ASTM F2213-06(2011)

(Test Method)Standard Test Method for Measurement of Magnetically Induced Torque on Medical Devices in the Magnetic Resonance Environment

Standard Test Method for Measurement of Magnetically Induced Torque on Medical Devices in the Magnetic Resonance Environment

SIGNIFICANCE AND USE

This test method is one of those required to determine if the presence of a medical device may cause injury during a magnetic resonance examination and in the magnetic resonance environment. Other safety issues which should be addressed include but may not be limited to magnetically induced force (see Test Method F2052) and RF heating (see Test Method F2182). The terms and icons in Practice F2503 should be used to mark the device for safety in the magnetic resonance environment.

If the maximal torque is less than the product of the longest dimension of the medical device and its weight, then the magnetically induced deflection torque is less than the worst case torque on the device due to gravity. For this condition, it is assumed that any risk imposed by the application of the magnetically induced torque is no greater than any risk imposed by normal daily activity in the Earth's gravitational field. This is conservative; it is possible that greater torques would not pose a hazard to the patient.

This test method alone is not sufficient for determining if an implant is safe in the MR environment.

The sensitivity of the torque measurement apparatus must be greater than 1/10 the “gravity torque,” the product of device weight and the largest linear dimension.

The torque considered here is the magneto-static torque due to the interaction of the MRI static magnetic field with the magnetization in the implant. The dynamic torque due to interaction of the static field with eddy currents induced in a rotating device is not addressed in this test method. Currents in lead wires may induce a torque as well.

SCOPE

1.1 This test method covers the measurement of the magnetically induced torque produced by the static magnetic field in the magnetic resonance environment on medical devices and the comparison of that torque to the equivalent torque applied by the gravitational force to the implant.

1.2 This test method does not address other possible safety issues which include but are not limited to issues of magnetically induced force due to spatial gradients in the static magnetic field, RF heating, induced heating, acoustic noise, interaction among devices, and the functionality of the device and the MR system.

1.3 The torque considered here is the magneto-static torque due to the interaction of the MRI static magnetic field with the magnetization in the implant. The dynamic torque due to interaction of the static field with eddy currents induced in a rotating device is not addressed in this test method. Currents in lead wires may induce a torque as well.

1.4 The sensitivity of the torque measurement apparatus must be greater than 1/10 the “gravity torque,” the product of the device's maximum linear dimension and its weight.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2213 − 06 (Reapproved 2011)

Standard Test Method for

Measurement of Magnetically Induced Torque on Medical

Devices in the Magnetic Resonance Environment

This standard is issued under the fixed designation F2213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the measurement of the mag- 2.1 ASTM Standards:

netically induced torque produced by the static magnetic field F2052Test Method for Measurement of Magnetically In-

inthemagneticresonanceenvironmentonmedicaldevicesand duced Displacement Force on Medical Devices in the

the comparison of that torque to the equivalent torque applied Magnetic Resonance Environment

by the gravitational force to the implant. F2119Test Method for Evaluation of MR Image Artifacts

from Passive Implants

1.2 This test method does not address other possible safety

F2182Test Method for Measurement of Radio Frequency

issues which include but are not limited to issues of magneti-

Induced Heating On or Near Passive Implants During

cally induced force due to spatial gradients in the static

Magnetic Resonance Imaging

magnetic field, RF heating, induced heating, acoustic noise,

F2503Practice for Marking Medical Devices and Other

interaction among devices, and the functionality of the device

Items for Safety in the Magnetic Resonance Environment

and the MR system.

