ASTM E340-00(2006)

(Test Method)Standard Test Method for Macroetching Metals and Alloys

Standard Test Method for Macroetching Metals and Alloys

SCOPE

1.1 These test procedures describe the methods of macro- etching metals and alloys to reveal their macrostructure.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.2, 7.1, 8.1.3, 8.2.1, 8.8.3, 8.10.1.1, and 8.13.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E340 − 00(Reapproved 2006)

Standard Test Method for

Macroetching Metals and Alloys

This standard is issued under the fixed designation E340; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope and ferrite banding, coring, inclusions, and depth of carburiza-

tion or decarburization. The information provided about varia-

1.1 These test procedures describe the methods of mac-

tions in chemical composition is strictly qualitative but the

roetching metals and alloys to reveal their macrostructure.

location of extremes in segregation will be shown. Chemical

1.2 The values stated in inch-pound units are to be regarded

analyses or other means of determining the chemical compo-

as the standard.The SI equivalents of inch-pound units may be

sition would have to be performed to determine the extent of

approximate.

variation. Macroetching will also show the presence of discon-

1.3 This standard does not purport to address all of the

tinuities and voids, such as seams, laps, porosity, flakes, bursts,

safety concerns, if any, associated with its use. It is the

extrusion rupture, cracks, etc.

responsibility of the user of this standard to establish appro-

3.1.3 Other applications of macroetching in the fabrication

priate safety and health practices and determine the applica-

of metals are the study of weld structure, definition of weld

bility of regulatory limitations prior to use. For specific

penetration, dilution of filler metal by base metals, entrapment

warning statements, see 6.2, 7.1, 8.1.3, 8.2.1, 8.8.3, 8.10.1.1,

of flux, porosity, and cracks in weld and heat affected zones,

and 8.13.2.

etc. It is also used in the heat-treating shop to determine

location of hard or soft spots, tong marks, quenching cracks,

2. Referenced Documents

case depth in shallow-hardening steels, case depth in carbur-

2.1 ASTM Standards:

ization of dies, effectiveness of stop-off coatings in

E3 Guide for Preparation of Metallographic Specimens

carburization, etc. In the machine shop, it can be used for the

E381 Method of Macroetch Testing Steel Bars, Billets,

determination of grinding cracks in tools and dies.

Blooms, and Forgings

3.1.4 Macroetchingisusedextensivelyforqualitycontrolin

3. Significance and Use

the steel industry, to determine the tone of a heat in billets with

respect to inclusions, segregation, and structure. Forge shops,

3.1 Applications of Macroetching:

in addition, use macroetching to reveal flow lines in setting up

3.1.1 Macroetching is used to reveal the heterogeneity of

the best forging practice, die design, and metal flow. For an

metals and alloys. Metallographic specimens and chemical

example of the use of macroetching in the steel forging

analyses will provide the necessary detailed information about

industry see Method E381. Forging shops and foundries also

specific localities but they cannot give data about variation

use macroetching to determine the presence of internal faults

from one place to another unless an inordinate number of

and surface defects.The copper industry uses macroetching for

specimens are taken.

control of surface porosity in wire bar. In the aluminum

3.1.2 Macroetching, on the other hand, will provide infor-

industry, macroetching is used to evaluate extrusions as well as

mation on variations in (1) structure, such as grain size, flow

the other products such as forgings, sheets, etc. Defects such as

lines, columnar structure, dendrites, etc.; (2) variations in

chemical composition as evidenced by segregation, carbide coring, cracks, and porthole die welds are identified.

