ASTM D3326-07(2011)

(Practice)Standard Practice for Preparation of Samples for Identification of Waterborne Oils

Standard Practice for Preparation of Samples for Identification of Waterborne Oils

SIGNIFICANCE AND USE

Identification of a recovered oil is determined by comparison with known oils selected because of their possible relationship to the particular recovered oil, for example, suspected or questioned sources. Thus, samples of such known oils must be collected and submitted along with the unknown for analysis. It is unlikely that identification of the sources of an unknown oil by itself can be made without direct matching, that is, solely with a library of analyses.

SCOPE

1.1 This practice covers the preparation for analysis of waterborne oils recovered from water. The identification is based upon the comparison of physical and chemical characteristics of the waterborne oils with oils from suspect sources. These oils may be of petroleum or vegetable/animal origin, or both. Seven procedures are given as follows:

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3326 −07 (Reapproved 2011)

Standard Practice for

Preparation of Samples for Identification of Waterborne

Oils

This standard is issued under the fixed designation D3326; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers the preparation for analysis of

D95Test Method for Water in Petroleum Products and

waterborne oils recovered from water. The identification is

Bituminous Materials by Distillation

based upon the comparison of physical and chemical charac-

D1129Terminology Relating to Water

teristics of the waterborne oils with oils from suspect sources.

D1193Specification for Reagent Water

These oils may be of petroleum or vegetable/animal origin, or

D3325Practice for Preservation of Waterborne Oil Samples

both. Seven procedures are given as follows:

D3328Test Methods for Comparison of Waterborne Petro-

Sections

leum Oils by Gas Chromatography

Procedure A (for samples of more than 50-mL volume

containing significant quantities of hydrocarbons

D3414Test Method for Comparison of Waterborne Petro-

with boiling points above 280°C) 8 to 12

leum Oils by Infrared Spectroscopy

Procedure B (for samples containing significant quantities of

D3415Practice for Identification of Waterborne Oils

hydrocarbons with boiling points above 280°C) 13 to 17

Procedure C (for waterborne oils containing significant

D3650Test Method for Comparison of Waterborne Petro-

amounts of components boiling below 280°C and

leum Oils By Fluorescence Analysis

to mixtures of these and higher boiling components) 18 to 22

D4489Practices for Sampling of Waterborne Oils

Procedure D (for samples containing both petroleum and

vegetable/animal derived oils) 23 to 27

E1Specification for ASTM Liquid-in-Glass Thermometers

Procedure E (for samples of light crudes and medium distillate

E133Specification for Distillation Equipment

fuels) 28 to 34

Procedure F (for thin films of oil-on-water) 35 to 39

3. Terminology

Procedure G (for oil-soaked samples) 40 to 44

3.1 Definitions—For definitions of terms used in this

1.2 Procedures for the analytical examination of the water-

practice, refer to Terminology D1129.

borne oil samples are described in Practice D3415, D3328,

D3414, and D3650. Refer to the individual oil identification

3.2 Definitions of Terms Specific to This Standard:

test methods for the sample preparation method of choice.The

3.2.1 animal/vegetable-derived oils—a mixture made of

deasphalting effects of the sample preparation method should

mono-, di-, and triglyceride esters of fatty acids and other

be considered in selecting the best methods.

substances of animal or vegetable origin, or both.

1.3 The values stated in SI units are to be regarded as 3.2.2 Simulated weathering of waterborne oils by distilla-

standard. No other units of measurement are included in this tionconsidersonlytheeffectofevaporation,whichlikelyisthe

standard. most significant short-term weathering effect in the environ-

ment.

1.4 This standard does not purport to address all of the

3.2.3 Simulated weathering of waterborne oils by evapora-

safety concerns, if any, associated with its use. It is the

tion under ultraviolet light simulates the loss of light compo-

responsibility of the user of this standard to establish appro-

nents on weathering, as well as some oxidative weathering.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific caution

4. Significance and Use

statements are given in Sections 6 and 32.

