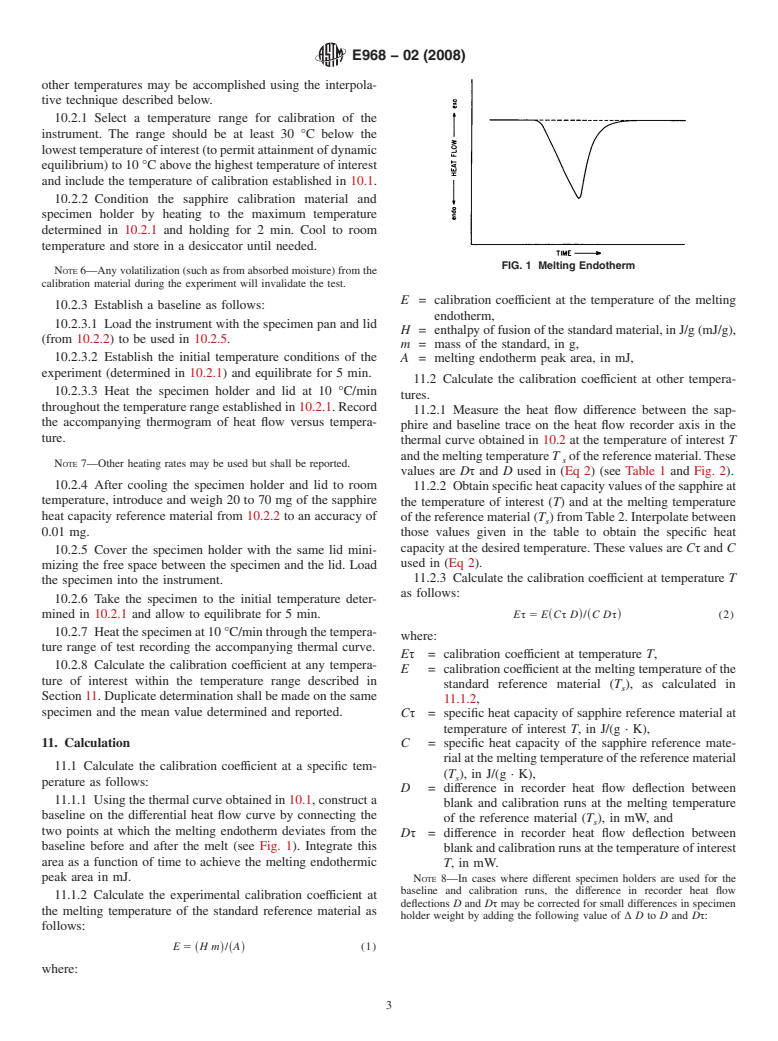

4.2 This practice consists of calibrating the heat flow

tial Scanning Calorimeters and Differential ThermalAna-

response of a differential scanning calorimeter (that is, deter-

lyzers

mining the calibration coefficient) by recording the melting

E1142Terminology Relating to Thermophysical Properties

endothermofahigh-puritystandardmaterial(wheretheheatof

fusion is known to better than 61.5% (rel)) as a function of

3. Terminology

time. The peak is then integrated (over time) to yield an area

3.1 Definitions—Specific technical terms used in this prac-

measurement proportional to the enthalpy of melting of the

tice are in accordance with Terminologies E473 and E1142.

standard material.

3.2 Definitions of Terms Specific to This Standard:

4.3 Calibration of the instrument is extended to tempera-

3.2.1 coeffıcient of variation, n—a measure of relative pre-

tures other than that of the melting point of the standard

cision calculated as the standard deviation of a series of values

material through the recording of the specific heat capacity of

a (second) standard material over the temperature range of

interest.The ratio of the measured specific heat capacity at the

1

This practice is under the jurisdiction of ASTM Committee E37 on Thermal

temperature of interest to that of the temperature of calibration

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

rimetry and Mass Loss.

provides an instrument calibration coefficient at the new

Current edition approved Sept. 1, 2008. Published October 2008. Originally

temperature.

approved in 1983. Last previous edition approved in 2002 as E968–02. DOI:

10.1520/E0968-02R08.

4.4 Oncethecalibrationcoefficientatagiventemperatureis

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

determined, it may be used to determine the desired energy

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

value associated with an enthalpic transition in an unknown

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specimen at that temperature (see Test Method E793).

Copyright © ASTM International, 100 Barr Har

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E968–99 Designation: E 968 – 02 (Reapproved 2008)

Standard Practice for

1

Heat Flow Calibration of Differential Scanning Calorimeters

This standard is issued under the fixed designation E968; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the heat flow calibration of differential scanning calorimeters over the temperature range from−130

°C to+800 °C.

1.2 Values given in SI units are to be regarded as the standard.

1.3 Computer or electronic based instruments, techniques or data manipulation equivalent to this practice may also be used.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use. See also Section 7.

2. Referenced Documents

2.1 ASTM Standards:

2

E473Terminology Relating to Thermal Analysis ASTM Standards:

E473 Terminology Relating to Thermal Analysis and Rheology

E793 Test Method for HeatsEnthalpies of Fusion and Crystallization by Differential Scanning Calorimetry

2

E967Practice for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers Test

Method for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

E1142 Terminology Relating to Thermophysical Properties

3. Terminology

3.1 Definitions— Specific technical terms used in this practice are in accordance with Terminologies E474E473 and E1142.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 coeffıcient of variation, n—ameasureofrelativeprecisioncalculatedasthestandarddeviationofaseriesofvaluesdivided

by their average. It is usually multiplied by 100 and expressed as a percentage.

NOTE 1—The term quantitative differential thermal analysis refers to differential thermal analyzers that are designed to obtain quantitative or

semiquantitative heat flow results. This procedure may also be used to calibrate such apparatus.

4. Summary of Practice

4.1 Differential scanning calorimeters measure heat flow (power) into or out of a test specimen and provide a signal output

proportionaltothismeasurement.Thissignaloftenisrecordedasafunctionofasecondsignalproportionaltotemperatureortime.

If this heat flow signal is integrated over time, the resultant value is proportional to energy (or enthalpy or heat). To obtain the

desired energy information, the observed instrument response (such as the area under the curve scribed) must be multiplied by a

proportionality constant that converts the units of instrument output into the desired energy units. This proportionality constant is

called the instrument calibration coefficient ( E). The value and dimensions (units) of E depend upon the particular differential

scanning calorimeter and recording system being used and, moreover, may vary with temperature.

4.2 This practice consists of calibrating the heat flow response of a differential scanning calorimeter (that is, measuringdeter-

miningthecalibrationcoefficient)byrecordingthemeltingendothermofahigh-puritystandardmaterial(wheretheheatoffusion

is known to better than 6 1.5% (rel)) as a function of time.The peak is then integrated (over time) to yield an area measurement

proportional to the enthalpy of melting of the standard material.

1

ThispracticeisunderthejurisdictionofASTMCommitteeE-37onThermalMeasurementsandisthedirectresponsibilityofSubcommitteeE37.01onThermalAnalysis

Methods.

Current edition approved March 10, 1999. Published May 1999. Originally published as E968 – 83. Last previous edition E968 – 83 (1993).

1

This practice is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on Thermal Test

Methods and Practices.

Current edition approved Sept. 1, 2008. Published October 2008. Originally approved in 1983. Last previous edition approved in 2002 as E968 – 99(2002).

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Ha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.