ASTM D4688/D4688M-14

(Test Method)Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

SIGNIFICANCE AND USE

4.1 This test method is specifically designed to measure the performance of adhesives in finger joints manufactured under production line conditions.

4.1.1 The test method can be adapted to evaluate the adhesive performance of laboratory produced finger joints using commercial finger joint cutting heads with finger joints produced following the adhesive manufacturers recommendations. The conditions under which the finger joints were produced, including any limitations, are to be reported in 9.1.2.2 (see Note 2).

Note 2: If laboratory prepared finger joints are to be produced, record details related to adhesive used, its preparation, application to the cut finger joint, appropriate bonding parameters and limitations in the production of the finger joint assemblies.

4.2 The results of the test method may be used to certify an adhesive as suitable for finger jointing lumber under production line conditions where the intended end use of the finger jointed lumber may be in a variety of bonded structural wood products.

4.2.1 When the test results are to be used for certification of an adhesive a standard wood species shall be used.

4.2.1.1 Standard species may be found in Table 1 of Specification D2559.

SCOPE

1.1 This test method is designed to evaluate adhesives for finger jointing lumber used in the manufacture of a variety of bonded structural wood products such as structural glued laminated timber. It tests the tensile strength of joints under the following treatments: dry with no treatment, wet after one vacuum-pressure soak treatment, and wet after cyclic boil-dry treatment.

1.2 This test method is intended neither for quality control as the test assemblies are selected for the absence of defects usually found in run-of-the-mill finger joints nor as a substitute for in-plant qualification of end joints, including full-scale joint tests.

Note 1: This test method is specifically designed to evaluate adhesives for use in finger jointing lumber using small scale test specimens cut from carefully selected finger joint assemblies. In contrast, plant qualification and quality control require tests of full scale end joints selected randomly from production, designed to evaluate parameters beyond adhesive performance which affect the performance of the end use product.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4688/D4688M − 14

Standard Test Method for

1

Evaluating Structural Adhesives for Finger Jointing Lumber

This standard is issued under the fixed designation D4688/D4688M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2559Specification for Adhesives for Bonded Structural

Wood Products for Use Under Exterior Exposure Condi-

1.1 This test method is designed to evaluate adhesives for

tions

finger jointing lumber used in the manufacture of a variety of

D5266Practice for Estimating the Percentage of Wood

bonded structural wood products such as structural glued

Failure in Adhesive Bonded Joints

laminatedtimber.Itteststhetensilestrengthofjointsunderthe

E4Practices for Force Verification of Testing Machines

following treatments: dry with no treatment, wet after one

vacuum-pressure soak treatment, and wet after cyclic boil-dry

3. Terminology

treatment.

3.1 Definitions—Many terms in this test method are defined

1.2 This test method is intended neither for quality control

in Terminology D907.

as the test assemblies are selected for the absence of defects

3.2 Definitions of Terms Specific to This Standard:

usuallyfoundinrun-of-the-millfingerjointsnorasasubstitute

3.2.1 billet, n—a piece cut from a vertical finger joint

forin-plantqualificationofendjoints,includingfull-scalejoint

assembly as an intermediate step in making specimens.

tests.

