ASTM F2038-00(2011)

(Guide)Standard Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part I—Formulations and Uncured Materials

Standard Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part I—Formulations and Uncured Materials

SIGNIFICANCE AND USE

4.1 This guide is intended to provide guidance for the specification and selection of silicone materials for medical device applications.

Silicone manufacturers supplying materials to the medical device industry should readily provide information regarding non-proprietary product formulation to their customers either directly, or through the US FDA master file program.

SCOPE

1.1 This guide is intended to educate potential users of silicone elastomers, gels, and foams relative to their formulation and use. It does not provide information relative to silicone powders, fluids, and other silicones. The information provided is offered to guide users in the selection of appropriate materials, after consideration of the chemical, physical, and toxicological properties of individual ingredients or by-products. This guide offers general information about silicone materials typically used for medical applications. Detail on the crosslinking and fabrication of silicone materials is found in Part II of this guide.

1.2 Fabrication and properties of elastomers is covered in the companion document, F604, Part II. This monograph addresses only components of uncured elastomers, gels, and foams.

1.3 Silicone biocompatibility issues can be addressed at several levels, but ultimately the device manufacturer must assess biological suitability relative to intended use.

1.4 Biological and physical properties tend to be more reproducible when materials are manufactured in accordance with accepted quality standards such as ANSI ISO 9001 and current FDA Quality System Regulations/Good Manufacturing Practice Regulations.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Users are also advised to refer to Material Safety Data Sheets provided with uncured silicone components.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2038 − 00 (Reapproved 2011)

Standard Guide for

Silicone Elastomers, Gels, and Foams Used in Medical

Applications Part I—Formulations and Uncured Materials

This standard is issued under the fixed designation F2038; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide is intended to educate potential users of 2.1 ASTM Standards:

silicone elastomers, gels, and foams relative to their formula- D1566 Terminology Relating to Rubber

tionanduse.Itdoesnotprovideinformationrelativetosilicone F813 Practice for Direct Contact Cell Culture Evaluation of

powders, fluids, and other silicones. The information provided Materials for Medical Devices

is offered to guide users in the selection of appropriate

2.2 Sterility Standards:

materials, after consideration of the chemical, physical, and

ANSI/AAMI ST41 Good Hospital Practice: Ethylene Oxide

toxicological properties of individual ingredients or by-

Sterilization and Sterility Assurance

products. This guide offers general information about silicone

ANSI/AAMI ST50 Dry Heat (Heated Air) Sterilizers

materials typically used for medical applications. Detail on the

ANSI/AAMIST29 RecommendedPracticeforDetermining

crosslinking and fabrication of silicone materials is found in

Ethylene Oxide in Medical Devices

Part II of this guide.

ANSI/AAM1 ST30 Determining Residual Ethylene Chlo-

rohydrin and Ethylene Glycol in Medical Devices

1.2 Fabrication and properties of elastomers is covered in

AAMI 13409-251 Sterilization of Health Care Products—

the companion document, F604, Part II. This monograph

Radiation Sterilization—Substantiation of 25kGy as a

addresses only components of uncured elastomers, gels, and

Sterilization Dose for Small or Infrequent Production

foams.

Batches

1.3 Silicone biocompatibility issues can be addressed at

AAMI TIRS-251 Microbiological Methods for Gamma Irra-

several levels, but ultimately the device manufacturer must

diation Sterilization of Medical Devices

assess biological suitability relative to intended use.

2.3 Quality Standards :

1.4 Biological and physical properties tend to be more

ANSI/ASQC Q9001 Quality Systems—Model for Quality

reproducible when materials are manufactured in accordance

Assurance in Design, Development Production,

with accepted quality standards such as ANSI ISO 9001 and

Installation, and Servicing

current FDAQuality System Regulations/Good Manufacturing

21 CFR 820 Quality System Regulation (current revision)

Practice Regulations.

21 CFR 210 Current Good Manufacturing Practice in

Manufacturing, Processing, Packing or Holding of Drugs;

1.5 The values stated in inch-pound units are to be regarded

General (current revision)

as standard. The values given in parentheses are mathematical

21 CFR 211 Current Good Manufacturing Practice for Fin-

conversions to SI units that are provided for information only

ished Pharmaceuticals (current revision)

and are not considered standard.