2.2 Other Standards:

1.3 The torque considered here is the magneto-static torque

IEC 60601-2-33Ed. 2.0 Medical Electrical Equipment—

due to the interaction of the MRI static magnetic field with the

Part2:ParticularRequirementsfortheSafetyofMagnetic

magnetization in the implant. The dynamic torque due to

Resonance Equipment for Medical Diagnosis, 2002

interaction of the static field with eddy currents induced in a

ISO 13485:2003(E) Medical Devices—Quality Manage-

rotatingdeviceisnotaddressedinthistestmethod.Currentsin

ment Systems—Requirements for Regulatory Purposes,

lead wires may induce a torque as well.

definition 3.7

1.4 The sensitivity of the torque measurement apparatus

3. Terminology

mustbegreaterthan ⁄10the“gravitytorque,”theproductofthe

3.1 Definitions—For the purposes of this test method, the

device’s maximum linear dimension and its weight.

definitions in 3.1.1 – 3.1.18 shall apply:

1.5 The values stated in SI units are to be regarded as

3.1.1 diamagnetic material—a material whose relative per-

standard. No other units of measurement are included in this

meability is less than unity.

standard.

3.1.2 ferromagnetic material—a material whose magnetic

1.6 This standard does not purport to address all of the

moments are ordered and parallel producing magnetization in

safety concerns, if any, associated with its use. It is the

one direction.

responsibility of the user of this standard to establish appro-

3.1.3 magnetic induction or magnetic flux density (B in

priate safety and health practices and determine the applica-

T)—that magnetic vector quantity which at any point in a

bility of regulatory limitations prior to use.

magnetic field is measured either by the mechanical force

1 2

ThistestmethodisunderthejurisdictionofASTMCommitteeF04onMedical For referenced ASTM standards, visit the ASTM website, www.astm.org, or

andSurgicalMaterialsandDevicesandisthedirectresponsibilityofSubcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F04.15 on Material Test Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2011. Published October 2011. Originally the ASTM website.

approved in 2002. Last previous edition approved in 2006 as F2213–06. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F2213-06R11. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2213 − 06 (2011)

experiencedbyanelementofelectriccurrentatthepoint,orby article, intended by the manufacturer to be used, alone or in

the electromotive force induced in an elementary loop during combination, for human beings for one or more of the specific

any change in flux linkages with the loop at the point. The purpose(s) of:

magnetic induction is frequently referred to as the magnetic

(1) diagnosis, prevention, monitoring, treatment, or allevia-

tion of disease,

field. B isthestaticfieldinanMRsystem.Plaintypeindicates

(2) diagnosis, monitoring, treatment, alleviation of, or com-

a scalar (for example, B) and bold type indicates a vector (for

pensation for an injury,

example,B).

(3) investigation, replacement, modification, or support of the

anatomy or of a physiological process,

3.1.4 magnetic field strength (H in A/m)—strength of the

(4) supporting or sustaining life,

(5) control of conception,

applied magnetic field.

(6) disinfection of medical devices, and

3.1.5 magnetic resonance (MR)—resonant absorption of (7) providing information for medical purposes by means of

in vitro examination of specimens derived from the hu-

electromagnetic energy by an ensemble of atomic particle

man body, and which does not achieve its primary in-

situated in a magnetic field.

tended action in or on the human body by

pharmacological, immunological, or metabolic means,

3.1.6 magnetic resonance diagnostic device—a device in-

but which may be assisted in its function by such means.

tended for general diagnostic use to present images which

ISO 13485

reflectthespatialdistributionormagneticresonancespectra,or

3.1.16 paramagnetic material—a material having a relative

both, which reflect frequency and distribution of nuclei exhib-

permeability which is slightly greater than unity, and which is

iting nuclear magnetic resonance. Other physical parameters

practically independent of the magnetizing force.

derived from the images or spectra, or both, may also be

3.1.17 passive implant—an implant that serves its function

produced.

without the supply of electrical power.

3.1.7 magnetic resonance (MR) environment—volume

3.1.18 tesla, (T)—the SI unit of magnetic induction equal to

within the 0.50 mT(5 gauss (G)) line of an MR system, which 4

10 gauss (G).

includes the entire three dimensional volume of space sur-

4. Summary of Test Method

rounding the MR scanner. For cases where the 0.50 mT line is

contained within the Faraday shielded volume, the entire room

4.1 Thestaticfieldinamagneticresonancesystemproduces

shall be considered the MR environment.

