ASTM D7972-14(2020)

(Test Method)Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

SIGNIFICANCE AND USE

4.1 This test method provides a framework for material development, quality control, characterization, and design data generation purposes. The user needs to assess the applicability of the method on the specific material and for the intended use, as shown by the interlaboratory study.

4.2 This test method determines the maximum loading on a graphite specimen with simple beam geometry in three–point bending, and it provides a means for the calculation of flexural strength at ambient temperature and environmental conditions.

4.3 The flexure stress is computed based on simple beam theory with assumptions that the material is isotropic and homogeneous, the moduli of elasticity in tension and compression are identical, and the material is linearly elastic. For materials with large grains, the minimum specimen dimension should be significantly larger than the maximum grain size (see Guide D7775).

4.4 Flexural strength of a group of test specimens is influenced by several parameters associated with the test procedure. Such factors include the loading rate, test environment, specimen size, specimen preparation, and test fixtures. Specimen sizes and fixtures should be chosen to reduce errors due to material variability or testing parameters, such as friction and non-parallelism of specimen surfaces.

4.5 The flexural strength of a manufactured graphite or carbon material is dependent on both its inherent resistance to fracture and the size and severity of flaws. Variations in these cause a natural scatter in test results for a sample of test specimens. Fractographic analysis of fracture surfaces, although beyond the scope of this standard, is highly recommended for all purposes, especially if the data will be used for design as discussed in Practices C1239 and C1322.

4.6 The three-point test configuration exposes only a very small portion of the specimen to the maximum stress. Therefore, three-point flexural strengths are likely to be much greater than four-po...

SCOPE

1.1 This test method covers determination of the flexural strength of manufactured carbon and graphite articles using a square, rectangular or cylindrical beam in three-point loading at room temperature.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7972 −14 (Reapproved 2020)

Standard Test Method for

Flexural Strength of Manufactured Carbon and Graphite

Articles Using Three-Point Loading at Room Temperature

This standard is issued under the fixed designation D7972; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Fracture Origins in Advanced Ceramics

D7775 Guide for Measurements on Small Graphite Speci-

1.1 This test method covers determination of the flexural

mens

strength of manufactured carbon and graphite articles using a

E4 Practices for Force Verification of Testing Machines

square, rectangular or cylindrical beam in three-point loading

E691 Practice for Conducting an Interlaboratory Study to

at room temperature.

Determine the Precision of a Test Method

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 flexural strength, n—a measure of the ultimate load

safety concerns, if any, associated with its use. It is the

carrying capacity of a specified beam in bending.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.1.2 grain, n—in manufactured (synthetic) carbon and

graphite, particle of filler material (usually coke or graphite) in

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor- the starting mix formulation. Also referred to as granular

material, filler particle, or aggregate material.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 This test method provides a framework for material

Barriers to Trade (TBT) Committee.

development, quality control, characterization, and design data

generation purposes. The user needs to assess the applicability

2. Referenced Documents

of the method on the specific material and for the intended use,

2.1 ASTM Standards:

as shown by the interlaboratory study.

C78 Test Method for Flexural Strength of Concrete (Using

4.2 This test method determines the maximum loading on a

Simple Beam with Third-Point Loading)

graphite specimen with simple beam geometry in three–point

C559 Test Method for Bulk Density by Physical Measure-

bending, and it provides a means for the calculation of flexural

ments of Manufactured Carbon and Graphite Articles

strength at ambient temperature and environmental conditions.

C1161 Test Method for Flexural Strength of Advanced

Ceramics at Ambient Temperature

4.3 The flexure stress is computed based on simple beam

C1239 Practice for Reporting Uniaxial Strength Data and

theory with assumptions that the material is isotropic and

Estimating Weibull Distribution Parameters forAdvanced

homogeneous, the moduli of elasticity in tension and compres-

Ceramics

sion are identical, and the material is linearly elastic. For

C1322 Practice for Fractography and Characterization of

materials with large grains, the minimum specimen dimension

shouldbesignificantlylargerthanthemaximumgrainsize(see

Guide D7775).