1.6 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Additional pertinent definitions can be found in Termi-

responsibility of the user of this standard to establish appro-

nology D1566.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Users are also

advised to refer to Material Safety Data Sheets provided with

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

uncured silicone components.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This specification is under the jurisdiction of ASTM Committee F04 on the ASTM website.

Medical and Surgical Materials and Devices and is the direct responsibility of Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Subcommittee F04.11 on Polymeric Materials. 4th Floor, New York, NY 10036, http://www.ansi.org.

Current edition approved Dec. 1, 2011. Published January 2012. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

published in 2000. Last previous edition approved in 2005 as F2038 – 00 (2005). 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

DOI: 10.1520/F2038-00R11. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2038 − 00 (2011)

3.2 Definitions: 3.2.10.1 high consistency rubbers (HCRS)—are materials

which cannot be pumped by conventional pumping equipment.

3.2.1 silicone polymer—polymer chains having a backbone

They normally must be processed using high shear equipment

consisting of repeating silicon-oxygen atoms where each

such as a two-roll mill and parts are typically fabricated using

silicon atom bears two organic groups. The organic groups are

compression or transfer molding techniques.

typically methyl, but can be vinyl, phenyl, fluorine, or other

organic groups.

3.2.10.2 low consistency rubbers or liquid silicone rubbers

(LSRS)—are normally flowable materials which can be readily

3.2.2 cyclics and linears—low molecular weight volatile

pumped. They can be mixed by pumping through static mixers

cyclic siloxane species are referred to using the “D” nomen-

and parts can be fabricated using injection molding techniques.

clature which designates the number of Si-O linkages in the

material (usually D -D ); species from D to D (or more)

3.2.10.3 RTVs (room temperature vulcanization)— are one-

4 20 7 40

may be called “macrocyclics”. Linears are straight chain

part elastomers which cure in the presence of atmospheric

oligomers that may be volatile or of higher molecular weight,

moisture. Little, if any, acceleration of cure rate is realized by

depending on chain length; they are designated by “M” and

increasing temperature. Because cure is dependent upon diffu-

“D”combinations,where“M”isR Si-O,andDisasexplained

sion of water into the elastomer, cure in depths greater than

above; “R” is usually methyl. (For example, MDM is

0.25 in. (0.635 cm) is not recommended.

(CH ) SiOSiOSi(CH ) ). Low molecular weight species are

3 3 3 3

3.2.10.4 gels—arelightlycrosslinkedmaterialshavingnoor

present in silicone components to varying degrees depending

relatively low levels of reinforcement beyond that provided by

on process and storage. The levels of macrocyclics that can be

the crosslinked polymer. They are usually two-part formula-

removed from silicone polymers by vacuum, high temperature

tions utilizing a platinum catalyzed addition cure system. The

stripping, or oven post-cure is dependent on the conditions

hardness of the gel can be adjusted within wide limits. The

used.

material is not usually designed to bear heavy loads but rather

3.2.3 catalyst—a component of a silicone elastomer formu-

to conform to an irregular surface providing intimate contact.

lation that initiates the crosslinking reaction when the material

As a result, loads are distributed over a wider area. These

is vulcanized.

materials may also be used to provide protection from envi-

ronmental contaminants.

3.2.4 crosslinker or crosslinking agent—a component of a

silicone elastomer that is a reactant in the crosslinking reaction 3.2.10.5 foams—are crosslinked materials which have a

that occurs when an elastomer is vulcanized. component added to them that generates a volatile gas as the

material is being vulcanized. This results in a material with a

3.2.5 inhibitor—a component of a silicone elastomer added

very low density. These are usually two-part formulations

to moderate the rate of the crosslinking reaction.

utilizing a platinum catalyzed addition cure system. They

3.2.6 filler—a finely divided solid that is intimately mixed

conform to an irregular surface as they expand to provide

with silicone polymers during manufacture to achieve specific

intimate contact and protection from the environment but are

properties. The fillers used in silicone elastomers are one of

more rigid and provide more strength than gels. Since foams

two types:

are expanded elastomers, on a weight basis they are highly

crosslinked relative to gels. Most cure conditions will result in

3.2.6.1 reinforcing fillers—usually have high surface areas

a closed cell foam.

