ASTM D7434-08

(Test Method)Standard Test Method for Determining the Performance of Passive Radio Frequency Identification (RFID) Transponders on Palletized or Unitized Loads

Standard Test Method for Determining the Performance of Passive Radio Frequency Identification (RFID) Transponders on Palletized or Unitized Loads

SIGNIFICANCE AND USE

Many materials used in the production of goods can have an adverse affect on the performance of an RFID system. This test method qualifies the performance of an RFID system applied to a unit load.

This test method is intended for systems used exclusively within the United States. Additional test standards from ISO or other standards bodies may apply to internationally handled goods and may include additional test scenarios not outlined in this test method.

SCOPE

1.1 This test method quantitatively evaluates the readability of radio frequency identification (RFID) pallet transponders placed on pallet loads that are mechanically handled by material handling equipment such as fork trucks, pallet jacks, and automated guided vehicle systems.

1.2 This test method is intended for use in laboratory settings that simulate, as closely as is practicable, the distribution environment of the product being tested.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7434 −08

StandardTest Method for

Determining the Performance of Passive Radio Frequency

Identification (RFID) Transponders on Palletized or Unitized

Loads

This standard is issued under the fixed designation D7434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 critical transponder distance—the distance between

1.1 This test method quantitatively evaluates the readability

the transponder and the interrogator antenna at which a

of radio frequency identification (RFID) pallet transponders

transponder becomes undetectable by an RFID system, when

placed on pallet loads that are mechanically handled by

moving the RFID transponder out of the read field.

material handling equipment such as fork trucks, pallet jacks,

and automated guided vehicle systems.

3.2.2 direct line of sight—an unobstructed visible path from

1.2 This test method is intended for use in laboratory one object to another.

settings that simulate, as closely as is practicable, the distribu-

3.2.3 firmware—a series of programmable instructions,

tion environment of the product being tested.

stored in read only memory (ROM), which controls the

1.3 The values stated in inch-pound units are to be regarded

capabilities of an interrogator.

as standard. The values given in parentheses are mathematical

3.2.4 radio frequency identification (RFID)— a wireless

conversions to SI units that are provided for information only

data communication technology that uses radio waves to

and are not considered standard.

transfer data from one source to another.

1.4 This standard does not purport to address all of the

3.2.5 read field—the area in which an RFID transponder is

safety concerns, if any, associated with its use. It is the

capable of responding to the interrogator. The outermost

responsibility of the user of this standard to establish appro-

boundary of the read field correlates to the critical transponder

priate safety and health practices and determine the applica-

distance. The distance between the critical transponder dis-

bility of regulatory limitations prior to use.

tance and the transponder acquisition distance represents an

2. Referenced Documents

area of RF energy that may or may not be sufficient to activate

a passive transponder.

2.1 ASTM Standards:

D996 Terminology of Packaging and Distribution Environ-

3.2.6 RF—the energy used by RFID systems to activate

ments

transponders and wirelessly transfer information.

D4332 Practice for Conditioning Containers, Packages, or

3.2.7 RF inhibiting—a substance or material that causes a

Packaging Components for Testing

significant reduction in the effectiveness of radio waves that

E337 Test Method for Measuring Humidity with a Psy-

reach an RFID transponder.

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

peratures)

3.2.8 software—an array of logic, displayed as an

application, used to access and control a device.

3. Terminology

3.2.9 transponder acquisition distance—the distance be-

3.1 Definitions—Terms and definitions used in this test

tween the transponder and the interrogator antenna at which a

method may be found in Terminology D996.

transponder is first detected by an RFID system, when moving

the transponder into the read field.

This test method is under the jurisdiction of ASTM Committee D10 on

Packaging and is the direct responsibility of Subcommittee D10.17 on Auto-ID

Applications .

4. Summary of Test Method

Current edition approved Aug. 1, 2008. Published September 2008. DOI:

10.1520/D7434-08.

