ASTM D5950-14(2020)

(Test Method)Standard Test Method for Pour Point of Petroleum Products (Automatic Tilt Method)

Standard Test Method for Pour Point of Petroleum Products (Automatic Tilt Method)

SIGNIFICANCE AND USE

5.1 The pour point of a petroleum product is an index of the lowest temperature of its utility for certain applications. Flow characteristics, like pour point, can be critical for the correct operation of lubricating oil systems, fuel systems, and pipeline operations.

5.2 Petroleum blending operations require precise measurement of the pour point.

5.3 This test method can determine the pour point of the test specimen with a resolution of 1.0 °C.

5.4 Test results from this test method can be determined at either 1 °C or 3 °C intervals.

5.5 This test method yields a pour point in a format similar to Test Method D97/IP15 when the 3 °C interval results are reported.

Note 3: Since some users may wish to report their results in a format similar to Test Method D97 (in 3 °C intervals) the precisions were derived for the temperatures rounded to the 3 °C intervals. For statements on bias relative to Test Method D97, see 13.3.

5.6 This test method has better repeatability and reproducibility relative to Test Method D97/IP15 as measured in the 1998 interlaboratory test program. (See Section 13.)

SCOPE

1.1 This test method covers the determination of pour point of petroleum products by an automatic instrument that tilts the test jar during cooling and detects movement of the surface of the test specimen with an optical device.

1.2 This test method is designed to cover the range of temperatures from −66 °C to +51 °C; however, the range of temperatures included in the 1992 interlaboratory test program only covered the temperature range from −39 °C to +6 °C, and the range of temperatures included in the 1998 interlaboratory test program was −51 °C to −11 °C. (See Section 13.)

1.3 Test results from this test method can be determined at 1 °C or 3 °C intervals.

1.4 This test method is not intended for use with crude oils.

Note 1: The applicability of this test method on residual fuel samples has not been verified. For further information on applicability, refer to 13.4.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5950 −14 (Reapproved 2020)

Standard Test Method for

Pour Point of Petroleum Products (Automatic Tilt Method)

This standard is issued under the fixed designation D5950; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method covers an alternative procedure for the determination of pour point of petroleum

products using an automatic apparatus.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of pour point

2.1 ASTM Standards:

of petroleum products by an automatic instrument that tilts the

D97Test Method for Pour Point of Petroleum Products

test jar during cooling and detects movement of the surface of

D4057Practice for Manual Sampling of Petroleum and

the test specimen with an optical device.

Petroleum Products

D4177Practice for Automatic Sampling of Petroleum and

1.2 This test method is designed to cover the range of

Petroleum Products

temperatures from −66°C to +51°C; however, the range of

D6708Practice for StatisticalAssessment and Improvement

temperatures included in the 1992 interlaboratory test program

of Expected Agreement Between Two Test Methods that

only covered the temperature range from −39°C to +6°C, and

Purport to Measure the Same Property of a Material

the range of temperatures included in the 1998 interlaboratory

test program was −51°C to −11°C. (See Section 13.)

2.2 Energy Institute Standard:

IP15Test Method for Pour Point of Petroleum Products

1.3 Test results from this test method can be determined at

1°C or 3°C intervals.

3. Terminology

1.4 This test method is not intended for use with crude oils.

3.1 Definitions:

NOTE 1—The applicability of this test method on residual fuel samples

3.1.1 pour point, n—in petroleum products, the lowest

has not been verified. For further information on applicability, refer to

temperature at which movement of the test specimen is

13.4.

observed under the prescribed conditions of this test method.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.2 Definitions of Terms Specific to This Standard:

standard.