and are amorphous in nature such as fumed or precipitated

silica. Such fillers impart high strength and elastomeric physi-

3.2.11 lot or batch—a quantity of material made with a

cal properties to the elastomer. fixed, specified formulation in a single, manufacturing run

carried out under specific processing techniques and condi-

3.2.6.2 extending fillers—typically have lower surface area

tions.

and lower cost than reinforcing fillers.They include crystalline

forms of silica and diatomaceous earths. While they provide 3.2.12 vulcanization—an irreversible process in which co-

some reinforcement, because they are relatively inexpensive, valent chemical bonds are formed between silicone polymer

they are used primarily to extend the bulk of the silicone. chains. During vulcanization, the material changes from a

flowable or moldable compound to an elastomeric material

3.2.7 additives—a component of a silicone elastomer used

which cannot be reshaped except by its physical destruction.

in relatively small amounts to perform functions such as

3.2.13 types of cure—based upon the cure chemistry

marking, coloring, or providing opacity to the elastomer.

employed,siliconeelastomersusedinmedicalapplicationsfall

3.2.8 silicone base—a uniformly blended mixture of sili-

into one of three categories: condensation cure, peroxide cure,

cone polymers, fillers, and additives which does not contain

and addition cure.

crosslinkers or catalyst.

3.2.13.1 condensation cure—these materials liberate an or-

3.2.9 uncured elastomer—a silicone base which contains

ganic leaving group during curing and are normally catalyzed

crosslinker and/or catalyst but has not been vulcanized.

by an organometallic compound.

3.2.10 silicone elastomer—an uncured elastomer that has one-part—material supplied ready to use in an air tight

been subjected to conditions which cause it to become cross- container which cures upon exposure to atmospheric moisture.

linked.Elastomersmaybeeitherhighconsistencyrubbers,low The material cures from the surface down and cure depths of

consistency rubbers, or RTVs (see below). greater than about 0.25 inches (0.635 cm) are not practical.

F2038 − 00 (2011)

two-part—material supplied in two separate containers 5.1.2.2 tin—one-part condensation cure formulations will

which must be intimately mixed in the prescribed proportions typically contain from 0.1 to 0.5 wt percent of an organotin

shortly before use. Because they do not rely upon dispersion of compound.Two-part condensation cure formulations will typi-

atmospheric moisture into the silicone, the cure depth is not cally contain from 0.5 to 2.0 weight percent organotin com-

limited. pound.The ligands attached totin will be some combinationof

alkyl groups, alkoxy groups, or the anions of a carboxylic acid.

3.2.13.2 peroxide cure—one-part formulations vulcanized

5.1.3 Crosslinker or crosslinking agent:

by free radicals generated by the decomposition of an organic

5.1.3.1 Two-part, addition cure formulation—the cross-

peroxide.

linker is a polymer of the structure shown in Fig. 2 where R is

3.2.13.3 addition cure—two-part elastomers which must

generally a methyl or a hydrogen group such as to provide at

first be mixed together and then cure by addition of a

least 2.0 SiH groups per chain and x and y are integers greater

silylhydride to a vinyl silane in the presence of a platinum

than or equal to zero. In order to avoid chain extension, the

catalyst.

functionality of either the vinyl-containing polymer or the

3.2.14 dispersion—an uncured silicone elastomer dispersed

SiH-containing crosslinker must be at least 3.0.

in a suitable solvent to allow application of a thin layer of

Because of the limitless possibilities for the structure of both

elastomer to a substrate by either dipping or spraying.

thecrosslinkerandthefunctional(vinylcontaining)polymer,it

would be meaningless to define a weight range for the level of

4. Significance and Use

crosslinker in a formulation. However, the amount of cross-

4.1 This guide is intended to provide guidance for the

linker will typically be sufficient to provide a stoichiometric

specification and selection of silicone materials for medical

excess of SiH groups over the amount of unsaturated alkyl

device applications.

groups when the 2 components (parts) of the addition cure

silicone elastomer are mixed together in the manufacturer’s

4.2 Silicone manufacturers supplying materials to the medi-

recommended ratio.

cal device industry should readily provide information regard-

5.1.3.2 One-part RTVs and two-part addition cure

ing non-proprietary product formulation to their customers

formulations—the crosslinker may be an organosilane mono-

either directly, or through the US FDA master file program.

mer of the general formula:

5. Formulation

R Si OR’ (1)

~ !

x 42x

5.1 Elastomers,gels,andfoamsshallbemanufacturedusing

where:

formulations containing combinations of the following raw

R = organic group excluding phenyl

materials.

