ASTM B368-97

(Test Method)Standard Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

Standard Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS Test)

SCOPE

1.1 This method prescribes the conditions required in copper-accelerated acetic acid-salt spray (CASS) testing for specification purposes. The standard does not specify the type of test specimen or exposure periods to be used for a specific product, nor the interpretation to be given to the results.

1.2 This method is applicable to evaluating the corrosive performance of decorative copper/nickel/chromium or nickel/chromium coatings on steel, zinc alloys, aluminum alloys, and plastics designed for severe service. It is also applicable to the testing of anodized aluminum. The suitability of this test and correlation of results with service experience should be determined before it is specified for coating systems or materials other than those mentioned in this paragraph. Note 1-The following standards are not requirements. They are referenced for information only: Practices B537 and E50, Specifications B456 and B604, and Test Method B602.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific safety precautionary information see 8.1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 368 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Method for

Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing

(CASS Test)

This standard is issued under the fixed designation B 368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope to Atmospheric Exposure

B 602 Test Method for Attribute Sampling of Metallic and

1.1 This method prescribes the conditions required in

Inorganic Coatings

copper-accelerated acetic acid-salt spray (CASS) testing for

B 604 Specification for Decorative Electroplated Coatings

specification purposes. The standard does not specify the type

of Copper/Nickel/Chromium on Plastics

of test specimen or exposure periods to be used for a specific

D 1193 Specification for Reagent Water

product, nor the interpretation to be given to the results.

E 50 Practices for Apparatus, Reagents, and Safety Precau-

1.2 This method is applicable to evaluating the corrosive

tions for Chemical Analysis of Metals

performance of decorative copper/nickel/chromium or nickel/

chromium coatings on steel, zinc alloys, aluminum alloys, and

3. Significance and Use

plastics designed for severe service. It is also applicable to the

3.1 The CASS test is widely employed and is useful for

testing of anodized aluminum. The suitability of this test and

specification acceptance, simulated service evaluation, manu-

correlation of results with service experience should be deter-

facturing control, and research and development. It was devel-

mined before it is specified for coating systems or materials

oped specifically for use with decorative, electrodeposited

other than those mentioned in this paragraph.

nickel/chromium and copper/nickel/chromium coatings. Use of

NOTE 1—The following standards are not requirements. They are

the test has improved the quality of electroplated parts and led

referenced for information only: Practices B 537 and E 50, Specifications

to the development of new and superior electroplating pro-

B 456 and B 604, and Test Method B 602.

cesses.

1.3 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 The apparatus required for the CASS test consists of a

priate safety and health practices and determine the applica-

fog chamber, a salt-solution reservoir, a supply of compressed

bility of regulatory limitations prior to use. For more specific

air, one or more atomizing nozzles, specimen supports, provi-

safety precautionary information see 8.1.1.

sion for heating the chamber, and necessary means of control.

4.2 The size and detailed construction of the apparatus are

2. Referenced Documents

optional, provided the conditions meet the requirements of this

2.1 ASTM Standards:

method. The construction of the apparatus is described in the

B 117 Practice for Operating Salt Spray (Fog) Apparatus

appendix of Test Method B 117. For the CASS test, however,

B 162 Specification for Nickel Plate, Sheet, and Strip

the requirements for air pressure and temperature are typically

B 456 Specification for Electrodeposited Coatings of Cop-

0.08 to 0.12 MPa and 60 to 65°C, respectively. The actual air

per Plus Nickel Plus Chromium and Nickel Plus Chro-

pressure will be that required to produce the proper collection

mium

rate (see 8.3.1).

B 537 Practice for Rating of Electroplated Panels Subjected

4.3 The apparatus shall be constructed so that drops of

solution that accumulate on the ceiling or cover of the chamber

do not fall on the specimens being tested. Drops of solution

This method is under the jurisdiction of ASTM Committee B-8 on Metallic and

Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on

that fall from the specimens shall not be returned to the

General Test Methods.

solution reservoir for respraying.