3.2.1 no-flow point, n—in petroleum products, the tempera-

ture of the test specimen at which a wax crystal structure or

1.6 This standard does not purport to address all of the

viscosity increase, or both, impedes movement of the surface

safety concerns, if any, associated with its use. It is the

of the test specimen under the conditions of the test.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.2.1.1 Discussion—The no-flow point occurs when, upon

mine the applicability of regulatory limitations prior to use.

cooling,theformationofwaxcrystalstructuresortheviscosity

1.7 This international standard was developed in accor-

increase,orboth,hasprogressedtothepointwheretheapplied

dance with internationally recognized principles on standard-

observation device no longer detects movement under the

ization established in the Decision on Principles for the

conditions of the test. The preceding observation temperature,

Development of International Standards, Guides and Recom-

at which flow of the test specimen is last observed, is the pour

mendations issued by the World Trade Organization Technical

point.

Barriers to Trade (TBT) Committee.

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.07 on Flow Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2020. Published June 2020. Originally the ASTM website.

approved in 1996. Last previous edition approved in 2014 as D5950–14. DOI: Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

10.1520/D5950-14R20. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5950 − 14 (2020)

TABLE 1 Jacket and Specimen Temperature Cooling Profile

Specimen Temperature, °C Jacket Temperature, °C

+27>=ST > +9 0±0.5

+9>=ST > −6 −18±0.5

−6>=ST > −24 −33±0.5

−24>=ST > −42 −51±0.5

−42>=ST > −60 −69±0.5

−60>=ST > −78 −87±0.5

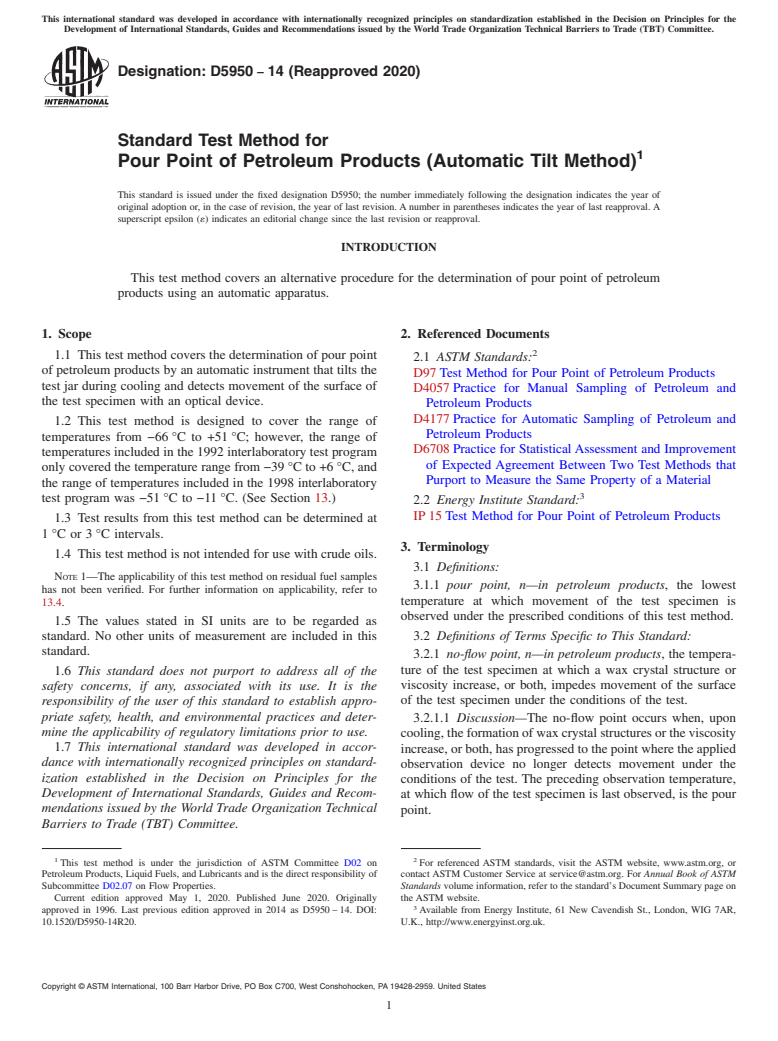

FIG. 1 Optical Detection System

5.5 This test method yields a pour point in a format similar

to Test Method D97/IP15 when the 3°C interval results are

reported.

