ASTM D979/D979M-11

(Practice)Standard Practice for Sampling Bituminous Paving Mixtures

Standard Practice for Sampling Bituminous Paving Mixtures

SIGNIFICANCE AND USE

General:

Sampling is equally as important as the testing, and the sampler shall take every precaution to obtain samples that will yield an acceptable estimate of the nature and conditions of the materials which they represent.

Samples for the development of preliminary data are obtained by the party responsible for the development of the data. Samples for control of the product at the source of manufacture or storage, or at the site of use, are obtained by the manufacturer, contractor, or other parties responsible for accomplishing the work. Samples for tests to be used in acceptance or rejection decisions by the purchaser are obtained by the purchaser or his authorized representative.

This standard shall not be used for the sampling of compacted bituminous paving mixtures. shall be used.

SCOPE

1.1 This practice covers sampling of bituminous paving mixtures at points of manufacture, storage, delivery, or in place.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D979/D979M–11

Standard Practice for

1

Sampling Bituminous Paving Mixtures

This standard is issued under the fixed designation D979/D979M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Changes were made editorially throughout the text in July 2006.

1. Scope D6307 Test Method for Asphalt Content of Hot-Mix As-

phalt by Ignition Method

1.1 This practice covers sampling of bituminous paving

D6925 Test Method for Preparation and Determination of

mixtures at points of manufacture, storage, delivery, or in

the Relative Density of Hot Mix Asphalt (HMA) Speci-

place.

mens by Means of the Superpave Gyratory Compactor

1.2 The values stated in SI units are to be regarded as the

D6926 Practice for Preparation of Bituminous Specimens

standard. The values in parentheses are provided for informa-

Using Marshall Apparatus

tion purposes only.

D6927 Test Method for Marshall Stability and Flow of

1.3 This standard does not purport to address all of the

Bituminous Mixtures

safety concerns, if any, associated with its use. It is the

E105 Practice for Probability Sampling of Materials

responsibility of the user of this standard to establish appro-

E122 Practice for Calculating Sample Size to Estimate,

priate safety and health practices and determine the applica-

With Specified Precision, the Average for a Characteristic

bility of regulatory limitations prior to use.

of a Lot or Process

2. Referenced Documents E141 Practice for Acceptance of Evidence Based on the

2

Results of Probability Sampling

2.1 ASTM Standards:

C702 Practice for Reducing Samples of Aggregate to Test-

3. Terminology

ing Size

3.1 Definitions of Terms Specific to This Standard:

D2041 Test Method for Theoretical Maximum Specific

3.1.1 field sample, n—a quantity of the material to be tested

Gravity and Density of Bituminous Paving Mixtures

of sufficient size to provide an acceptable estimate of the

D2234/D2234M Practice for Collection of a Gross Sample

average quality of a unit.

of Coal

3.1.2 increment, n—part of a sample.

D2726 Test Method for Bulk Specific Gravity and Density

3.1.3 lot, n—a sizable isolated quantity of bulk material

of Non-Absorptive Compacted Bituminous Mixtures

from a single source, assumed to have been produced by the

D3665 Practice for Random Sampling of Construction Ma-

same process (for example, a day’s production or a specific

terials

mass or volume).

D5361 Practice for Sampling Compacted Bituminous Mix-

3.1.4 test portion, n—a quantity of the material of sufficient

tures for Laboratory Testing

size extracted from the larger field sample by a procedure

D5444 Test Method for Mechanical Size Analysis of Ex-

designed to ensure accurate representation of the field sample,

tracted Aggregate

and thus of the unit sampled.

3.1.5 unit, n—a batch or finite subdivision of a lot of bulk

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and

material (for example, a truck load or a specific area covered).

Paving Materials and are the direct responsibility of Subcommittee D04.30 on

Methods of Sampling.

4. Significance and Use

Current edition approved June 15, 2011. Published July 2011. Originally

4.1 General:

approved in 1948. Last previous edition approved in 2006 as D979 – 06e01. DOI:

10.1520/D0979_D0979M-11.

4.1.1 Sampling is equally as important as the testing, and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the sampler shall take every precaution to obtain samples that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

will yield an acceptable estimate of the nature and conditions

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of the materials which they represent.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D979/D979M–11