Current edition approved Oct. 10, 1997. Published March 1998. Originally

4.4 Materials of construction shall not affect the corrosive-

published as B 368 – 61 T. Last previous edition B 368 – 85 (1997).

The CASS test was developed by the initiative of the Research Board of the ness of the fog, nor be themselves corroded by the fog.

American Electroplaters Society under AES Project 15.

Annual Book of ASTM Standards, Vol 03.02.

3 5

Annual Book of ASTM Standards, Vol 02.04. Annual Book of ASTM Standards, Vol 11.01.

4 6

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 03.05.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 368

5. Test Solution clean decorative copper/nickel/chromium or nickel/chromium

coatings immediately before testing by wiping significant

5.1 Prepare the salt solution by dissolving 5 parts by weight

surfaces with a cotton pad saturated with a slurry containing 10

of salt in 95 parts of water conforming to Specification D 1193,

g of pure magnesium oxide powder (ACS reagent grade) in 100

Type IV. The salt shall be sodium chloride (NaCl), ACS reagent

mL of distilled water. Upon rinsing in warm running water, be

grade, or equivalent. The pH of this solution shall be between

sure that the clean surface is free of water break. Anodized

6.0 and 7.0. Impurities or contam-ination of either the salt or

aluminum parts may be cleaned with inhibited 1,1,1-

the water, or both, should be suspected if the pH is outside of

trichloroethane or other suitable organic solvent (see 8.1.1). Do

this range (Note 2).

not clean organic and other nonmetallic coated specimens.

5.2 Add 0.25 g of reagent grade copper chloride

Other methods of cleaning, such as the use of a nitric-acid

(CuCl ·2H O) to each litre of the salt solution; dissolve and

2 2

solution for the chemical cleaning or passivation of stainless

mix thoroughly.

steel specimens, are permissible when agreed upon between

5.3 The pH of the salt-copper solution shall be adjusted to

the purchaser and the supplier. Take care that the specimens

the range of 3.1 to 3.3, as measured on a sample of the

after cleaning are not recontaminated by excessive or careless

collected spray, by the addition of glacial acetic acid, ACS

handling. Protect the cut edges of plated, coated, or multilay-

reagent grade, or equivalent (Note 3). The pH measurement

ered materials and areas containing identification marks or in

shall be made electrometrically at 25°C. Before the solution is

contact with the racks or supports with a coating that is stable

atomized, it shall be free of suspended solids (Note 4).

under the conditions of the test, such as wax, stop-off lacquer,

NOTE 2—A solution having a specific gravity of 1.030 to 1.040, when

or pressure-sensitive tape.

measured at a temperature of 25°C, will meet the concentration require-

8.1.1 Caution—1,1,1-Trichloroethane should be used in a

ment. It is suggested that a daily check be made.

well-ventilated area away from open flames.

NOTE 3—The initial solution may be adjusted to a pH of 3.0 to 3.1, with

8.2 Positioning of Specimens—Position the specimens in

the exception that the pH of the collected fog will be within the specified

limits. Adjustment of the initial pH for makeup solution is based upon the the CASS test chamber during the test so that the following

requirements to maintain the required pH of the collected samples. If less

conditions are met:

than 1.3 or more than 1.6 mL of the glacial acetic acid are required per litre

8.2.1 Support or suspend the specimens 15 6 2° from the

of sodium chloride and copper solution to attain the specified pH, some

vertical and preferably parallel to the principal direction of

discrepancy in the system may be suspected (the purity of the water or

horizontal flow of fog through the chamber, based upon the

salt, or both; the accuracy of the pH meter; the general cleanliness of the

dominant surface being tested. Support or suspend automobile

system; etc.).

parts, however, so as to expose all significant surfaces at the

NOTE 4—The freshly prepared salt solution may be filtered or decanted

before it is placed in the reservoir, or the end of the tube leading from the general level of the condensate collectors. If the position on the

solution to the atomizer may be covered with a double layer of cheese

automobile is vertical, place the part in an incline position 15°

cloth to prevent plugging of the nozzle.

from vertical to allow surface wetting by the condensate. If the

position on the automobile is facing down, rotate the part

6. Air Supply

approximately 180° to test the significant surface. If there are

6.1 The compressed air supply to the nozzle or nozzles for

several significant surfaces at different angles, expose each

atomizing the test solution shall be free of oil and dirt (Note 5).

surface of one or more specimens.

