ASTM D3192-09(2019)

(Test Method)Standard Test Methods for Carbon Black Evaluation in NR (Natural Rubber)

Standard Test Methods for Carbon Black Evaluation in NR (Natural Rubber)

SIGNIFICANCE AND USE

3.1 The major portion of carbon black consumed by the rubber industry is used to improve the physical properties, life expectancy, and utility of rubber products. These test methods provide a natural rubber formulation and directions for evaluating carbon black intended for use in rubber products.

3.2 These test methods may be used to characterize carbon black in terms of specific properties of the standard compound. These test methods are useful for the quality assurance of carbon black production. They may also be used for the preparation of reference compounds, to confirm the day-to-day reliability of testing operations used in the rubber industry, for the evaluation of experimental compounds, and quality control of production compounds.

SCOPE

1.1 These test methods cover the standard materials, test formulation, mixing procedure, and test methods for the evaluation and production control of carbon blacks in natural rubber (NR).

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3192 − 09 (Reapproved 2019)

Standard Test Methods for

Carbon Black Evaluation in NR (Natural Rubber)

This standard is issued under the fixed designation D3192; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Standard Vulcanized Sheets

D4483 Practice for Evaluating Precision for Test Method

1.1 These test methods cover the standard materials, test

Standards in the Rubber and Carbon Black Manufacturing

formulation, mixing procedure, and test methods for the

Industries

evaluation and production control of carbon blacks in natural

rubber (NR).

3. Significance and Use

1.2 The values stated in SI units are to be regarded as the

3.1 The major portion of carbon black consumed by the

standard. The values in parentheses are for information only.

rubber industry is used to improve the physical properties, life

1.3 This standard does not purport to address all of the

expectancy, and utility of rubber products. These test methods

safety concerns, if any, associated with its use. It is the

provide a natural rubber formulation and directions for evalu-

responsibility of the user of this standard to establish appro-

ating carbon black intended for use in rubber products.

priate safety, health, and environmental practices and deter-

3.2 These test methods may be used to characterize carbon

mine the applicability of regulatory limitations prior to use.

black in terms of specific properties of the standard compound.

1.4 This international standard was developed in accor-

These test methods are useful for the quality assurance of

dance with internationally recognized principles on standard-

carbon black production. They may also be used for the

ization established in the Decision on Principles for the

preparation of reference compounds, to confirm the day-to-day

Development of International Standards, Guides and Recom-

reliability of testing operations used in the rubber industry, for

mendations issued by the World Trade Organization Technical

the evaluation of experimental compounds, and quality control

Barriers to Trade (TBT) Committee.

of production compounds.