4. Sampling

This test method is under the jurisdiction of ASTM Committee E04 on

MetallographyandisthedirectresponsibilityofSubcommitteeE04.01onSpecimen

4.1 As in any method of examination, sampling is very

Preparation.

important. When macroetching is used to solve a problem, the

Current edition approved Oct. 1, 2006. Published October 2006. Originally

ε1

problemitselflargelydictatesthesourceofthesampleastothe

approved in 1968. Last previous edition approved in 2000 as E340 – 00 . DOI:

10.1520/E0340-00R06.

location on the work piece and the stage of manufacture; for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

example, when looking for pipe, the sample should represent

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the top of the ingot, or when looking for bursts or flakes, the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sample should be taken as soon after hot working as possible.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E340 − 00 (2006)

4.2 When macroetching is used as an inspection procedure, 4.5.5 Machined and Ground Parts—When looking for

sampling ought to be done in an early stage of manufacturing grinding cracks, etc., the surface itself is used as a sample.

so that if the material proves faulty, no wasteful unnecessary Because the machined or ground part is often the finished part,

work is done. However, the sample should not be taken so it may be undesirable to immerse the part in acid. In this case,

early that further working can introduce serious defects. In the other methods such as dye penetrant methods may be more

steel industry, for example, the sample is usually taken after desirable.

ingot breakdown and after most chances of bursts or flakes

5. Preparation

occurring have passed. Billets or blooms going into small sizes

5.1 Sample preparation need not be elaborate. Any method

are sampled after initial breakdown. Material going into

ofpresentingasmoothsurfacewithaminimumamountofcold

forging billets or die blocks is sampled near finish size.

work will be satisfactory. Disks may be faced on a lathe or a

Sampling may be done systematically or on a random basis.

shaper. The usual procedure is to take a roughing cut, then a

4.3 Samples may be cold cut from the source by any

finishcut.Thiswillgenerateasmoothsurfaceandremovecold

convenient fashion; saws and abrasive cutoff wheels are

work from prior operations. Sharp tools are necessary to

particularly effective. The use of torch cutting or hot cutting

produce a good specimen. Grinding is usually conducted in the

should be used only when necessary to cut a sample from a

same manner, using free-cutting wheels and light finishing

large piece. The sample then is sectioned well away from the

cuts. When fine detail is required, the specimen should be

hot-cut surface.An example of permissible use of torch cutting

ground down through the series of metallographic papers (see

is the excising of a piece from a large plate and then cutting a

Methods E3). Where necessary, details are given in the

sample for macroetching 4 to 5 in. (102 to 127 mm) away from

tabulation of procedures.

the torch-cut edge.

5.2 After surface preparation, the sample is cleaned care-

4.4 Some common methods of sampling, listed by source,

fully with suitable solvents. Any grease, oil, or other residue

are as follows:

willproduceunevenattack.Oncecleaned,careshouldbetaken

4.5 Billets, Blooms, and Hot-Rolled Products—Disks are

not to touch the sample surface or contaminate it in any way.

usually cut from these products near the end. Samples cut too

close to the end, however, may have false structures because of 6. Solutions

fish-tailing. Disks from large blooms are sometimes cut into

6.1 The solutions used for macroetching are given in the

smaller pieces for ease in handling.

tables listed under each alloy. In most cases a good grade of

4.5.1 Forgings and Extrusions—Disks cut transverse to the

reagent should be used but need not be chemically pure or of

longdimensionwillshowflakes,bursts,etc.Forgingsmayalso

analytical quality. The so-called technical grades are usually

be cut parallel to the long dimension to show flow lines. In

satisfactory. The solution should be clean and clear, free of

complicated forgings, some thought will have to be given to

suspended particles, scum, etc.

the proper method of cutting so as to show flow lines.

6.2 Caution must be observed in mixing. Many of the

Macroetching of an unprepared specimen will show surface

etchants are strong acids. In all cases, the various chemicals

defects such as shuts, flats, seams, etc. In extrusions, coring

should be added slowly to the water or solvent while stirring.

and coarse grain are more commonly found in the back end of

In the cases where hydrofluoric acid is used, the solution

the extrusion.

should be mixed and used in polyethylene vessels.

