ASTM D5084-00

(Test Method)Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter

Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter

SCOPE

1.1 These test methods cover laboratory measurement of the hydraulic conductivity (also referred to as coefficient of permeability) of water-saturated porous materials with a flexible wall permeameter at temperatures between about 15 and 30oC (59 and 86oF). Temperatures outside this range may be used, however, the user would have to determine the specific gravity of mercury and RT (see 10.3) at those temperatures using data from Handbook of Chemistry and Physics. There are six alternate methods or hydraulic systems, that may be used to measure the hydraulic conductivity. These hydraulic systems are as follows:

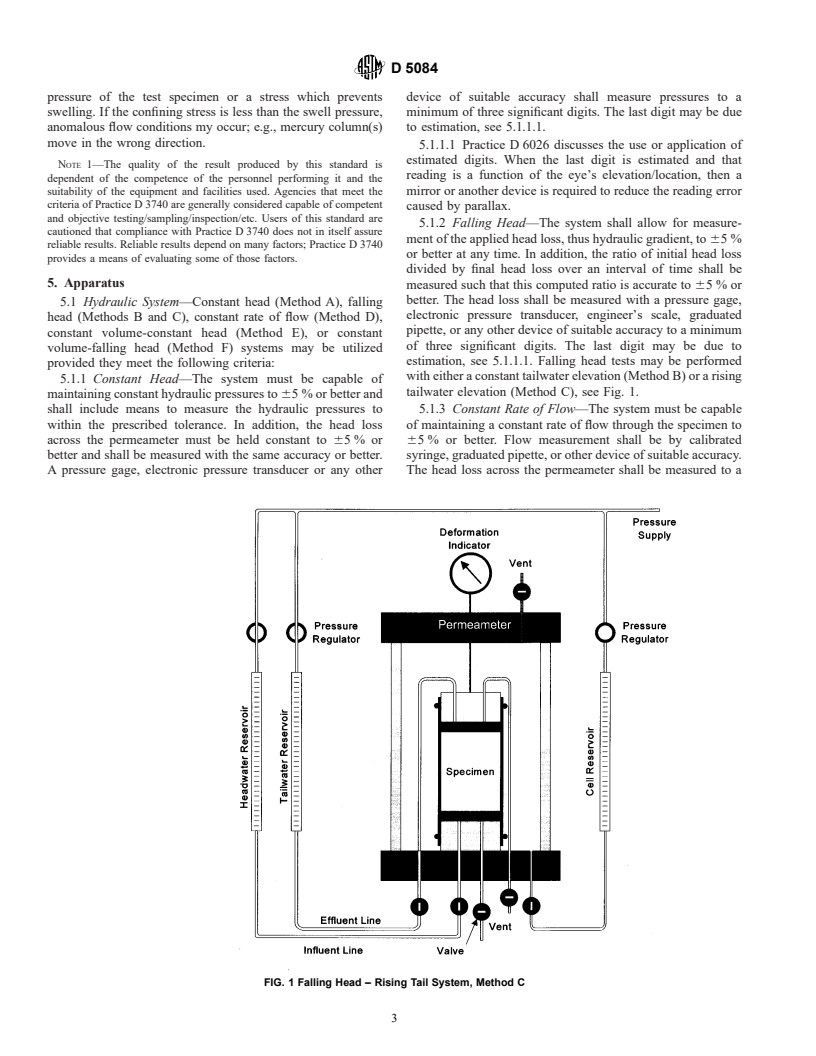

1.1.1 Method A—Constant Head

1.1.2 Method B—Falling Head, constant tailwater elevation

1.1.3 Method C—Falling Head, rising tailwater elevation

1.1.4 Method D—Constant Rate of Flow

1.1.5 Method E—Constant Volume-Constant Head (by mercury)

1.1.6 Method F—Constant Volume-Falling Head (by mercury), rising tailwater elevation

1.2 These test methods may be utilized on all specimen types (undisturbed, reconstituted, remolded, compacted, etc.) that have a hydraulic conductivity less than about 1 X 10-6 m/s (1 X 10-4 cm/s), providing the head loss requirements of are met. For the constant-volume methods, the hydraulic conductivity typically has to be less than about 1 X 10-7 m/s.

1.2.1 If the hydraulic conductivity is greater than about 1 X 10-6 m/s, but not more than about 1 X 10-5 m/s; then the size of the hydraulic tubing needs to be increased along with the porosity of the porous end pieces. Other strategies, such as using higher viscosity fluid or properly decreasing the cross-sectional area of the test specimen, or both, may also be possible. The key criterion is that the requirements covered in Section 5 have to be met.

1.2.2 If the hydraulic conductivity is less than about 1 X 10-10 m/s, then standard hydraulic systems and temperature environments will typically not suffice. Strategies that may be possible when dealing with such impervious materials may include the following. Tightening the temperature control. The adoption of unsteady state measurements by using high-accuracy equipment along with the rigorous analyses for determining the hydraulic parameters (this approach reduces testing duration according to Zhang et al. (1)). Properly shortening the length or enlarging the cross-sectional area, or both, of the test specimen. Other items, such as use of higher hydraulic gradients, lower viscosity fluid, elimination of any possible chemical gradients and bacterial growth, and strict verification of leakage, may also be considered.

