ASTM D5443-93(2003)e1

(Test Method)Standard Test Method for Paraffin, Naphthene, and Aromatic Hydrocarbon Type Analysis in Petroleum Distillates Through 200°C by Multi-Dimensional Gas Chromatography

Standard Test Method for Paraffin, Naphthene, and Aromatic Hydrocarbon Type Analysis in Petroleum Distillates Through 200°C by Multi-Dimensional Gas Chromatography

SCOPE

1.1 This test method provides for the determination of paraffins, naphthenes, and aromatics by carbon number in low olefinic hydrocarbon streams having final boiling points of 200°C or less. Hydrocarbons with boiling points greater than 200°C and less than 270°C are reported as a single group. Olefins, if present, are hydrogenated and the resultant saturates are included in the paraffin and naphthene distribution. Aromatics boiling at C9 and above are reported as a single aromatic group.

1.2 This test method is not intended to determine individual components except for benzene and toluene that are the only C6 and C7 aromatics, respectively, and cyclopentane, that is the only C5 naphthene. The lower limit of detection for a single hydrocarbon component or group is 0.05 mass %.

1.3 This test method is applicable to hydrocarbon mixtures including virgin, catalytically converted, thermally converted, alkylated and blended naphthas.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7 and Table 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: D 5443 – 93 (Reapproved 2003)

Standard Test Method for

Paraffin, Naphthene, and Aromatic Hydrocarbon Type

Analysis in Petroleum Distillates Through 200°C by Multi-

Dimensional Gas Chromatography

This standard is issued under the fixed designation D 5443; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Warning notes were editorially moved into the standard text in August 2003.

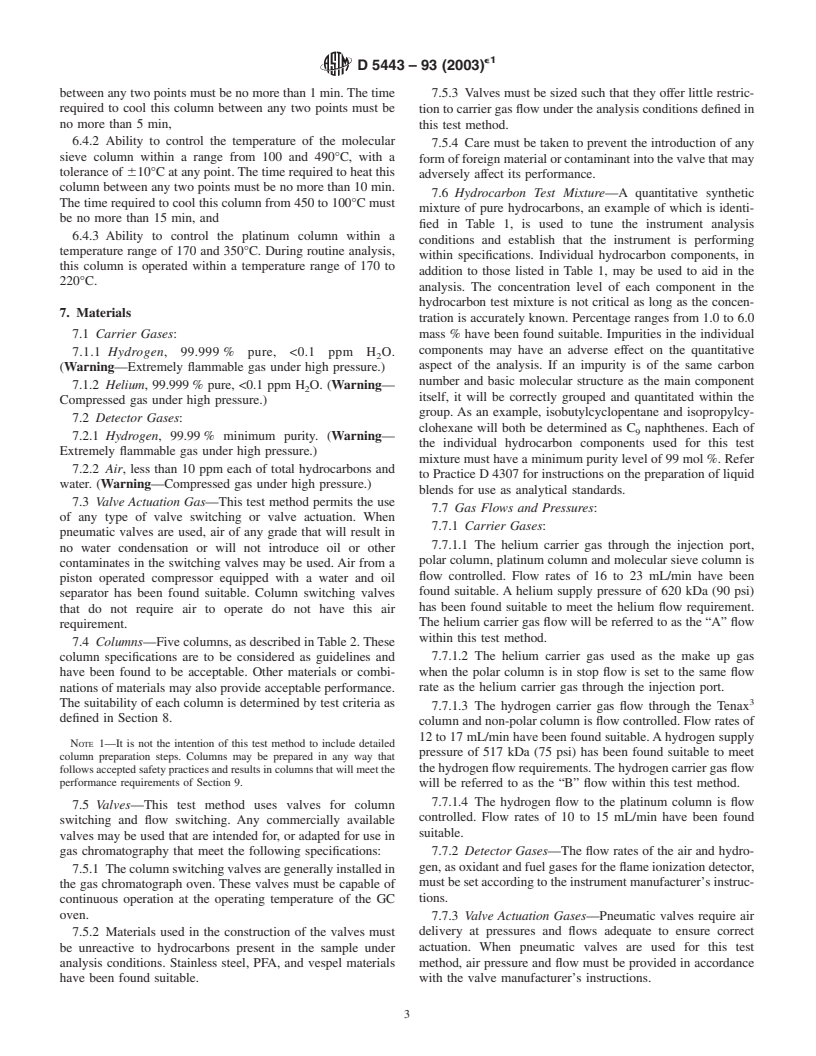

TABLE 1 Hydrocarbon Test Mixture

1. Scope

Hydrocarbons Warning

1.1 This test method provides for the determination of

Cyclopentane (Warning—Extremely Flammable. Harmful if inhaled.)

paraffins, naphthenes, and aromatics by carbon number in low

Pentane (Warning—Extremely Flammable. Harmful if inhaled.)

olefinic hydrocarbon streams having final boiling points of

Cyclohexane (Warning—Extremely Flammable. Harmful if inhaled.)