NOTE 3—Since some users may wish to report their results in a format

similartoTestMethodD97(in3°Cintervals)theprecisionswerederived

for the temperatures rounded to the 3°C intervals. For statements on bias

relative to Test Method D97, see 13.3.

5.6 This test method has better repeatability and reproduc-

ibility relative to Test Method D97/IP15 as measured in the

1998 interlaboratory test program. (See Section 13.)

3.2.2 tilting, v—techniqueofmovementwherethetestjarin

a vertical position is moved towards a horizontal position to

6. Apparatus

induce specimen movement.

6.1 Optical Automatic Pour Point Apparatus —The auto-

3.2.2.1 Discussion—When the test jar is tilted and held in a

matic pour point apparatus described in this test method

horizontal position for 5 s without detection of specimen

consists of a microprocessor controller that is capable of

movement, this is the no-flow point and the test is complete.

controlling one or more independent test cells. The apparatus

shall include provisions for independently controlling the

4. Summary of Test Method

temperature of each cell according to the specified cooling

4.1 After preliminary heating, the test specimen is inserted

profile, monitoring continuously the specimen temperature,

into the automatic pour point apparatus. After starting the

anddetectinganymovementofthespecimenduringtilting(see

program, the specimen is cooled according to the cooling

Fig. 1). The instrument shall be operated according to the

profile listed in Table 1 and examined at either 1°C or 3°C

manufacturer’s instructions.

intervals. The lowest temperature at which movement of

6.2 Temperature Probe, IEC 751 Class A: ∆ T= 6

specimenisdetected,bytheautomaticequipment,isdisplayed

(0.15+0.002 |T|), capable of measurement from +70°C down

as the pour point.

to −80°C. The temperature probe shall be in the center of the

NOTE 2—If the automatic pour apparatus’s preheat option is utilized,

test jar and the top of the platinum tip immersed 3 mm below

place the test specimen into the apparatus.After starting the program, the

the surface of the oil.

apparatus will automatically carry out the preliminary heating.

6.3 Test Jar, clear cylindrical glass, flat bottom, 34mm 6

5. Significance and Use

0.5mm outside diameter, 1.4mm 6 0.15mm wall thickness,

120mm 6 0.5mm height, thickness of the bottom 2.4mm

5.1 Thepourpointofapetroleumproductisanindexofthe

maximum, marked with a line to indicate the sample height

lowest temperature of its utility for certain applications. Flow

54mm 6 0.5mm above the inside bottom.

characteristics, like pour point, can be critical for the correct

operation of lubricating oil systems, fuel systems, and pipeline

6.4 Jacket, brass, cylindrical, flat bottom, 113 mm 6

operations.

0.2mm in depth, 45+0,−0.1mm inside diameter. It shall be

cooled according to the cooling profile specified.

5.2 Petroleum blending operations require precise measure-

ment of the pour point.

5.3 Thistestmethodcandeterminethepourpointofthetest

The sole source of supply of the ISLModel CPP97-6, CPP97-2, and CPP-5Gs

specimen with a resolution of 1.0°C. knowntothecommitteeatthistimeisISLSA,BP40,14790Verson,France.Ifyou

are aware of alternative suppliers, please provide this information to ASTM

5.4 Test results from this test method can be determined at

International Headquarters. Your comments will receive careful consideration at a

either 1°C or 3°C intervals. meeting of the responsible technical committee, which you may attend.

D5950 − 14 (2020)

