ASTM E2261/E2261M-12

(Practice)Standard Practice for Examination of Welds Using the Alternating Current Field Measurement Technique

Standard Practice for Examination of Welds Using the Alternating Current Field Measurement Technique

SIGNIFICANCE AND USE

5.1 The purpose of the alternating current field measurement method is to evaluate welds for surface breaking discontinuities such as fabrication and fatigue cracks. The examination results may then be used by qualified organizations to assess weld service life or other engineering characteristics (beyond the scope of this practice). This practice is not intended for the examination of welds for non-surface breaking discontinuities.

SCOPE

1.1 This practice describes procedures to be followed during alternating current field measurement examination of welds for baseline and service-induced surface breaking discontinuities.

1.2 This practice is intended for use on welds in any metallic material.

1.3 This practice does not establish weld acceptance criteria.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system might not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2261/E2261M − 12

Standard Practice for

Examination of Welds Using the Alternating Current Field

1

Measurement Technique

ThisstandardisissuedunderthefixeddesignationE2261/E2261M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 Thispracticedescribesprocedurestobefollowedduring

3.1 Definitions—For definitions of terms relating to this

alternatingcurrentfieldmeasurementexaminationofweldsfor

practice refer to Terminology E1316, Section A, Common

baseline and service-induced surface breaking discontinuities.

NDT terms, and Section C, Electromagnetic testing. The

followingdefinitionsarespecifictothealternatingcurrentfield

1.2 This practice is intended for use on welds in any

measurement technique:

metallic material.

3.2 Definitions:

1.3 This practice does not establish weld acceptance crite-

3.2.1 exciter—a device that generates a time varying elec-

ria.

tromagnetic field, usually a coil energized with alternating

1.4 Units—The values stated in either inch-pound units or

current (AC); also known as a transmitter.

SI units are to be regarded separately as standard. The values

3.2.2 detector—one or more coils or elements used to sense

statedineachsystemmightnotbeexactequivalents;therefore,

or measure a magnetic field; also known as a receiver.

each system shall be used independently of the other. Combin-

ingvaluesfromthetwosystemsmayresultinnonconformance

3.2.3 uniform field—as applied to nondestructive testing

with the standard.

with magnetic fields, the area of uniform magnetic field over

the surface of the material under examination produced by a

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the parallel induced alternating current, which has been passed

through the weld and is observable beyond the direct coupling

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- of the exciting coil.

bility of regulatory limitations prior to use.

3.2.4 graduated field—as applied to nondestructive testing

with magnetic fields, a magnetic field having a controlled

2. Referenced Documents

gradient in its intensity.

2

2.1 ASTM Standards:

3.3 Definitions of Terms Specific to This Standard:

E543Specification forAgencies Performing Nondestructive

3.3.1 alternating current field measurement system—the

Testing

electronic instrumentation, software, probes, and all associated

E1316Terminology for Nondestructive Examinations

3

components and cables required for performing weld exami-

2.2 ASNT Standard:

nation using the alternating current field measurement tech-

SNT-TC-1APersonnel Qualification and Certification in

nique.

Nondestructive Testing

ANSI/ASNT-CP-189Standard for Qualification and Certifi- 3.3.2 operational reference standard—a reference standard

cation of Nondestructive Testing Personnel

with specified artificial slots, used to confirm the operation of

the system.

