ASTM D1478-11

(Test Method)Standard Test Method for Low-Temperature Torque of Ball Bearing Grease

Standard Test Method for Low-Temperature Torque of Ball Bearing Grease

SIGNIFICANCE AND USE

This test method was developed using greases having very low torque characteristics at −54°C (−65°F). Specifications for greases of this type commonly require testing at this temperature. Specifications for greases of other types can require testing at temperatures from −75 to −20°C (−100 to 0°F).

This test method has proved helpful in the selection of greases for low-powered mechanisms, such as instrument bearings used in aerospace applications. The suitability of this test method for other applications requiring different greases, speeds, and temperatures should be determined on an individual basis.

Test Method D4693 may be better suited for applications using larger bearings or greater loads. However, greases having such characteristics that permit torque evaluations by either this test method or Test Method D4693 will not give the same values in the two test methods (even when converted to the same torque units) because the apparatus and test bearings are different.

SCOPE

1.1 This test method covers the determination of the extent to which a grease retards the rotation of a slow-speed ball bearing by measuring starting and running torques at low temperatures (below −20°C (0°F)).

1.1.1 Torque measurements are limited by the capacity of the torque-measuring equipment.

Note 1—When initially developed, the original dynamometer scale limited the torque capacity to approximately 30 000 g·cm; the original dynamometer scale is obsolete, however. The suggested replacement scale has not been evaluated; it could extend the limit to approximately 75 000 g·cm.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only. The exception is torque values that are given in cgs-metric units, which are universally used in grease specifications.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard and warning statements, see 6.1.1, 7.2, 7.4, 8.7, and 8.11.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1478 − 11

Standard Test Method for

1

Low-Temperature Torque of Ball Bearing Grease

This standard is issued under the fixed designation D1478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

3

1. Scope BMA Code 20BCO2JO)

2.3 ASTM Adjuncts:

1.1 This test method covers the determination of the extent

4

Standard ball bearings (set of 5 ball bearings)

to which a grease retards the rotation of a slow-speed ball

bearing by measuring starting and running torques at low

3. Terminology

temperatures (below−20°C (0°F)).

1.1.1 Torque measurements are limited by the capacity of

3.1 Definitions of Terms Specific to This Standard:

the torque-measuring equipment. 3.1.1 low-temperature torque, n—the torque in g·cm re-

quired to restrain the outer ring of a No. 6204 size open ball

NOTE 1—When initially developed, the original dynamometer scale

bearing lubricated with the test grease while the inner ring is

limited the torque capacity to approximately 30000 g·cm; the original

rotated at 1 6 0.05 r/min at the test temperature.

dynamometerscaleisobsolete,however.Thesuggestedreplacementscale

has not been evaluated; it could extend the limit to approximately 75000

3.1.2 running torque, n—the 15-s average value of the

g·cm.

torque after rotation for a specified period of time (60 min).

1.2 The values stated in SI units are to be regarded as

3.1.3 starting torque, n—the maximum torque measured at

standard. The values given in parentheses are for information

the start of rotation.

only. The exception is torque values that are given in cgs-

metric units, which are universally used in grease specifica-

4. Summary of Test Method

tions.