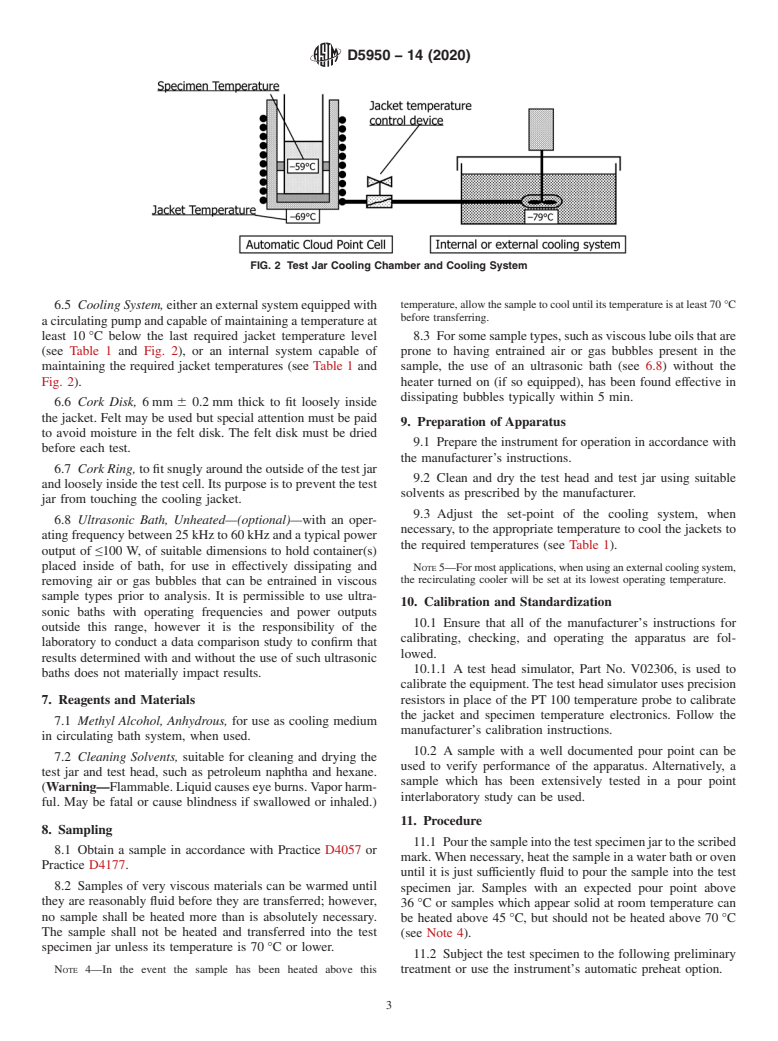

FIG. 2 Test Jar Cooling Chamber and Cooling System

temperature,allowthesampletocooluntilitstemperatureisatleast70°C

6.5 Cooling System,eitheranexternalsystemequippedwith

before transferring.

acirculatingpumpandcapableofmaintainingatemperatureat

least 10°C below the last required jacket temperature level 8.3 Forsomesampletypes,suchasviscouslubeoilsthatare

(see Table 1 and Fig. 2), or an internal system capable of prone to having entrained air or gas bubbles present in the

maintaining the required jacket temperatures (see Table 1 and sample, the use of an ultrasonic bath (see 6.8) without the

Fig. 2). heater turned on (if so equipped), has been found effective in

dissipating bubbles typically within 5 min.

6.6 Cork Disk, 6mm 6 0.2mm thick to fit loosely inside

the jacket. Felt may be used but special attention must be paid

9. Preparation of Apparatus

to avoid moisture in the felt disk. The felt disk must be dried

9.1 Prepare the instrument for operation in accordance with

before each test.

the manufacturer’s instructions.

6.7 Cork Ring,tofitsnuglyaroundtheoutsideofthetestjar

9.2 Clean and dry the test head and test jar using suitable

andlooselyinsidethetestcell.Itspurposeistopreventthetest

solvents as prescribed by the manufacturer.

jar from touching the cooling jacket.

9.3 Adjust the set-point of the cooling system, when

6.8 Ultrasonic Bath, Unheated—(optional)—with an oper-

necessary, to the appropriate temperature to cool the jackets to

atingfrequencybetween25kHzto60kHzandatypicalpower

the required temperatures (see Table 1).

output of ≤100 W, of suitable dimensions to hold container(s)

placed inside of bath, for use in effectively dissipating and

NOTE5—Formostapplications,whenusinganexternalcoolingsystem,

the recirculating cooler will be set at its lowest operating temperature.