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

4.4 Flexural strength of a group of test specimens is

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products.

influenced by several parameters associated with the test

Current edition approved May 1, 2020. Published June 2020. Originally

procedure. Such factors include the loading rate, test

approved in 2014. Last previous edition approved in 2014 as D7972 – 14. DOI:

10.1520/D7972-14R20.

environment, specimen size, specimen preparation, and test

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fixtures. Specimen sizes and fixtures should be chosen to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

reduce errors due to material variability or testing parameters,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. such as friction and non-parallelism of specimen surfaces.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D7972 − 14 (2020)

TABLE 1 Specimen Sizes and Testing Configurations in the

4.5 The flexural strength of a manufactured graphite or

Interlaboratory Study

carbon material is dependent on both its inherent resistance to

Nominal Crosshead

fracture and the size and severity of flaws. Variations in these

Specimen Support

Specimen Speed,

Configuration Thickness, d Span, L

cause a natural scatter in test results for a sample of test

Size mm/s

(mm) (mm)

specimens. Fractographic analysis of fracture surfaces, al-

(mm) (mm/m)

though beyond the scope of this standard, is highly recom- I 10×10× 10 50.00 0.0042 (0.25)

mended for all purposes, especially if the data will be used for

II 9.5 × 4.8 × 4.8 50.00 0.0087 (0.52)

design as discussed in Practices C1239 and C1322.

III Ø10 × 64 10 50.00 0.0042 (0.25)

4.6 The three-point test configuration exposes only a very

IV 25×25× 25 100.00 0.0067 (0.40)

small portion of the specimen to the maximum stress.

V Ø25 × 150 25 100.00 0.0067 (0.40)

Therefore, three-point flexural strengths are likely to be much

greater than four-point flexural strengths. Three-point flexure

has some advantages. It uses simpler test fixtures, allowing

small specimen testing and fracture toughness measurements.

5.3.2 Fully-articulated Three-point Fixture—Specimens

However, four-point flexure is preferred and recommended for

that do not meet the parallelism requirements of 6.1 shall be

most characterization purposes.

tested in a fully-articulated fixture. Well-machined specimens

may also be tested in a fully-articulating fixture. The two

5. Apparatus

support (outer) bearings shall be free to roll outwards. The

middle bearing shall not roll.Any two of the bearings shall be

5.1 Loading—Specimens may be loaded in any suitable

capable of articulating to match the specimen surface.All three

testing machine provided that uniform rates of loading can be

bearings shall rest uniformly and evenly across the specimen

maintained. The testing machine shall be equipped with a

surface.The fixture shall be designed to apply equal load to the

means for retaining read-out of the maximum force applied to

two outer bearings.

the specimen. The accuracy of the testing machine shall be in

accordance with Practice E4.

6. Test Specimen

5.2 Fixture—The three-point loading fixture shall consist of

6.1 Specimen Size—The size and geometry of the test

bearing blocks or cylindrical bearings spaced in a three-point

specimensusedinthisinterlaboratorystudyareshowninTable

loading configuration (see Test Method C1161). A hardened

1. It is recommended that the size of the test specimen is

steel bearing block or its equivalent is necessary to prevent

selected such that the minimum dimension of the specimen is

distortion of the loading member.

greater than 5 times the largest particle dimension. It is

5.2.1 Thefixtureshallensurethatforcesappliedtothebeam

recommended that the test specimen has a length to thickness/

are normal only and without eccentricity through the use of

diameter ratio of at least 6, and a width to thickness ratio not

spherical bearing blocks (see Test Method C78) or articulating

greater than 2.

roller bearing assemblies (see 5.3 and Test Method C1161).

6.1.1 For test specimens that do not meet this ratio for

5.2.2 The cylindrical bearing length shall be such that the 3

strength testing, see Ref (1) and Guide D7775.

test specimen width is fully supported, and the cylindrical

6.2 Preparation—The test specimen shall be prepared to

bearing diameter shall be 0.75 to 1.5 times the specimen

yield a parallelepiped of square or rectangular cross section or

thickness/diameter.

a cylinder. The faces of the parallelepiped specimens shall be

5.2.3 The lower support bearings shall be free to rotate in

parallelandflatwithin0.025 mm⁄mm.Inaddition,thesamples

order to relieve frictional constraints. The middle load bearing

having a maximum particle size less than 0.15 mm in diameter

of the three-point fixture need not rotate. The three bearings

must be finished so that the surface roughness is less than 3 µm

shall be parallel over their length. The load application bearing

Ra. Sample edges should be free from visible flaws and chips.