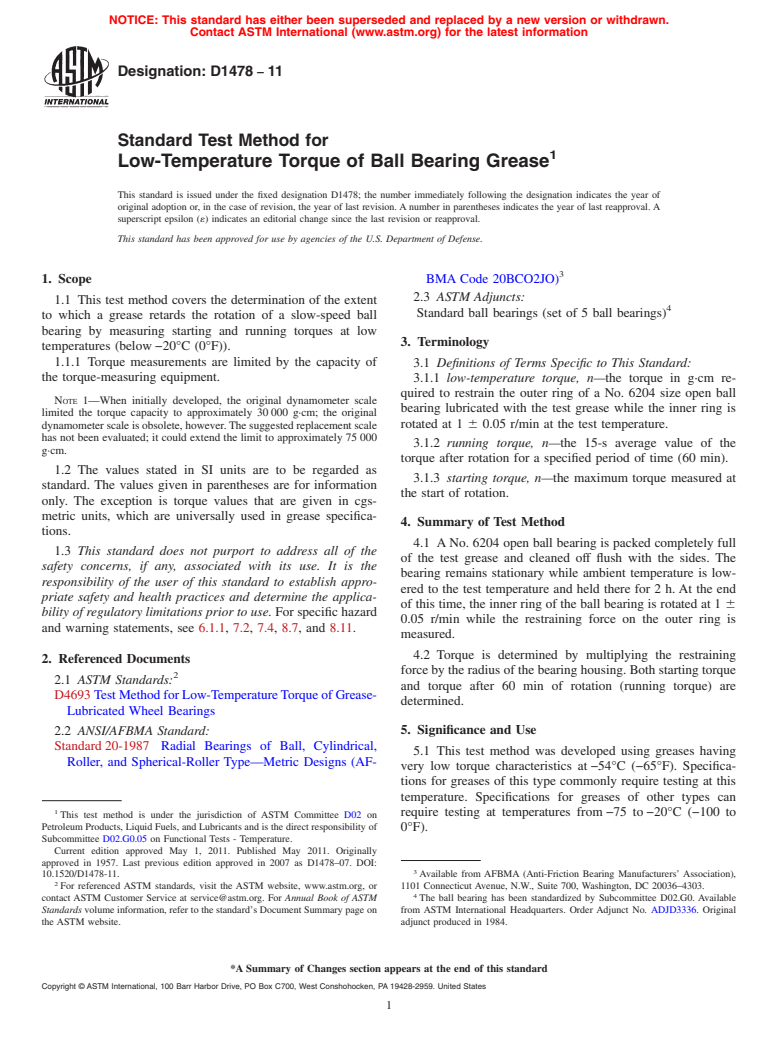

4.1 ANo. 6204 open ball bearing is packed completely full

1.3 This standard does not purport to address all of the

of the test grease and cleaned off flush with the sides. The

safety concerns, if any, associated with its use. It is the

bearing remains stationary while ambient temperature is low-

responsibility of the user of this standard to establish appro-

ered to the test temperature and held there for 2 h. At the end

priate safety and health practices and determine the applica-

of this time, the inner ring of the ball bearing is rotated at 1 6

bility of regulatory limitations prior to use. For specific hazard

0.05 r/min while the restraining force on the outer ring is

and warning statements, see 6.1.1, 7.2, 7.4, 8.7, and 8.11.

measured.

4.2 Torque is determined by multiplying the restraining

2. Referenced Documents

forcebytheradiusofthebearinghousing.Bothstartingtorque

2

2.1 ASTM Standards:

and torque after 60 min of rotation (running torque) are

D4693TestMethodforLow-TemperatureTorqueofGrease-

determined.

Lubricated Wheel Bearings

5. Significance and Use

2.2 ANSI/AFBMA Standard:

Standard20-1987 Radial Bearings of Ball, Cylindrical,

5.1 This test method was developed using greases having

Roller, and Spherical-Roller Type—Metric Designs (AF-

very low torque characteristics at−54°C (−65°F). Specifica-

tions for greases of this type commonly require testing at this

temperature. Specifications for greases of other types can

1

require testing at temperatures from−75 to−20°C (−100 to

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

0°F).

Subcommittee D02.G0.05 on Functional Tests - Temperature.

Current edition approved May 1, 2011. Published May 2011. Originally

approved in 1957. Last previous edition approved in 2007 as D1478–07. DOI:

3

10.1520/D1478-11. Available from AFBMA (Anti-Friction Bearing Manufacturers’ Association),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 1101 Connecticut Avenue, N.W., Suite 700, Washington, DC 20036–4303.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The ball bearing has been standardized by Subcommittee D02.G0. Available

Standards volume information, refer to the standard’s Document Summary page on from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original

the ASTM website. adjunct produced in 1984.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1478 − 11