Pressure shall be adequate to provide a specified condensate

8.2.2 Make sure the specimens do not come in contact with

rate. Pressure of 0.10 6 0.02 MPa has been found satisfactory

each other or any other metallic material or any material

(Note 6).

capable of acting as a wick.

8.2.3 Place each specimen so as to permit free settling of fog

NOTE 5—The air supply can be freed of oil and dirt by passing it

through a water scrubber or at least 60 cm of suitable cleaning material, on all specimens.

such as sheep’s wool, excelsior, slag wool, or activated alumina. Com-

8.2.4 Make sure the salt solution from one specimen does

mercial filters for compressed air may be used.

not drip on any other specimen.

NOTE 6—Atomizing nozzles may have a critical pressure, at which an

8.2.5 Place the specimens in the chamber just prior to

abnormal increase in the corrosiveness of the salt fog occurs. If the critical

bringing the test chamber to the required temperature and

pressure of a nozzle has not been determined with certainty, control of

turning on the air, since storage in an idle chamber overnight,

fluctuation in the air pressure within 60.0007 MPa by installing a pressure

or for other significant length of time, can affect test results.

regulator valve minimizes the possibility that the nozzle will be operated

at its critical pressure.

NOTE 7—Suitable materials for the construction or coating of racks and

supports are glass, rubber, plastic, or suitably coated wood. Bare metal

7. Test Specimens

should not be used. Specimens are preferably supported from the bottom

7.1 The type and number of test specimens to be used, as

or the side. Slotted wooden strips are suitable for the support of flat panels.

well as the criteria for the evaluation of the test results, shall be

Suspension from glass hooks or waxed string may be used as long as the

defined in the specifications covering the material or product specified position of the specimens is obtained. If necessary, such

suspension may be made by means of secondary support at the bottom of

being tested or shall be mutually agreed upon between the

the specimens.

purchaser and the supplier.

8.3 Conditions in the Salt-Spray Chamber—Maintain the

8. Procedure

exposure zone of the CASS test chamber at a temperature of

8.1 Preparation of Test Specimens—Clean metallic and 496 1°C during the exposure period (Note 8). After closing the

metallic coated specimens. Unless otherwise agreed upon, test chamber, bring the temperature to 49°C before the fog is

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 368

turned on. The test duration shall commence when the tem- the spray can impinge directly on the test specimens.

perature is 49 6 1°C and fog is present in the chamber. Heat

8.4 Continuity of Test—Unless otherwise specified in the

the air supply by passing fine bubbles through heated distilled

specification covering the material or product being tested, the

or deionized water (see Specification D 1193, Type IV) so that

test shall be continuous for the duration of the entire test

the temperature of the air after expansion at the nozzle is 49 6

period. Continuous operation implies that the chamber be

1°C. Record the temperature within the exposure zone of the

closed and the spray operating continuously, except for the

closed cabinet (Note 9) twice a day at least 7 h apart (except

short daily interruptions necessary to inspect, rearrange, or

Saturdays, Sundays, and holidays, when the salt-spray test is

remove test specimens, to check and replenish the solution in

not interrupted for exposing, rearranging, or removing test

the reservoir, and to make necessary recordings as described in

specimens or to check and replenish the solution in the

8.3. Schedule operations so that these interruptions are held to

reservoir).

a minimum.

8.5 Period of Test—Designate the period of test by the

NOTE 8—This can be best accomplished by preheating the chamber to

specifications covering the material or product being tested or

49°C before starting solution atomization.

