ASTM E1797-12

(Specification)Standard Specification for Reinforced Liquid Coating Encapsulation Products for Leaded Paint in Buildings

Standard Specification for Reinforced Liquid Coating Encapsulation Products for Leaded Paint in Buildings

ABSTRACT

This specification covers minimum material performance requirements and laboratory test procedures for reinforced liquid coating encapsulation products (single- or multiple-coat systems) for leaded paint in buildings. It applies to any liquid-applied product incorporating reinforcement materials as part of the system. Reinforcement materials are continuous fabric or mesh and are applied in the field. These materials are typically applied between a base and top coat. These products are used to encapsulate a leaded paint surface with the intent of reducing human exposure to lead in paint. These are classified into three types which are Type I which are encapsulation products are intended for interior use, Type II which are encapsulation products intended for exterior use, and Type III which defines encapsulation products intended for either interior or exterior use. Different tests shall be conducted in order to determine the following performance properties for reinforced liquid coating encapsulation products such as impact resistance, adhesion, dry abrasion resistance, water vapor transmission, water resistance, chemical resistance, surface burning characteristics, volatile organic compound content, weathering, aging, scrub resistance, mildew resistance, paint ability and repairability. Testing conducted shall be performed on the entire encapsulation product system, whether single or multiple coat, as applied in the field, except for scrub resistance, volatile organic compound (VOC) content, and permeability, which are performed on the top coat only.