atorqueonadevicethatactstoalignthelongaxisoftheobject

with the magnetic field. The torque is evaluated using a

3.1.8 magnetic resonance equipment—medical electrical

torsional pendulum method. A device is placed on a holder

equipment which is intended for in-vivo magnetic resonance

suspended by a torsional spring.The apparatus is placed in the

examination of a patient. The MR equipment comprises all

center of the magnetic resonance equipment magnet where the

parts in hardware and software from the supply mains to the

magnetic field is uniform. The torque is determined from the

display monitor. The MR equipment is a Programmable

measurement of the deflection angle of the holder from its

Electrical Medical System (PEMS).

equilibrium position. The frame holding the spring and holder

3.1.9 magnetic resonance examination (MR Examination)—

assembly is rotated and the torque as a function of angle of the

process of acquiring data by magnetic resonance from a

implant is determined. The maximal magnetic torque is com-

patient.

paredtotheworstcasegravitytorque,definedastheproductof

the maximum linear dimension of the device and the device

3.1.10 magnetic resonance imaging (MRI)—imaging tech-

nique that uses static and time varying magnetic fields to weight.

provide images of tissue by the magnetic resonance of nuclei.

5. Significance and Use

3.1.11 magnetic resonance system (MR System)—ensemble

5.1 Thistestmethodisoneofthoserequiredtodetermineif

of MR equipment, accessories including means for display,

the presence of a medical device may cause injury during a

control, energy supplies, and the MR environment.

magnetic resonance examination and in the magnetic reso-

IEC 60601–2–33

nance environment. Other safety issues which should be

3.1.12 magnetically induced displacement force—forcepro- addressed include but may not be limited to magnetically

induced force (see Test Method F2052) and RF heating (see

ducedwhenamagneticobjectisexposedtothespatialgradient

of a magnetic field. This force will tend to cause the object to Test Method F2182). The terms and icons in Practice F2503

should be used to mark the device for safety in the magnetic

translate in the gradient field.

resonance environment.

3.1.13 magnetically induced torque—torqueproducedwhen

5.2 If the maximal torque is less than the product of the

a magnetic object is exposed to a magnetic field. This torque

longest dimension of the medical device and its weight, then

will tend to cause the object to align itself along the magnetic

the magnetically induced deflection torque is less than the

field in an equilibrium direction that induces no torque.

worst case torque on the device due to gravity. For this

3.1.14 magnetization (M in T)—magnetic moment per unit

condition, it is assumed that any risk imposed by the applica-

volume.

tion of the magnetically induced torque is no greater than any

3.1.15 medical device—any instrument, apparatus, risk imposed by normal daily activity in the Earth’s gravita-

implement, machine, appliance, implant, in vitro reagent or tional field. This is conservative; it is possible that greater

calilbrator, software, material, or other similar or related torques would not pose a hazard to the patient.

F2213 − 06 (2011)

5.3 This test method alone is not sufficient for determining manufactured devices that have been processed to a finished

if an implant is safe in the MR environment. condition (for example, sterilized).

5.4 The sensitivity of the torque measurement apparatus

7.2 Forpurposesofdevicequalification,anyalterationfrom

must be greater than ⁄10 the “gravity torque,” the product of

the finished condition should be reported. For instance, if

device weight and the largest linear dimension.

sections are cut from the device for testing, this should be

reported.

