ASTM A763-14

(Practice)Standard Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

Standard Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

ABSTRACT

This practices covers the detecting susceptibility to intergranular attack in ferritic stainless steel. Different method of preparing steel test specimens are presented. Four practices, including Practice W, X, Y, and Z, are used for determining susceptibility to intergranular attack in ferritic stainless steel. These practices cover the following tests; oxalic acid etch test, ferritic sulphate-sulfuric acid test, copper-copper sulphate-50% sulfuric acid test, and copper-copper sulphate-16% sulfuric acid test. Test specimens shall be examined for the ferritic sulphate-sulfuric acid test and copper-copper sulphate-50% sulphuric acid test under a binocular microscope at 40x magnification. The bend test evaluations for the steel test specimens are presented.

SCOPE

1.1 These practices cover the following four tests:

1.1.1 Practice W—Oxalic acid etch test for detecting susceptibility to intergranular attack in stabilized ferritic stainless steels by classification of the etching structures (see Sections 3 – 10).

1.1.2 Practice X—Ferric sulfate-sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 11 – 16).

1.1.3 Practice Y—Copper-copper sulfate-50 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 17 – 22).

1.1.4 Practice Z—Copper-copper sulfate-16 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 23 – 29).

1.2 The following factors govern the application of these practices (1-6)2:

1.2.1 Practice W, oxalic acid test, is a rapid method of identifying, by simple electrolytic etching, those specimens of certain ferritic alloys that are not susceptible to intergranular corrosion associated with chromium carbide precipitation. Practice W is used as a screening test to avoid the necessity, for acceptable specimens, of more extensive testing required by Practices X, Y, and Z. See Table 1 for a listing of alloys for which Practice W is appropriate. (A) Polished surface examined at 250 to 500× with a metallurgical microscope (see 3.1.6). All other microscopical examinations are of the corroded surface under 40× binocular examination (see Section 27).(B) A = Applicable.(C) Preferred criterion, these criteria are the most sensitive for the particular combination of alloy and test.(D) Weight loss measurements can be used to detect severely sensitized material, but they are not very sensitive for alloys noted with this superscript and may not detect slight or moderate sensitization.(E) NA = Not applicable.

1.2.2 Practices X, Y, and Z can be used to detect the susceptibility of certain ferritic alloys to intergranular attack associated with the precipitation of chromium carbides or nitrides.

1.2.3 Practices W, X, Y, and Z can also be used to evaluate the effect of heat treatment or of fusion welding on susceptibility to intergranular corrosion.

1.2.4 Table 2 lists the identification ferritic stainless steels for which data on the application of at least one of the standard practices is available. (A) Types 430, 434, 436, and 446 are nonstabilized grades that are generally not used in the as-welded or sensitized condition in other than mildly corrosive environments. In the annealed condition, they are not subject to intergranular corrosion. For any studies of IGA on Types 430, 434, 436, or 446, the indicated test methods are suggested.

1.2.5 Some stabilized ferritic stainless steels may show high rates when tested by Practice X because of metallurgical factors not associated with chromium carbide or nitride precipitation. This possibility must be considered in selecting the test method. Combinations of alloys and test methods for which successful experience is available are shown in Table 1. Application of these standard tests to the other ferritic stainless steels will be by specific agreement between produc...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A763 − 14

StandardPractices for

Detecting Susceptibility to Intergranular Attack in Ferritic

1

Stainless Steels

This standard is issued under the fixed designation A763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.2.4 Table 2 lists the identification ferritic stainless steels

forwhichdataontheapplicationofatleastoneofthestandard

1.1 These practices cover the following four tests:

practices is available.