4.5.2 Sheets and Plates—Asufficiently large sample should

(Warning—Hydrofluoricacidshouldnotbeallowedtocontact

be taken when looking for surface defects. An ideal length

the skin since it can cause painful serious ulcers if not washed

would be the circumference of the last roll, but this may be

off immediately.)

inconveniently long. Several samples totaling some given

fraction of the circumference can be used; however, there is

7. Procedure

always a chance then that a defect arising from faulty rolls

7.1 Many of the solutions are aggressive and may give off

would not be detected. When seeking information on

irritating and corrosive fumes. Etching should be done in a

laminations, a transverse section is used. In many cases,

well-ventilated room, preferably under a fume hood. The

however, to reduce the size of the specimen, only a section out

solution should be mixed and placed in a corrosion resistant

of the center of the plate may be taken.

tray or dish and brought to the operating temperature. The

4.5.3 Weldments—A disk cut perpendicular to the direction

specimen or specimens should be placed in a tray of stainless

of welding will show weld penetration, heat affected zone,

steel screen or on some non-reactive support. Glass rods often

structure, etc. Careful preparation is usually rewarded with

are placed on the bottom of the acid container and the

highlydetailedstructuresgivingalargeamountofinformation.

specimens laid directly on the rods. When etching is

Welds involving dissimilar metals will produce problems in

completed, remove the specimens from the dish taking great

etching.The best method is to etch the least corrosion-resistant

care not to touch the etched surface. When desmutting is

portion first and the more resistant portion afterwards. Occa-

required, dip the specimen into a second solution.After rinsing

sionally an intermediary etchant may be required. The bound-

the specimen with hot water, blow dry with clean compressed

aries between etched and unetched portion will give an idea of

air.

weld penetration and dilution.

4.5.4 Castings—Cut the specimen to display the defect or 7.2 In the case of large specimens, such as ingot sections,

feature being sought. swabbing may be the only practical method of macroetching.

E340 − 00 (2006)