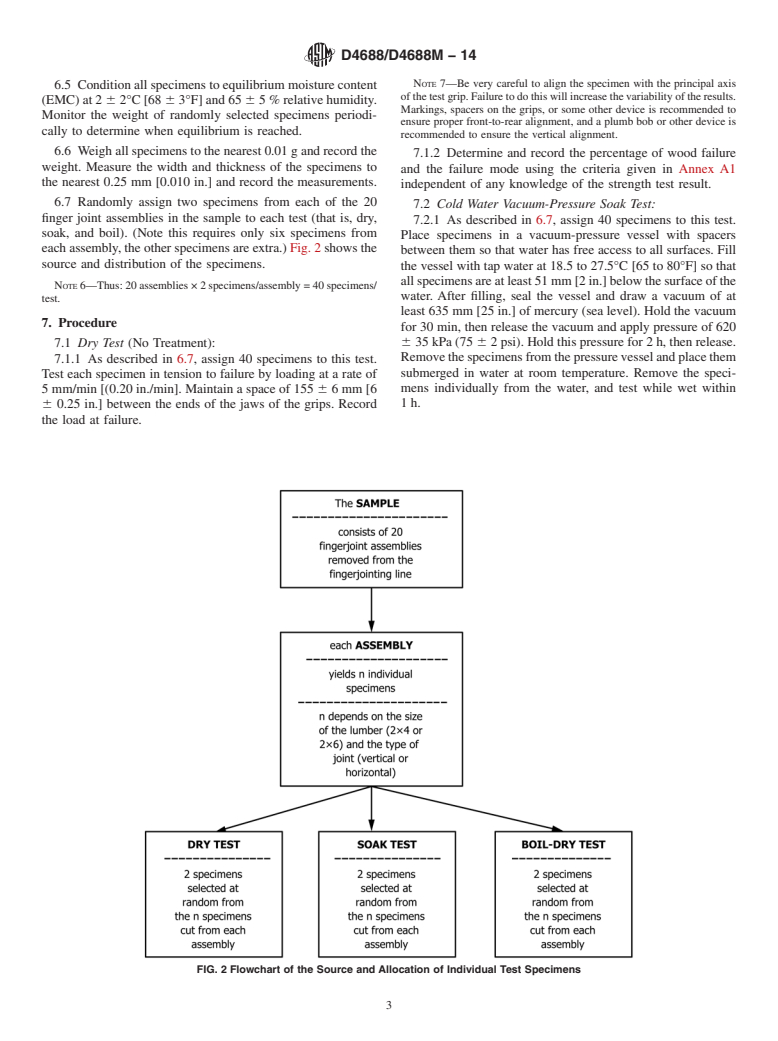

NOTE1—Thistestmethodisspecificallydesignedtoevaluateadhesives

3.2.2 horizontal finger joint, n—a joint formed by bonding

foruseinfingerjointinglumberusingsmallscaletestspecimenscutfrom

two precut members shaped like fingers where the profile is

carefully selected finger joint assemblies. In contrast, plant qualification

visible on the edge of the lumber (see Fig. 1a).

and quality control require tests of full scale end joints selected randomly

from production, designed to evaluate parameters beyond adhesive 3.2.3 vertical finger joint, n—ajointformedbybondingtwo

performance which affect the performance of the end use product.

precut members shaped like fingers where the profile is on the

wide face of the lumber (see Fig. 1b).

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3.2.4 finger joint assembly, n—ashortportionoftwoboards

each system may not be exact equivalents; therefore, each

joined at their ends by an adhesively bonded finger joint to

system shall be used independently of the other. Combining

create a longer piece, frequently referred to as an assembly.

values from the two systems may result in non-conformance

3.2.5 sample, n—agroupoffingerjointassembliesobtained

with the standard.

fromafingerjointproductionlineorlaboratorypreparedfinger

1.4 This standard does not purport to address all of the

joints selected for statistical purposes.

safety concerns, if any, associated with its use. It is the

3.2.6 specimen, n—an individual test piece prepared to

responsibility of the user of this standard to establish appro-

specific dimensions for the purpose of determining the adhe-

priate safety and health practices and determine the applica-

siveperformanceinaccordancewiththetensiontestsdescribed

bility of regulatory limitations prior to use.

in this test method.

2. Referenced Documents

4. Significance and Use

2

2.1 ASTM Standards:

4.1 This test method is specifically designed to measure the

D907Terminology of Adhesives

performance of adhesives in finger joints manufactured under

production line conditions.

4.1.1 The test method can be adapted to evaluate the

1

This test method is under the jurisdiction of ASTM Committee D14 on

adhesive performance of laboratory produced finger joints

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

using commercial finger joint cutting heads with finger joints

Adhesives.

Current edition approved Nov. 1, 2014. Published January 2015. Originally

produced following the adhesive manufacturers recommenda-

approved in 1987. Last previous edition approved in 2013 as D4688–99 (2013).

tions. The conditions under which the finger joints were

DOI: 10.1520/D4688_D4688M-14.

2 produced, including any limitations, are to be reported in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 9.1.2.2 (see Note 2).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ---------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4688 − 99 (Reapproved 2013) D4688/D4688M − 14

Standard Test Method for

1

Evaluating Structural Adhesives for Finger Jointing Lumber

This standard is issued under the fixed designation D4688;D4688/D4688M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is designed to evaluate adhesives for finger jointing lumber used in the manufacture of structural a variety

of bonded structural wood products such as structural glued laminated timber. It tests the tensile strength of joints under the

following treatments;treatments: dry with no treatment, wet after one vacuum-pressure soak treatment, and wet after cyclic boil-dry

treatment.

1.2 This test method is intended neither for quality control as the test assemblies are selected for the absence of defects usually

found in run-of-the-mill finger joints nor as a substitute for in-plant qualification of end joints, including full-scale joint tests.

