ASTM C230/C230M-14

(Specification)Standard Specification for Flow Table for Use in Tests of Hydraulic Cement

Standard Specification for Flow Table for Use in Tests of Hydraulic Cement

ABSTRACT

This specification covers requirements for the flow table and accessory apparatus used in making flow tests for consistency or mortars in tests of hydraulic cement. The flow table shall consist of an integrally cast rigid iron frame and a circular rigid table top. Other details of the flow table, its mounting and lubrication are described in the specification. The conical mold for casting the flow specimen and the caliper for measuring the diameter of the mortar after it has been spread by the operation of the table are also discussed.

SCOPE

1.1 This specification covers requirements for the flow table and accessory apparatus (Note 1) used in making flow tests for consistency of mortars in tests of hydraulic cement, such as but not limited to Test Method C1437.

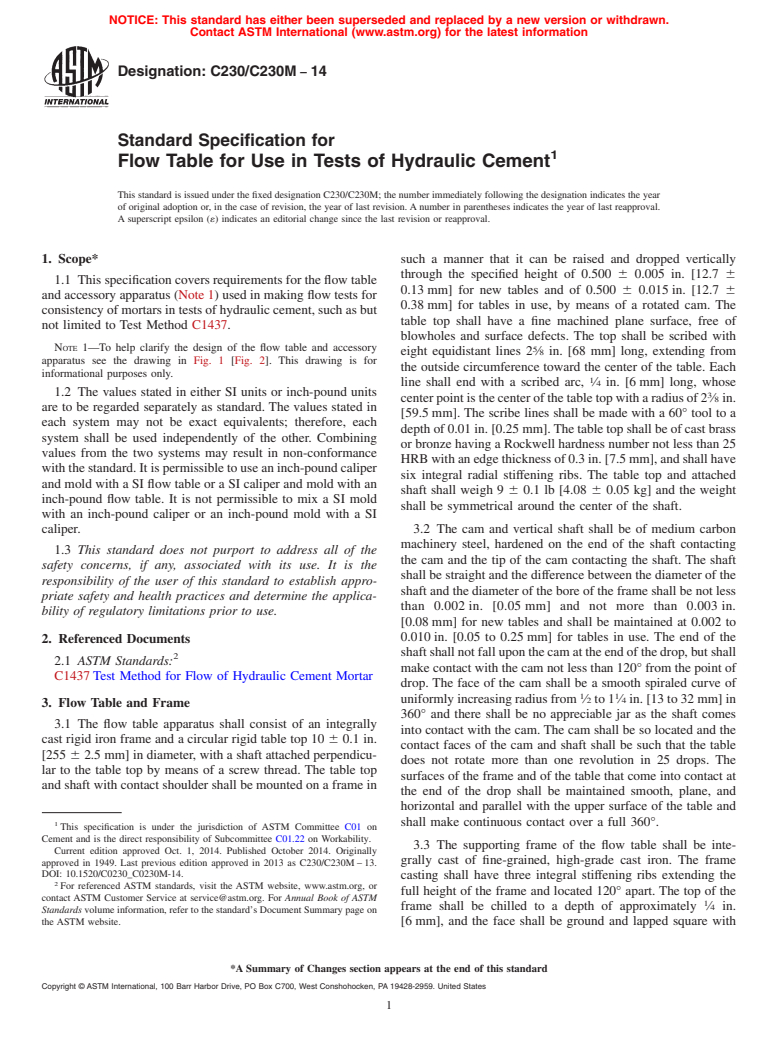

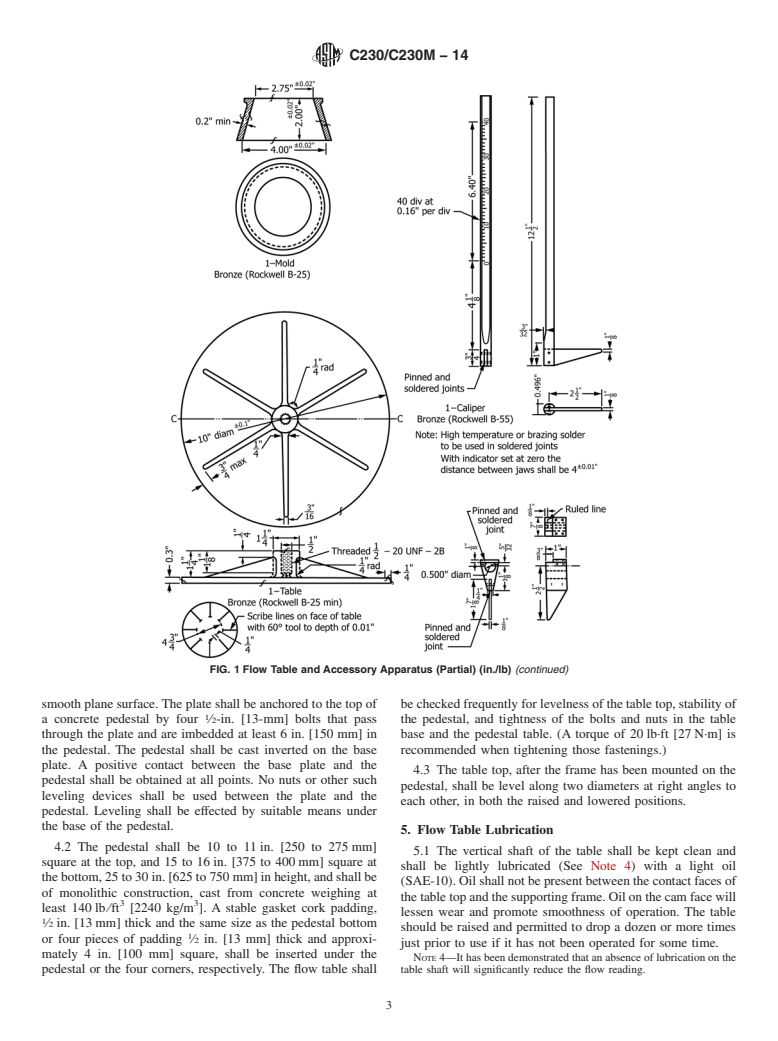

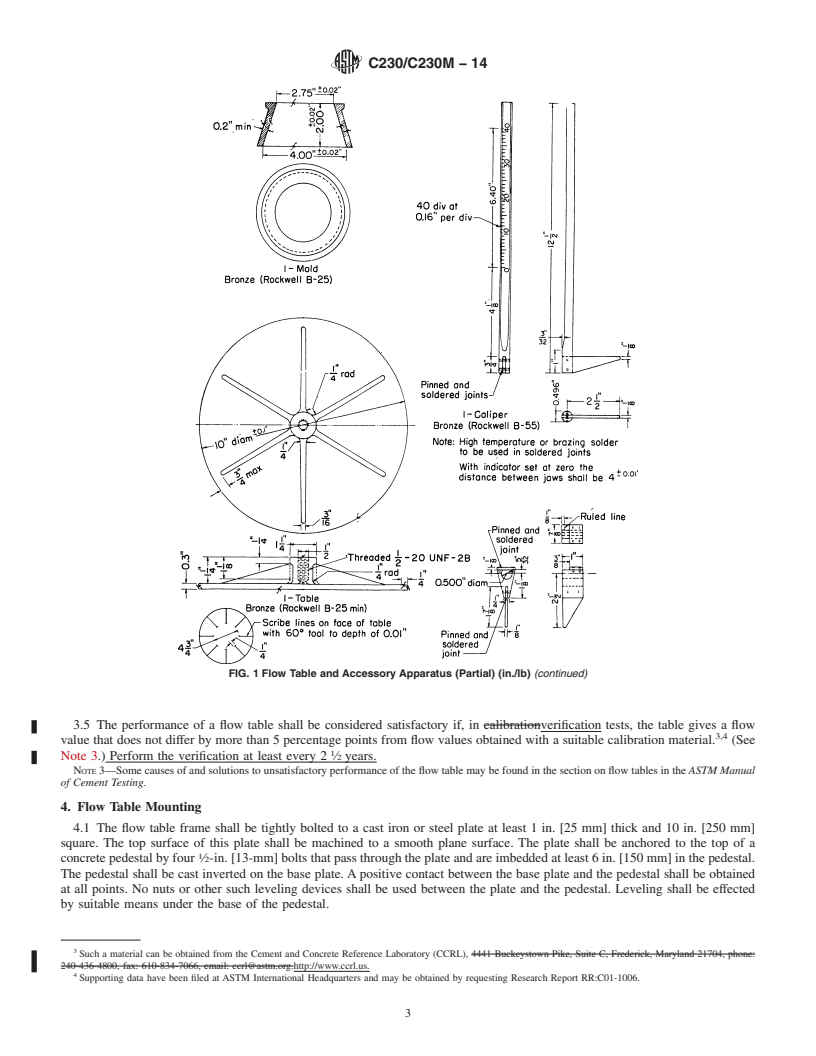

Note 1: To help clarify the design of the flow table and accessory apparatus see the drawing in Fig. 1 [Fig. 2]. This drawing is for informational purposes only.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. It is permissible to use an inch-pound caliper and mold with a SI flow table or a SI caliper and mold with an inch-pound flow table. It is not permissible to mix a SI mold with an inch-pound caliper or an inch-pound mold with a SI caliper.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C230/C230M −14

Standard Specification for

1

Flow Table for Use in Tests of Hydraulic Cement

This standard is issued under the fixed designation C230/C230M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* such a manner that it can be raised and dropped vertically

through the specified height of 0.500 6 0.005 in. [12.7 6

