ASTM D4017-02(2008)e1

(Test Method)Standard Test Method for Water in Paints and Paint Materials by Karl Fischer Method

Standard Test Method for Water in Paints and Paint Materials by Karl Fischer Method

SIGNIFICANCE AND USE

Control of water content is often important in controlling the performance of paint and paint ingredients, and it is critical in controlling volatile organic compound (VOC) content.

Paint materials are often insoluble in common Karl Fischer solvents such as methanol. Pyridine has been found to be a nearly universal solvent for these materials; however, the Karl Fischer reaction is too slow in that solvent at room temperature. To speed it up, 1-ethylpiperidine is added at 5 % as a buffer, or “catalyst.”

For nonpyridine-based reagents, a number of different solvent systems are available to increase solubility and to minimize interferences from ketones and aldehydes.

SCOPE

1.1 This test method is applicable to all paints and paint materials, including resins, monomers, and solvents, with the exception of aldehydes and certain active metals, metal oxides, and metal hydroxides. While the evaluation was limited to pigmented products containing amounts of water in the 30 to 70 % range, there is reason to believe that higher and lower concentrations can be determined by this test method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only..

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4017 − 02 (Reapproved2008)

Standard Test Method for

Water in Paints and Paint Materials by Karl Fischer Method

This standard is issued under the fixed designation D4017; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—The units statement in subsection 1.2 was corrected editorially in April 2008.

1. Scope 2.2 Other Standard:

EPAFederalReferenceMethod24DeterminationofVolatile

1.1 This test method is applicable to all paints and paint

Matter Content, Density, Volume Solids, and Weight

materials, including resins, monomers, and solvents, with the

Solids of Surface Coatings

exceptionofaldehydesandcertainactivemetals,metaloxides,

and metal hydroxides. While the evaluation was limited to

3. Summary of Test Method

pigmented products containing amounts of water in the 30 to

3.1 The material is dissolved in a suitable solvent, and

70% range, there is reason to believe that higher and lower

titrated directly with standardized Karl Fischer reagent, to an

concentrations can be determined by this test method.

electrometric end point. The sluggish reaction with water in

1.2 The values stated in SI units are to be regarded as the

pyridine is accelerated with a chemical catalyst,

standard. The values given in parentheses are for information

1-ethylpiperidine.

only.

3.1.1 Karl Fischer reagent is a mixture of iodine, amine,

1.3 This standard does not purport to address all of the

sulfur dioxide, and an alcohol. In the reaction with water,

safety concerns, if any, associated with its use. It is the

iodine is reduced to hydrogen iodide. Once all the water is

responsibility of the user of this standard to establish appro-

consumed, the appearance of free iodine is detected electro-

priate safety and health practices and determine the applica-

chemically and the titration is stopped. The following depicts

bility of regulatory limitations prior to use. Specific hazard

the chemistry that takes place:

statements are given in Section 7.

ROH+SO +RN↔ (RNH)SO R

2 3

HO+I +(RNH)SO R+2RN→ (RNH)SO R+2(RNH)I

2 2 3 4

2. Referenced Documents

3.2 In classical Karl Fischer titrations the base used is

2.1 ASTM Standards:

pyridine, and the solvent either methanol or methoxy ethanol.

D1193Specification for Reagent Water In order to accelerate the reaction when pyridine is used,

D3960PracticeforDeterminingVolatileOrganicCompound

1-ethylpiperidine is used as a catalyst/buffer. The additional

(VOC) Content of Paints and Related Coatings buffer capacity is usually already built in to most nonpyridine

E180Practice for Determining the Precision of ASTM

based reagents such as hydranal (see Hydranal Manual).

Methods for Analysis and Testing of Industrial and Spe-

4. Significance and Use

cialty Chemicals (Withdrawn 2009)

E203Test Method for Water Using Volumetric Karl Fischer

4.1 Control of water content is often important in control-

Titration

ling the performance of paint and paint ingredients, and it is

critical in controlling volatile organic compound (VOC) con-

tent.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

4.2 Paint materials are often insoluble in common Karl

andRelatedCoatings,Materials,andApplicationsandisthedirectresponsibilityof

Fischer solvents such as methanol. Pyridine has been found to

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

be a nearly universal solvent for these materials; however, the

Current edition approved Feb. 1, 2008. Published April 2008. Originally

approved in 1981. Last previous edition approved in 2002 as D4017–02. DOI: Karl Fischer reaction is too slow in that solvent at room

10.1520/D4017-02R08E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

3 5

The last approved version of this historical standard is referenced on AvailablefromHoechstCelaneseCorporation,HydranalTechnicalCenter,U.S.

www.astm.org. Highway 43, Bucks, AL 36512.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

´1

D4017 − 02 (2008)

temperature. To speed it up, 1-ethylpiperidine is added at 5% 7. Hazards

as a buffer, or “catalyst.”

