ASTM D913-15

(Practice)Standard Practice for Evaluating Degree of Traffic Marking Line Wear

Standard Practice for Evaluating Degree of Traffic Marking Line Wear

SIGNIFICANCE AND USE

4.1 This practice is designed to evaluate the resistance to wear of a traffic marking. It must be remembered that a high degree of performance of traffic marking applied to a bare road surface may not guarantee similar results when the same traffic marking is applied over old markings.

SCOPE

1.1 This practice covers the evaluation of degree of resistance to wear that may occur with traffic markings in road tests (see Practice D713) or in actual service, using photographic standards for comparative evaluation.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D913 − 15

Standard Practice for

1

Evaluating Degree of Traffic Marking Line Wear

This standard is issued under the fixed designation D913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers the evaluation of degree of resis-

4.1 This practice is designed to evaluate the resistance to

tance to wear that may occur with traffic markings in road tests

wear of a traffic marking. It must be remembered that a high

(see Practice D713) or in actual service, using photographic

degree of performance of traffic marking applied to a bare road

standards for comparative evaluation.

surface may not guarantee similar results when the same traffic

1.2 This standard does not purport to address all of the marking is applied over old markings.

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Type of Failure

priate safety and health practices and determine the applica-

5.1 The failure as described in Section 3 does not presume

bility of regulatory limitations prior to use.

any specific mechanism, and all areas where the substrate is

visible shall be considered a failure.

2. Referenced Documents

2

2.1 ASTM Standards:

6. Use of Photographic References

D713 Practice for Conducting Road Service Tests on Fluid

3

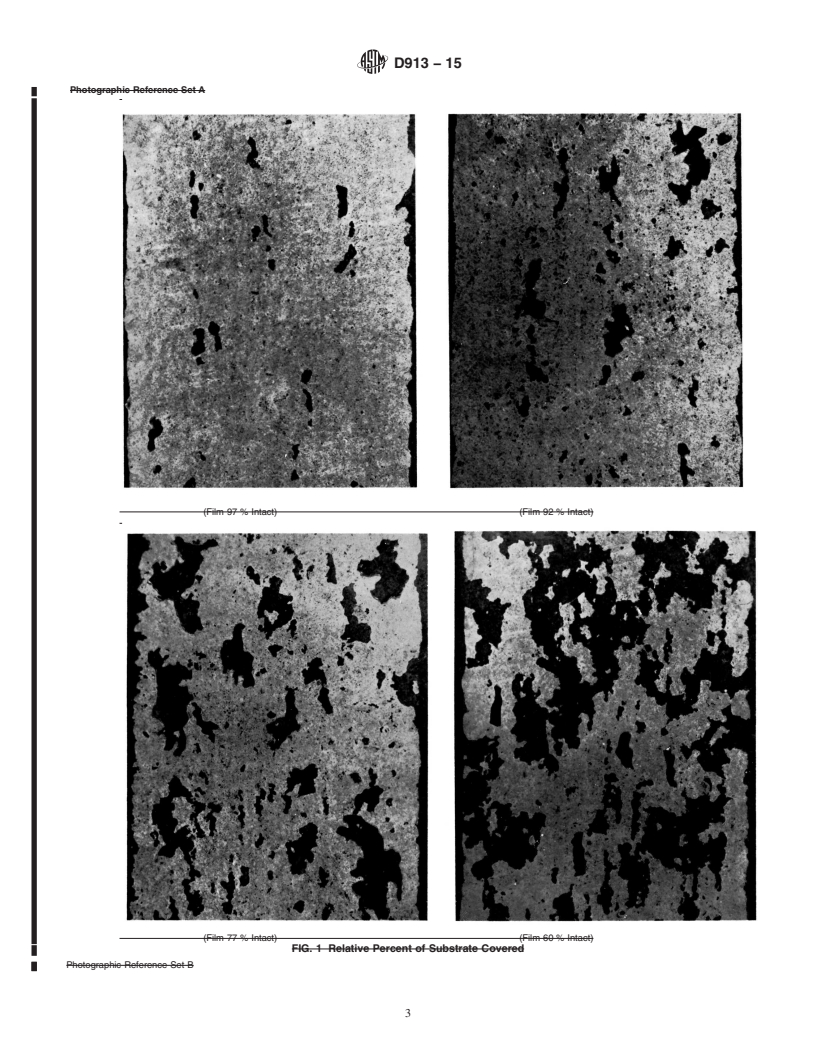

6.1 The photographic references that are part of this

Traffic Marking Materials

practice are representative of the degrees of resistance to wear

2.2 ASTM Adjuncts:

of stripes of traffic markings (Fig. 1).

3

Glossy Prints of Photographic Reference

6.1.1 The degree of resistance to wear is likely to vary over

any given area. It is therefore preferable to use one of the

3. Terminology

following grading methods:

3.1 Definitions of Terms Specific to This Standard:

6.1.1.1 Select an area as representative and base the relative

3.1.1 failure, described by these photographic references,

performance of the traffic marking on this area or

n—that condition manifested in traffic markings by actual

6.1.1.2 Grade segments of the traffic marking and average

detachment of sections of the film from its substrate or erosion

these gradings.

of sections of the marking down to the substrate.

3.1.1.1 Discussion—The degree of resistance to failure is

NOTE 1—The photographic references are representative of stripes of

judged by the amount of substrate that is covered.

traffic markings. The percentage of surface covered is shown on each

reference.

3.1.2 substrate, n—the roadway surface or previously ap-

plied traffic marking over which the traf

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D913 − 10 D913 − 15

Standard Practice for

1

Evaluating Degree of Traffic PaintMarking Line Wear

This standard is issued under the fixed designation D913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the evaluation of degree of resistance to wear that may occur with traffic paints (traffic markings)

markings in road tests (see Practice D713) or in actual service, using photographic standards for comparative evaluation.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D713 Practice for Conducting Road Service Tests on Fluid Traffic Marking Materials

2.2 ASTM Adjuncts:

3

Glossy Prints of Photographic Reference

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 failure, described by these photographic references, n—that condition manifested in traffic paintmarkings by actual

detachment of sections of the film from its substrate or erosion of sections of paint the marking down to the substrate.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.44 on Traffic Coatings.

Current edition approved July 1, 2010Dec. 1, 2015. Published July 2010December 2015. Originally approved in 1947. Last previous edition approved in 20032010 as as

ε1

D913 – 03D913 – 10. . DOI: 10.1520/D0913-10.10.1520/D0913-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Full-size (8 by 10-in. (203 by 254-mm)) glossy prints of the photographic reference showing degrees of chipping are available from ASTM International Headquarters.

Order Adjunct No: ADJD0913.

3.1.1.1 Discussion—

The degree of resistance to failure is judged by the amount of substrate that is covered.

3.1.2 substrate, n—the roadway surface or previously applied traffic marking over which the traffic paintmarking being tested

was appliedapplied.

4. Significance and Use

4.1 This practice is designed to evaluate the resistance to wear of a traffic paint.marking. It must be remembered that a high

degree of performance of paint traffic marking applied to a bare road surface may not guarantee similar results when the same paint

traffic marking is applied over old paint lines.markings.

5. Type of Failure

5.1 The failure as described in Section 3 does not presume any specific mechanism, and all areas where the substrate is visible

shall be considered a failure.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.