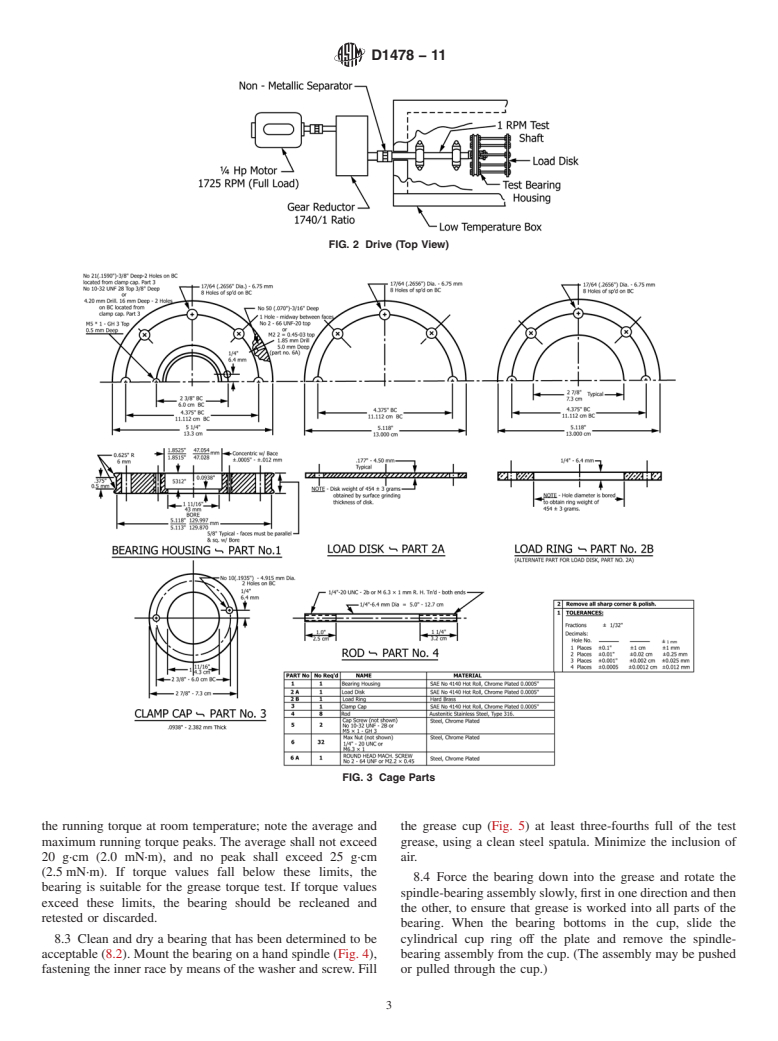

5.2 This test method has proved helpful in the selection of (1 lb). Alternatively, if Part 2B (load ring) is used, adjust the

greases for low-powered mecha

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1478–07 Designation:D1478–11

Standard Test Method for

1

Low-Temperature Torque of Ball Bearing Grease

This standard is issued under the fixed designation D1478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the extent to which a grease retards the rotation of a slow-speed ball bearing

by measuring starting and running torques at low temperatures (below−20°C (0°F)).

1.1.1 Torque measurements are limited by the capacity of the torque-measuring equipment.

NOTE 1—When initially developed, the original dynamometer scale limited the torque capacity to approximately 30000 g·cm; the original

dynamometerscaleisobsolete,however.Thesuggestedreplacementscalehasnotbeenevaluated;itcouldextendthelimittoapproximately75000g·cm.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only. The

exception is torque values that are given in cgs-metric units, which are universally used in grease specifications.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard and warning statements, see 6.1.1, 7.2, 7.4, 8.7, and 8.11.

2. Referenced Documents

2

2.1 ASTM Standards:

D4693 Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings

2.2 ANSI/AFBMA Standard:

Standard20-1987 Radial Bearings of Ball, Cylindrical, Roller, and Spherical-Roller Type—Metric Designs (AFBMA Code

3

20BCO2JO)

2.3 ASTM Adjuncts:

4

Standard ball bearings (set of 5 ball bearings)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