7.1 Karl Fischer reagent contains four toxic compounds,

4.3 For nonpyridine-based reagents, a number of different namelyiodine,sulfurdioxide,pyridine,andmethanolorglycol

solvent systems are available to increase solubility and to ether.Prepareanddispensethereagentinahood.Caremustbe

minimize interferences from ketones and aldehydes. exercised to avoid inhalation or skin contact. Following acci-

dental contact or spillage, wash with large quantities of water.

5. Apparatus

7.2 Treatpyridineandmethanolsolventswiththesamecare

5.1 Karl Fischer Apparatus, manual or automatic, encom-

as Karl Fischer reagent.

passed by the description in Test Method E203. Apparatus

7.3 1-ethylpiperidine is of unknown toxicity and, therefore,

shouldbeequippedwitha25-mLburet,ClassA,orequivalent.

handlewiththesamecareasthematerialslistedin7.1and7.2.

5.2 Syringe, 100-µL capacity, with needle.

7.4 Handle also nonpyridine based reagents with the same

5.3 Syringes,1-mLand10-mLcapacity,withoutneedle,but

care as the chemicals listed in 7.1 and 7.2.

equipped with caps.

8. Procedure

6. Reagents

8.1 Standardization of Karl Fischer Reagent:

6.1 Purity of Reagents—Reagent grade chemicals shall be

8.1.1 Addenoughfreshsolventtocovertheelectrodetip.If

used in all tests. Unless otherwise indicated, it is intended that

using pyridine, also add 1 mLof 1-ethylpiperidine catalyst per

all reagents shall conform to the specifications of the Commit-

20mLofpyridine.Catalystperformsbestataconcentrationof

tee onAnalytical Reagents of theAmerican Chemical Society,

about 5% of the volume present.

where such specifications are available. Other grades may be

8.1.2 Fillthe100-µLsyringetoabouthalffullwithdistilled

used,provideditisascertainedthatthereagentisofsufficiently

water and weigh to the nearest 0.1 mg.

high purity to permit its use without lessening the accuracy of

8.1.3 Pretitrate the solvent to the end point indicated by the

the determination.

equipment manufacturer, by adding just enough Karl Fischer

Reagent I (KFR) to cause the end point to hold for at least 30

s.