1.1 This specification covers requirements for the flow table

0.13 mm] for new tables and of 0.500 6 0.015 in. [12.7 6

and accessory apparatus (Note 1) used in making flow tests for

0.38 mm] for tables in use, by means of a rotated cam. The

consistency of mortars in tests of hydraulic cement, such as but

table top shall have a fine machined plane surface, free of

not limited to Test Method C1437.

blowholes and surface defects. The top shall be scribed with

NOTE 1—To help clarify the design of the flow table and accessory

5

eight equidistant lines 2 ⁄8 in. [68 mm] long, extending from

apparatus see the drawing in Fig. 1 [Fig. 2]. This drawing is for

the outside circumference toward the center of the table. Each

informational purposes only.

1

line shall end with a scribed arc, ⁄4 in. [6 mm] long, whose

1.2 The values stated in either SI units or inch-pound units

3

centerpointisthecenterofthetabletopwitharadiusof2 ⁄8 in.

are to be regarded separately as standard. The values stated in

[59.5 mm]. The scribe lines shall be made with a 60° tool to a

each system may not be exact equivalents; therefore, each

depth of 0.01 in. [0.25 mm].The table top shall be of cast brass

system shall be used independently of the other. Combining

or bronze having a Rockwell hardness number not less than 25

values from the two systems may result in non-conformance

HRB with an edge thickness of 0.3 in. [7.5 mm], and shall have

with the standard. It is permissible to use an inch-pound caliper

six integral radial stiffening ribs. The table top and attached

and mold with a SI flow table or a SI caliper and mold with an

shaft shall weigh 9 6 0.1 lb [4.08 6 0.05 kg] and the weight

inch-pound flow table. It is not permissible to mix a SI mold

shall be symmetrical around the center of the shaft.

with an inch-pound caliper or an inch-pound mold with a SI

caliper. 3.2 The cam and vertical shaft shall be of medium carbon