1.1.1 Practice W—Oxalic acid etch test for detecting sus-

1.2.5 Somestabilizedferriticstainlesssteelsmayshowhigh

ceptibility to intergranular attack in stabilized ferritic stainless

rates when tested by Practice X because of metallurgical

steels by classification of the etching structures (see Sections 3

factors not associated with chromium carbide or nitride pre-

–10).

cipitation. This possibility must be considered in selecting the

1.1.2 PracticeX—Ferricsulfate-sulfuricacidtestfordetect-

test method. Combinations of alloys and test methods for

ing susceptibility to intergranular attack in ferritic stainless

which successful experience is available are shown in Table 1.

steels (Sections11–16).

Applicationofthesestandardteststotheotherferriticstainless

1.1.3 Practice Y—Copper-copper sulfate-50% sulfuric acid

steelswillbebyspecificagreementbetweenproduceranduser.

testfordetectingsusceptibilitytointergranularattackinferritic

1.3 Depending on the test and alloy, evaluations may be

stainless steels (Sections17–22).

accomplished by weight loss determination, microscopical

1.1.4 Practice Z—Copper-copper sulfate-16% sulfuric acid

examination,orbendtest(Sections30and31).Thechoicesare

testfordetectingsusceptibilitytointergranularattackinferritic

listed in Table 1.

stainless steels (Sections23–29).

1.4 This standard does not purport to address all of the

1.2 The following factors govern the application of these safety problems, if any, associated with its use. It is the

2

practices (1-6) : responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.2.1 Practice W, oxalic acid test, is a rapid method of

bility of regulatory limitations prior to use. For specific safety

identifying, by simple electrolytic etching, those specimens of

precautionary statements, see 3.2.5, Section 7, 13.1, and 19.1.

certain ferritic alloys that are not susceptible to intergranular

corrosion associated with chromium carbide precipitation.

2. Referenced Documents

PracticeWisusedasascreeningtesttoavoidthenecessity,for

3

acceptable specimens, of more extensive testing required by

2.1 ASTM Standards:

Practices X, Y, and Z. See Table 1 for a listing of alloys for

A370Test Methods and Definitions for Mechanical Testing

which Practice W is appropriate.