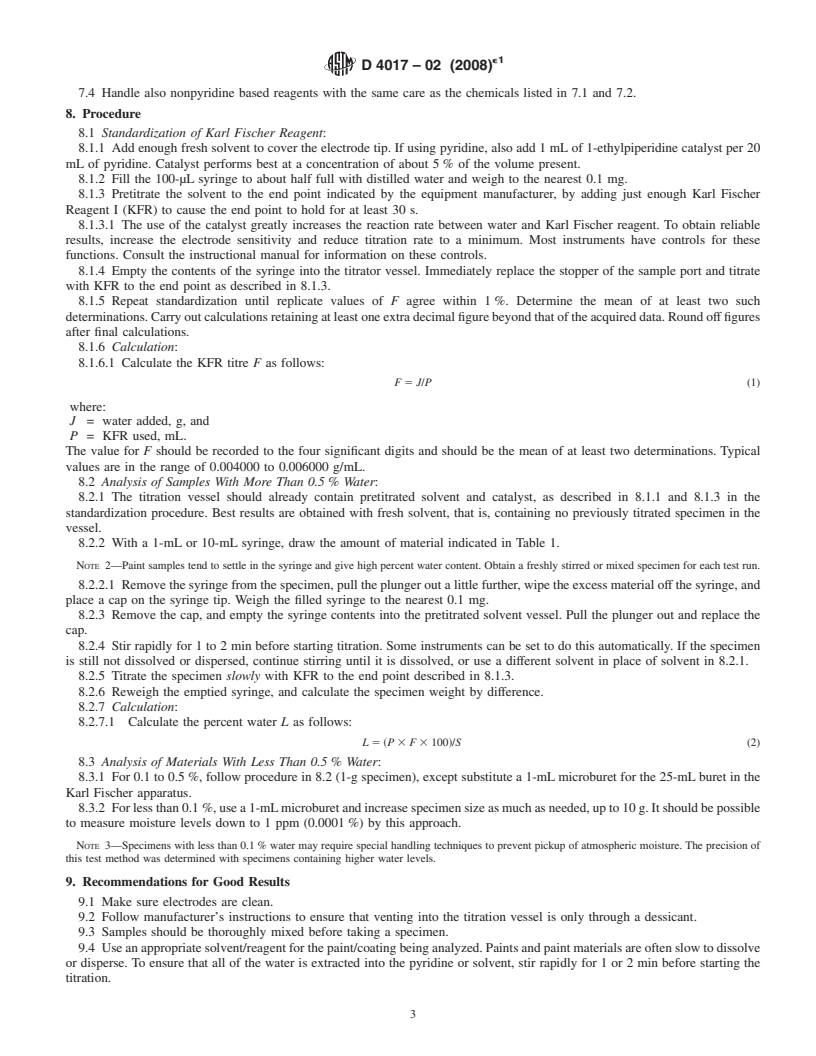

TABLE 1 Specimen Guidelines

8.1.3.1 The use of the catalyst greatly increases the reaction

Approximate Approximate

Expected

ratebetweenwaterandKarlFischerreagent.Toobtainreliable

Specimen Titrant Volume

water,

Weight, at 5 mg/mL

results, increase the electrode sensitivity and reduce titration

%

g titre, mL

rate to a minimum. Most instruments have controls for these

0.5–1.0 5 5–10

functions. Consult the instructional manual for information on

1–3 2–5 10–20

3–10 1–2 10–20 these controls.

10–30 0.4–1.0 20–25

8.1.4 Empty the contents of the syringe into the titrator

30–70 0.1–0.4 15–25

vessel. Immediately replace the stopper of the sample port and

>70 0.1 20

titrate with KFR to the end point as described in 8.1.3.

8.1.5 Repeat standardization until replicate values of F

agree within 1%. Determine the mean of at least two such

6.2 Purity of Water—Unless otherwise indicated, references

determinations. Carry out calculations retaining at least one

to water shall be understood to mean reagent grade water

extra decimal figure beyond that of the acquired data. Round

conforming to Type II of Specification D1193.

off figures after final calculations.

6.3 Classical Karl Fischer Reagent.

8.1.6 Calculation:

6.3.1 Nonpyridine Based Karl Fischer Reagent (KFR).

8.1.6.1 Calculate the KFR titre F as follows:

6.4 Pyridine.

F 5 J/P (1)

6.5 1-Ethylpiperidine.

where:

6.6 Hydrochloric Acid (HCl), concentrated.

J = water added, g, and

P = KFR used, mL.

NOTE 1—All reagents must be fresh. Do not use reagents that are more

than 9 months old. Karl Fischer reagent deteriorates with age. Check The value for F should be recorded to the four significant

expiration dates on the reagent bottle.

digits and should be the mean of at least two determinations.

Typical values are in the range of 0.004000 to 0.006000 g/mL.

Reagent Chemicals, American Chemical Society Specifications, American

8.2 Analysis of Samples With More Than 0.5 % Water:

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

8.2.1 The titration vessel should already contain pretitrated

listed by the American Chemical Society, see Analar Standards for Laboratory

solvent and catalyst, as described in 8.1.1 and 8.1.3 in the

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

standardization procedure. Best results are obtained with fresh

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

solvent, that is, containing no previously titrated specimen in

So-K-3 available from Fischer Scientific Co., or equivalent has been found

the vessel.

suitable for this purpose.

8.2.2 With a 1-mL or 10-mL syringe, draw the amount of

Use1-ethylpiperidine,manufacturedbytheAldrichChemicalCo.,Milwaukee,

WI 53233, for the best results. material indicated in Table 1.