SCOPE

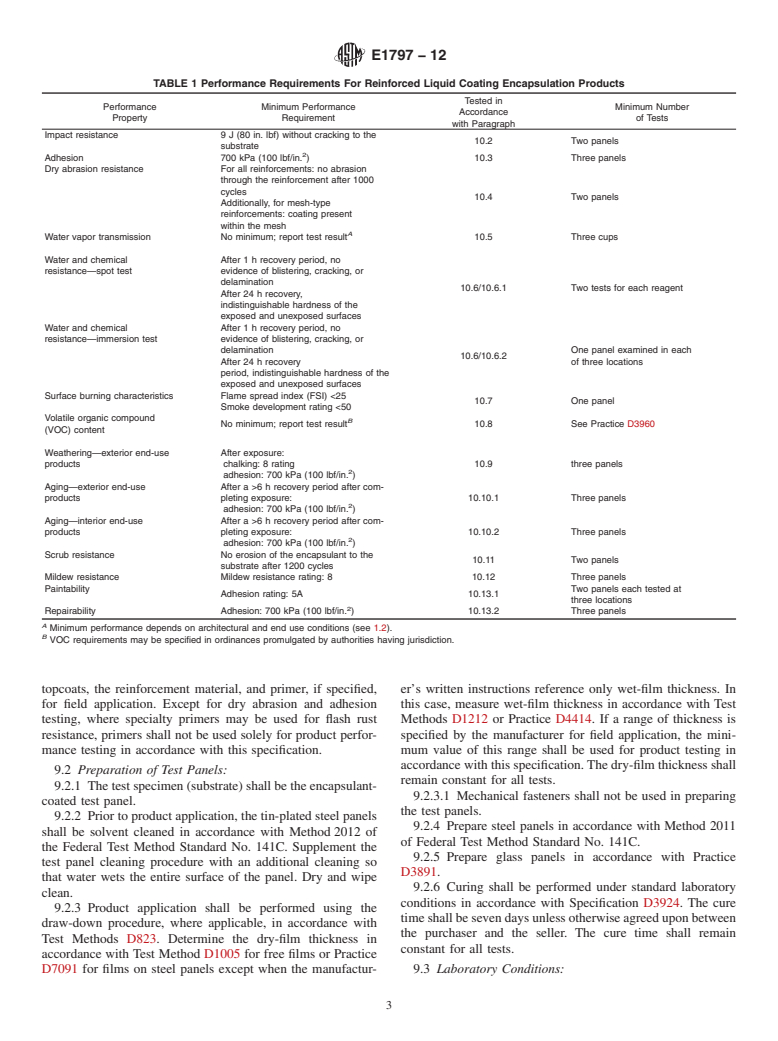

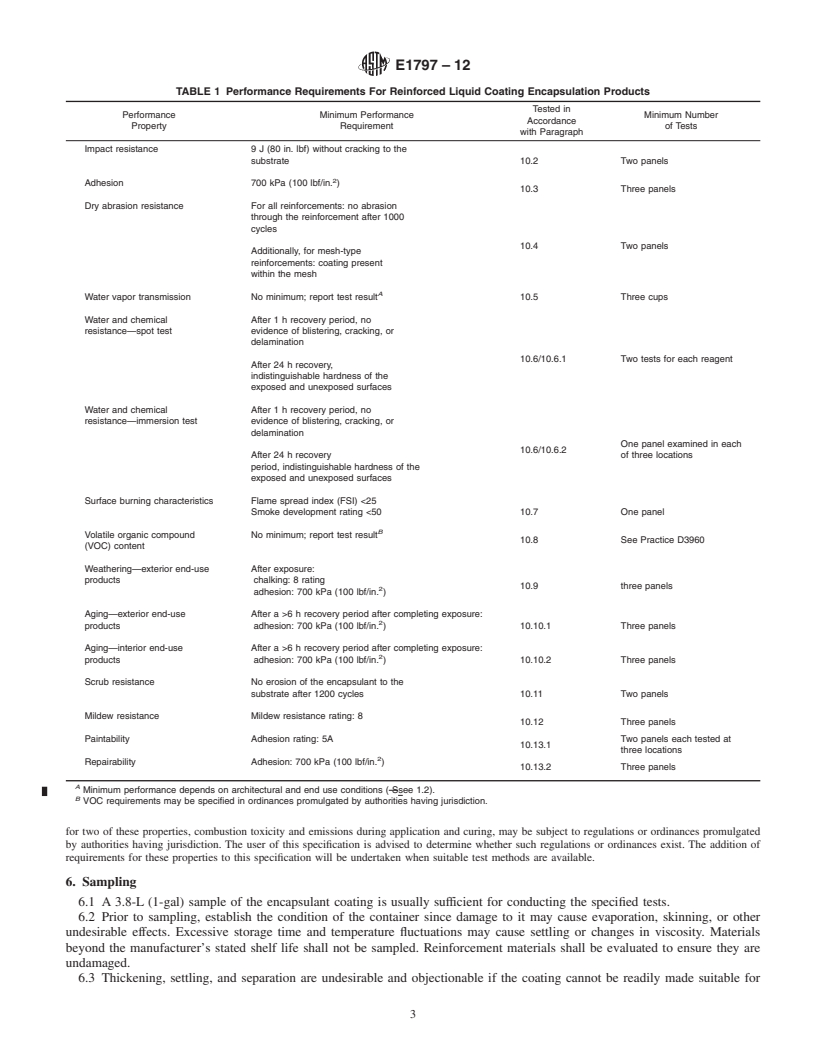

1.1 This specification covers minimum material performance requirements and laboratory test procedures for reinforced liquid coating encapsulation products (single- or multiple-coat systems) for leaded paint in buildings. Performance properties addressed in this specification are:

1.1.1 Impact Resistance,

1.1.2 Adhesion,

1.1.3 Dry Abrasion Resistance,

1.1.4 Water Vapor Transmission,

1.1.5 Water and Chemical Resistance,

1.1.6 Surface Burning Characteristics,

1.1.7 Volatile Organic Compound (VOC) Content,

1.1.8 Weathering,

1.1.9 Aging,

1.1.10 Scrub Resistance,

1.1.11 Mildew Resistance,

1.1.12 Paintability/Repairability,

1.2 This specification does not address the selection of an encapsulation product for specific use conditions. Specific use conditions may require performance values other than those stated in this specification. See Guide E1796 for guidance.

1.3 This specification complements Specification E1795 for non-reinforced liquid coating encapsulation products.

1.4 This specification does not cover the use of encapsulation products on industrial steel structures nor residential exterior coated metal surfaces because no corrosion control requirements are included.

1.5 This specification applies to any liquid-applied product incorporating reinforcement materials as part of the system. Reinforcement materials are continuous fabric or mesh and are applied in the field. These materials are typically applied between a base and top coat. These products are used to encapsulate a leaded paint surface with the intent of reducing human exposure to lead in paint.

1.6 The results of the test methods included in this specification will not necessarily predict field performance.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1797 −12

Standard Specification for

Reinforced Liquid Coating Encapsulation Products for

1

Leaded Paint in Buildings

This standard is issued under the fixed designation E1797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The results of the test methods included in this specifi-

cation will not necessarily predict field performance.

1.1 This specification covers minimum material perfor-

mance requirements and laboratory test procedures for rein- 1.7 The values stated in SI units are to be regarded as the

forced liquid coating encapsulation products (single- or standard. The values given in parentheses are for information

multiple-coat systems) for leaded paint in buildings. Perfor- only.

mance properties addressed in this specification are:

1.8 This standard does not purport to address all of the

1.1.1 Impact Resistance,

safety concerns, if any, associated with its use. It is the

1.1.2 Adhesion,

responsibility of the user of this standard to establish appro-

1.1.3 Dry Abrasion Resistance,

priate safety and health practices and determine the applica-

1.1.4 Water Vapor Transmission,

bility of regulatory limitations prior to use.

1.1.5 Water and Chemical Resistance,

1.1.6 Surface Burning Characteristics,

2. Referenced Documents

1.1.7 Volatile Organic Compound (VOC) Content,

2

2.1 ASTM Standards:

1.1.8 Weathering,

D16TerminologyforPaint,RelatedCoatings,Materials,and

1.1.9 Aging,

Applications

1.1.10 Scrub Resistance,

D823Practices for Producing Films of Uniform Thickness

1.1.11 Mildew Resistance,

of Paint, Varnish, and Related Products on Test Panels

1.1.12 Paintability/Repairability,

D1005Test Method for Measurement of Dry-Film Thick-

1.2 This specification does not address the selection of an

ness of Organic Coatings Using Micrometers

encapsulation product for specific use conditions. Specific use

D1212Test Methods for Measurement of Wet Film Thick-

conditions may require performance values other than those

ness of Organic Coatings

stated in this specification. See Guide E1796 for guidance.