machinery steel, hardened on the end of the shaft contacting

1.3 This standard does not purport to address all of the

the cam and the tip of the cam contacting the shaft. The shaft

safety concerns, if any, associated with its use. It is the

shall be straight and the difference between the diameter of the

responsibility of the user of this standard to establish appro-

shaft and the diameter of the bore of the frame shall be not less

priate safety and health practices and determine the applica-

than 0.002 in. [0.05 mm] and not more than 0.003 in.

bility of regulatory limitations prior to use.

[0.08 mm] for new tables and shall be maintained at 0.002 to

0.010 in. [0.05 to 0.25 mm] for tables in use. The end of the

2. Referenced Documents

shaftshallnotfalluponthecamattheendofthedrop,butshall

2

2.1 ASTM Standards:

make contact with the cam not less than 120° from the point of

C1437 Test Method for Flow of Hydraulic Cement Mortar

drop. The face of the cam shall be a smooth spiraled curve of

1 1

uniformly increasing radius from ⁄2 to 1 ⁄4 in. [13 to 32 mm] in

3. Flow Table and Frame

360° and there shall be no appreciable jar as the shaft comes

3.1 The flow table apparatus shall consist of an integrally

into contact with the cam. The cam shall be so located and the

cast rigid iron frame and a circular rigid table top 10 6 0.1 in.

contact faces of the cam and shaft shall be such that the table

[255 6 2.5 mm] in diameter, with a shaft attached perpendicu-

does not rotate more than one revolution in 25 drops. The

lar to the table top by means of a screw thread. The table top

surfaces of the frame and of the table that come into contact at

and shaft with contact shoulder shall be mounted on a frame in

the end of the drop shall be maintained smooth, plane, and

horizontal and parallel with the upper surface of the table and

shall make continuous contact over a full 360°.