´1

D4017 − 02 (2008)

NOTE 2—Paint samples tend to settle in the syringe and give high

9.8 For difficult-to-dissolve samples, extract the water with

percentwatercontent.Obtainafreshlystirredormixedspecimenforeach

a suitable solvent, such as dry methanol. An example of this

test run.

procedure is outlined in Appendix X1.

8.2.2.1 Remove the syringe from the specimen, pull the

10. Maintenance

plunger out a little further, wipe the excess material off the

10.1 Cleanup—Clean the titration vessel by rinsing with

syringe, and place a cap on the syringe tip. Weigh the filled

fresh pyridine. Do not use methanol or other solvents.

syringe to the nearest 0.1 mg.

8.2.3 Remove the cap, and empty the syringe contents into

10.2 Dryness—Check frequently to be sure that all drying

the pretitrated solvent vessel. Pull the plunger out and replace

tubes are in good condition and tightly connected. Replace

the cap.

dessicant when indicator color changes through half of the

8.2.4 Stir rapidly for 1 to 2 min before starting titration.

tube.

Some instruments can be set to do this automatically. If the

10.3 Electrode Performance—If electrode response is slug-

specimen is still not dissolved or dispersed, continue stirring

gishorotherwiseoffstandard,takethefollowingsteps,inturn,

until it is dissolved, or use a different solvent in place of

to correct the problem. Test the electrode with a titration after

solvent in 8.2.1.

each step, to determine if the next step is required.

8.2.5 Titratethespecimen slowlywithKFRtotheendpoint

10.3.1 Wipe the electrode tip with a clean paper towel.

described in 8.1.3.

10.3.2 Wash the electrode by dipping in concentrated hy-

8.2.6 Reweigh the emptied syringe, and calculate the speci-

drochloric acid for at least 1 min. Rinse first with distilled

men weight by difference.

water, then with methanol.

8.2.7 Calculation:

10.3.3 Follow manufacturer’s instructions on resetting end

8.2.7.1 Calculate the percent water L as follows: point meter.

10.3.4 Replace power source. See manual for replacement

L 5 ~P 3 F 3100!/S (2)

procedure.

8.3 Analysis of Materials With Less Than 0.5 % Water:

10.3.5 Replace the electrode.

8.3.1 For 0.1 to 0.5%, follow procedure in 8.2 (1-g

11. Precision and Bias

specimen), except substitute a 1-mLmicroburet for the 25-mL

buret in the Karl Fischer apparatus. 11.1 Theprecisionestimatesarebasedonaninterlaboratory

study in which one operator in each of seven different

8.3.2 For less than 0.1%, use a 1-mL microburet and

increasespecimensizeasmuchasneeded,upto10g.Itshould laboratories analyzed in duplicate on two different days seven

samples of water-based paints of various types containing

be possible to measure moisture levels down to 1 ppm

(0.0001%) by this approach. between 25 to 75% water. The results were analyzed statisti-

cally in accordance with Practice E180. The within-laboratory

NOTE 3—Specimens with less than 0.1% water may require special

coefficient of variation was found to be 0.9% relative at 23 df,

handling techniques to prevent pickup of atmospheric moisture. The

and the between-laboratory coefficient of variation was 1.9%

precision of this test method was determined with specimens containing

higher water levels. relative, at 18 df. Based on these coefficients, the following

criteria should be used for judging the acceptability of results

9. Recommendations for Good Results at the 95% confidence level.

11.1.1 Repeatability—Two results, each the mean of dupli-

9.1 Make sure electrodes are clean.

catedeterminations,obtainedbythesameoperatorondifferent

9.2 Follow manufacturer’s instructions to ensure that vent-

days should be considered suspect if they differ by more than

ing into the titration vessel is only through a dessicant.

3.5% relative.

11.1.2 Reproducibility—Two results, each the mean of du-

9.3 Samples should be thoroughly mixed before taking a

plicate determinations, obtained by operators in different labo-

specimen.

ratories should be considered suspect if they differ by more

9.4 Use an appropriate solvent/reagent for the paint/coating

than 5.5% relative.

being analyzed. Paints and paint materials are often slow to

11.2 Bias—Bias cannot be determined because there are no

dissolveordisperse.Toensurethatallofthewaterisextracted

accepted standards for water content of paints.

into the pyridine or solvent, stir rapidly for 1 or 2 min before

starting the titration.