2. Referenced Documents

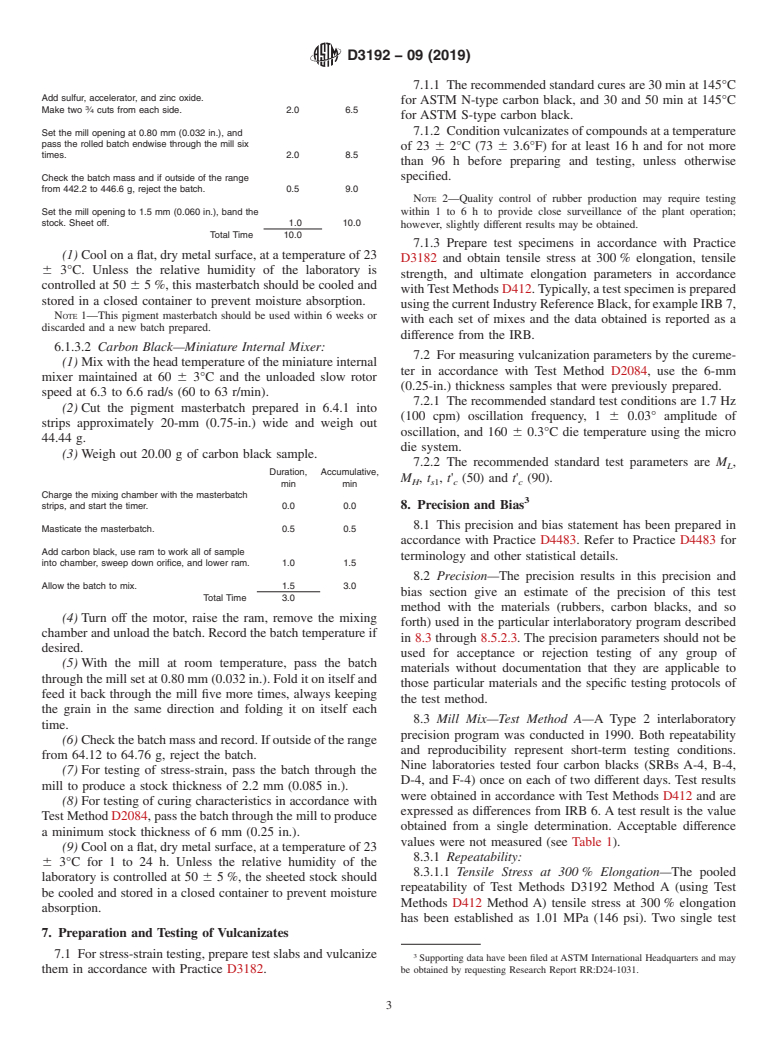

4. Standard Test Formula

2.1 ASTM Standards:

4.1 Standard Formula:

D412 Test Methods forVulcanized Rubber andThermoplas-

A

Material IRM No. Quantity, parts

tic Elastomers—Tension

by mass

D1799 Practice for Carbon Black—Sampling Packaged

B

Natural rubber . 100.00

Shipments

Stearic acid 21 3.00

D1900 Practice for Carbon Black—Sampling Bulk Ship-

Zinc oxide 91 5.00

ments Benzothiazyl disulfide 2 0.60

Sulfur 31 2.50

D2084 Test Method for Rubber Property—Vulcanization

C

Carbon black . 50.00

Using Oscillating Disk Cure Meter

Total 161.10

D

D3182 PracticeforRubber—Materials,Equipment,andPro- Batch factor:

Test Method A—Mill 4.00

cedures for Mixing Standard Compounds and Preparing

Test Method B—Internal Mixer 6.00

Test Method C—Miniature Internal 0.40

Mixer

These test methods are under the jurisdiction of ASTM Committee D24 on

_____________

Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon

Black Testing in Rubber.

A

IRM 91 is available from R. E. Carroll, Inc., 1570 North OldenAve., Trenton, NJ

Current edition approved May 1, 2019. Published June 2019. Originally

08638; (800) 257–9365. IRM 2, IRM 21, and IRM 31 are available from Akron

approved in 1973. Last previous edition approved in 2014 as D3192 – 09 (2014).

Rubber Development Lab, 2887 Gilchrist Road, Akron, OH 44305; (330)

DOI: 10.1520/D3192-09R19.

794–6600.

B

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

SMR L and STR L have been found to give satisfactory performance. Other

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sources of rubber may give satisfactory results but have not been investigated by

Standardsvolume information, refer to the standard’s Document Summary page on

Subcommittee D24.71. Other sources of rubber should be checked to ensure that

the ASTM website. results equivalent to SMR L are attained before using in this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3192 − 09 (2019)

C

Use 75.00 parts by mass of carbon blacks in the N-800 and N-900 series.

6.1.1.3 Cool on a flat, dry metal surface, at a temperature of

D

Weigh rubber and carbon black to the nearest 1 g, sulfur and accelerator to the

23 6 3°C for 1 to 24 h. Unless the relative humidity of the

nearest 0.02 g, and all other compounding materials to the nearest 0.1 g.

laboratory is controlled at 50 6 5 %, the sheeted stock should

5. Sampling and Sample Preparation be cooled and stored in a closed container to prevent moisture

absorption.

5.1 Samples shall be taken in accordance with Practice

6.1.2 Test Method B—Internal Mixer:

D1799 or Practice D1900.

Duration, Accumulative,

5.2 The carbon black shall be conditioned before weighing

min min

Adjust the internal mixer temperature to create a

and mixing by heating for1hinan oven set at 125 6 1°C.The

dump temperature between 110 and 125°C.

black shall be placed in an open vessel of suitable dimensions

Close the discharge gate, start the rotor, raise the

so that the depth of black is no more than 10 mm during

ram, and charge the materials as described.

Lower the ram after each operation. 0 0

conditioning.The black conditioned as above shall be stored in

a closed moisture-proof container until ready for mixing.

Add the rubber. 0.5 0.5

6. Mixing Procedures Add the benzothiazyl disulfide. 0.5 1.0

6.1 For general mixing procedure refer to Practice D3182.

Add the stearic acid. 1.0 2.0

The following mixing procedures are acceptable in testing

Add the zinc oxide and one-half the carbon black. 1.5 3.5

carbon black: (1) Test Method A—Mill Mix, (2) Test Method

B—Internal Mixer, and (3)Test Method C—Miniature Internal

Add the remainder of the carbon black. 1.5 5.0

Mixer.