D1308Test Method for Effect of Household Chemicals on

Clear and Pigmented Organic Finishes

1.3 This specification complements Specification E1795 for

D1475Test Method For Density of Liquid Coatings, Inks,

non-reinforced liquid coating encapsulation products.

and Related Products

1.4 This specification does not cover the use of encapsula-

D1653Test Methods for Water Vapor Transmission of Or-

tion products on industrial steel structures nor residential

ganic Coating Films

exterior coated metal surfaces because no corrosion control

D2486Test Methods for Scrub Resistance of Wall Paints

requirements are included.

D2794Test Method for Resistance of Organic Coatings to

1.5 This specification applies to any liquid-applied product

the Effects of Rapid Deformation (Impact)

incorporating reinforcement materials as part of the system. D3273TestMethodforResistancetoGrowthofMoldonthe

Reinforcementmaterialsarecontinuousfabricormeshandare

Surface of Interior Coatings in an Environmental Cham-

applied in the field. These materials are typically applied ber

between a base and top coat. These products are used to

D3274Test Method for Evaluating Degree of Surface Dis-

encapsulate a leaded paint surface with the intent of reducing figurement of Paint Films by Fungal or Algal Growth, or

human exposure to lead in paint.

Soil and Dirt Accumulation

D3359Test Methods for Measuring Adhesion by Tape Test

1

This specification is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.23

2

on Lead Hazards Associated with Buildings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 15, 2012. Published August 2012. Originally contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

approved in 1995. Last previous edition approved in 2004 as E1797–04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1797-12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1797−12

D3924Specification for Environment for Conditioning and 4.3 Type III: Either Exterior or Interior Use—Type III

Testing Paint, Varnish, Lacquer, and Related Materials defines encapsulation products intended for either interior or

D3925Practice for Sampling Liquid Paints and Related exterior use. These products shall meet all the requirements of

Pigmented Coatin

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1797–04 Designation: E1797 – 12

Standard Specification for

Reinforced Liquid Coating Encapsulation Products for

1

Leaded Paint in Buildings

This standard is issued under the fixed designation E1797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers minimum material performance requirements and laboratory test procedures for reinforced liquid

coating encapsulation products (single- or multiple-coat systems) for leaded paint in buildings. Performance properties addressed

in this specification are:

1.1.1 Impact Resistance,

1.1.2 Adhesion,

1.1.3 Dry Abrasion Resistance,

1.1.4 Water Vapor Transmission,

1.1.5 Water and Chemical Resistance,

1.1.6 Surface Burning Characteristics,

1.1.7 Volatile Organic Compound (VOC) Content,

1.1.8 Weathering,

1.1.9 Aging,

1.1.10 Scrub Resistance,

1.1.11 Mildew Resistance,

1.1.12 Paintability/Repairability,

1.2 This specification does not address the selection of an encapsulation product for specific use conditions. Specific use

conditions may require performance values other than those stated in this specification. See Guide E1796 for guidance.

1.3 This specification complements Specification E1795 for non-reinforced liquid coating encapsulation products.

1.4 This specification does not cover the use of encapsulation products on industrial steel structures nor residential exterior

coated metal surfaces because no corrosion control requirements are included.

1.5 This specification applies to any liquid-applied product incorporating reinforcement materials as part of the system.

Reinforcement materials are continuous fabric or mesh and are applied in the field.These materials are typically applied between

a base and top coat. These products are used to encapsulate a leaded paint surface with the intent of reducing human exposure to

lead in paint.

1.6 The results of the test methods included in this specification will not necessarily predict field performance.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D823 Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels

D1005 Test Method for Measurement of Dry-FilmThickness of Organic Coatings Using Micrometers D1186Test Methods for

Nondestructive

1

This specification is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.23 on Lead

Hazards Associated with Buildings.

CurrenteditionapprovedApril1,2004.PublishedApril2004.Originallyapprovedin1995.Lastpreviouseditionapprovedin2003asE1797–03.DOI:10.1520/E1797-04.

Current edition approved July 15, 2012. Published August 2012. Originally approved in 1995. Last previous edition approved in 2004 as E1797–04. DOI:

10.1520/E1797-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1797 – 12

Measurement of

Dry Film Thickness

of Nonmagnetic

Coatings Applied to

a Ferrous Base

D1212 Test Methods for Measurement of Wet Film Thickness of Organic Coatings

D1308 Test Method for Effect of Household Chemicals on Clear and Pigmented Organic Finishes

D1475 Test Method For Density of Liquid Coatings, Inks, and Related Products

D1653 Test Methods for Water Vapor Transmission of Organic Coating Films

D2486 Test Methods for Scrub Resistance of Wall Paints

D2794 Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact)

D3273 Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.