12. Keywords

9.5 Run the titration slowly with rapid stirring. 12.1 Karl Fischer reagent method; moisture content; water

content

9.6 Throw out the first result in fresh pyridine.

9.7 UseonlyAldrich’s1-ethylpiperidine. Ithasbeenfound 9

Supporting data have been filed atASTM International Headquarters and may

that other brands produce variable results. be obtained by requesting Research Report RR:D01-1096.

´1

D4017 − 02 (2008)

APPENDIXES

(Nonmandatory Information)

X1. TEST METHOD FOR KARL FISCHER WATER DETERMINATION FOR LATEX PAINTS USING

EXTRACTION WITH METHANOL

X1.1 Scope X1.4.5 For further informat

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:D4017–96a Designation:D4017–02(Reapproved2008)

Standard Test Method for

Water in Paints and Paint Materials by Karl Fischer Method

This standard is issued under the fixed designation D4017; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—The units statement in subsection 1.2 was corrected editorially in April 2008.

1. Scope

1.1 Thistestmethodisapplicabletoallpaintsandpaintmaterials,includingresins,monomers,andsolvents,withtheexception

of aldehydes and certain active metals, metal oxides, and metal hydroxides. While the evaluation was limited to pigmented

products containing amounts of water in the 30 to 70% range, there is reason to believe that higher and lower concentrations can

be determined by this test method.

1.2

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazard statements are given in Section 7.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D3960 Practice for Determining Volatile Organic Compound (VOC) Content of Paints and Related Coatings

E180 PracticeforDeterminingthePrecisionofASTMMethodsforAnalysisandTestingofIndustrialandSpecialtyChemicals

E203 Test Method for Water Using Volumetric Karl Fischer Reagent Titration

2.2 Other Standard:

EPA Federal Reference Method24—DeterminationMethod24 Determination of Volatile Matter Content, Density, Volume

Solids, and Weight Solids of Surface Coatings

3. Summary of Test Method

3.1 The material is dissolved in a suitable solvent, and titrated directly with standardized Karl Fischer reagent, to an

electrometric end point. The sluggish reaction with water in pyridine is accelerated with a chemical catalyst, 1-ethylpiperidine.

3.1.1 Karl Fischer reagent is a mixture of iodine, amine, sulfur dioxide, and an alcohol. In the reaction with water, iodine is

reduced to hydrogen iodide. Once all the water is consumed, the appearance of free iodine is detected electrochemically and the

titration is stopped. The following depicts the chemistry that takes place:

ROH+SO +RN↔ (RNH)SO R

2 3

H O+I +(RNH)SO R+2RN→ (RNH)SO R+2(RNH)I

2 2 3 4

3.2 In classical Karl Fischer titrations the base used is pyridine, and the solvent either methanol or methoxy ethanol. In order

to accelerate the reaction when pyridine is used, 1-ethylpiperidine is used as a catalyst/buffer. The additional buffer capacity is

usually already built in to most nonpyridine based reagents such as hydranal (see Hydranal Manual).

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials .

Current edition approved July 10,1996. Feb. 1, 2008. Published September 1996.April 2008. Originally published as D4017–81.approved in 1981. Last previous edition

D4017–96.approved in 2002 as D4017–02.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 06.01.

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Annual Book of ASTM Standards, Vol 15.05.

Available from Hoechst Celanese Corporation, Hydranal Technical Center, U.S. Highway 43, Bucks, AL 36512.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

e1

D4017–02 (2008)

4. Significance and Use

4.1 Control of water content is often important in controlling the performance of paint and paint ingredients, and it is critical

in controlling volatile organic compound (VOC) content.

4.2 Paint materials are often insoluble in common Karl Fischer solvents such as methanol. Pyridine has been found to be a

nearly universal solvent for these materials; however, the Karl Fischer reaction is too slow in that solvent at room temperature.

To speed it up, 1-ethylpiperidine is added at 5% as a buffer, or “catalyst”.”

4.3 For nonpyridine-based reagents, a number of different solvent systems are available to increase solubility and to minimize

interferences from ketones and aldehydes.

5. Apparatus

5.1 Karl Fischer Apparatus, manual or automatic, encompassed by the description inTest Method E203.Apparatus should be

equipped with a 25-mL buret, Class A, or equivalent.

