ASTM D3233-93(2003)

(Test Method)Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

Standard Test Methods for Measurement of Extreme Pressure Properties of Fluid Lubricants (Falex Pin and Vee Block Methods)

SCOPE

1.1 These test methods cover two procedures for making a preliminary evaluation of the load-carrying properties of fluid lubricants by means of the Falex Pin and Vee Block Test Machine.

Note 1—Additional information can be found in regarding coefficient of friction, load gage conversions, and load gage cablibration curve.

1.2 The values stated in SI units are to be regarded as standard. Because the equipment used in these test methods is available only in inch-pound units, the SI units are omitted when referring to the equipment and the test specimens.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3233–93 (Reapproved 2003)

Standard Test Methods for

Measurement of Extreme Pressure Properties of Fluid

1

Lubricants (Falex Pin and Vee Block Methods)

This standard is issued under the fixed designation D3233; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 direct load, n—that which is applied linearly, bisect-

ing the angle of the vee block corrected to either the 800 or

1.1 These test methods cover two procedures for making a

3000-lbf gage reference.

preliminary evaluation of the load-carrying properties of fluid

3.1.2.1 Discussion—This load is equivalent to the true load

lubricants by means of the Falex Pin and Vee Block Test

times the cos 42°.

Machine.

3.1.3 true load, n—the sum of the applied forces normal to

NOTE 1—Additional information can be found inAppendix X1 regard-

the tangents of contact between the faces of one vee block and

ing coefficient of friction, load gage conversions, and load gage cablibra-

the journal pin corrected to the 4500 lbf gage reference line.

tion curve.

3.1.4 true load failure value, n—the true load at which the

1.2 The values stated in SI units are to be regarded as

lubricanttestedcannolongersupporttheappliedloadresulting

standard. Because the equipment used in these test methods is

in either test pin or shear pin breakage, or inability to maintain

available only in inch-pound units, the SI units are omitted

or increase load.

when referring to the equipment and the test specimens.

3.1.4.1 Discussion—This value is also referred to as the

1.3 This standard does not purport to address all of the

limit of extreme pressure.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4. Summary of Test Methods

priate safety and health practices and determine the applica-

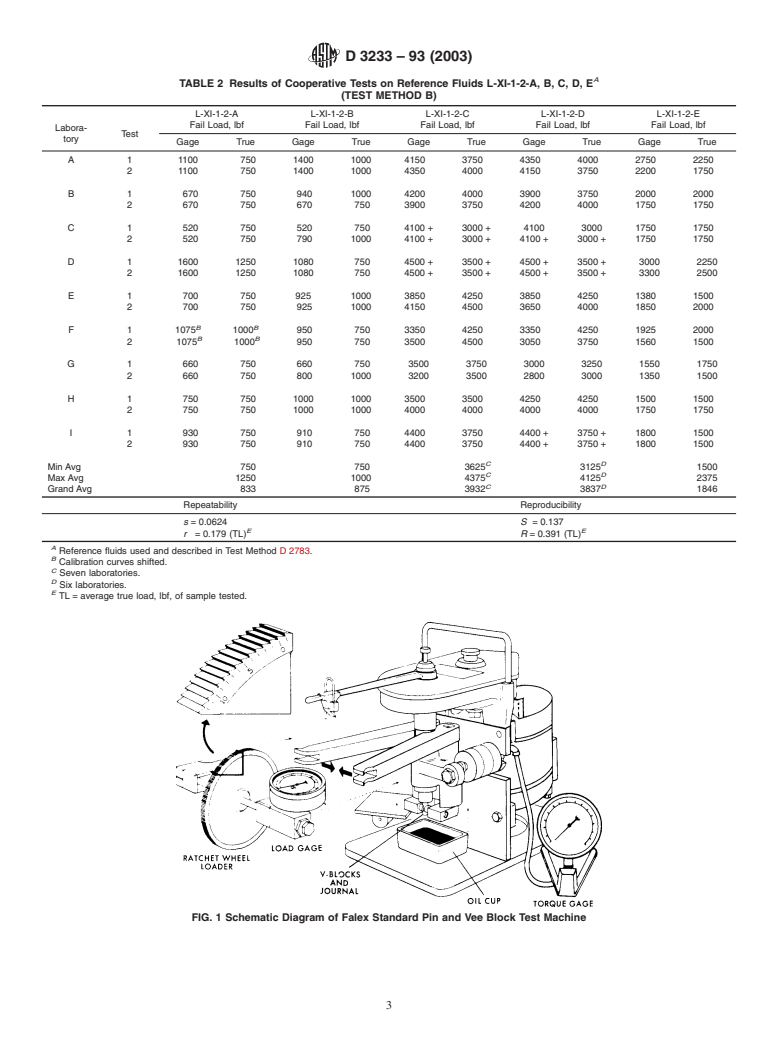

4.1 Both test methods consist of running a rotating steel

bility of regulatory limitations prior to use.

