ASTM F672-01

(Test Method)Standard Test Method for Measuring Resistivity Profiles Perpendicular to the Surface of a Silicon Wafer Using a Spreading Resistance Probe (Withdrawn 2003)

Standard Test Method for Measuring Resistivity Profiles Perpendicular to the Surface of a Silicon Wafer Using a Spreading Resistance Probe (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 This test method covers measurement of the resistivity profile perpendicular to the surface of a silicon wafer of known orientation and type.

Note 1--This test method may also be applicable to other semiconductor materials, but feasibility and precision have been evaluated only for silicon and germanium.

1.2 This test method may be used on epitaxial films, substrates, diffused layers, or ion-implanted layers, or any combination of these.

1.3 This test method is comparative in that the resistivity profile of an unknown specimen is determined by comparing its measured spreading resistance value with those of calibration standards of known resistivity. These calibration standards must have the same surface preparation, conductivity type, and crystallographic orientation as the unknown specimen.

1.4 This test method is intended for use on silicon wafers in any resistivity range for which there exist suitable standards. Polished, lapped, or ground surfaces may be used.

1.5 This test method is destructive in that the specimen must be beveled.

1.6 Correction factors, which take into account the effects of boundaries or local resistivity variations with depth, are needed prior to using calibration data to calculate resistivity from the spreading resistance values.

Note 2--This test method extends Method F525 to depth profiling.

Note 3--This test method provides means for directly determining the resistivity profile of a silicon specimen normal to the specimen surface. Unlike Test Methods F84, F374, F1392, and F1393, it can provide lateral spatial resolution of resistivity on the order of a few micrometres, and an in-depth spatial resolution on the order of 10 nm (100 A). This test method can be used to profile through p-n junctions.

1.7 This test method is primarily a measurement for determining the resistivity profile in a silicon wafer. However, common practice is to convert the resistivity profile information to a density profile. For such purposes, a conversion between resistivity and majority carrier density is provided in Appendix X2.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 672 – 01

Standard Test Method for

Measuring Resistivity Profiles Perpendicular to the Surface

1

of a Silicon Wafer Using a Spreading Resistance Probe

This standard is issued under the fixed designation F 672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The measurement of resistivity profile by means of a spreading resistance probe is a complex

procedure, with a number of commonly accepted options for carrying out the component measure-

ments. ASTM Committee F-1 on Electronics has designed this test method to allow a range of choices,

consistent with good practice, for the electronic configuration, type of specimen preparation, and

method for measuring bevel angle. Items not specified by this test method are to be agreed upon by

the parties to the test, usually from a specified set of choices in the context of a general restriction. The

measurement of bevel angle is particularly difficult to specify, as the selection of an appropriate

method depends not only on the range of angle measured but also on the quality of the instrumentation

available for that method. Although ideally the beveled surface and the original surface should be two

planes intersecting along a straight line, the actual geometry may differ from this ideal, further

complicating the measurement. These points are recognized in the section on interferences and in

Appendix X1 and associated references on the bevel-angle measurement.

1. Scope 1.5 This test method is destructive in that the specimen must

be beveled.

1.1 This test method covers measurement of the resistivity

1.6 Correction factors, which take into account the effects of

profile perpendicular to the surface of a silicon wafer of known

boundaries or local resistivity variations with depth, are needed

orientation and type.

prior to using calibration data to calculate resistivity from the

NOTE 1—This test method may also be applicable to other semicon-

spreading resistance values.

ductor materials, but feasibility and precision have been evaluated only for

silicon and germanium. NOTE 2—This test method extends Method F 525 to depth profiling.