of Steel Products

1.2.2 Practices X, Y, and Z can be used to detect the

susceptibility of certain ferritic alloys to intergranular attack

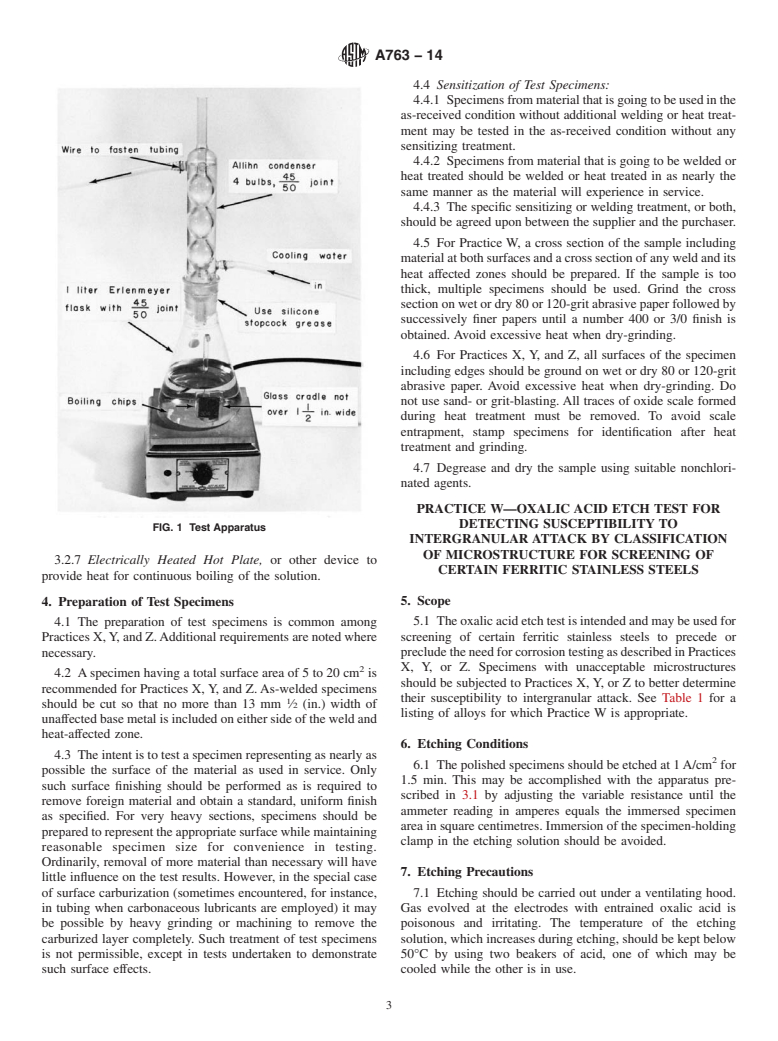

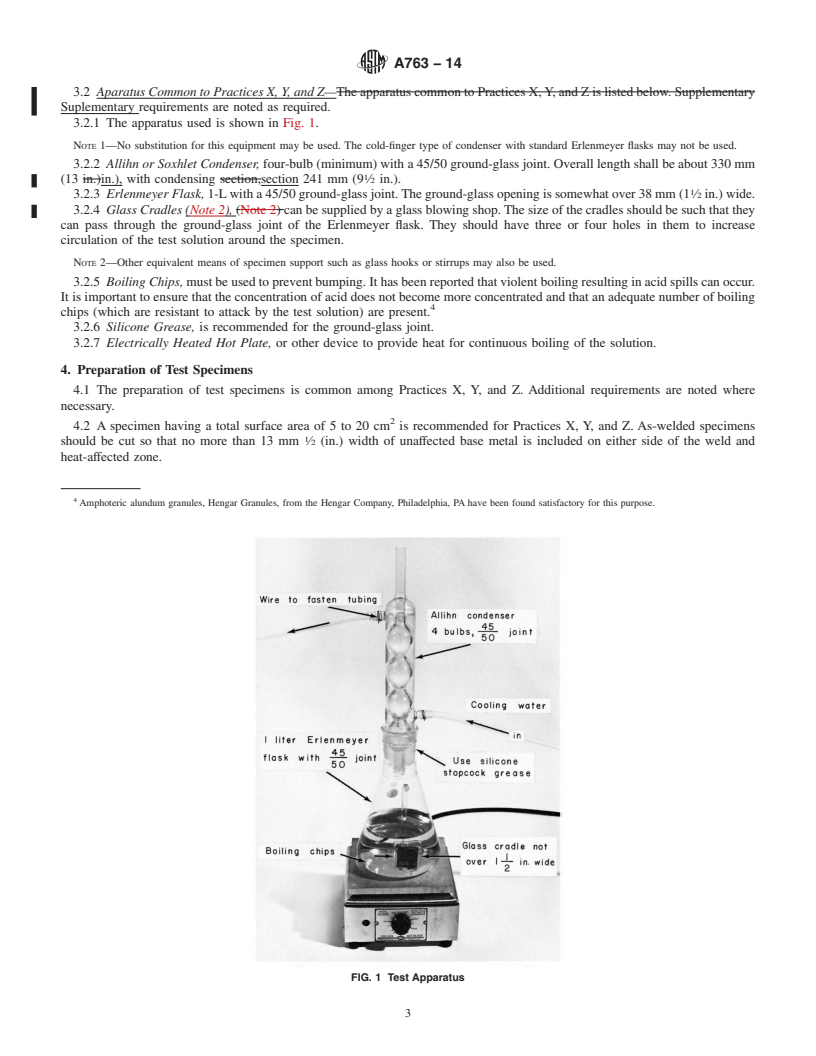

3. Apparatus

associated with the precipitation of chromium carbides or

3.1 Apparatus for Practice W, Oxalic Acid Etch Test:

nitrides.