OR’ = hydrolyzable group such as alkoxy, acetoxy,

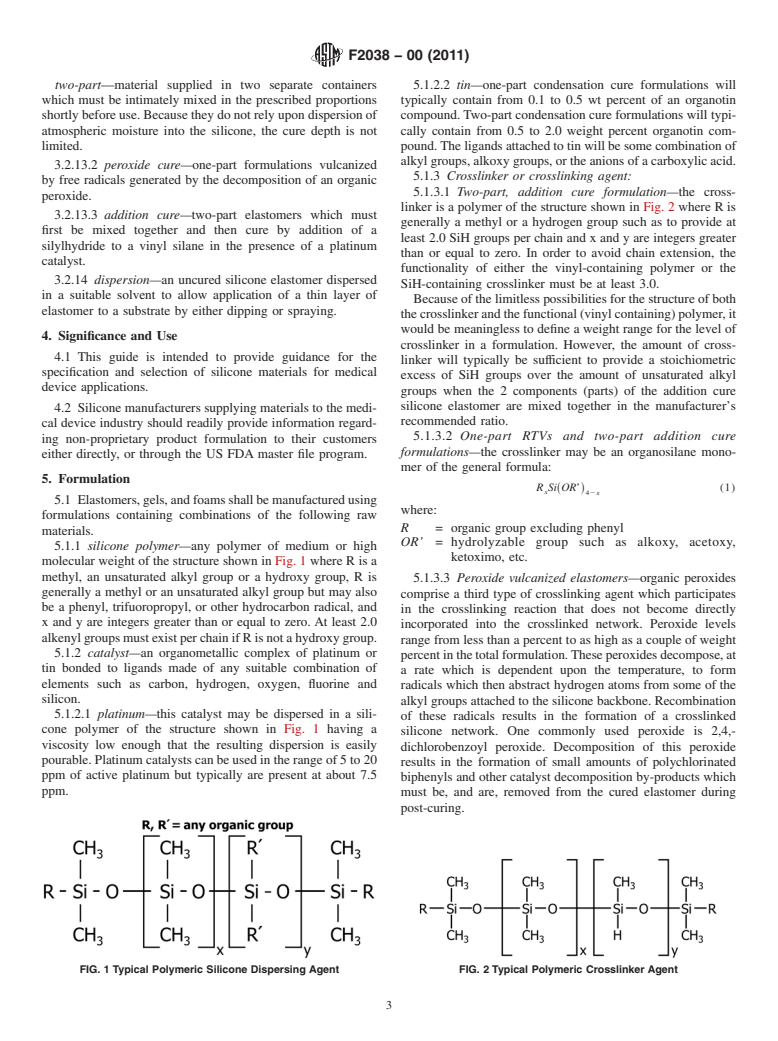

5.1.1 silicone polymer—any polymer of medium or high

ketoximo, etc.

molecular weight of the structure shown in Fig. 1 where R is a

methyl, an unsaturated alkyl group or a hydroxy group, R is

5.1.3.3 Peroxide vulcanized elastomers—organic peroxides

generally a methyl or an unsaturated alkyl group but may also

comprise a third type of crosslinking agent which participates

be a phenyl, trifuoropropyl, or other hydrocarbon radical, and

in the crosslinking reaction that does not become directly

x and y are integers greater than or equal to zero. At least 2.0

incorporated into the crosslinked network. Peroxide levels

alkenylgroupsmustexistperchainifRisnotahydroxygroup.

range from less than a percent to as high as a couple of weight

5.1.2 catalyst—an organometallic complex of platinum or

percentinthetotalformulation.Theseperoxidesdecompose,at

tin bonded to ligands made of any suitable combination of

a rate which is dependent upon the temperature, to form

elements such as carbon, hydrogen, oxygen, fluorine and

radicals which then abstract hydrogen atoms from some of the

silicon.

alkyl groups attached to the silicone bac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.