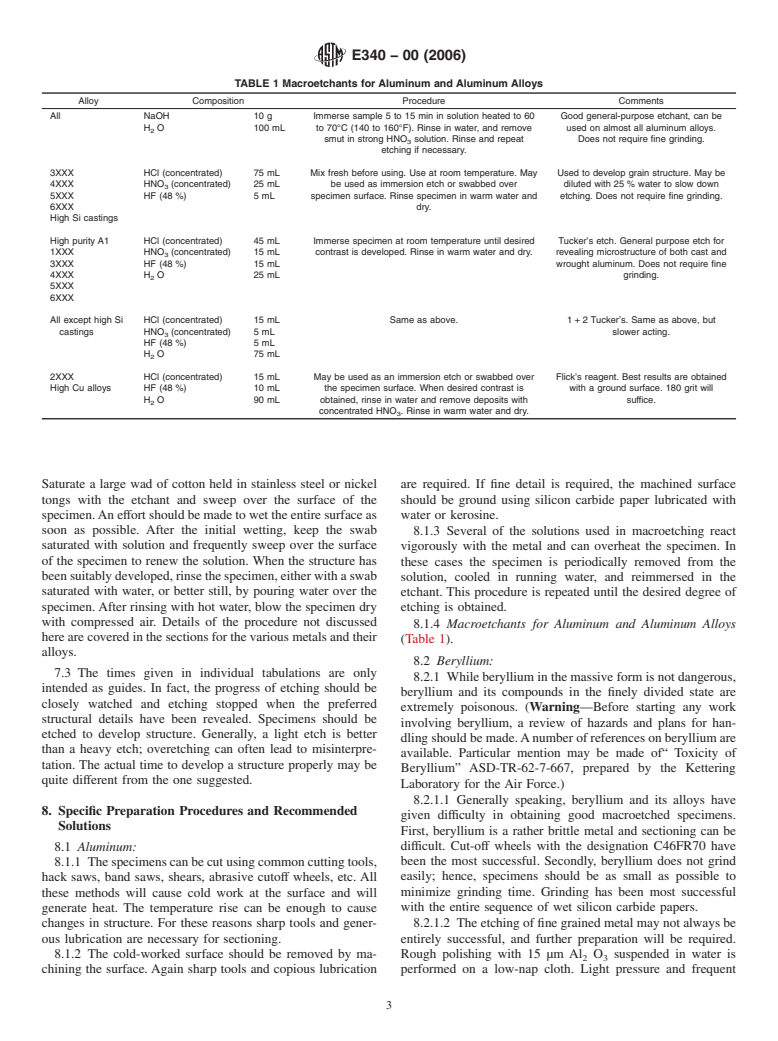

TABLE 1 Macroetchants for Aluminum and Aluminum Alloys

Alloy Composition Procedure Comments

All NaOH 10 g Immerse sample 5 to 15 min in solution heated to 60 Good general-purpose etchant, can be

H O 100 mL to 70°C (140 to 160°F). Rinse in water, and remove used on almost all aluminum alloys.

smut in strong HNO solution. Rinse and repeat Does not require fine grinding.

etching if necessary.

3XXX HCl (concentrated) 75 mL Mix fresh before using. Use at room temperature. May Used to develop grain structure. May be

4XXX HNO (concentrated) 25 mL be used as immersion etch or swabbed over diluted with 25 % water to slow down

5XXX HF (48 %) 5mL specimen surface. Rinse specimen in warm water and etching. Does not require fine grinding.

6XXX dry.

High Si castings

High purity A1 HCl (concentrated) 45 mL Immerse specimen at room temperature until desired Tucker’s etch. General purpose etch for

1XXX HNO (concentrated) 15 mL contrast is developed. Rinse in warm water and dry. revealing microstructure of both cast and

3XXX HF (48 %) 15 mL wrought aluminum. Does not require fine

4XXX H O 25 mL grinding.

5XXX

6XXX

All except high Si HCl (concentrated) 15 mL Same as above. 1 + 2 Tucker’s. Same as above, but

castings HNO (concentrated) 5mL slower acting.

HF (48 %) 5mL

H O 75 mL

2XXX HCl (concentrated) 15 mL May be used as an immersion etch or swabbed over Flick’s reagent. Best results are obtained

High Cu alloys HF (48 %) 10 mL the specimen surface. When desired contrast is with a ground surface. 180 grit will

H O 90 mL obtained, rinse in water and remove deposits with suffice.

concentrated HNO . Rinse in warm water and dry.

Saturate a large wad of cotton held in stainless steel or nickel are required. If fine detail is required, the machined surface

tongs with the etchant and sweep over the surface of the should be ground using silicon carbide paper lubricated with

specimen.An effort should be made to wet the entire surface as water or kerosine.

soon as possible. After the initial wetting, keep the swab 8.1.3 Several of the solutions used in macroetching react

saturated with solution and frequently sweep over the surface

vigorously with the metal and can overheat the specimen. In

of the specimen to renew the solution. When the structure has these cases the specimen is periodically removed from the

beensuitablydeveloped,rinsethespecimen,eitherwithaswab

solution, cooled in running water, and reimmersed in the

saturated with water, or better still, by pouring water over the

etchant. This procedure is repeated until the desired degree of

specimen.After rinsing with hot water, blow the specimen dry

etching is obtained.

with compressed air. Details of the procedure not discussed

8.1.4 Macroetchants for Aluminum and Aluminum Alloys

here are covered in the sections for the various metals and their

(Table 1).

alloys.

8.2 Beryllium:

7.3 The times given in individual tabulations are only

8.2.1 While beryllium in the massive form is not dangerous,

intended as guides. In fact, the progress of etching should be

beryllium and its compounds in the finely divided state are

closely watched and etching stopped when the preferred

extremely poisonous. (Warning—Before starting any work

structural details have been revealed. Specimens should be

involving beryllium, a review of hazards and plans for han-

etched to develop structure. Generally, a light etch is better

dling should be made.Anumber of references on beryllium are

than a heavy etch; overetching can often lead to misinterpre-

available. Particular mention

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.