4.1 This procedure is used to determine the read perfor-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

manceoftheRFsystemwhileaffixedtoafullyassembled,unit

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

load. The read field is developed by determining the critical

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. transponder distance and the transponder acquisition distance

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7434−08

5. Significance and Use 8.3.2 Interrogator Antenna—A manufactured device that

emitsRFenergytotranspondersandreceivesinformationfrom

5.1 Many materials used in the production of goods can

transponders in the form of reflected RF energy.

have an adverse affect on the performance of an RFID system.

8.3.3 Transponder (pallet transponder)— A microchip with

This test method qualifies the performance of an RFID system

a small conductive antenna that receives RF energy from the

applied to a unit load.

interrogator antenna and reflects the information on the micro

5.2 This test method is intended for systems used exclu-

chip back to the interrogator antenna in the form of RF energy.

sively within the United States. Additional test standards from

8.3.4 Host Computer—Any computer with the proper soft-

ISO or other standards bodies may apply to internationally

ware to communicate with and operate the RFID interrogator.

handled goods and may include additional test scenarios not

outlined in this test method.

9. Test Specimen

9.1 Each unit load shall be comprised of a specified quantity

6. Interferences

of unit case load(s), representative of a production run unit

6.1 RFID systems are subject to interference from metal,

load.

water, and ambient RF energy. If significant levels of any of

9.2 Each unit case load shall consist of a representative

these interferences are present in the immediate testing area,

production run package, or components of an assembled

the observed read field will be affected. Due to uncontrolled

packaging system, to include primary, secondary, and/or ter-

variation in testing facilities, numerical values for interference

tiary packaging up through the shipping case level.

cannot be stated. Possible sources of interference shall be

9.3 An RFID transponder specimen shall be a randomly

documented in the final report.

selected transponder from an RFID transponder inventory.

6.1.1 Documentation of interference shall include informa-

tion regarding, material, size, and location relative to interro-

10. Conditioning

gator antenna.

10.1 Test specimens shall be conditioned at the standard

6.2 If significant levels of interference are unavoidable,

conditioning atmosphere of 23 6 2°C (73.4 6 3.6°F) for a

testing shall be conducted in such a manner that interferences

minimum of 24 h prior to testing (see Practice D4332) unless

remain unchanged throughout testing.

otherwise noted as per 13.1.1.