journal at 290 6 10 rpm against two stationary V-blocks

immersed in the lubricant sample. Load is applied to the

2. Referenced Documents

V-blocks by a ratchet mechanism. In Test MethodA(Note 1),

2.1 ASTM Standards:

increasing load is applied continuously. In Test Method B

B16/B16M SpecificationforFree-CuttingBrass,Rod,Bar

(Note 1), load is applied in 250-lbf (1112-N) increments with

2

and Shapes for Use in Screw Machines

load maintained constant for 1 min at each load increment. In

D2670 Test Method for Measuring Wear Properties of

both methods the load-fail value obtained is the criteria for

3

Fluid Lubricants (Falex Pen and Vee Block Method)

level of load-carrying properties. Both methods require cali-

D2783 Test Method for Measurement of Extreme-Pressure

bration of the load gage and reporting of test results as true

3

Properties of Lubricating Fluids (Four-Ball Method)

(corrected) loads rather than actual gage loads.

3. Terminology NOTE 2—Test Method A is referred to as the Falex Run-Up Test. Test

Method B is referred to as the Falex One-Minute Step Test.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 actual gage load, n—thevalueobtainedfromthegage

5. Significance and Use

while running the test and before any corrections are made.

5.1 Evaluations by both test methods differentiate between

3.1.1.1 Discussion—This gage reading is irrespective of the

fluidshavinglow,medium,andhighlevelsofextreme-pressure

particular gage used, and corrections are made by comparison

properties. The user should establish any correlation between

to a standard reference.

results by either method and service performance.

NOTE 3—Relative ratings by both test methods on the reference fluids

1

These test methods are under the jurisdiction of ASTM Committee D02 on

covered in Table 1 and Table 2 are in good general agreement with

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.L0 on Industrial Lubricants.

Current edition approvedAug. 10, 2003. Published September 2003. Originally

approved in 1986. Last previous edition approved in 1998 as D3233–93(1998).

2

Annual Book of ASTM Standards, Vol 02.01.

3

Annual Book of ASTM Standards, Vol 05.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

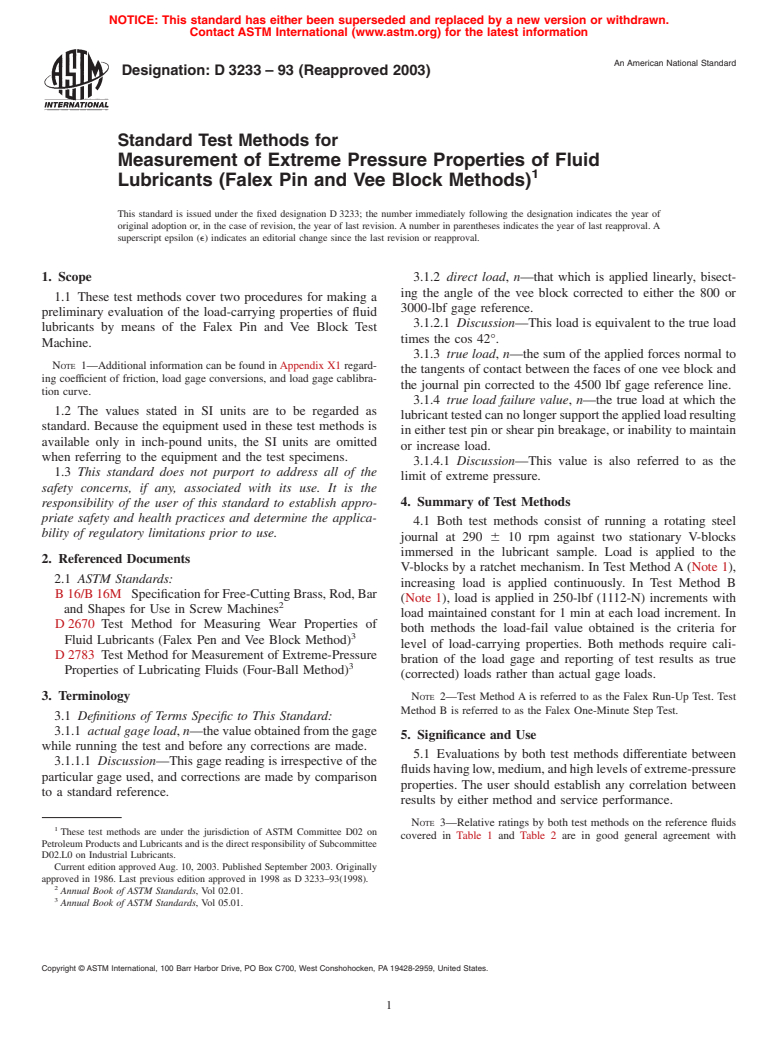

D3233–93 (2003)

A

TABLE 1 Results of Cooperative Tests on Reference Fluids L-XI-1-2-A, B, C, D, E

(TEST METHOD A)

L-XI-1-2-A L-XI-1-2-B L-XI-1-2-C L-XI-1-2-D L-XI-1-2-E

Labora-

Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf Fail Load, lbf

Test

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.