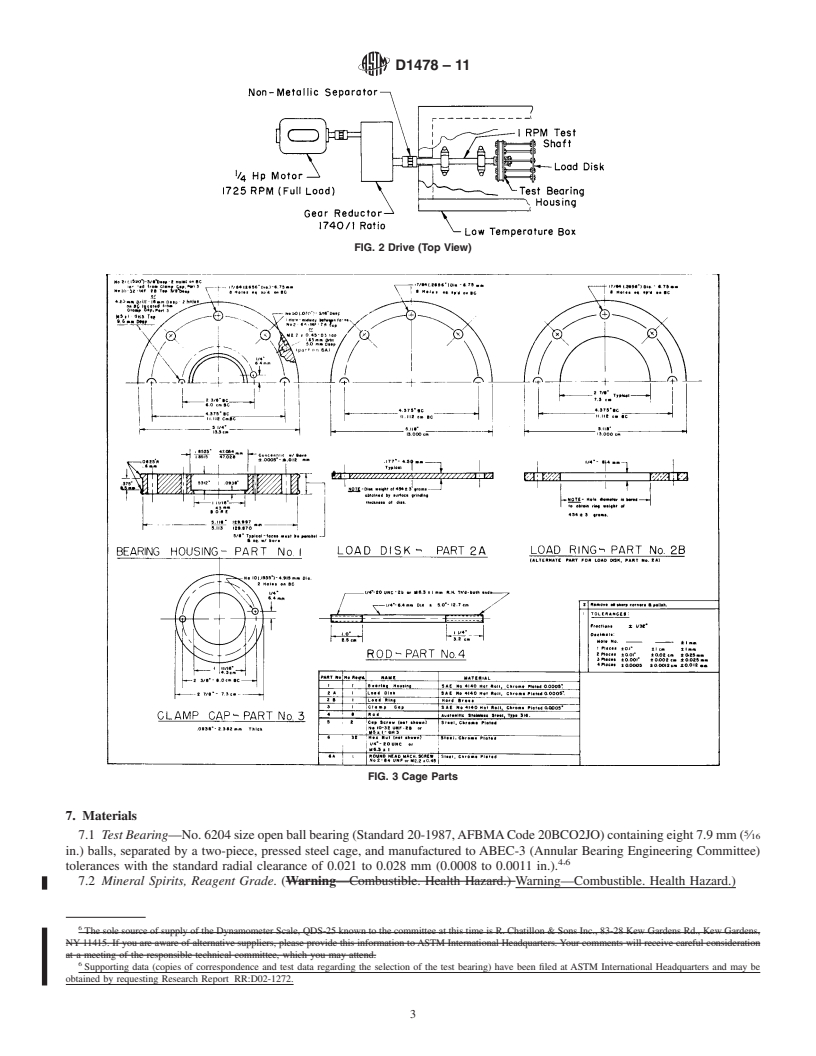

3.1.1 low-temperature torque, n—the torque in g·cm required to restrain the outer ring of a No. 6204 size open ball bearing

lubricated with the test grease while the inner ring is rotated at 1 6 0.05 r/min at the test temperature.

3.1.2 running torque, n—the 15-s average value of the torque after rotation for a specified period of time (60 min).

3.1.3 starting torque, n—the maximum torque measured at the start of rotation.

4. Summary of Test Method

4.1 ANo. 6204 open ball bearing is packed completely full of the test grease and cleaned off flush with the sides. The bearing

remains stationary while ambient temperature is lowered to the test temperature and held there for 2 h.At the end of this time, the

inner ring of the ball bearing is rotated at 1 6 0.05 r/min while the restraining force on the outer ring is measured.

4.2 Torque is determined by multiplying the restraining force by the radius of the bearing housing. Both starting torque and

torque after 60 min of rotation (running torque) are determined.

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.G0.05

on Functional Tests - Temperature.

Current edition approved July 15, 2007. Published August 2007. Originally approved in 1957. Last previous edition approved in 2002 as D1478–02. DOI:

10.1520/D1478-07.

CurrenteditionapprovedMay1,2011.PublishedMay2011.Originallyapprovedin1957.Lastpreviouseditionapprovedin2007asD1478–07.DOI:10.1520/D1478-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from AFBMA (Anti-Friction Bearing Manufacturers’ Association), 1101 Connecticut Avenue, N.W., Suite 700, Washington, DC 20036–4303.

4

The ball bearing has been standardized by Subcommittee D02.G0. Available from ASTM International Headquarters. Order Adjunct No. ADJD3336. Original adjunct

produced in 1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1478–11

5. Significance and Use

5.1 This test method was developed using greases having very low torque characteristics at−54°C (−65°F). Specifications for

greases

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.