(upper bearing) shall be centered with respect to the two lower

NOTE 1—For ease of machining to conventional standards, 3 µm Ra is

support bearings within 60.10 mm.

equivalent to 125 µin. AA. For finishing of specimens with maximum

particle sizes of greater than 0.150 mm, grain structure and porosity can

5.3 Thedirectionsofloadsandreactionsmaybemaintained

limit the accurate measurement of roughness. In these cases, the surface

parallel by judicious use of linkages, rocker bearings, and

roughness should be visually equivalent to 3 µm Ra as estimated based on

flexure plates. Eccentricity of loading can be avoided by the

the visible surface of the graphite.

use of spherical bearing blocks or articulating roller bearings.

NOTE 2—Surface preparation of test specimens can introduce machin-

ing microcracks which may have a pronounced effect on flexural strength.

5.3.1 Semi-articulated Three-point Fixture—Specimenspre-

Machining damage imposed during specimen preparation can be either a

pared in accordance with the parallelism requirements of 6.1

random interfering factor, or an inherent part of the strength characteristic

may be tested in a semi-articulated fixture. The middle bearing

to be measured. With proper care and good machining practice, it is

shall be fixed and not free to roll. The two outer bearings shall

possible to obtain fractures during strength testing from the material’s

be parallel to each other over their length. The two outer natural flaws. Surface preparation can also lead to residual stresses.

Universal or standardized test methods of surface preparation do not exist.

bearings shall articulate together as a pair to match the

It should be understood that final machining steps may or may not negate

specimen surface, or the middle bearing shall articulate to

match the specimen surface. All three bearings shall rest

uniformly and evenly across the specimen surface. The fixture

The boldface numbers in parentheses refer to the list of references at the end of

shall be designed to apply equal load to the two outer bearings. this standard.

D7972 − 14 (2020)