5.5 The torque considered here is the magneto-static torque

due to the interaction of the MRI static magnetic field with the

8. Procedure

magnetization in the implant. The dynamic torque due to

interaction of the static field with eddy currents induced in a

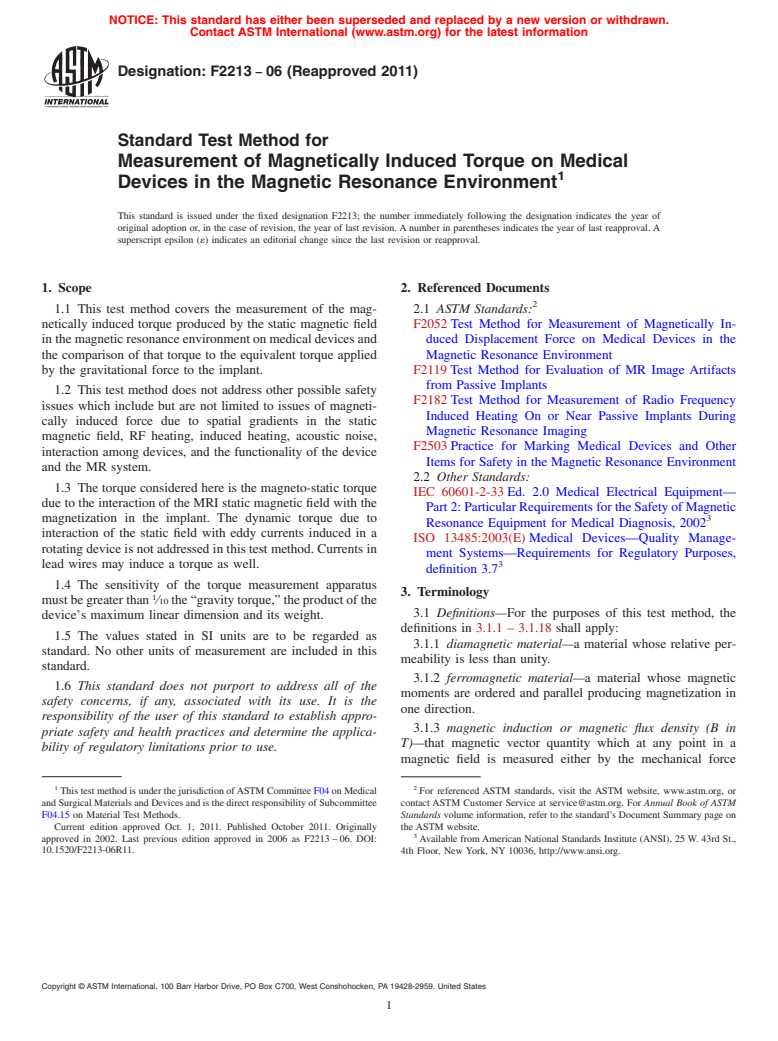

8.1 Fig. 1 depicts the test fixture, which is placed in the

rotatingdeviceisnotaddressedinthistestmethod.Currentsin

middle of the magnet where the magnetic field is uniform.The

lead wires may induce a torque as well.

test device is placed on the holding platform with one of its

principal axes in the vertical direction. The entire apparatus is

6. Apparatus

placed in the center of the magnet in the region of uniform

6.1 The test fixture is depicted in Fig. 1. It consists of a

magnetic field. Rotate the fixed base and measure the deflec-

sturdy structure supporting a holding platform supported by a

tionofthedevicewithrespecttothebaseat10°incrementsfor

torsional spring. Materials should be non-ferromagnetic. The

angles between 0° and 360°. Note that at angular values where

device may be taped or otherwise attached to the holding

the angular derivative of the torque changes sign, there will be

platform. The supporting structure will have fixed to it a

anabruptchangeindeflectionangleasthedeviceswingstothe

protractor with 1° graduated markings and the holding plat-

next equilibrium position. Try to measure the deflection angle

form will have a marker so that the angle between the basket

as close as possible to this swing so that the maximal torque

and the support structure can be measured. The supporting

will be determined.

structure is rotated with the turning knob. The equilibrium

angle between the supporting structure and the holding plat- 8.2 Repeat the process in 8.1 twice, once for each of the

other two principal axes of the device in the vertical direction.

form outside the magnetic field represents the zero torque

angle. The torque inside the magnet is equal to the product of

8.3 Lead wires should be arranged in a manner that is

the deflection angle and spring constant. The torsional spring

representativeofthe in vivoconfiguration.Iffeasible,thewires

diametershouldbechosensothatthemaximaldeflectionangle

should carry the currents that are applied in vivo.