5.2 Syringe, 100-µL capacity, with needle.

5.3 Syringes, 1-mL and 10-mL capacity, without needle, but equipped with caps.

6. Reagents

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

suchspecificationsareavailable. Othergradesmaybeused,provideditisascertainedthatthereagentisofsufficientlyhighpurity

to permit its use without lessening the accuracy of the determination.

TABLE 1 Specimen Guidelines

Approximate Approximate

Expected

Specimen Titrant Volume

water,

Weight, at 5 mg/mL

%

g titre, mL

0.5–1.0 5 5–10

1–3 2–5 10–20

3–10 1–2 10–20

10–30 0.4–1.0 20–25

30–70 0.1–0.4 15–25

>70 0.1 20

6.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent grade water

conforming to Type II of Specification D1193.

6.3 Classical Karl Fischer Reagent.

6.3.1 Nonpyridine Based Karl Fischer Reagent (KFR).

6.4 Pyridine.

6.5 1-Ethylpiperidine.

6.6 Hydrochloric Acid (HCl), concentrated.

NOTE 1—Allreagentsmustbefresh.Donotusereagentsthataremorethan9monthsold.KarlFischerreagentdeteriorateswithage.Checkexpiration

dates on the reagent bottle.

7. Hazards

7.1 Karl Fischer reagent contains four toxic compounds, namely iodine, sulfur dioxide, pyridine, and methanol or glycol ether.

Prepare and dispense the reagent in a hood. Care must be exercised to avoid inhalation or skin contact. Following accidental

contact or spillage, wash with large quantities of water.

7.2 Treat pyridine and methanol solvents with the same care as Karl Fischer reagent.

7.3 1-ethylpiperidine is of unknown toxicity and, therefore, handle with the same care as the materials listed in 7.1 and 7.2.

Available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

Reagent Chemicals, American Chemical Society Specifications ,American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

Available from Hoechst Celanese Corporation, Hydranal Technical Center, U.S. Highway 43, Bucks, AL 36512.

So-K-3 available from Fischer Scientific Co., or equivalent has been found suitable for this purpose.

Reagent Chemicals,American Chemical Society Specifications,American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville, MD.

Use 1-ethylpiperidine, manufactured by the Aldrich Chemical Co., Milwaukee, WI 53233, for the best results.

e1

D4017–02 (2008)

7.4 Handle also nonpyridine based reagents with the same care as the chemicals listed in 7.1 and 7.2.

8. Procedure

8.1 Standardization of Karl Fischer Reagent:

8.1.1 Add enough fresh solvent to cover the electrode tip. If using pyridine, also add 1 mLof 1-ethylpiperidine catalyst per 20

mL of pyridine. Catalyst performs best at a concentration of about 5% of the volume present.

8.1.2 Fill the 100-µL syringe to about half full with distilled water and weigh to the nearest 0.1 mg.

8.1.3 Pretitrate the solvent to the end point indicated by the equipment manufacturer, by adding just enough Karl Fischer

Reagent I (KFR) to cause the end point to hold for at least 30 s.

8.1.3.1 The use of the catalyst greatly increases the reaction rate between water and Karl Fischer reagent. To obtain reliable

results, increase the electrode sensitivity and reduce titration rate to a minimum. Most instruments have controls for these

functions. Consult the instructional manual for information on these controls.

8.1.4 Empty the contents of the syringe into the titrator vessel. Immediately replace the stopper of the sample port and titrate

with KFR to the end point as described in 8.1.3.

8.1.5 Repeat standardization until replicate values of F agree within 1%. Determine the mean of at least two such

determinations.Carryoutcalculationsretainingatleastoneextradecimalfigurebeyondthatoftheacquireddata.Roundofffigures

after final calculations.

8.1.6 Calculation:

8.1.6.1 Calculate the KFR titre F as follows:

F 5 J/P (1)

where:

J = water added, g, and

P = KFR used, mL.

The value for F should be recorded to the four significant digits and should be the mean of at least two determinations. Typical

values are in the range of 0.004000 to 0.006000 g/mL.

8.2 Analysis of Samples With More Than 0.5 % Water:

8.2.1 The titration vessel should already contain pretitrated solvent and catalyst, as described in 8.1.1 and 8.1.3 in the

standardization procedure. Best results are obtained with fresh solvent, that is, containing no previously titrated specimen in the

vessel.