1

This specification is under the jurisdiction of ASTM Committee C01 on

Cement and is the direct responsibility of Subcommittee C01.22 on Workability.

3.3 The supporting frame of the flow table shall be inte-

Current edition approved Oct. 1, 2014. Published October 2014. Originally

grally cast of fine-grained, high-grade cast iron. The frame

approved in 1949. Last previous edition approved in 2013 as C230/C230M – 13.

DOI: 10.1520/C0230_C0230

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C230/C230M − 13 C230/C230M − 14

Standard Specification for

1

Flow Table for Use in Tests of Hydraulic Cement

This standard is issued under the fixed designation C230/C230M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers requirements for the flow table and accessory apparatus (Note 1) used in making flow tests for

consistency of mortars in tests of hydraulic cement, such as but not limited to Test Method C1437.

NOTE 1—To help clarify the design of the flow table and accessory apparatus see the drawing in Fig. 1 [Fig. 2]. This drawing is for informational

purposes only.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard. It is permissible to use an inch-pound caliper and mold with a SI

flow table or a SI caliper and mold with an inch-pound flow table. It is not permissible to mix a SI mold with an inch-pound caliper

or an inch-pound mold with a SI caliper.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C1437 Test Method for Flow of Hydraulic Cement Mortar

3. Flow Table and Frame

3.1 The flow table apparatus shall consist of an integrally cast rigid iron frame and a circular rigid table top 10 6 0.1 in. [255

6 2.5 mm] in diameter, with a shaft attached perpendicular to the table top by means of a screw thread. The table top and shaft

with contact shoulder shall be mounted on a frame in such a manner that it can be raised and dropped vertically through the

specified height of 0.500 6 0.005 in. [12.7 6 0.13 mm] 0.13 mm] for new tables and of 0.500 6 0.015 in. 0.015 in. [12.7 6 0.38

mm] 0.38 mm] for tables in use, by means of a rotated cam. The table top shall have a fine machined plane surface, free of

5

blowholes and surface defects. The top shall be scribed with eight equidistant lines 2 ⁄8 in. [68 mm] long, extending from the

1

outside circumference toward the center of the table. Each line shall end with a scribed arc, ⁄4 in. [6 mm] [6 mm] long, whose

3

center point is the center of the table top with a radius of 2 ⁄8 in. [59.5 mm]. in. [59.5 mm]. The scribe lines shall be made with

a 60° tool to a depth of 0.01 in. [0.25 mm]. 0.01 in. [0.25 mm]. The table top shall be of cast brass or bronze having a Rockwell

hardness number not less than 25 HRB with an edge thickness of 0.3 in. [7.5 mm], and shall have six integral radial stiffening ribs.

The table top and attached shaft shall weigh 9 6 0.1 lb [4.08 6 0.05 kg] and the weight shall be symmetrical around the center

of the shaft.

3.2 The cam and vertical shaft shall be of medium carbon machinery steel, hardened on the end of the shaft contacting the cam

and the tip of the cam contacting the shaft. The shaft shall be straight and the difference between the diameter of the shaft and the

diameter of the bore of the frame shall be not less than 0.002 in. [0.05 mm] 0.002 in. [0.05 mm] and not more than 0.003 in. [0.08

mm] 0.003 in. [0.08 mm] for new tables and shall be maintained at 0.002 to 0.010 in. 0.010 in. [0.05 to 0.25 mm] 0.25 mm] for

tables in use. The end of the shaft shall not fall upon the cam at the end of the drop, but shall make contact with the cam not less

1

than 120° from the point of drop. The face of the cam shall be a smooth spiraled curve of uniformly increasing radius from ⁄2 to

1

1 ⁄4 in. [13 to 32 mm] 32 mm] in 360° and there shall be no appreciable jar as the shaft comes into contact with the cam. The cam

1

This specification is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.22 on Workability.

Current edition approved June 1, 2013Oct. 1, 2014. Published July 2013October 2014. Originally approved in 1949. Last previous edition approved in 20082013 as

C230/C230M – 08.C230/C230M – 13. DOI: 10.1520/C0230_C0230M-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.