4.1 Identification of a recovered oil is determined by com-

parison with known oils selected because of their possible

relationship to the particular recovered oil, for example,

This practice is under the jurisdiction ofASTM Committee D19 on Water and

is the direct responsibility of Subcommittee D19.06 on Methods for Analysis for

Organic Substances in Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2011. Published June 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1974. Last previous edition approved in 2007 as D3326–07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3326-07R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3326−07 (2011)

NOTE 1—The boiling point may be ascertained by injecting the neat

suspectedorquestionedsources.Thus,samplesofsuchknown

samples into the gas chromatograph and checking the elution times above

oils must be collected and submitted along with the unknown

that of pentadecane on a nonpolar column.

for analysis. It is unlikely that identification of the sources of

8.2 Thepreparationofsamplescontainingmostlyhydrocar-

an unknown oil by itself can be made without direct matching,

that is, solely with a library of analyses. bons of boiling points below 280°C, such as petroleum

distillate fuels, is beyond the scope of this procedure (see

5. Reagents and Materials

Procedure C or E).

5.1 Purity of Reagents—Reagent grade chemicals shall be

9. Summary of Procedure

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

9.1 A neat portion of the waterborne oil is retained. If not

teeonAnalyticalReagentsoftheAmericanChemicalSociety.

possible to obtain a neat portion, then retain a portion of the

Special ancillary procedures such as fluorescence may require

waterborne oil as received.This is to be used in those analyses

higher purity grades of solvents. Other grades may be used

performed on samples containing significant quantities of

provided it is first ascertained that the reagent is of sufficiently

hydrocarbons with boiling points below 280°C. Preparation of

high purity to permit its use without lessening the accuracy of

these samples is beyond the scope of this procedure, but are

the determination.

covered in Procedure C.

5.2 Purity of Water—Unless otherwise indicated, references

NOTE 2—Waterborne oil samples containing significant quantities of

to water shall be understood to mean reagent water that meets

hydrocarbons with boiling points below 280°C (see Note 1), such as

thepurityspecificationsofTypeIorTypeIIwater,asspecified

gasoline and kerosene, can usually be obtained as neat samples without

in Specification D1193. any sample preparation.

9.2 The waterborne oil sample is dissolved in an equal

6. Caution

volume of chloroform or dichloromethane and centrifuged to

6.1 Solventsusedinthispracticearevolatile,flammable,or

remove the free water, solids, and debris. The water layer, if

may cause the harm to the health of the user. Specifically,

present, is separated from the organic layer. Other debris, if

benzene is a known carcinogen, while chloroform and carbon

present, is removed by filtration through glass wool.

tetrachloride are suspected carcinogens. Consequently, it is

NOTE 3—The use of spectrograde cyclohexane is required for the

important that extractions and separations utilizing these sub-

extractionofsamplestobeanalyzedbyfluorescencespectrometrybyTest

stances must be carried out in a laboratory hood with a

Method D3650. Separation of water may be accomplished by centrifuga-

minimum linear face velocity of 38 to 45 m/min (125 to 150

tion or dying, or both, with anhydrous sodium sulfate.

ft/min)locatedinaregulatedareapostedwithsignsbearingthe

9.3 Whencentrifugationwillnotseparatethewaterfromthe

legends: NO SMOKING or (if appropriate) DANGER-

chloroform solution of the sample, it is refluxed with an

CHEMICAL CARCINOGEN-AUTHORIZED PERSONNEL

aromaticorpetroleumdistillatesolventinaccordancewithTest

ONLY, or both.

Method D95.

7. Sampling

NOTE 4—Pressure filtration has also been found useful for breaking

emulsions.

7.1 Collect representative samples in accordance with Prac-

tices D4489.

9.4 Aportionofthesolvent/samplesolutionisretained.The

solvent may be removed by evaporation. This portion of the

7.2 Preserve the waterborne oil samples in accordance with

sample may be used in the preliminary gas chromatographic

Practice D3325.

analysis, Test Methods D3328 (Test Method A), and other

7.3 Theportionofthesampleusedmustberepresentativeof

analyses in which the results are unaffected by weathering.