7. Atmospheric Conditions

11. Procedure

7.1 Testing shall be conducted at standard conditioning

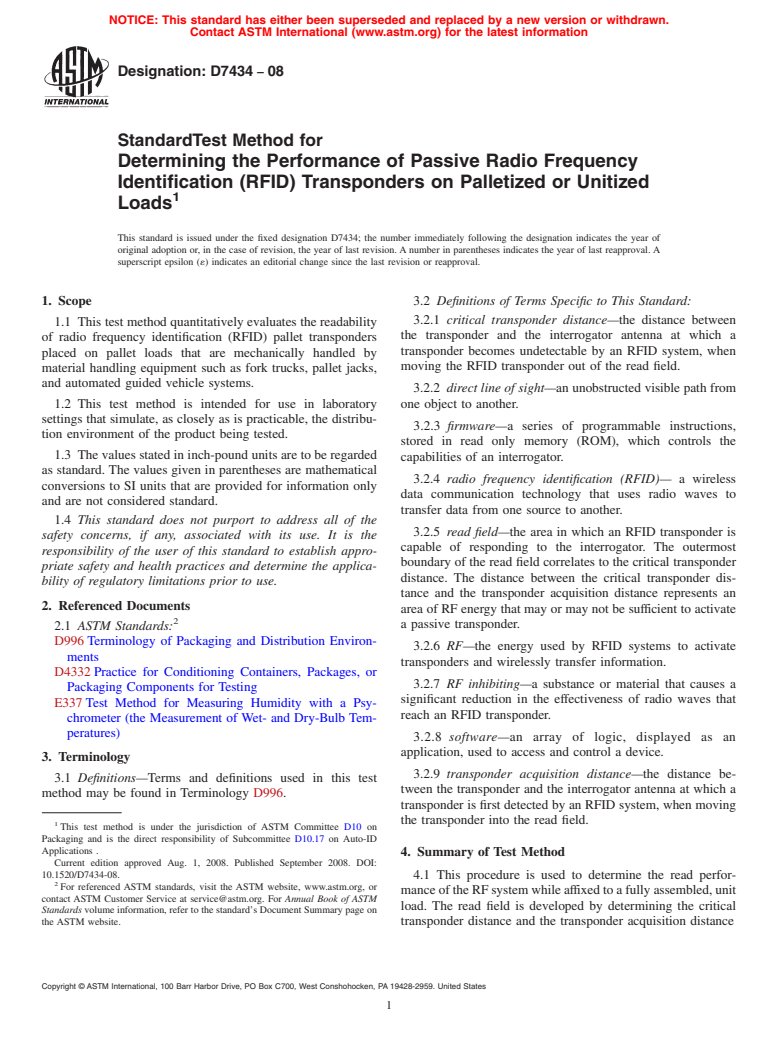

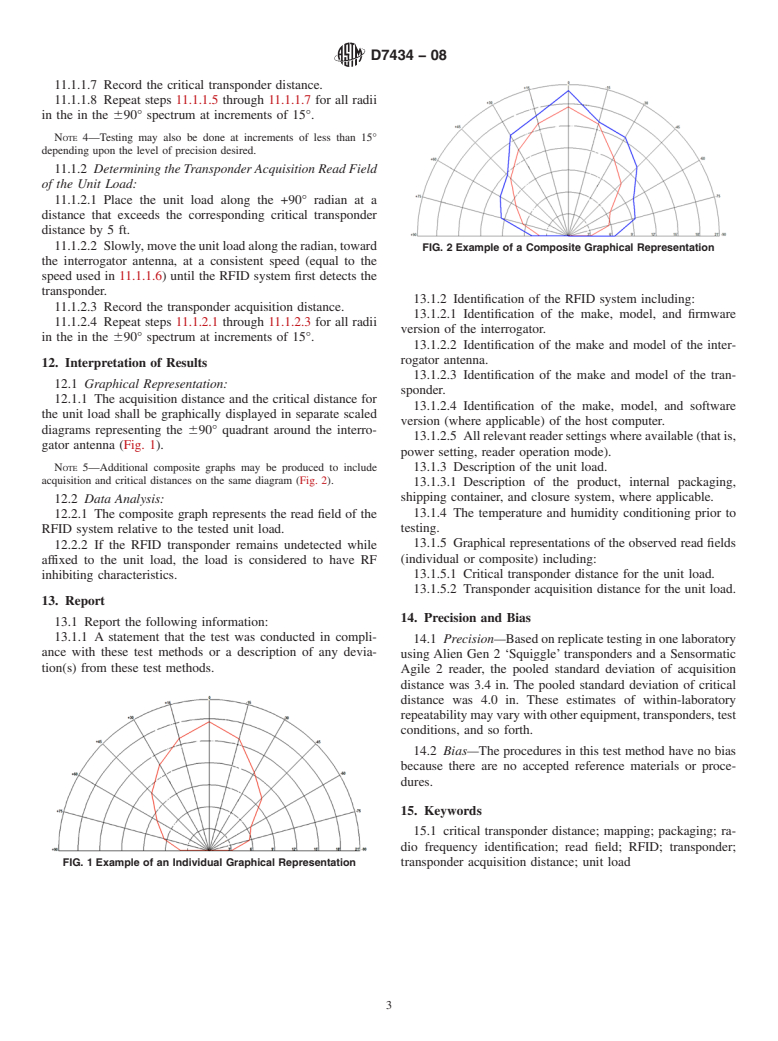

11.1 Mapping the Read Field:

atmosphere 23 6 1°C (73.4 6 2°F) and 50 6 2 % relative

11.1.1 Determining the Critical Distance Read Field of the

humidity, unless otherwise noted as per 13.1.1.

Unit Load:

7.2 The exact measurement of temperature and relative

11.1.1.1 Assemble RFID system.

humidity of the testing atmosphere shall be made as close

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.