8.2.2 With a 1-mL or 10-mL syringe, draw the amount of material indicated in Table 1.

NOTE 2—Paint samples tend to settle in the syringe and give high percent water content. Obtain a freshly stirred or mixed specimen for each test run.

8.2.2.1 Removethesyringefromthespecimen,pulltheplungeroutalittlefurther,wipetheexcessmaterialoffthesyringe,and

place a cap on the syringe tip. Weigh the filled syringe to the nearest 0.1 mg.

8.2.3 Remove the cap, and empty the syringe contents into the pretitrated solvent vessel. Pull the plunger out and replace the

cap.

8.2.4 Stir rapidly for 1 to 2 min before starting titration. Some instruments can be set to do this automatically. If the specimen

is still not dissolved or dispersed, continue stirring until it is dissolved, or use a different solvent in place of solvent in 8.2.1.

8.2.5 Titrate the specimen slowly with KFR to the end point described in 8.1.3.

8.2.6 Reweigh the emptied syringe, and calculate the specimen weight by difference.

8.2.7 Calculation:

8.2.7.1 Calculate the percent water L as follows:

L 5 ~P 3 F 3100!/S (2)

8.3 Analysis of Materials With Less Than 0.5 % Water:

8.3.1 For 0.1 to 0.5%, follow procedure in 8.2 (1-g specimen), except substitute a 1-mLmicroburet for the 25-mLburet in the

Karl Fischer apparatus.

8.3.2 Forlessthan0.1%,usea1-mLmicroburetandincreasespecimensizeasmuchasneeded,upto10g.Itshouldbepossible

to measure moisture levels down to 1 ppm (0.0001%) by this approach.

NOTE 3—Specimens with less than 0.1% water may require special handling techniques to prevent pickup of atmospheric moisture. The precision of

this test method was determined with specimens containing higher water levels.

9. Recommendations for Good Results

9.1 Make sure electrodes are clean.

9.2 Follow manufacturer’s instructions to ensure that venting into the titration vessel is only through a dessicant.

9.3 Samples should be thoroughly mixed before taking a specimen.

9.4 Useanappropriatesolvent/reagentforthepaint/coatingbeinganalyzed.Paintsandpaintmaterialsareoftenslowtodissolve

or disperse. To ensure that all of the water is extracted into the pyridine or solvent, stir rapidly for 1 or 2 min before starting the

titration.

e1

D4017–02 (2008)

9.5 Run the titration slowly with rapid stirring.

9.6 Throw out the first result in fresh pyridine.

9.7 Use only Aldrich’s 1-ethylpiperidine. It has been found that other brands produce variable results.

9.8 For difficult-to-dissolve samples, extract the water with a suitable solvent, such as dry methanol. An example of this

procedure is outlined in Appendix X1.

10. Maintenance

10.1 Cleanup—Clean the titration vessel by rinsing with fresh pyridine. Do not use methanol or other solvents.

10.2 Dryness—Checkfrequentlytobesurethatalldryingtubesareingoodconditionandtightlyconnected.Replacedessicant

when indicator color changes through half of the tube.

10.3 Electrode Performance—If electrode response is sluggish or otherwise off standard, take the following steps, in turn, to

correct the problem. Test the electrode with a titration after each step, to determine if the next step is required.

10.3.1 Wipe the electrode tip with a clean paper towel.

10.3.2 Wash the electrode by dipping in concentrated hydrochloric acid for at least 1 min. Rinse first with distilled water, then

with methanol.

10.3.3 Follow manufacturer’s instructions on resetting end point meter.

10.3.4 Replace power source. See manual for replacement procedure.

10.3.5 Replace the electrode.

11. Precision and Bias

11.1 The precision estimates are based on an interlaboratory study in which one operator in each of seven different laboratories

analyzed in duplicate on two different days seven samples of water-based paints of various types containing between 25 to 75%

water.TheresultswereanalyzedstatisticallyinaccordancewithPracticeE180.Thewithin-laboratorycoefficientofvariationwas

foundtobe0.9%relativeat23df,andthebetween-laboratorycoefficientofvariationwas1.9%relative,at18df.Basedonthese

coefficients, the following criteria should be used for judging the acceptability

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.