1.3 The hydraulic conductivity of materials with hydraulic conductivities greater than 1 X 10-5 m/s may be determined by Test Method D2434.

1.4 All observed and calculated values shall conform to the guide for significant digits and rounding established in Practice D6026.

1.4.1 The procedures used to specify how data are collected/recorded and calculated in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that should generally be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user's objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.5 The values stated in SI units are to be regarded as the standard, unless other units are specifically given. By tradition in U.S. practice, hydraulic conductivity is reported in centimeters per second, although the common SI units for hydraulic conductivity is meters per second.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish a...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5084 – 00

Standard Test Methods for

Measurement of Hydraulic Conductivity of Saturated Porous

1

Materials Using a Flexible Wall Permeameter

This standard is issued under the fixed designation D 5084; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * be possible when dealing with such impervious materials may

include the following. Tightening the temperature control. The

1.1 These test methods cover laboratory measurement of the

adoption of unsteady state measurements by using high-

hydraulic conductivity (also referred to as coeffıcient of per-

accuracy equipment along with the rigorous analyses for

meability) of water-saturated porous materials with a flexible

determining the hydraulic parameters (this approach reduces

wall permeameter at temperatures between about 15 and 30°C

2

testing duration according to Zhang et al. (1) ). Properly

(59 and 86°F). Temperatures outside this range may be used,

shortening the length or enlarging the cross-sectional area, or

however, the user would have to determine the specific gravity

both, of the test specimen. Other items, such as use of higher

of mercury and R (see 10.3) at those temperatures using data

T

hydraulic gradients, lower viscosity fluid, elimination of any

from Handbook of Chemistry and Physics. There are six

possible chemical gradients and bacterial growth, and strict

alternate methods or hydraulic systems, that may be used to

verification of leakage, may also be considered.

measure the hydraulic conductivity. These hydraulic systems

1.3 The hydraulic conductivity of materials with hydraulic

are as follows:

−5

conductivities greater than 1 3 10 m/s may be determined by

1.1.1 Method A—Constant Head

Test Method D 2434.

1.1.2 Method B—Falling Head, constant tailwater elevation

1.4 All observed and calculated values shall conform to the

1.1.3 Method C—Falling Head, rising tailwater elevation

guide for significant digits and rounding established in Practice

1.1.4 Method D—Constant Rate of Flow

D 6026.

1.1.5 Method E—Constant Volume–Constant Head (by

1.4.1 The procedures used to specify how data are collected/

mercury)

recorded and calculated in this standard are regarded as the

1.1.6 Method F—Constant Volume–Falling Head (by mer-

industry standard. In addition, they are representative of the

cury), rising tailwater elevation

significant digits that should generally be retained. The proce-

1.2 These test methods may be utilized on all specimen

dures used do not consider material variation, purpose for

types (undisturbed, reconstituted, remolded, compacted, etc.)

−6

obtaining the data, special purpose studies, or any consider-

that have a hydraulic conductivity less than about 1 3 10 m/s

−4

ations for the user’s objectives; and it is common practice to

(1 3 10 cm/s), providing the head loss requirements of 5.2.3

increase or reduce significant digits of reported data to be

are met. For the constant-volume methods, the hydraulic

−7

commensurate with these considerations. It is beyond the scope

conductivity typically has to be less than about 1 3 10 m/s.

of this standard to consider significant digits used in analysis

1.2.1 If the hydraulic conductivity is greater than about

−6 −5

methods for engineering design.

1 3 10 m/s, but not more than about 1 3 10 m/s; then the

1.5 The values stated in SI units are to be regarded as the

size of the hydraulic tubing needs to be increased along with

standard, unless other units are specifically given. By tradition

the porosity of the porous end pieces. Other strategies, such as

in U.S. practice, hydraulic conductivity is reported in centime-

using higher viscosity fluid or properly decreasing the cross-

ters per second, although the common SI units for hydraulic

sectional area of the test specimen, or both, may also be

conductivity is meters per second.

possible. The key criterion is that the requirements covered in

1.6 This standard does not purport to address all of the

Section 5 have to be met.

safety concerns, if any, associated with its use. It is the

1.2.2 If the hydraulic conductivity is less than about

−10

responsibility of the user of this standard to establish appro-

1 3 10 m/s, then standard hydraulic systems and tempera-

priate safety and health practices and determine the applica-

ture environments will typically not suffice. Strategies that may

bility of regulatory limitations prior to use.

1.7 This standard also contains a Hazards section about

1

This standard is under the jurisdiction of ASTM Committee D18 on Soil and

using mercury, see Section 7.

Rock and is the direct responsibility

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.