ASTM D3576-04

(Test Method)Standard Test Method for Cell Size of Rigid Cellular Plastics

Standard Test Method for Cell Size of Rigid Cellular Plastics

SIGNIFICANCE AND USE

Several physical properties of rigid cellular plastics are dependent on cell size and cell orientation. Measuring water absorption and open-cell content in accordance with Test Method D 2842 and Test Method D 2856 requires knowledge of surface cell volume, which uses cell size values in the calculations.

This test method provides an apparent cell size because it assumes that there is no measurable edge to edge or top to bottom variation in average cell size and that the cell size distribution about the average cell size is normal. If the analyst is concerned there may be significant variation in either the average cell size or the cell size distribution more detailed analysis may be required.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or a combination thereof, covered in the materials specification shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This test method covers the determination of the apparent cell size of rigid cellular plastics by counting the number of cell-wall intersections in a specified distance.

1.2 Procedure A requires the preparation of a thin slice, not more than one half the average cell diameter in thickness, that is mechanically stable. For most rigid cellular plastics this limits the test method to materials with an average cell size of at least 0.2 mm.

1.3 Procedure B is intended for use with materials whose friable nature makes it difficult to obtain a thin slice for viewing.

1.4 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The annex to ISO 2896 is technically equivalent to this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3576–04

Standard Test Method for

1

Cell Size of Rigid Cellular Plastics

This standard is issued under the fixed designation D3576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 ISO Standard:

ISO 2896 Cellular Plastics, Rigid—Determination of Water

1.1 This test method covers the determination of the appar-

4

Absorption

entcellsizeofrigidcellularplasticsbycountingthenumberof

cell-wall intersections in a specified distance.

3. Terminology

1.2 ProcedureArequires the preparation of a thin slice, not

3.1 Definitions:

more than one half the average cell diameter in thickness, that

3.1.1 Definitions of terms applicable to this test method are

is mechanically stable. For most rigid cellular plastics this

given in Terminology D883.

limits the test method to materials with an average cell size of

at least 0.2 mm.

4. Summary of Test Method

1.3 Procedure B is intended for use with materials whose

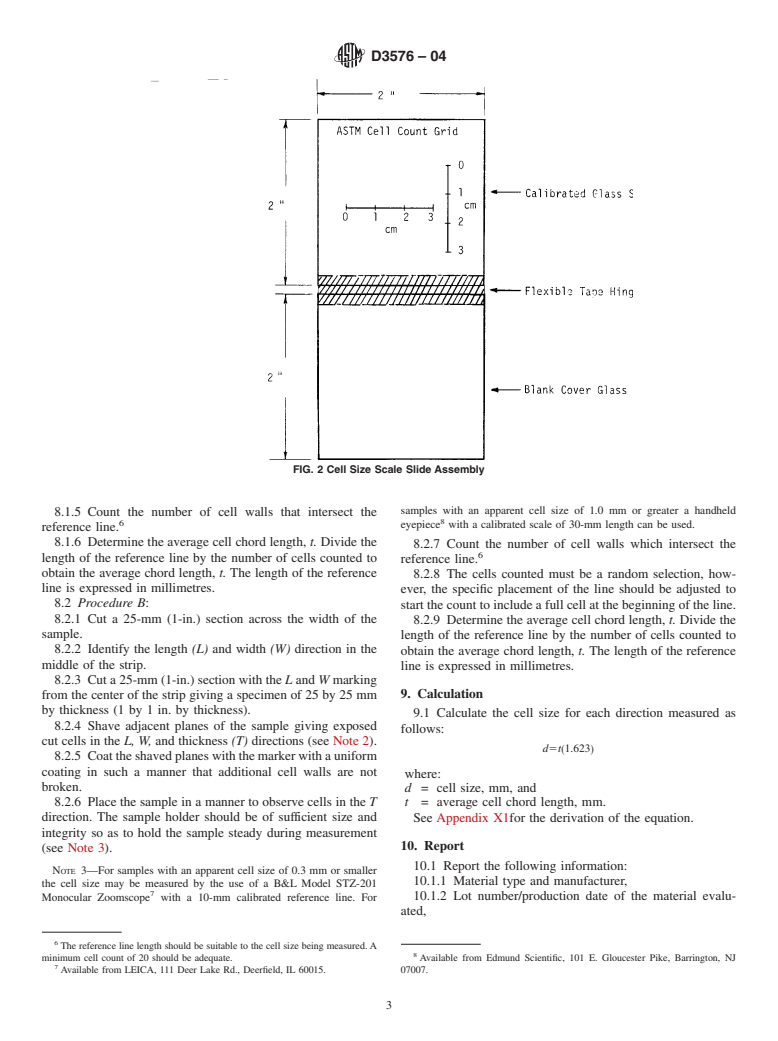

4.1 Procedure A— The cellular plastic specimen is cut to

friable nature makes it difficult to obtain a thin slice for

not more than one half the average cell diameter in thickness

viewing.

on a slicer and the shadowgraph is projected on a screen by the

1.4 The values stated in SI units are to be regarded as

use of a cell-size scale slide assembly and a projector. The

standard. The values given in parentheses are for information

average chord length is obtained by counting the cells on

only.

cell-wall intersections and converting this value to average cell

1.5 This standard does not purport to address all of the

size by mathematical derivation.

safety concerns, if any, associated with its use. It is the

4.2 Procedure B—The cellular plastic specimen is sliced to

responsibility of the user of this standard to establish appro-

provide a smooth surface. The cell walls are accented by the

priate safety and health practices and determine the applica-

use of a marking pen. The average chord length is obtained by

bility of regulatory limitations prior to use.

countingthecellwallintersectionsandconvertingthisvalueto

NOTE 1—The annex to ISO 2896 is technically equivalent to this test

average cell size by mathematical derivation.

method.

5. Significance and Use

2. Referenced Documents

5.1 Several physical properties of rigid cellular plastics are

2

2.1 ASTM Standards:

dependent on cell size and cell orientation. Measuring water

D883 Terminology Relating to Plastics

absorption and open-cell content in accordance with Test

D2842 Test Method for WaterAbsorption of Rigid Cellular

Method D2842 andTest Method D2856 requires knowledge of

Plastics

surface cell volume, which uses cell size values in the

D2856 Test Method for Open-Cell Content of Rigid Cellu-

calculations.

3

lar Plastics by the Air Pycnometer

5.2 This test method provides an apparent cell size because

E691 Practice for Conducting an Interlaboratory Study to

it assumes that there is no measurable edge to edge or top to

Determine the Precision of a Test Method

bottom variation in average cell size and that the cell size

distribution about the average cell size is normal. If the analyst

1

is concerned there may be significant variation in either the

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

average cell size or the cell size distribution more detailed

Plastics and Elastomers.

analysis may be required.

CurrenteditionapprovedJuly1,2004.PublishedJuly2004.Originallyapproved

5.3 Before proceeding with this test method, reference

in 1977. Last previous edition approved in 1998 as D3576 - 98. DOI: 10.1520/

D3576-04. shouldbemadetothespecificationofthematerialbeingtested.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Any test specimen preparation, conditioning, dimensions, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Withdrawn. The last approved version of this historical standard is referenced Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

on www.astm.org. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3576–04

FIG. 1 Razor Blade Cell Size Specimen Slicer

testing parameters, or a combination thereof, covered in the 7. Sampling

materials

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.