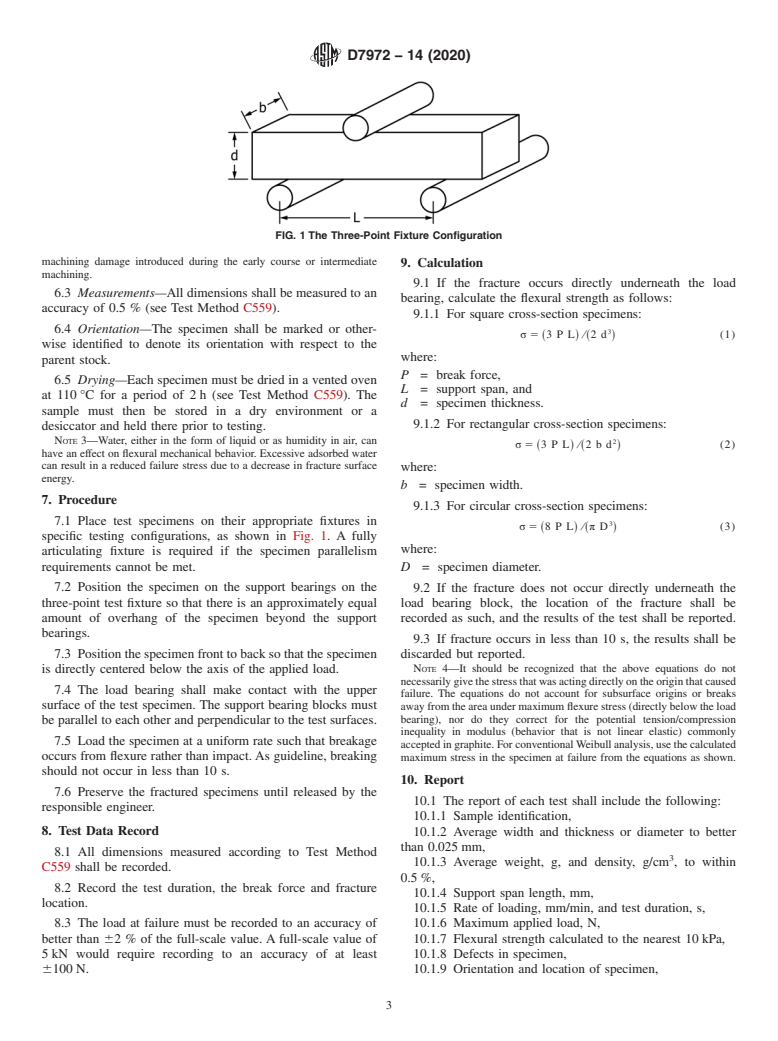

FIG. 1 The Three-Point Fixture Configuration

machining damage introduced during the early course or intermediate

9. Calculation

machining.

9.1 If the fracture occurs directly underneath the load

6.3 Measurements—All dimensions shall be measured to an

bearing, calculate the flexural strength as follows:

accuracy of 0.5 % (see Test Method C559).

9.1.1 For square cross-section specimens:

6.4 Orientation—The specimen shall be marked or other- 3

σ 5 3PL ⁄ 2d (1)

~ ! ~ !

wise identified to denote its orientation with respect to the

where:

parent stock.

P = break force,

6.5 Drying—Each specimen must be dried in a vented oven

L = support span, and

at 110 °C for a period of 2 h (see Test Method C559). The

d = specimen thickness.

sample must then be stored in a dry environment or a

9.1.2 For rectangular cross-section specimens:

desiccator and held there prior to testing.

NOTE 3—Water, either in the form of liquid or as humidity in air, can 2

σ 5 3PL ⁄ 2bd (2)

~ ! ~ !

have an effect on flexural mechanical behavior. Excessive adsorbed water

can result in a reduced failure stress due to a decrease in fracture surface

where:

energy.

b = specimen width.

7. Procedure

9.1.3 For circular cross-section specimens:

7.1 Place test specimens on their appropriate fixtures in

σ 5 ~8PL! ⁄~π D ! (3)

specific testing configurations, as shown in Fig. 1. A fully

where:

articulating fixture is required if the specimen parallelism

requirements cannot be met. D = specimen diameter.

7.2 Position the specimen on the support bearings on the 9.2 If the fracture does not occur directly underneath the

three-point test fixture so that there is an approximately equal load bearing block, the location of the fracture shall be

amount of overhang of the specimen beyond the support

recorded as such, and the results of the test shall be reported.

bearings.

9.3 If fracture occurs in less than 10 s, the results shall be

7.3 Position the specimen front to back so that the specimen

discarded but reported.

NOTE 4—It should be recognized that the above equations do not

is directly centered below the axis of the applied load.

necessarilygivethestressthatwasactingdirectlyontheoriginthatcaused

7.4 The load bearing shall make contact with the upper

failure. The equations do not account for subsurface origins or breaks

surface of the test specimen. The support bearing blocks must

awayfromtheareaundermaximumflexurestress(directlybelowtheload

bearing), nor do they correct for the potential tension/compression

be parallel to each other and perpendicular to the test surfaces.

inequality in modulus (behavior that is not linear elastic) commonly

7.5 Load the specimen at a uniform rate such that breakage

acceptedingraphite.ForconventionalWeibullanalysis,usethecalculated

occurs from flexure rather than impact.As guideline, breaking

maximum stress in the specimen at failure from the equations as shown.

should not occur in less than 10 s.

10. Report

7.6 Preserve the fractured specimens until released by the

10.1 The report of each test shall include the following:

responsible engineer.

10.1.1 Sample identification,

8. Test Data Record

10.1.2 Average width and thickness or diameter to better

than 0.025 mm,

8.1 All dimensions measured according to Test Method

10.1.3 Average weight, g, and density, g/cm , to within

C559 shall be recorded.

0.5 %,

8.2 Record the test duration, the break force and fracture

10.1.4 Support span length, mm,

location.

10.1.5 Rate of loading, mm/min, and test duration, s,

8.3 The load at failure must be recorded to an accuracy of 10.1.6 Maximum applied load, N,

better than 62 %

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.