the total sample. If the material is liquid, thoroughly stir the

sampleasreceived,warmingifnecessarytoensureuniformity. 9.5 Theremainderofthesolvent/samplesolutionisdistilled

using nitrogen purge to a liquid temperature of 280°C to

PROCEDURE A—LARGE SAMPLES

remove the solvent and simulate weathering conditions as

nearlyaspossible.Thedistillatemaybediscardedorsavedfor

8. Scope

characterization by gas chromatography (Test Methods

8.1 This procedure covers the preparation for analysis of

D3328). This simulated weathering treatment is necessary to

samples in which the volumes of waterborne oil in the

bring the unweathered suspect samples and the waterborne oil

environmental and suspect source samples equal or exceed 50

sample to as nearly comparable physical condition for subse-

mLandinwhichtheoilportioncontainssignificantamountsof

quent analysis as possible. Analyses requiring the use of this

hydrocarbons with boiling points above 280°C.

treated residue include elemental analysis; gas chromato-

graphicanalysis(TestMethodsD3328,TestMethodsAandB);

aninfraredprocedure(TestMethodD3414);afluorescencetest

Reagent Chemicals, American Chemical Society Specifications, American

method (Test Method D3650); and any applicable test method

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory or practice described in Practice D3415.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, NOTE 5—The distillate might yield useful information but is discarded

MD. in this practice.

D3326−07 (2011)

10. Apparatus 11.3 Solvent—Chloroform (stabilized with ethanol) or di-

chloromethane is used for dissolution of the waterborne oil

10.1 Centrifuge, capable of whirling two or more filled

samples. If water is to be removed by distillation, an aromatic,

100-mLcentrifuge tubes at a speed that is controlled to give a

petroleum distillate, or volatile spirits solvent is required as

relative centrifugal force (rcf) between 500 and 800 at the tip

specified in Test Method D95. The safety precautions associ-

of the tubes.

ated with the use of the solvent selected should be considered

10.2 Centrifuge Tubes, cone shaped, 100 mL.

before it is used (see Note 3).

10.3 Distillation Apparatus for Water Determination, as

specified in Test Method D95.