NOTE 1—This test method is specifically designed to evaluate adhesives for use in finger jointing lumber using small scale test specimens cut from

carefully selected finger joint assemblies. In contrast, plant qualification and quality control require tests of full scale end joints selected randomly from

production, designed to evaluate parameters beyond adhesive performance which affect the performance of the end use product.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The values given in

parentheses are for information only.stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D907 Terminology of Adhesives

D2559 Specification for Adhesives for Bonded Structural Wood Products for Use Under Exterior Exposure Conditions

D5266 Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 Definitions—Many terms in this test method are defined in Terminology D907.

3.2 Definitions of Terms Specific to This Standard:

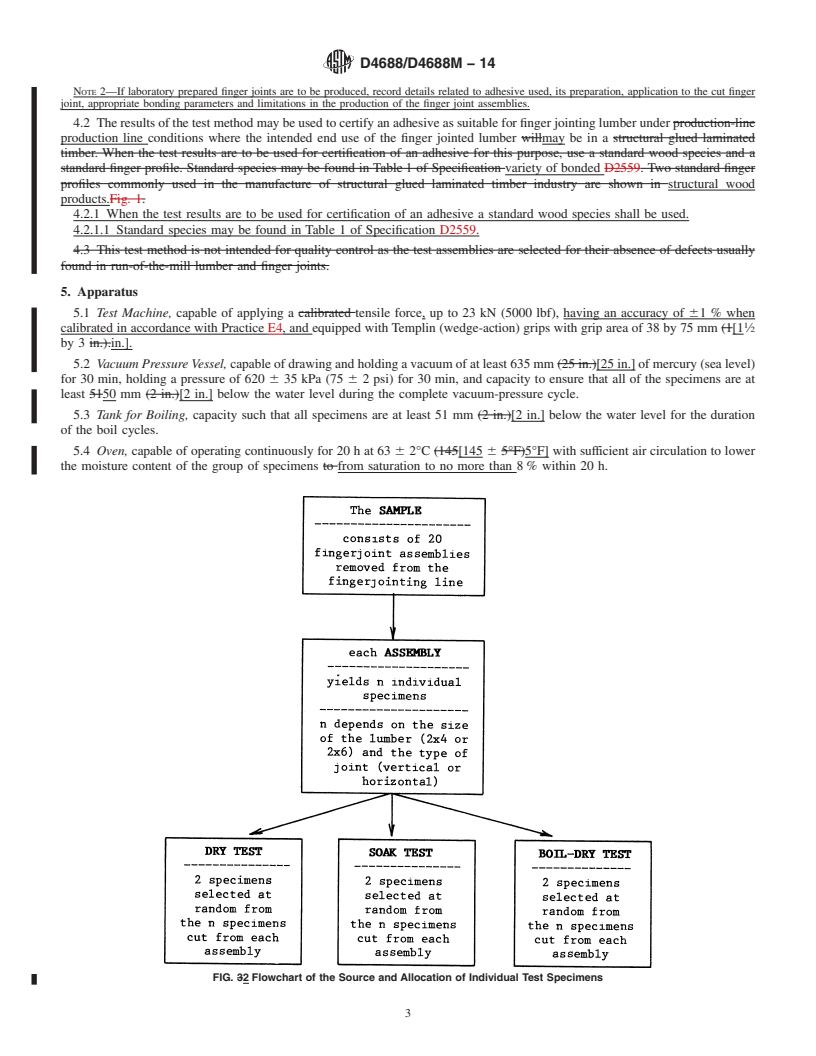

3.2.1 billet, n—a piece cut from a vertical finger joint assembly as an intermediate step in making specimens.

3.2.2 horizontal finger joint, n—a joint formed by bonding two precut members shaped like fingers where the profile is visible

on the edge of the lumber (see Fig. 1a).

3.2.3 vertical finger joint, n—a joint formed by bonding two precut members shaped like fingers where the profile is on the wide

face of the lumber (see Fig. 1b).

3.2.4 finger joint assembly, n—a short portion of two boards joined at their ends by a an adhesively bonded finger joint obtained

from a finger joint production line for testing, to create a longer piece, frequently referred to as an assembly.

3.2.5 sample, n—a group of finger joint assemblies obtained from a finger joint production line or laboratory prepared finger

joints selected for statistical purposes.

1

This test method is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood Adhesives.

Current edition approved Oct. 1, 2013Nov. 1, 2014. Published October 2013January 2015. Originally approved in 1987. Last previous edition approved in 20052013 as

D4688 – 99 (2005).(2013). DOI: 10.1520/D4688-99R13.10.1520/D4688_D4688M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4688/D4688M − 14

3.2.3.1 Discussion—

FIG. 21 Finger Joint Assembly and Specimen Descriptions

In the laminating industry the term sample is use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.