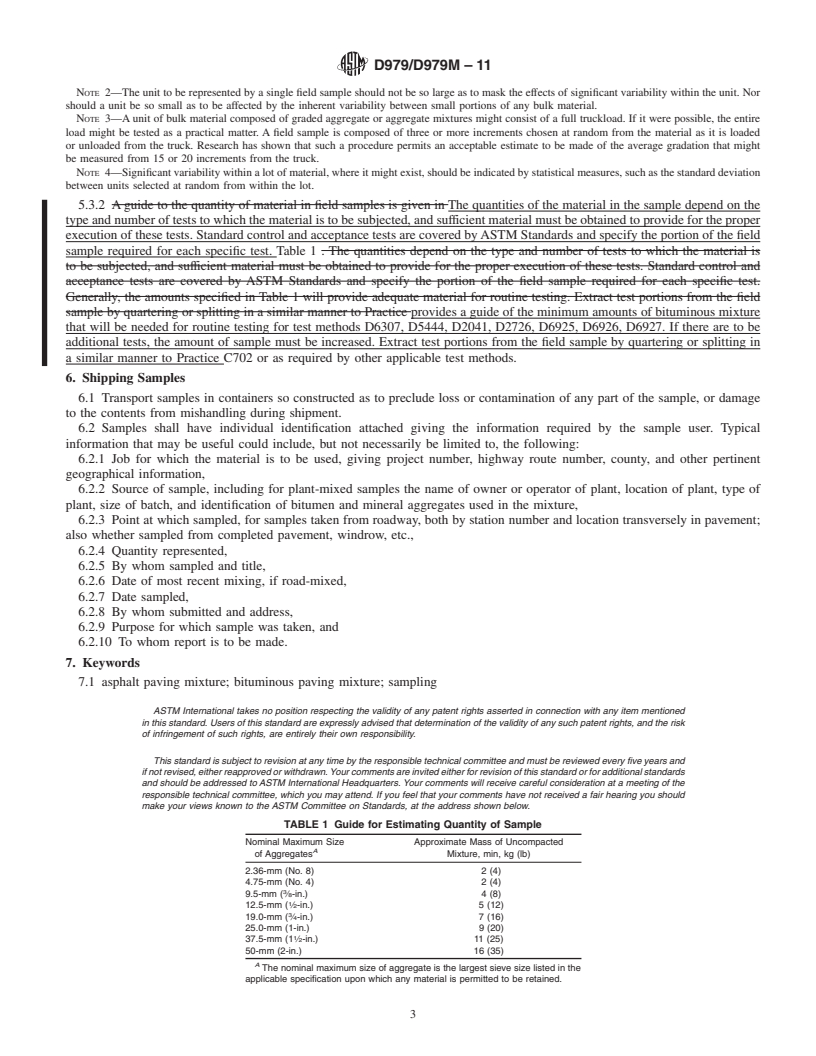

4.1.2 Samples for the development of preliminary data are from the top to the bottom of the pile. Obtain three approxi-

obtained by the party responsible for the development of the mately equal increments from the top, middle, and bottom of

data. Samples for control of the product at the source of the furrow depositing each increment in a container. The

manufactureorstorage,oratthesiteofuse,areobtainedbythe combined increments should form a field sample whose

manufacturer, contractor, or other parties responsible for ac- quantity equals or exceeds the minimum recommended in

com

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D979–01 (Reapproved 2006) Designation:D979/D979M–11

Standard Practice for

1

Sampling Bituminous Paving Mixtures

This standard is issued under the fixed designation D979/D979M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Changes were made editorially throughout the text in July 2006.

1. Scope

1.1 This practice covers sampling of bituminous paving mixtures at points of manufacture, storage, delivery, or in place.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are provided for information

purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C702 Practice for Reducing Samples of Aggregate to Testing Size

D2041 Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D2726 Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Bituminous Mixtures

D3665 Practice for Random Sampling of Construction Materials

D5361 Practice for Sampling Compacted Bituminous Mixtures for Laboratory Testing

D5444 Test Method for Mechanical Size Analysis of Extracted Aggregate

D6307 Test Method for Asphalt Content of Hot-Mix Asphalt by Ignition Method

D6925 Test Method for Preparation and Determination of the Relative Density of Hot Mix Asphalt (HMA) Specimens by

Means of the Superpave Gyratory Compactor

D6926 Practice for Preparation of Bituminous Specimens Using Marshall Apparatus

D6927 Test Method for Marshall Stability and Flow of Bituminous Mixtures

E105 Practice for Probability Sampling of Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E141 Practice for Acceptance of Evidence Based on the Results of Probability Sampling

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 field sample, n—a quantity of the material to be tested of sufficient size to provide an acceptable estimate of the average

quality of a unit.

3.1.2 increment, n—part of a sample.

3.1.3 lot, n—a sizable isolated quantity of bulk material from a single source, assumed to have been produced by the same

process (for example, a day’s production or a specific mass or volume).

3.1.4 test portion, n—a quantity of the material of sufficient size extracted from the larger field sample by a procedure designed

to ensure accurate representation of the field sample, and thus of the unit sampled.

3.1.5 unit, n—a batch or finite subdivision of a lot of bulk material (for example, a truck load or a specific area covered).

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and are the direct responsibility of Subcommittee D04.30 on Methods

of Sampling.

Current edition approved July 1, 2006.June 15, 2011. Published July 2006.2011. Originally approved in 1948. Last previous edition approved in 20012006 as

D979 – 06e01. DOI: 10.1520/D0979-01R06E01.10.1520/D0979_D0979M-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D979/D979M–11

4. Significance and Use

4.1 General:

4.1.1 Sampling is equally as important as the testing, and the sampler shall take every precaution to obtain samples that will

yield an acceptable estimate of the nature and conditions of the materials which they represent.

4.1.2 Samples for the development of preliminary data are obtained by the party responsible for the development of the data.

Samples for control of the product at the source of manufacture or storage, or at the site of use, are obtained by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.