200°C or less. Hydrocarbons with boiling points greater than

2,3-Dimethylbutane (Warning—Extremely Flammable. Harmful if inhaled.)

Hexane (Warning—Extremely Flammable. Harmful if inhaled.)

200°C and less than 270°C are reported as a single group.

1-Hexene (Warning—Extremely Flammable. Harmful if inhaled.)

Olefins, if present, are hydrogenated and the resultant saturates

Methylcyclohexane (Warning—Extremely Flammable. Harmful if inhaled.)

are included in the paraffin and naphthene distribution. Aro-

4-Methyl-1-hexene (Warning—Extremely Flammable. Harmful if inhaled.)

Heptane (Warning—Flammable. Harmful if inhaled.)

maticsboilingatC andabovearereportedasasinglearomatic

1,cis-2-Dimethylcyclohexane (Warning—Extremely Flammable. Harmful if

group.

inhaled.)

1.2 This test method is not intended to determine individual

2,2,4-Trimethylpentane (iso-octane) (Warning—Flammable. Harmful if inhaled.)

Octane (Warning—Flammable. Harmful if inhaled.)

components except for benzene and toluene that are the only

1,cis-2,cis-4-Trimethylcyclohexane (Warning—Flammable. Harmful if inhaled.)

C and C aromatics,respectively,andcyclopentane,thatisthe

6 7

Nonane (Warning—Flammable. Harmful if inhaled.)

only C naphthene. The lower limit of detection for a single

Decane (Warning—Flammable. Harmful if inhaled.)

Undecane (Warning—Flammable. Harmful if inhaled.)

hydrocarbon component or group is 0.05 mass %.

Dodecane (Warning—Flammable. Harmful if inhaled.)

1.3 This test method is applicable to hydrocarbon mixtures

Benzene (Warning—Extremely Flammable. Harmful if inhaled.)

including virgin, catalytically converted, thermally converted, Methylbenzene (Toluene) (Warning—Flammable. Harmful if inhaled.)

trans-Decahydronaphthalene (Decalin) (Warning—Flammable. Harmful if

alkylated and blended naphthas.

inhaled.)

1.4 The values stated in SI units are to be regarded as the

Tetradecane (Warning—Harmful if inhaled.)

standard. The values given in parentheses are for information Ethylbenzene (Warning—Extremely Flammable. Harmful if inhaled.)

1,2-Dimethylbenzene (o-Xylene) (Warning—Extremely Flammable. Harmful if

only.

inhaled.)

1.5 This standard does not purport to address all of the

Propylbenzene (Warning—Extremely Flammable. Harmful if inhaled.)

safety concerns, if any, associated with its use. It is the 1,2,4-Trimethylbenzene (Warning—Extremely Flammable. Harmful if inhaled.)

1,2,3-Trimethylbenzene (Warning—Extremely Flammable. Harmful if inhaled.)

responsibility of the user of this standard to establish appro-

1,2,4,5-Tetramethylbenzene (Warning—Flammable. Harmful if inhaled.)

priate safety and health practices and determine the applica-

Pentamethylbenzene (Warning—Harmful if inhaled.)

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 7 and Table 1.

D 4307 Practice for Preparation of Liquid Blends for Use

2. Referenced Documents

As Analytical Standards

2.1 ASTM Standards:

3. Summary of Test Method

D 4057 Practice for Manual Sampling of Petroleum and

3.1 A representative sample is introduced into a gas chro-

Petroleum Products

matographicsystemcontainingaseriesofcolumnsandswitch-

ing valves. As the sample passes through a polar column, the

polar aromatic compounds, bi-naphthenes, and high boiling

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

(>200°C) paraffins and naphthenes are retained. The fraction

D02.04 on Hydrocarbon Analysis.

not retained elutes to a platinum column, that hydrogenates

Current edition approved May 10, 2003. Published August 2003. Originally

olefins,ifpresent,inthisfraction,andthentoamolecularsieve

approved in 1993. Last previous edition approved in 1998 as D 5443–93(1998).