1

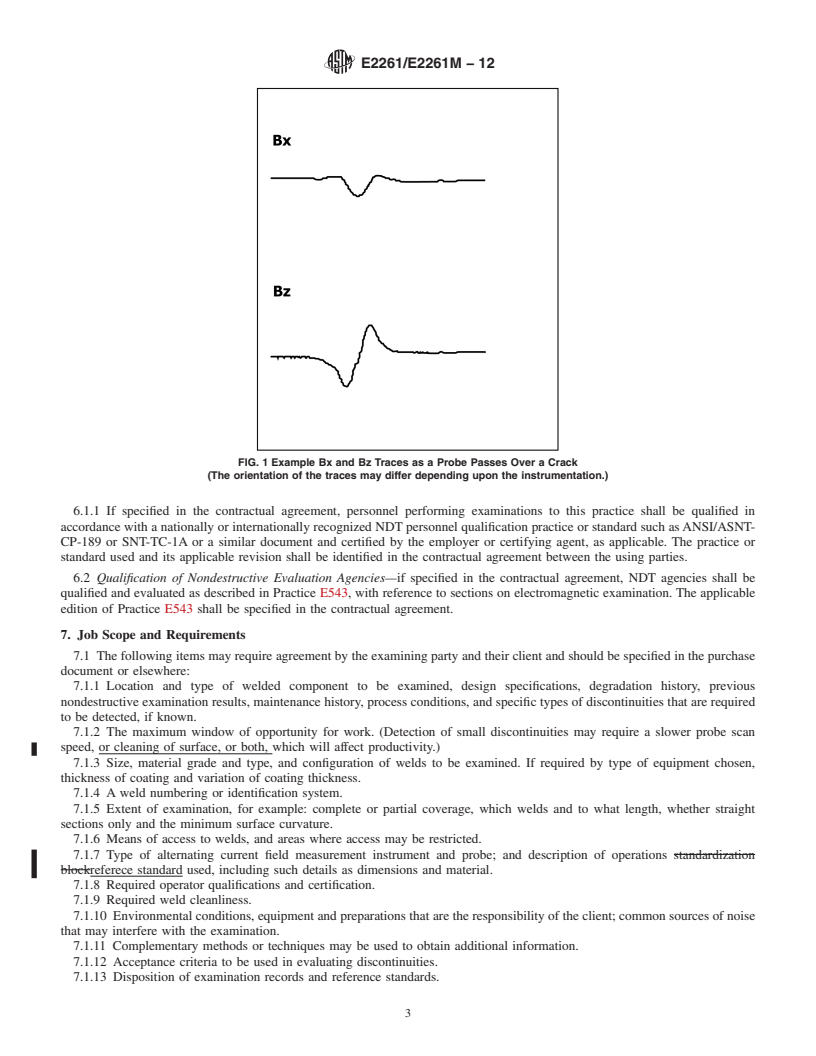

3.3.3 Bx—the x component of the magnetic field, parallel to

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.07 on

the weld toe, the magnitude of which is proportional to the

Electromagnetic Method.

current density set up by the electric field.

Current edition approved Nov. 1, 2012. Published November 2012. Originally

approved in 2003. Last previous edition approved in 2007 as E2261-07. DOI:

3.3.4 Bz—the z component of the magnetic field normal to

10.1520/E2261_E2261M-12.

the inspected base metal/heat affected zone surface, the mag-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

nitude of which is proportional to the lateral deflection of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on induced currents in the plane of that surface.

the ASTM website.

3

3.3.5 X-Y Plot—an X-Ygraph with two orthogonal compo-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. nents of magnetic field plotted against each other.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2261/E2261M − 12

3.3.6 time base plots—these plot the relationship between

Bx or Bz values with time.

3.3.7 surface plot—for use with array probes. This type of

plot has one c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2261 − 07 E2261/E2261M − 12

Standard Practice for

Examination of Welds Using the Alternating Current Field

1

Measurement Technique

This standard is issued under the fixed designation E2261;E2261/E2261M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice describes procedures to be followed during alternating current field measurement examination of welds for

baseline and service-induced surface breaking discontinuities.

1.2 This practice is intended for use on welds in any metallic material.

1.3 This practice does not establish weld acceptance criteria.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated

in each system might not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1316 Terminology for Nondestructive Examinations

3

2.2 ASNT Standard:

SNT-TC-1A Personnel Qualification and Certification in Nondestructive Testing

ANSI/ASNT-CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

3. Terminology

3.1 Definitions—GeneralFor definitions of terms used inrelating to this practice can be found in refer to Terminology E1316,

Section A, Common NDT terms, and Section C, Electromagnetic testing. The following definitions are specific to the alternating

current field measurement technique:

3.2 Definitions:

3.2.1 exciter—a device that generates a time varying electromagnetic field, usually a coil energized with alternating current

(AC); also known as a transmitter.

3.2.2 detector—one or more coils or elements used to sense or measure a magnetic field; also known as a receiver.

3.2.3 uniform field—as applied to nondestructive testing with magnetic fields, the area of uniform magnetic field over the surface

of the material under examination produced by a parallel induced alternating current, which has been passed through the weld and

is observable beyond the direct coupling of the exciting coil.

3.2.4 graduated field—as applied to nondestructive testing with magnetic fields, a magnetic field having a controlled gradient

in its intensity.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.07 on Electromagnetic

Method.

Current edition approved Dec. 1, 2007Nov. 1, 2012. Published January 2008November 2012. Originally approved in 2003. Last previous edition approved in 20032007

as E2261 - 03.E2261 - 07. DOI: 10.1520/E2261-07.10.1520/E2261_E2261M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2261/E2261M − 12

3.3 Definitions of Terms Specific to This Standard:

3.3.1 alternating current field measurement system—the electronic instrumentation, software, probes, and all associated

components and cables required for performing weld examination using the alternating current field measurement technique.

3.3.2 operational standardization block—reference standard—a reference standard with specified artificial slots, used to confirm

the operation of the system.

3.3.3 Bx—the x component of the magnetic field, parallel to the weld toe, the magnitude of which is proportional to the current

density set up by the electric field.

3.3.4 Bz—the z component of the m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.