Add the sulfur. Clean the mixer throat and the top of

6.1.1 Test Method A—Mill Mix:

the ram. 1.0 6.0

Duration, Accumulative,

Dump at 7 min. 1.0 7.0

min min

Subtotal 7.0

Set the mill opening at 1.4 mm (0.055 in.) and

adjust and maintain roll temperature at 70 ± 5°C. 0 0 Set the mill opening at 0.80 mm (0.032 in.) and

maintain the roll temperature at 70 ± 5°C.

Add rubber and band on the front roll. Pass the rolled batch endwise through the mill six

times. 2.0 9.0

Make two ⁄4 cuts from each side. 2.0 2.0

Open the mill to give a minimum stock thickness of

Set mill opening at 1.65 mm (0.065 in.).

Add stearic acid. 6 mm (0.25 in.) and pass the stock through the rolls

four times, folding it back on itself each time. 1.0 10.0

Make one ⁄4 cut from each side. 2.5 4.5

Total Time 10.0

Add sulfur, accelerator, and zinc oxide.

6.1.2.1 Check the batch mass and record. If outside of the

Make two ⁄4 cuts from each side. 2.0 6.5

range from 961.8 to 971.4 g, reject the batch. From this stock,

Add all the black.

cut enough sample to allow testing of curing characteristics in

When that portion of the carbon black that was

accordance with Test Method D2084, if desired.

added has dropped through to the mill pan and the

6.1.2.2 Open the mill and sheet off to produce a stock

bank is dry, make two ⁄4 cuts from each side.

Open the mill to 1.9 mm (0.075 in.) and add the

thickness of 2.2 mm (0.085 in.).

carbon black from the mill pan until all is

6.1.2.3 Unless otherwise specified, condition the sheeted

incorporated.

Make three ⁄4 cuts from each side. 7.5 14.0 compoundfor1to24hat23 63°C(73.4 65.4°F)atarelative

humidity not greater than 55 %. For maximum precision,

Note—Do not cut any stock while free carbon black

condition for 1 to 24 h in a closed container to prevent

is evident in the bank or on the milling surface. Be

certain to return any pigments that drop through the absorption of moisture from the air, or in an area controlled at

mill to the milling stock.

35 6 5 % relative humidity in accordance with Practice

D3182. Vulcanize and test in accordance with Section 7.

Set the mill opening at 0.80 mm (0.032 in.) and

pass the rolled batch endwise through the mill six

6.1.3 Test Method C—Miniature Internal Mixer:

times. 2.0 16.0

6.1.3.1 Pigment Masterbatch Preparation—Mill Mix:

Open the mill to give a minimum stock thickness of Duration, Accumulative,

6 mm (0.25 in.) and pass the stock through the rolls min min

four times, folding it back on itself each time. 1.0 17.0 (Batch Factor 4.00) Set the mill opening at 1.4 mm

Total Time 17.0 (0.055 in.) and adjust and maintain roll temperature

at 70 ± 5°C. 0.0 0.0

6.1.1.1 Check the batch mass and record. If outside of the

range from 641.2 to 647.6 g, reject the batch. From this stock,

Add rubber and band on the front roll.

Make two ⁄4 cuts from each side. 2.0 2.0

cut enough sample to allow testing of or curing characteristics

in accordance with Test Method D2084, if desired.

Set mill opening at 1.65 mm (0.065 in.).

6.1.1.2 Open the mill and sheet off to produce a thickness of Add stearic acid.

Make one ⁄4 cut from each side. 2.5 4.5

2.2 mm (0.085 in.).

D3192 − 09 (2019)

7.1.1 The recommended standard cures are 30 min at 145°C

Add sulfur, accelerator, and zinc oxide.

for ASTM N-type carbon black, and 30 and 50 min at 145°C

Make two ⁄4 cuts from each side. 2.0 6.5

for ASTM S-type carbon black.

7.1.2 Condition vulcanizates of compounds at a temperature

Set the mill opening at 0.80 mm (0.032 in.), and

pass the rolled batch endwise through the mill six

of 23 6 2°C (73 6 3.6°F) for at least 16 h and for not more

times. 2.0 8.5

than 96 h before preparing and testing, unless otherwise

specified.

Check the batch mass and if outside of the range

from 442.2 to 446.6 g, reject the batch. 0.5 9.0

NOTE 2—Quality control of rubber production may require testing

Set the mill opening to 1.5 mm (0.060 in.), band the within 1 to6hto provide close surveillance of the plant operation;

stock. Sheet off. 1.0 10.0

however, slightly different results may be obtained.