NOTE 9—A suitable method to record the temperature is by a thermom- as mutually agreed upon between the purchaser and the

eter that can be read from outside the closed cabinet. The recorded

supplier.

temperature must be obtained with the salt-spray chamber closed to avoid

a false low reading, because of wet-bulb effect when the chamber is open. NOTE 14—Typical exposure periods are: 6, 16, 22, 48, 96, 192, 240,

Automatic control of temperature in the chamber and a continuous record 504, and 720 h.

of temperature are desirable.

8.6 Cleaning Tested Specimens—Unless specified in the

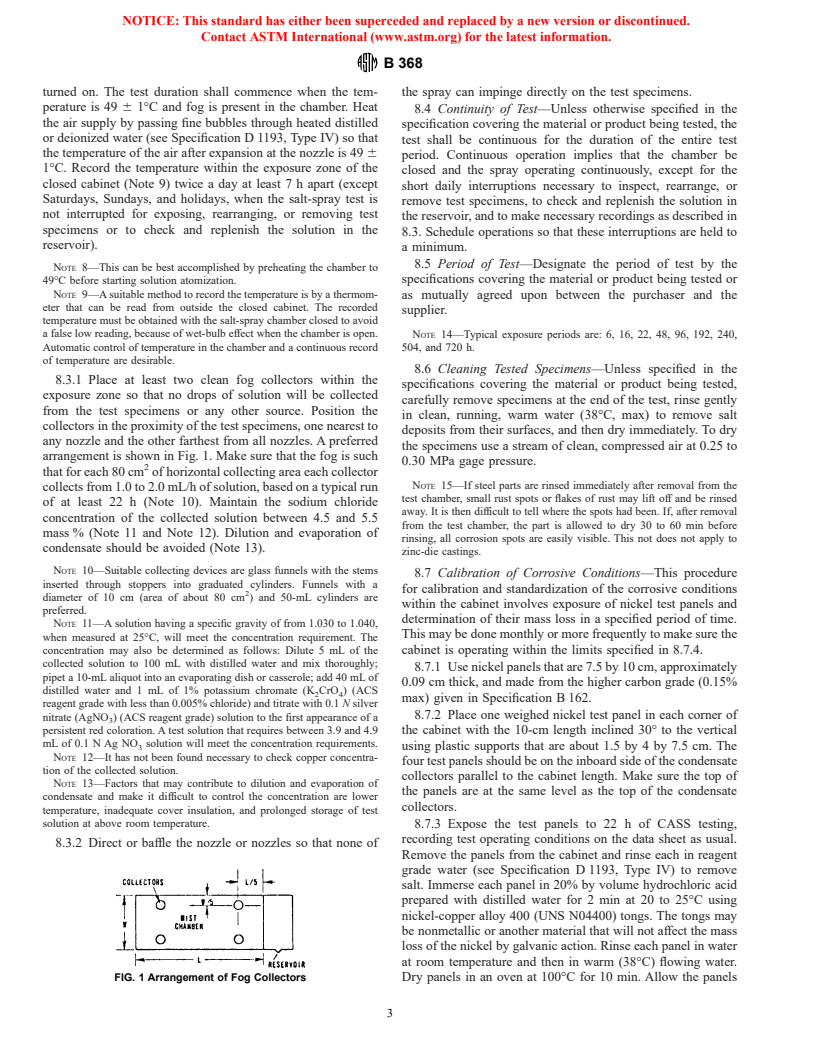

8.3.1 Place at least two clean fog collectors within the

specifications covering the material or product being tested,

exposure zone so that no drops of solution will be collected

carefully remove specimens at the end of the test, rinse gently

from the test specimens or any other source. Position the

in clean, running, warm water (38°C, max) to remove salt

collectors in the proximity of the test specimens, one nearest to

deposits from their surfaces, and then dry immediately. To dry

any nozzle and the other farthest from all nozzles. A preferred

the specimens use a stream of clean, compressed air at 0.25 to

arrangement is shown in Fig. 1. Make sure that the fog is such

0.30 MPa gage pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.