Annual Book of ASTM Standards, Vol 05.02. column which performs a carbon number separation based on

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 5443 – 93 (2003)

TABLE 2 Typical Column Specifications

Column Type

Specification

3 A A

Polar Non-Polar Tenax Molsieve Platinum

Column length, m 3 4 0.16 to 0.18 1.8 0.002 to 0.06

Column inside diameter, mm 2.0 to 2.1 1.8 to 2.0 2.5 1.6 to 2.0 1.6

B B

Liquid phase OV-275 OV-101 . . .

Percent liquid phase 30 4–5 . . .

C C

Support material Chromasorb Chromasorb . . .

PAW WAW . . .

3 D,E

Packing material . . Tenax Molecular sieve 13X .

Mesh size 60/80 80/100 80/100 . .

A

Available from AC Analytical Controls, 3448 Progress Dr., Bensalem, PA 19020.

B

OV- 101 and OV-275 are registered trademarks of Ohio Valley Specialty Chemical Co., 115 Industry Rd., Marietta, OH 45750.

C

Chromasorb is a registered trademark of Manville Corp., Box 519, Lompoc, CA 93438.

D

Sodium form of molecular sieve 13X.

E

May also contain a mix of molecular sieves 13X and 5A to separate normal and iso-paraffins.

molecular structure, that is, naphthenes and paraffins. The equipped with a prefractionating column.The sample may also

fraction remaining on the polar column is further divided into be diluted with a component that is not present in the sample

three separate fractions that are then separated on a non-polar and this component will then not be included in the normalized

column by boiling point. Eluting compounds are detected by a report.

flame ionization detector.

6.2 Sample Introduction System—Manual or automatic liq-

3.2 The mass concentration of each group is determined by uid sample system operated in a splitless mode. Although this

the multiplication of detected peak areas by flame ionization

test method is intended primarily for use with syringe sample

detector response factors and normalization to 100 %. injection, automatic sampling valves have also been found

satisfactory. Devices capable of a reproducible injection vol-

4. Significance and Use

ume of 0.1 to 0.5 µL are suitable. The sample introduction

system must be capable of heating the sample to a temperature

4.1 A knowledge of the composition of hydrocarbon refin-

ery streams is useful for process control and quality assurance. that ensures total sample vaporization. A temperature range of

120 to 180°C has been found suitable.

4.2 Aromatics in gasoline are soon to be limited by federal

mandate. This test method can be used to provide such 6.3 Electronic Data Acquisition System—The data acquisi-

information. tion and integration device used for detection and integration

must meet or exceed the following specifications:

5. Interferences

6.3.1 Capacity for at least 75 peaks for each analysis,

5.1 Chemicals of a non-hydrocarbon composition may elute 6.3.2 Normalized area percent calculation,

within the hydrocarbon groups, depending on their polarity,

6.3.3 Noise and spike rejection capability,

boiling point, and molecular size. Included in this group are

6.3.4 Sampling rates for fast (<2 s) peaks,

ethers (for example, methyl-tertiary butyl ether) and alcohols

6.3.5 Peak width detection for narrow and broad peaks, and

(for example, ethanol).

6.3.6 Perpendicular drop and tangent skimming as required.

6.4 Independent Temperature Control—This test method

6. Apparatus

requires the temperature control of five columns, column

6.1 Chromatograph—A gas chromatograph capable of iso-

switching valves and sample lines. The columns consist of

thermal operation at 130 6 0.1°C. The gas chromatograph

polar, non-polar, Tenax , platinum, and molecular sieve col-

must contain the following:

umns. The specifications for these columns are listed in Table

6.1.1 A heated flash vaporization sample inlet system ca-

2. The polar column, non-polar column, column switching

pable of operation in a splitless mode.

valves, and sample lines require isothermal operation at a

6.1.2 Associated gas controls with adequate precision to

temperature equivalent to the temperature of the gas chromato-

provide reproducible flows and pressures.

graph oven. These components may be located in the gas

6.1.3 Aflame ionization detection system optimized for use

chromatograph oven. The Tenax column, platinum column,

with packed columns and capable of the following:

and molecular sieve column require operation at temperatures

Isothermal temperature operation 150 to 170°C other than the gas chromatograph oven temperature. These

Sensitivity >0.015 coulombs/g

columns may be temperature controlled by any means that will

−12

Minimum detectability 5 3 10 g carbon/second

7 meet the following specifications:

Linearity >10

6.4.1 Ability to control the temperature of the Tenax

Some instruments will produce a non-linear response for

column within a range from 60 to 280°C, with a tolerance of

benzene, above approximately 5.5 mass %, and for toluene

65°C at any point. The time required to heat this column

above approximately 15 mass %. The linearity of these

components above these concentrations must be verified with

appropriate blends. Where non-linearity has been shown to

exist,samples,thatcontainnohigherthanC ,canbeanalyzed

13 Tenax is a registered trademark ofAKZO, Velperiveg 76, P.O. Box 9300, 6800

if the sample is diluted with n-C and the instrument is SB Arnhem, The Netherlands.

e1

D 5443 – 93 (2003)

between any two points must be no more than 1 min. The time 7.5.3 Valves must be sized such that they offer little restric-

required to cool this column between any two points must be tion to carrier gas flow under the analysis conditions defined in

no more than 5 min,

this test method.

6.4.2 Ability to control the temperature of the molecular

7.5.4 Care must be taken to prevent the introduction of any

sieve column within a range from 100 and 490°C, with a

formofforeignmaterialorcontaminantintothevalvethatmay

tolerance of 610°C at any point.The time required to heat this

adversely affect its performance.

column between any two points must be no more than 10 min.

7.6 Hydrocarbon Test Mixture—A quantitative synthetic

The time required to cool this column from 450 to 100°C must

mixture of pure hydrocarbons, an example of which is identi-

be no more than 15 min, and

fied in Table 1, is used to tune the instrument analysis

6.4.3 Ability to control the platinum column within a

conditions and establish that the instrument is performing

temperature range of 170 and 350°C. During routine analysis,

within specifications. Individual hydrocarbon components, in

this column is operated within a temperature range of 170 to

addition to those listed in Table 1, may be used to aid in the

220°C.

analysis. The concentration level of each component in the

hydrocarbon test mixture is not critical as long as the concen-

7. Materials

tration is accurately known. Percentage ranges from 1.0 to 6.0

7.1 Carrier Gases: mass % have been found suitable. Impurities in the individual

components may have an adverse effect on the quantitative

7.1.1 Hydrogen, 99.999 % pure, <0.1 ppm H O.

aspect of the analysis. If an impurity is of the same carbon

(Warning—Extremely flammable gas under high pressure.)

number and basic molecular structure as the main component

7.1.2 Helium, 99.999 % pure, <0.1 ppm H O. (Warning—

itself, it will be correctly grouped and quantitated within the

Compressed gas under high pressure.)

group. As an example, isobutylcyclopentane and isopropylcy-

7.2 Detector Gases:

clohexane will both be determined as C naphthenes. Each of

7.2.1 Hydrogen, 99.99 % minimum purity. (Warning—

the individual hydrocarbon components used for this test

Extremely flammable gas under high pressure.)

mixture must have a minimum purity level of 99 mol %. Refer

7.2.2 Air, less than 10 ppm each of total hydrocarbons and

to Practice D 4307 for instructions on the preparation of liquid

water. (Warning—Compressed gas under high pressure.)

blends for use as analytical standards.

7.3 Valve Actuation Gas—This test method permits the use

7.7 Gas Flows and Pressures:

of any type of valve switching or valve actuation. When

7.7.1 Carrier Gases:

pneumatic valves are used, air of any grade that will result in

7.7.1.1 The helium carrier gas through the injection port,

no water condensation or will not introduce oil or other

polar column, platinum column and molecular sieve column is

contaminates in the switching valves may be used. Air from a

flow controlled. Flow rates of 16 to 23 mL/min have been

piston operated compressor equipped with a water and oil

found suitable. A helium supply pressure of 620 kDa (90 psi)

separator has been found suitable. Column switching valves

has been found suitable to meet the helium flow requirement.

that do not require air to operate do not have this air

The helium carrier gas flow will be referred to as the “A” flow

requirement.

within this test method.

7.4 Columns—Five columns, as described inTable 2.These

column specifications are to be considered as guidelines and 7.7.1.2 The helium carrier gas used as the make up gas

when the polar column is in stop flow is set to the same flow

have been found to be acceptable. Other materials or combi-

nations of materials may also provide acceptable performance. rate as the helium carrier gas through the injection port.

The suitability of each column is determined by test criteria as

7.7.1.3 The hydrogen carrier gas flow through the Tenax

defined in Section 8.

column and non-polar column is flow controlled. Flow rates of

12 to 17 mL/min have been found suitable.Ahydrogen supply

NOTE 1—It is not the intention of this test method to include detailed

pressure of 517 kDa (75 psi) has been found suitable to meet

column preparation steps. Columns may be prepared in any way that

thehydrogenflowrequirements

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.