removing air or gas bubbles that can be entrained in viscous

sample types prior to analysis. It is permissible to use ultra-

10. Calibration and Standardization

sonic baths with operating frequencies and power outputs

10.1 Ensure that all of the manufacturer’s instructions for

outside this range, however it is the responsibility of the

calibrating, checking, and operating the apparatus are fol-

laboratory to conduct a data comparison study to confirm that

lowed.

results determined with and without the use of such ultrasonic

10.1.1 A test head simulator, Part No. V02306, is used to

baths does not materially impact results.

calibrate the equipment.The test head simulator uses precision

7. Reagents and Materials resistors in place of the PT 100 temperature probe to calibrate

the jacket and specimen temperature electronics. Follow the

7.1 Methyl Alcohol, Anhydrous, for use as cooling medium

manufacturer’s calibration instructions.

in circulating bath system, when used.

10.2 A sample with a well documented pour point can be

7.2 Cleaning Solvents, suitable for cleaning and drying the

used to verify performance of the apparatus. Alternatively, a

test jar and test head, such as petroleum naphtha and hexane.

sample which has been extensively tested in a pour point

(Warning—Flammable.Liquidcauseseyeburns.Vaporharm-

interlaboratory study can be used.

ful. May be fatal or cause blindness if swallowed or inhaled.)

11. Procedure

8. Sampling

11.1 Pourthesampleintothetestspecimenjartothescribed

8.1 Obtain a sample in accordance with Practice D4057 or

mark.Whennecessary,heatthesampleinawaterbathoroven

Practice D4177.

until it is just sufficiently fluid to pour the sample into the test

8.2 Samples of very viscous materials can be warmed until

specimen jar. Samples with an expected pour point above

they are reasonably fluid before they are transferred; however,

36°C or samples which appear solid at room temperature can

no sample shall be heated more than is absolutely necessary.

be heated above 45°C, but should not be heated above 70°C

The sample shall not be heated and transferred into the test

(see Note 4).

specimen jar unless its temperature is 70°C or lower.

11.2 Subject the test specimen to the following preliminary

NOTE 4—In the event the sample has been heated above this treatment or use the instrument’s automatic preheat option.

D5950 − 14 (2020)

NOTE 6—Residual fuels have been known to be sensitive to thermal

12. Report

history. In the case where a residual fuel sample is tested, refer to Test

12.1 Reportthetemperaturerecordedin11.10togetherwith

Method D97 for sample treatment.

themodelandtestingintervalaspourpointinaccordancewith

11.2.1 When the expected pour point (EP) is known to be

Test Method D5950.

≤−33°C, heat the test specimen to 45°C in a bath or oven

maintained at 48°C.

13. Precision and Bias

11.2.2 When the expected pour point (EP) is known to be

13.1 Precision—The precision of this test method as deter-

>−33°C, heat the test specimen to EP+9°C, or at least to

mined by the statistical examination of the interlaboratory test

45°C but no higher than 70°C (see Note 4).

results is as follows:

13.1.1 Pour Point at 3 °C Testing Intervals:

11.3 Place a cork disk at the bottom of the jacket in the

13.1.1.1 Repeatability—The difference between successive

required cell and fit a cork ring to the test jar. The cork ring

test results, obtained by the same operator using the same

should be 25mm 6 3 mm above the bottom of the test jar.

apparatus under constant operating conditions on identical test

11.4 Place the test jar in the selected test cell. Attach the

material, would in the long run, in the normal and correct

detector head according to the manufacturer’s instructions.

operationofthistestmethod,exceedthefollowing,onlyinone

case in twenty.

11.5 Select the desired testing interval (1°C or 3°C).

3.9°C

11.6 Enter the expected pour point (EP). If 3°C testing

13.1.1.2 Reproducibility—The difference between two

intervals are chosen (11.5) you must enter an expected pour

single and independent test results, obtained by different

point that is a multiple of 3°C.

operators working in different laboratories on identical test

material,wouldinthelongrun,innormalandcorrectoperation

11.7 Start the test in accordance with the manufacturer’s

instructions. of this test method, exceed the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.