ASTM D5304-05

(Test Method)Standard Test Method for Assessing Middle Distillate Fuel Storage Stability by Oxygen Overpressure

Standard Test Method for Assessing Middle Distillate Fuel Storage Stability by Oxygen Overpressure

SCOPE

1.1 This test method covers a procedure for assessing the potential storage stability of middle distillate fuels such as Grade No. 1D and Grade No. 2D diesel fuels, in accordance with Specification D 975.

1.2 This test method is applicable to either freshly refined fuels or fuels already in storage.

1.3 This test method is suitable for fuels containing stabilizer additives as well as fuels containing no such additives.

1.4 Appendix X1 provides information on other suggested test times and temperatures for which this test method may be used.

1.5 The values in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 4.1, 6.2, 6.3, 7.4, 10.1, and 10.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D5304–05

Standard Test Method for

Assessing Middle Distillate Fuel Storage Stability by

1

Oxygen Overpressure

This standard is issued under the fixed designation D 5304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 4306 Practice for Aviation Fuel Sample Containers for

Tests Affected by Trace Contamination

1.1 This test method covers a procedure for assessing the

D 4625 Test Method for Distillate Fuel Storage Stability at

potential storage stability of middle distillate fuels such as

43°C (110°F)

Grade No. 1D and Grade No. 2D diesel fuels, in accordance

E1 Specification forASTM Liquid-in-Glass Thermometers

with Specification D 975.

1.2 This test method is applicable to either freshly refined

3. Terminology

fuels or fuels already in storage.

3.1 Definitions of Terms Specific to This Standard:

1.3 This test method is suitable for fuels containing stabi-

3.1.1 membrane filter, n—a thin medium of closely con-

lizer additives as well as fuels containing no such additives.

trolled pore size through which a liquid is passed and on which

1.4 Appendix X1 provides information on other suggested

particulate matter in suspension is retained.

test times and temperatures for which this test method may be

3.1.2 oxygen overpressure—partial pressures of oxygen

used.

higher than that of air at atmospheric pressure.

1.5 ThevaluesinSIunitsaretoberegardedasthestandard.

3.1.3 potential storage stability—the tendency of a fuel to

The values given in parentheses are for information only.

form insolubles under the conditions of this test method.

1.6 This standard does not purport to address all of the

3.1.4 reactor—any vessel capable of sustaining pressures

safety concerns, if any, associated with its use. It is the

and temperatures above ambient, sometimes designated pres-

responsibility of the user of this standard to establish appro-

sure vessel or bomb.

priate safety and health practices and determine the applica-

3.1.5 weighing assembly—a set of two filters and two

bility of regulatory limitations prior to use. For specific

aluminum weighing dishes used to determine total insolubles

warning statements, see 4.1, 6.2, 6.3, 7.4, 10.1, and 10.2.

for each sample or blank.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

4.1 A 100 mL aliquot of filtered fuel is placed in a

D 525 Test Method for Oxidation Stability of Gasoline

borosilicate glass container. The container is placed in a

(Induction Period Method)

pressure vessel which has been preheated to 90°C. The

D 975 Specification for Diesel Fuel Oils

pressure vessel is pressurized with oxygen to 800 kPa (abso-

D 4057 Practice for Manual Sampling of Petroleum and

lute) (100 psig) for the duration of the test.The pressure vessel

Petroleum Products

is placed in a forced air oven at 90°C for 16 h. (Warning—

D 4177 Practice for Automatic Sampling of Petroleum and

Observe all normal precautions while using oxygen under

Petroleum Products

pressure and at high temperatures in the presence of combus-

tible liquids. Appropriate shielding should be used for any

1

This test method is under the jurisdiction of ASTM Committee D02 on

containers under pressure. Pressurize and depressurize the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

containers slowly using appropriate personnel shielding. Never

D02.14 on Stability and Cleanliness of Liquid Fuels.

attempt to open the pressure vessel while it is pressurized. All

Current edition approved April 1, 2005. Published April 2005. Originally

approved in 1992. Last previous edition approved in 2003 as D 5304 – 03. fuel and solvent handling should be done in an appropriate

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fume hood only.) After aging and cooling, the total amount of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

fuel insoluble products is determined gravimetrically and

Standards volume information, refer to the standard’s Document Summary page on

corrected according to blank determinations.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5304–05

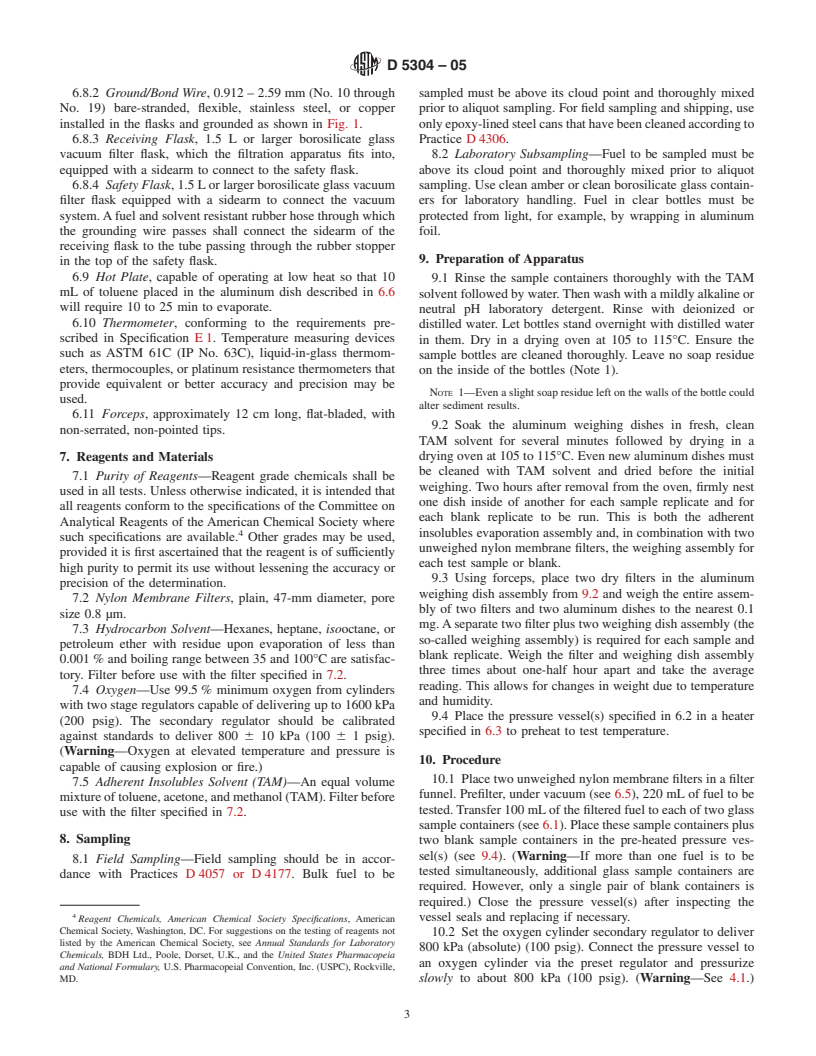

FIG. 1 Schematic of Filtration System

5. Significance and Use 20 kPa (5 psig)). The gage should be calibrated against

standards, and capable of holding the four sample containers

5.1 The results of this test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.