12. Procedure

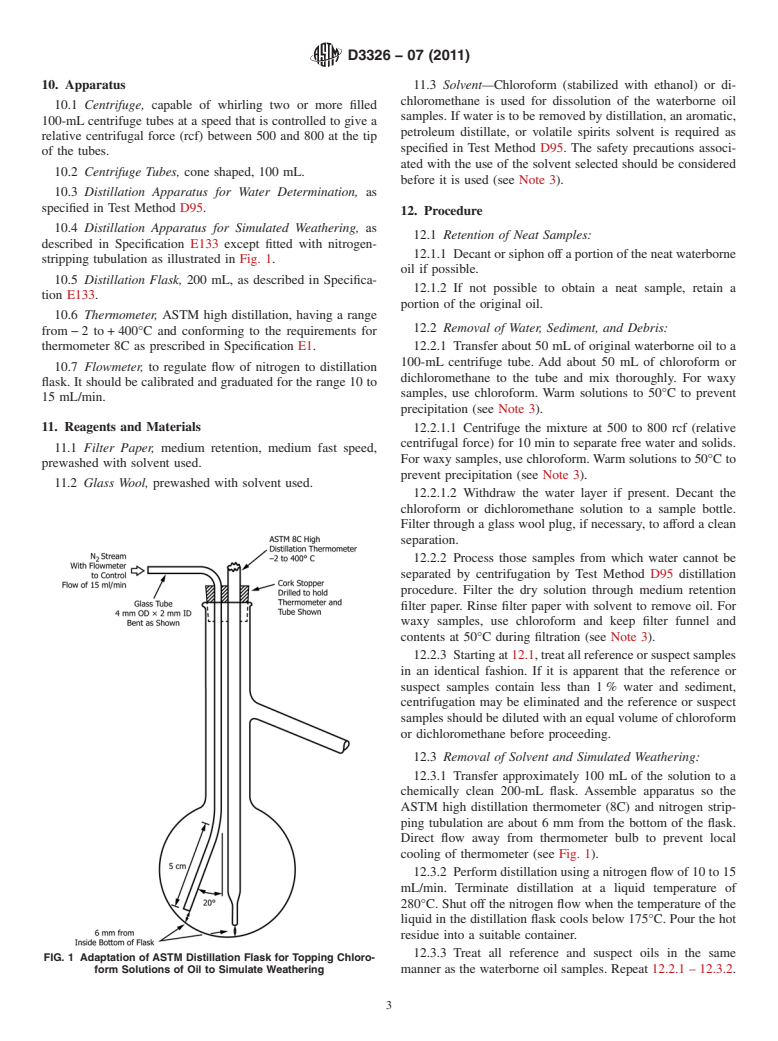

10.4 Distillation Apparatus for Simulated Weathering, as

12.1 Retention of Neat Samples:

described in Specification E133 except fitted with nitrogen-

12.1.1 Decantorsiphonoffaportionoftheneatwaterborne

stripping tubulation as illustrated in Fig. 1.

oil if possible.

10.5 Distillation Flask, 200 mL, as described in Specifica-

12.1.2 If not possible to obtain a neat sample, retain a

tion E133.

portion of the original oil.

10.6 Thermometer, ASTM high distillation, having a range

12.2 Removal of Water, Sediment, and Debris:

from−2 to+400°C and conforming to the requirements for

thermometer 8C as prescribed in Specification E1. 12.2.1 Transfer about 50 mLof original waterborne oil to a

100-mL centrifuge tube. Add about 50 mL of chloroform or

10.7 Flowmeter, to regulate flow of nitrogen to distillation

dichloromethane to the tube and mix thoroughly. For waxy

flask. It should be calibrated and graduated for the range 10 to

samples, use chloroform. Warm solutions to 50°C to prevent

15 mL/min.

precipitation (see Note 3).

11. Reagents and Materials

12.2.1.1 Centrifuge the mixture at 500 to 800 rcf (relative

centrifugal force) for 10 min to separate free water and solids.

11.1 Filter Paper, medium retention, medium fast speed,

For waxy samples, use chloroform.Warm solutions to 50°C to

prewashed with solvent used.

prevent precipitation (see Note 3).

11.2 Glass Wool, prewashed with solvent used.

12.2.1.2 Withdraw the water layer if present. Decant the

chloroform or dichloromethane solution to a sample bottle.

Filter through a glass wool plug, if necessary, to afford a clean

separation.

12.2.2 Process those samples from which water cannot be

separated by centrifugation by Test Method D95 distillation

procedure. Filter the dry solution through medium retention

filter paper. Rinse filter paper with solvent to remove oil. For

waxy samples, use chloroform and keep filter funnel and

contents at 50°C during filtration (see Note 3).

12.2.3 Startingat12.1,treatallreferenceorsuspectsamples

in an identical fashion. If it is apparent that the reference or

suspect samples contain less than 1% water and sediment,

centrifugation may be eliminated and the reference or suspect

samplesshouldbedilutedwithanequalvolumeofchloroform

or dichloromethane before proceeding.

12.3 Removal of Solvent and Simulated Weathering:

12.3.1 Transfer approximately 100 mL of the solution to a

chemically clean 200-mL flask. Assemble apparatus so the

ASTM high distillation thermometer (8C) and nitrogen strip-

ping tubulation are about 6 mm from the bottom of the flask.

Direct flow away from thermometer bulb to prevent local

cooling of thermometer (see Fig. 1).

12.3.2 Performdistillationusinganitrogenflowof10to15

mL/min. Terminate distillation at a liquid temperature of

280°C. Shut off the nitrogen flow when the temperature of the

liquid in the distillation flask cools below 175°C. Pour the hot

residue into a suitable container.

12.3.3 Treat all reference and suspect oils in the same

FIG. 1 Adaptation of ASTM Distillation Flask for Topping Chloro-

form Solutions of Oil to Simulate Weathering manner as the waterborne oil samples. Repeat 12.2.1 – 12.3.2.

D3326−07 (2011)

PROCEDURE B—LIMITED SAMPLE VOLUMES OF solvent removal. The samples can then be used for analysis in

HEAVY OILS accordance with Practice D3415.

NOTE 6—This treatment with 70 mg of oil, evaporated at 40°C for 15

13. Scope

min in the presence of an airstream, yielded gas chromatograms resem-

13.1 This procedure covers the preparation for analysis of bling those of the distillation test method in 12.3.

waterborne oil samples of petrol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.