ASTM D7358-07(2018)

(Test Method)Standard Test Method for Water Content of Paints by Quantitative Calcium Hydride Reaction Test Kit

Standard Test Method for Water Content of Paints by Quantitative Calcium Hydride Reaction Test Kit

SIGNIFICANCE AND USE

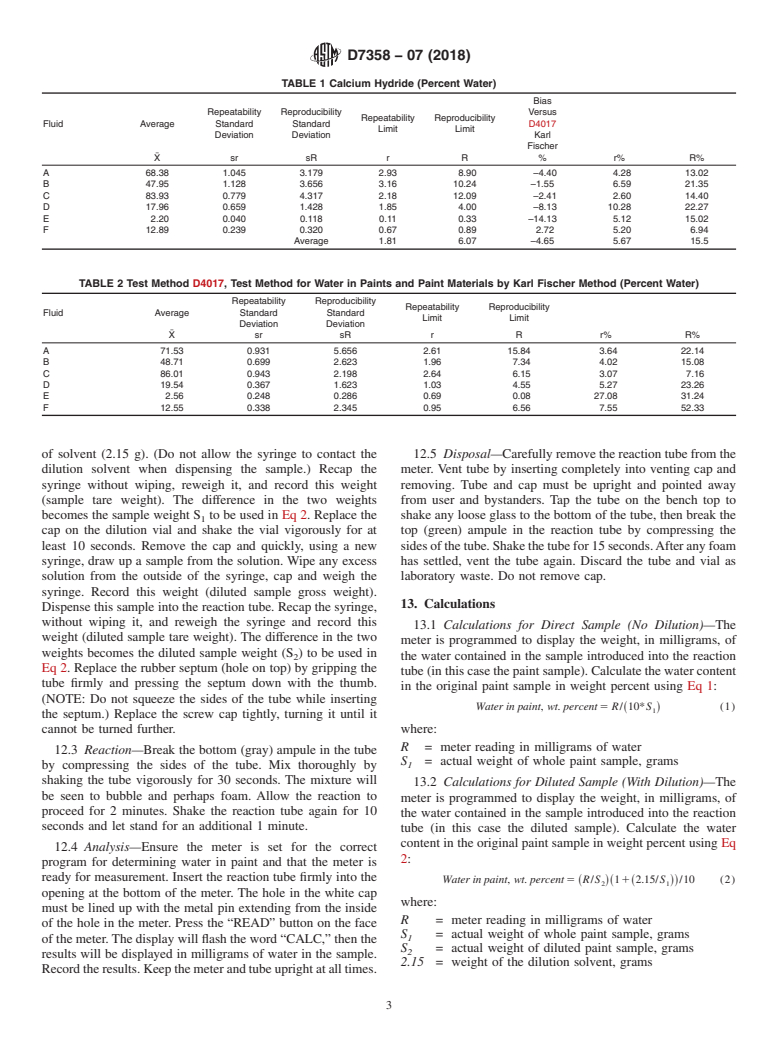

4.1 Although Test Method D4017 is widely used for the determination of water in paints and related materials, this method may overcome some of the variability found in the Karl Fischer method.

4.2 Control of water content is often important in controlling the performance of paints, and it is critical in determining volatile organic compound (VOC) content when VOC content is measured by difference from total volatile matter and water content as required in certain federal and state regulations.

SCOPE

1.1 This test method describes the determination of the total water content of paints using a calcium hydride reaction test kit, or water content between 2 and 85 % water.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7358 − 07 (Reapproved 2018)

Standard Test Method for

Water Content of Paints by Quantitative Calcium Hydride

Reaction Test Kit

This standard is issued under the fixed designation D7358; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope hydrogen gas. The reaction is carried out in a sealed pressure

vessel and the resulting pressure is then measured using a

1.1 This test method describes the determination of the total

specially designed meter programmed to convert gas pressure

water content of paints using a calcium hydride reaction test

into water content. The results are displayed in milligrams of

kit, or water content between 2 and 85 % water.

water in the reacted sample extract. The actual weight percent

1.2 The values stated in SI units are to be regarded as

water in the whole paint sample is manually calculated using

standard. No other units of measurement are included in this

the exact weights of the paint sample and the diluted extract

standard.

sample, if used.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Although Test Method D4017 is widely used for the

priate safety, health, and environmental practices and deter-

determination of water in paints and related materials, this

mine the applicability of regulatory limitations prior to use.

method may overcome some of the variability found in the

1.4 This international standard was developed in accor-

Karl Fischer method.

dance with internationally recognized principles on standard-

4.2 Control of water content is often important in control-

ization established in the Decision on Principles for the

ling the performance of paints, and it is critical in determining

Development of International Standards, Guides and Recom-

volatile organic compound (VOC) content when VOC content

mendations issued by the World Trade Organization Technical

is measured by difference from total volatile matter and water

Barriers to Trade (TBT) Committee.

content as required in certain federal and state regulations.

2. Referenced Documents

5. Interferences

2.1 ASTM Standards:

5.1 The following compounds, tested at twice the sample

D1193 Specification for Reagent Water

size,havebeenfoundtoproducenomeasurableresponsetothe

D3925 Practice for Sampling Liquid Paints and Related

calcium hydride reaction test kit and, therefore, cause no

Pigmented Coatings

interference at levels up to 40 %:

D4017 Test Method for Water in Paints and Paint Materials

Ethanol

by Karl Fischer Method

Methanol

E29 Practice for Using Significant Digits in Test Data to A

Acetone

Determine Conformance with Specifications

Methyl Ethyl Ketone

Tetrahydrofuran

Diethylene Glycol Dimethyl Ether

3. Summary of Test Method

A

Ethylene Glycol

Diethylene Glycol

3.1 A0.25 mLsample is reacted with a specially formulated

Dipropylene Glycol

calcium hydride reagent to convert water in the sample to

Stearic Acid

2–Ethyl Hexanoic Acid

Lead Oxide (II and III)

This test method is under the jurisdiction of ASTM Committee D01 on Paint Aluminum Oxide (Brockman I)

and Related Coatings, Materials, andApplications and is the direct responsibility of

A

0.25 mL sample size program A and B.