NOTE 3—This test method provides means for directly determining the

1.2 This test method may be used on epitaxial films,

resistivity profile of a silicon specimen normal to the specimen surface.

substrates, diffused layers, or ion-implanted layers, or any

Unlike Test Methods F 84, F 374, F 1392, and F 1393, it can provide

combination of these.

lateral spatial resolution of resistivity on the order of a few micrometres,

˚

1.3 This test method is comparative in that the resistivity

and an in-depth spatial resolution on the order of 10 nm (100 A). This test

method can be used to profile through p-n junctions.

profile of an unknown specimen is determined by comparing

its measured spreading resistance value with those of calibra-

1.7 This test method is primarily a measurement for deter-

tion standards of known resistivity. These calibration standards

mining the resistivity profile in a silicon wafer. However,

must have the same surface preparation, conductivity type, and

common practice is to convert the resistivity profile informa-

crystallographic orientation as the unknown specimen.

tion to a density profile. For such purposes, a conversion

1.4 This test method is intended for use on silicon wafers in

between resistivity and majority carrier density is provided in

any resistivity range for which there exist suitable standards.

Appendix X2.

Polished, lapped, or ground surfaces may be used.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1

This test method is under the jurisdiction of ASTM Committee F01 on

priate safety and health practices and determine the applica-

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon

bility of regulatory limitations prior to use. Specific hazard

Material and Process Control.

Current edition approved June 10, 2001. Published August 2001. Originally

statements are given in Section 9.

published as F 672 – 80. Last previous edition F 672 – 88.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 672–01

2. Referenced Documents 3.1.1 conducting

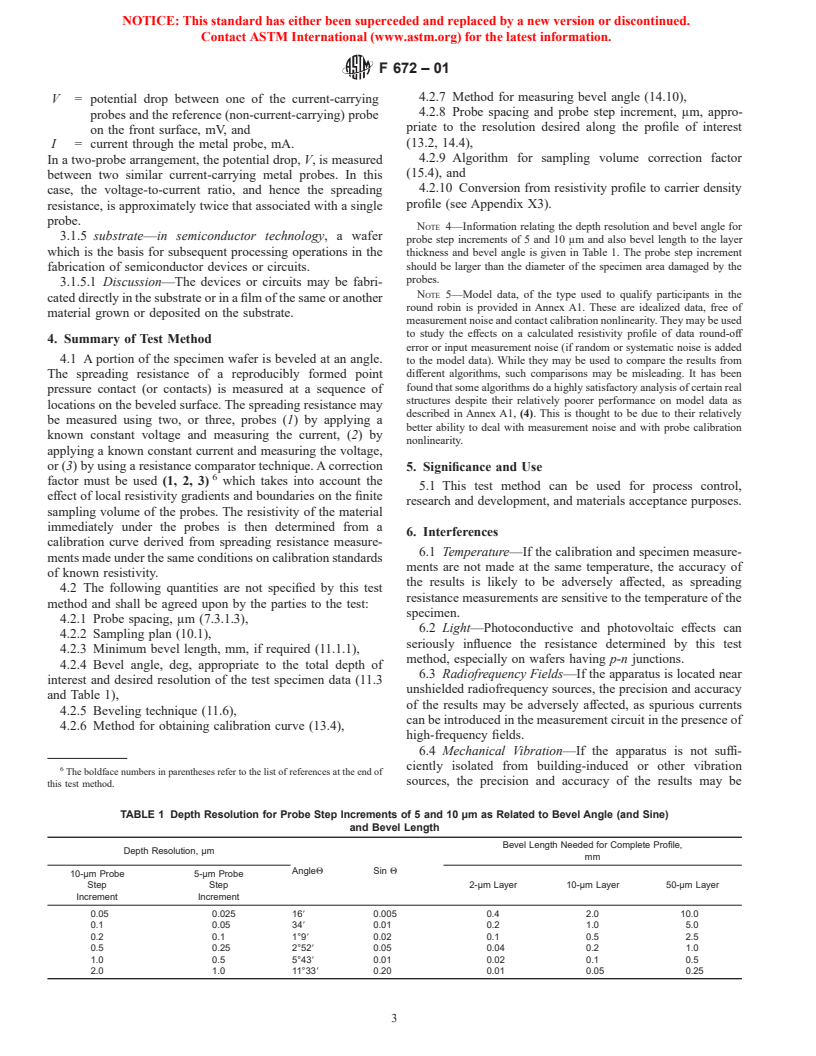

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.