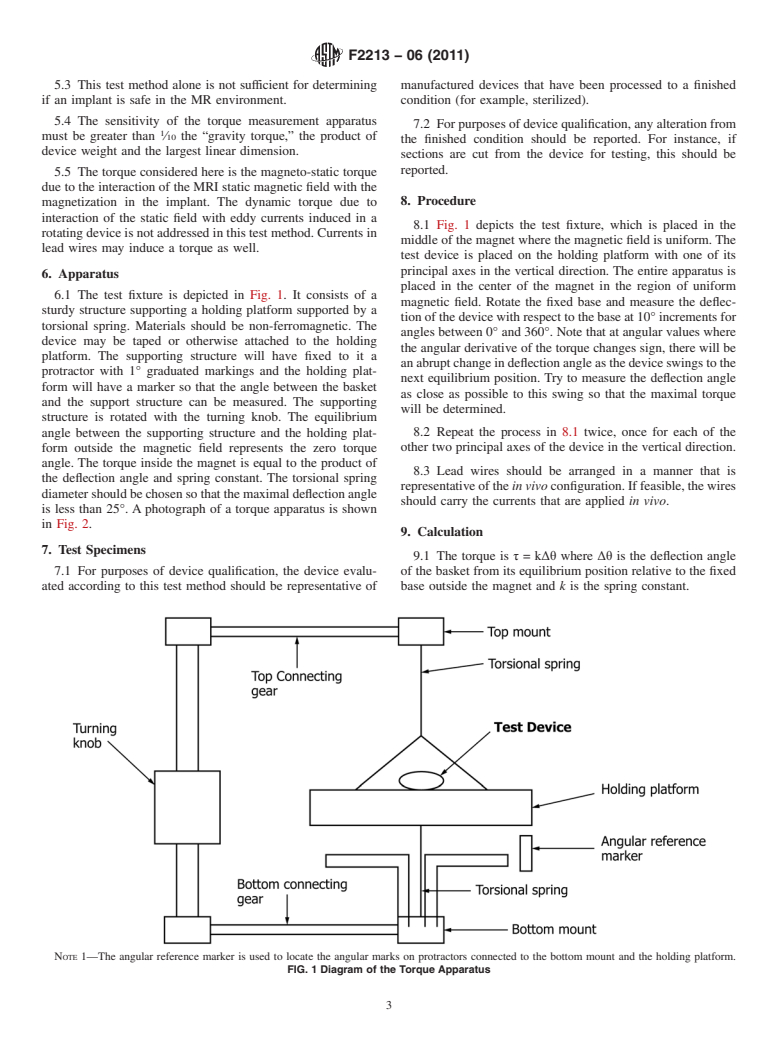

is less than 25°. A photograph of a torque apparatus is shown

in Fig. 2.

9. Calculation

7. Test Specimens

9.1 The torque is τ=k∆θ where ∆θ is the deflection angle

7.1 For purposes of device qualification, the device evalu- of the basket from its equilibrium position relative to the fixed

ated according to this test method should be representative of base outside the magnet and k is the spring constant.

NOTE 1—The angular reference marker is used to locate the angular marks on protractors connected to the bottom mount and the holding platform.

FIG. 1 Diagram of the Torque Apparatus

F2213 − 06 (2011)

NOTE 1—The turning knob is used to rotate the mounts supporting the torsional pendulum.

FIG. 2 Photograph of an Apparatus for Measurement of Magnetic Torque

10. Report coordinate system with origin at isocenter of the magnet.

Include a diagram showing the MR system and the coordinate

10.1 The report shall include the following for each speci-

axes.

men tested:

10.1.10 Diagram or photograph of the test apparatus, in-

10.1.1 Device product description including dimensioned

cluding the value of the spring constant.

drawing(s) or a photograph with dimensional scale.

10.1.11 Plots of torque in units of N-m versus angular

10.1.2 Adiagram or photograph showing the three configu-

position of a device axis with respect to the direction of the

rations of the device during the test.

staticfield.Therewillthreeplotsintotal,oneforeachprincipal

10.1.3 Deviceproductidentification(forexample,batch,lot

axis of the device oriented in the vertical direction.

number, type number, revision, serial number, date of manu-

10.1.12 Calculations of torque that would be exerted on

facture).

current loops in the device (see Appendix X4).

10.1.4 Materials of construction (ASTM designation or

10.1.13 Include a description and photograph of alterations

other).

that were done to the device.

10.1.5 Numberofspecime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.