3.1.1 Source of DC—Battery, generator, or rectifier capable

1.2.3 Practices W, X, Y, and Z can also be used to evaluate

of supplying 15 V and 20 A.

the effect of heat treatment or of fusion welding on suscepti-

3.1.2 Ammeter, range 0 to 30 A.

bility to intergranular corrosion.

3.1.3 Variable Resistance, for control of specimen current.

3.1.4 Cathode—One-litre stainless steel beaker or suitable

piece of stainless steel.

1

3.1.5 Electric Clamp, to hold etched specimen.

These practices are under the jurisdiction of ASTM Committee A01 on Steel,

StainlessSteelandRelatedAlloysandarethedirectresponsibilityofSubcommittee

A01.14 on Methods of Corrosion Testing.

Current edition approved Oct. 1, 2014. Published October 2014. Originally

3

approved in 1979. Last previous edition approved in 2009 as A763–93(2009). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0763-14. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references appended to Standards volume information, refer to the standard’s Document Summary page on

these practices. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A763 − 14

TABLE 1 Methods for Evaluating Ferritic Stainless Steels for Susceptibility to Intergranular Corrosion

Evaluation Criteria

Alloy Time

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A763 − 93 (Reapproved 2009) A763 − 14

Standard Practices for

Detecting Susceptibility to Intergranular Attack in Ferritic

1

Stainless Steels

This standard is issued under the fixed designation A763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 These practices cover the following four tests:

1.1.1 Practice W—Oxalic acid etch test for detecting susceptibility to intergranular attack in stabilized ferritic stainless steels

by classification of the etching structures (see Sections 33 – 10 through 10).

1.1.2 Practice X—Ferric sulfate-sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels

(Sections 1111 – 16 to 16).

1.1.3 Practice Y—Copper-copper sulfate-50 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic

stainless steels (Sections 1717 – 22 to 22).

1.1.4 Practice Z—Copper-copper sulfate-16 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic

stainless steels (Sections 2323 – 29 to 29).

2

1.2 The following factors govern the application of these practices (1-6) :

1.2.1 Practice W, oxalic acid test, is a rapid method of identifying, by simple,simple electrolytic etching, those specimens of

certain ferritic alloys that are not susceptible to intergranular corrosion associated with chromium carbide precipitation. Practice

W is used as a screening test to avoid the necessity, for acceptable specimens, of more extensive testing required by Practices X,

Y, and Z. See Table 1 for a listing of alloys for which Practice W is appropriate.

1.2.2 Practices X, Y, and Z can be used to detect the susceptibility of certain ferritic alloys to intergranular attack associated with

the precipitation of chromium carbides or nitrides.

1.2.3 Practices W, X, Y, and Z can also be used to evaluate the effect of heat treatment or of fusion welding on susceptibility

to intergranular corrosion.

1.2.4 Table 2 lists the identification ferritic stainless steels for which data on the application of at least one of the standard

practices is available.

1.2.5 Some stabilized ferritic stainless steels may show high rates when tested by Practice X because of metallurgical factors

not associated with chromium carbide or nitride precipitation. This possibility must be considered in selecting the test method.

Combinations of alloys and test methods for which successful experience is available are shown in Table 1. Application of these

standard tests to the other ferritic stainless steels will be by specific agreement between producer and user.

1.3 Depending on the test and alloy, evaluations may be accomplished by weight loss determination, microscopical

examination, or bend test (Sections 30 and 31). The choices are listed in Table 1.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific safety precautionary statements, see 3.2.5, Section 7, 13.1, and 19.1.

2. Referenced Documents

3

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

1

These practices are under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and are the direct responsibility of Subcommittee A01.14

on Methods of Corrosion Testing.

Current edition approved April 1, 2009Oct. 1, 2014. Published April 2009October 2014. Originally approved in 1979. Last previous edition approved in 20042009 as

A763 – 93 (2004).(2009). DOI: 10.1520/A0763-93R09.10.1520/A0763-14.

2

The boldface numbers in parentheses refer to the list of references appended to these practices.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A763 − 14

T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.