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved June 1, 2018. Published June 2018. Originally 5.2 When using the 5 mL sample size programs, that is,

approved in 2007. Last previous edition approved in 2013 as D7358 – 07 (2013).

programs C, D, or E, ethylene glycol and acids have been

DOI: 10.1520/D7358-07R18.

found to produce a positive result in the presence of a small

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. HydroSCOUT User’s Manual.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7358 − 07 (2018)

amount of water. Ethylene glycol responds at approximately seconds to ensure that the water contacting the remaining

7 % of the volumetric equivalent. calcium hydride does not overheat the side of the tube,

otherwise tube failure can result.

6. Apparatus

4 9. Sampling, Test Specimens, and Test Units

6.1 HydroSCOUT System—A test kit system consisting of

9.1 Sample Collection—Take a representative sample of the

theHydroSCOUTmeter,reactiontubes,samplingsyringesand

dilution vials. The entire analytical sequence, including liquid coatings in accordance with Practice D3925. Mix

thoroughly before taking specimens for individual tests.

sampling, sample dilution, chemical reactions and

quantification, is available in kit form using pre-dispensed and

10. Preparation

encapsulated reagents. An analytical balance is required in

order to obtain the most precise results. In addition, a mechani-

10.1 Preparation—Remove a sampling syringe with cap

cal shaker may be necessary to obtain a representative sample. and a test tube from the kit box. Check the contents to ensure

that all items are present and intact. If a dilution is to be used,

7. Reagents and Materials

remove a dilution vial and an additional sampling syringe and

cap. Remove the screw cap and rubber septum from the tube

7.1 Purity of Reagents—Reagent grade chemicals shall be

and the cap from the dilution vial, if used. Insert one green

usedinalltests.Allreagentsshallconformtothespecifications

water ampule into the top of the polypropylene ampule sleeve

of the Committee on Analytical reagents of the American

and replace the holder in the tube.

Chemical Society, where such specifications are available.

7.2 Purity of Water—Unless otherwise indicated, reference

11. Calibration and Standardization

to water shall mean reagent water conforming to Specification

11.1 The commercially available meter is calibrated at the

D1193, Type II.

factory over the pressure range of 0 to 60 psig. Each time the

7.3 Calcium Hydride (20 %) in HI SOL 10—contained in a

meter is turned on, the pressure transducer recalibrates the 0

crushable glass ampule.

psig point. If this changes significantly from the factory set

point, an error message will be displayed. This error will also

7.4 Water—contained in a crushable glass ampule.

appear if a tube is accidentally inserted into the meter before

7.5 Diethylene Glycol Dimethyl Ether (Diglyme)—2.25 mL

the meter is turned on.

contained in a glass vial.

12. Procedure

8. Hazards

12.1 Sample Introduction for Expected Water Content Less

8.1 Store ampules in a cool, dry place. Keep away from

Than 15 % (No Dilution)—Work the plunger on an empty

heat, sparks, water and open flames.

sampling syringe a few times to ensure that it slides easily.

8.2 See manufacturer’s instructions and Safety Data Sheet

Place the tip of the syringe into the paint sample to be tested

(SDS) before use.

andslowlypullbackontheplungeruntilitreachesthestopand

cannot be pulled further. Remove the syringe from the paint

8.3 The gray ampule in the tube contains calcium hydride,

sample and wipe any excess paint from the outside of the

which is a flammable solid and water reactive.

syringe with a tissue wipe provided with the kit. Cap the

8.4 Perform test only in a well ventilated area.

syringe with the cap provided and weigh; record the weight

8.5 Always wear rubber gloves and safety glasses.

(gross sample weight) to the nearest 0.1 mg. Dispense the

sample into the reaction tube. Recap the syringe without

8.6 Take care to ensure that fingers are not cut by glass in

wiping,reweighit,andrecordthisweight(sampletareweight).

the kits. Each ampule should be crushed only once to reduce

The difference in the two weights becomes the sample weight

the risk of glass pieces piercing the sides of the tube.

(S ) to be used in Eq 1. Replace the rubber septum (hole on

8.7 When venting reaction tube after completion of test,

top) by gripping the tube firmly and pressing the septum down

point tube upright and away from user and bystander.

with the thumb. (NOTE: Do not squeeze the sides of the tube

8.8 When breaking the green water ampule after completion while inserting the septum.) Replace the screw cap tightly,

of test, the tube must be shaken vigorously for the full 15

turning it until it cannot be turned further. Proceed to step 12.3.

12.2 Sample Introduction for Expected Water Content

Greater Than 15 % (With Dilution)—Work the plunger on an

HydroSCOUT is a trademark of the Dexsil Corporation.

5 empty sampling syringe a few times to ensure that it slides

The sole source of supply of this kit known to the committee at this time is

Dexsil Corporation, One Hamden Park Drive, Hamden, CT06517. If you are aware

easily. Place the tip of the syringe into the paint sample to be

of alternative suppliers, please provide this information to ASTM International

tested and slowly pull back on the plunger until it reaches the

Headquarters.Your comments will receive careful consideration at a meeting of the

1 stop and cannot be pulled further. Remove the syringe from the

responsible technical committee, which you may attend.

paint sample and wipe any excess paint from the outside of the

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.