Total Time 10.0

7.1.3 Prepare test specimens in accordance with Practice

(1) Cool on a flat, dry metal surface, at a temperature of 23

D3182 and obtain tensile stress at 300 % elongation, tensile

6 3°C. Unless the relative humidity of the laboratory is

strength, and ultimate elongation parameters in accordance

controlled at 50 6 5 %, this masterbatch should be cooled and

withTestMethodsD412.Typically,atestspecimenisprepared

stored in a closed container to prevent moisture absorption.

usingthecurrentIndustryReferenceBlack,forexampleIRB7,

NOTE 1—This pigment masterbatch should be used within 6 weeks or

with each set of mixes and the data obtained is reported as a

discarded and a new batch prepared.

difference from the IRB.

6.1.3.2 Carbon Black—Miniature Internal Mixer:

7.2 For measuring vulcanization parameters by the cureme-

(1) Mix with the head temperature of the miniature internal

ter in accordance with Test Method D2084, use the 6-mm

mixer maintained at 60 6 3°C and the unloaded slow rotor

(0.25-in.) thickness samples that were previously prepared.

speed at 6.3 to 6.6 rad/s (60 to 63 r/min).

7.2.1 The recommended standard test conditions are 1.7 Hz

(2) Cut the pigment masterbatch prepared in 6.4.1 into

(100 cpm) oscillation frequency, 1 6 0.03° amplitude of

strips approximately 20-mm (0.75-in.) wide and weigh out

oscillation, and 160 6 0.3°C die temperature using the micro

44.44 g.

die system.

(3) Weigh out 20.00 g of carbon black sample.

7.2.2 The recommended standard test parameters are M ,

L

Duration, Accumulative,

M , t , t' (50) and t' (90).

H s1 c c

min min

Charge the mixing chamber with the masterbatch

8. Precision and Bias

strips, and start the timer. 0.0 0.0

8.1 This precision and bias statement has been prepared in

Masticate the masterbatch. 0.5 0.5

accordance with Practice D4483. Refer to Practice D4483 for

Add carbon black, use ram to work all of sample

terminology and other statistical details.

into chamber, sweep down orifice, and lower ram. 1.0 1.5

8.2 Precision—The precision results in this precision and

Allow the batch to mix. 1.5 3.0

bias section give an estimate of the precision of this test

Total Time 3.0

method with the materials (rubbers, carbon blacks, and so

(4) Turn off the motor, raise the ram, remove the mixing

forth) used in the particular interlaboratory program described

chamber and unload the batch. Record the batch temperature if

in 8.3 through 8.5.2.3. The precision parameters should not be

desired.

used for acceptance or rejection testing of any group of

(5) With the mill at room temperature, pass the batch

materials without documentation that they are applicable to

through the mill set at 0.80 mm (0.032 in.). Fold it on itself and

those particular materials and the specific testing protocols of

feed it back through the mill five more times, always keeping

the test method.

the grain in the same direction and folding it on itself each

8.3 Mill Mix—Test Method A—A Type 2 interlaboratory

time.

precision program was conducted in 1990. Both repeatability

(6) Checkthebatchmassandrecord.Ifoutsideoftherange

and reproducibility represent short-term testing conditions.

from 64.12 to 64.76 g, reject the batch.

Nine laboratories tested four carbon blacks (SRBs A-4, B-4,

(7) For testing of stress-strain, pass the batch through the

D-4, and F-4) once on each of two different days. Test results

mill to produce a stock thickness of 2.2 mm (0.085 in.).

were obtained in accordance with Test Methods D412 and are

(8) For testing of curing characteristics in accordance with

expressed as differences from IRB 6. A test result is the value

Test Method D2084, pass the batch through the mill to produce

obtained from a single determination. Acceptable difference

a minimum stock thickness of 6 mm (0.25 in.).

values were not measured (see Table 1).

(9) Cool on a flat, dry metal surface, at a temperature of 23

8.3.1 Repeatability:

6 3°C for 1 to 24 h. Unless the relative humidity of the

8.3.1.1 Tensile Stress at 300% Elongation—The pooled

laboratory is controlled at 50 6 5 %, the sheeted stock should

repeatability of Test Methods D3192 Method A (using Test

be cooled and stored in a closed container to prevent moisture

Methods D412 Method A) tensile stress at 300 % elongation

absorption.

has been established as 1.01 MPa (146 psi). Two single test

7. Preparation and Testing of Vulcan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.